Laser oscillation filler single-side welding double-side forming welding method for thick framework T-shaped structure

A welding method and single-sided welding technology, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve problems such as poor stability, low efficiency, and difficulty in welding thick skeleton curve welds, and achieve consistency and control stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

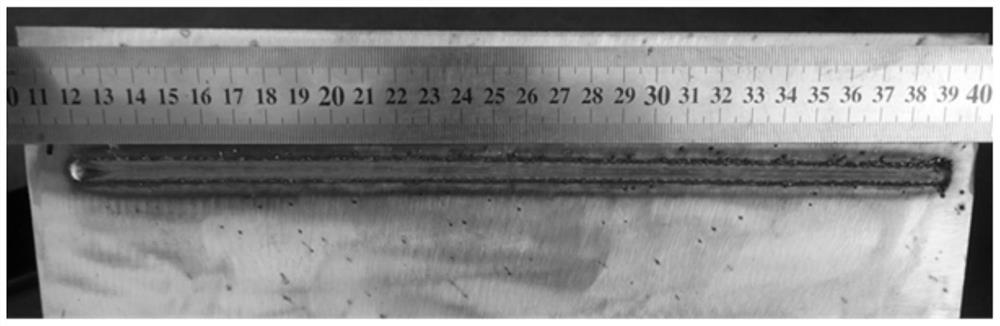

Examples

specific Embodiment approach 1

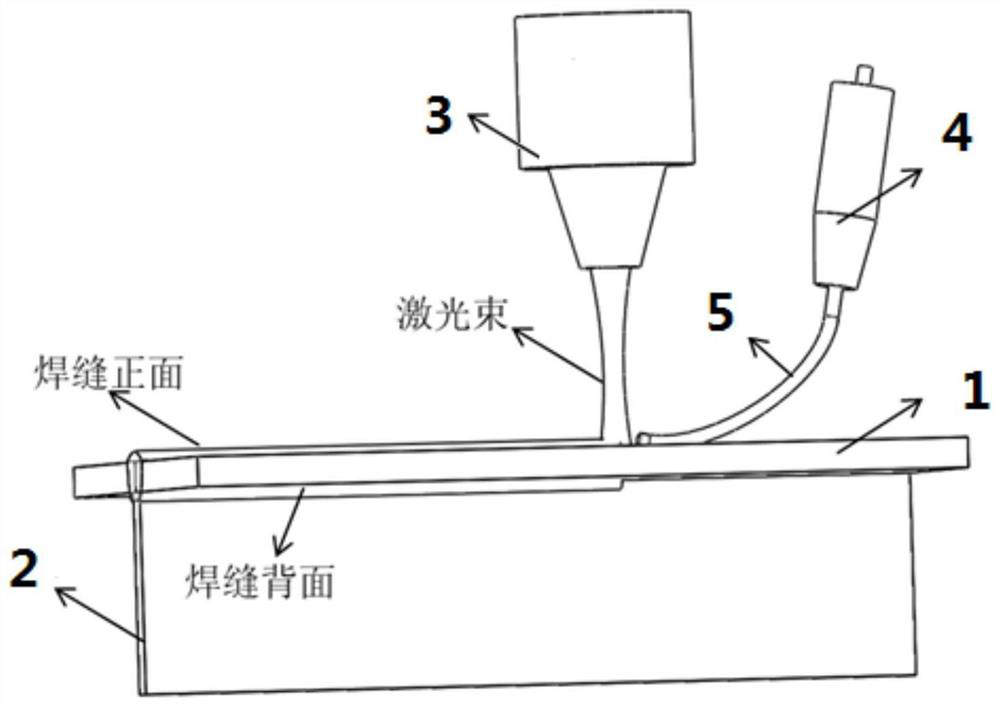

[0037] Specific implementation mode 1: This implementation mode is a kind of welding method for thick skeleton T-shaped structure laser oscillation filling wire single-sided welding and double-sided forming, which is specifically carried out according to the following steps:

[0038] 1. Carry out mechanical processing on the end face of the skeleton to be welded and the area to be welded on the skin; the thickness of the end face of the skeleton to be welded is d 1 3 ~ 12mm;

[0039] 2. Use a fixture to make the end surface of the skeleton to be welded in step 1 horizontal, and then fix it;

[0040] 3. Adjust the laser gun, and control the laser beam irradiation area to be located in the central area of the end face of the skeleton to be welded, and then move the laser welding head to perform point-by-point calibration;

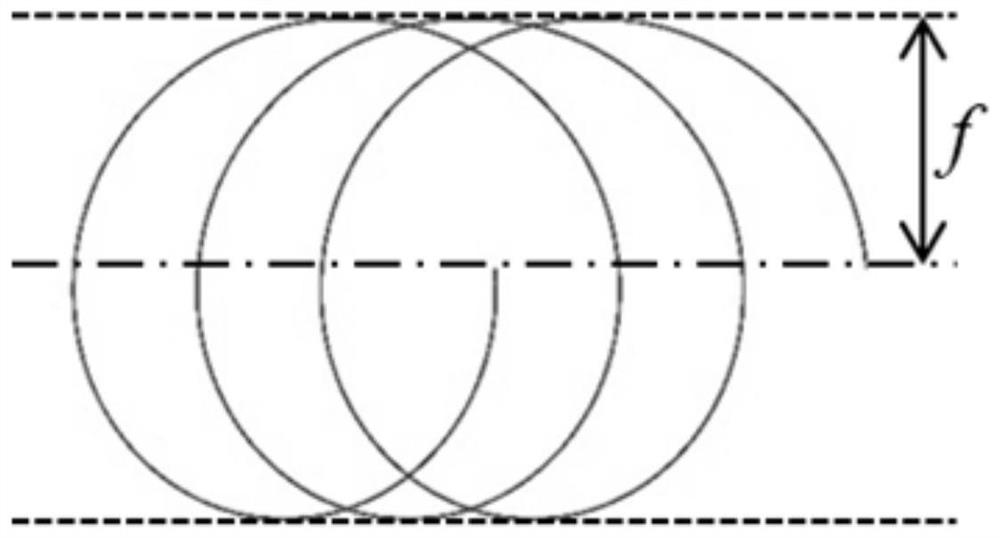

[0041] 4. Taking the center of the end face of the skeleton to be welded as the benchmark, check and adjust the walking path of the laser moving device to...

specific Embodiment approach 2

[0044] Embodiment 2: This embodiment differs from Embodiment 1 in that: the end surface of the skeleton to be welded in step 1 is a straight line or a curved surface. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the thickness d of the end surface of the skeleton to be welded described in step one 1 and skin thickness d 2 The ratio of is the bone-to-skin ratio γ, that is Wherein 0.2≤γ≤0.8. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com