N type silicon on insulator transverse insulated gate bipolar device

A silicon-on-insulator, bipolar device technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as easy deviation, improve reliability, improve anti-high temperature reverse bias stress, and increase costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

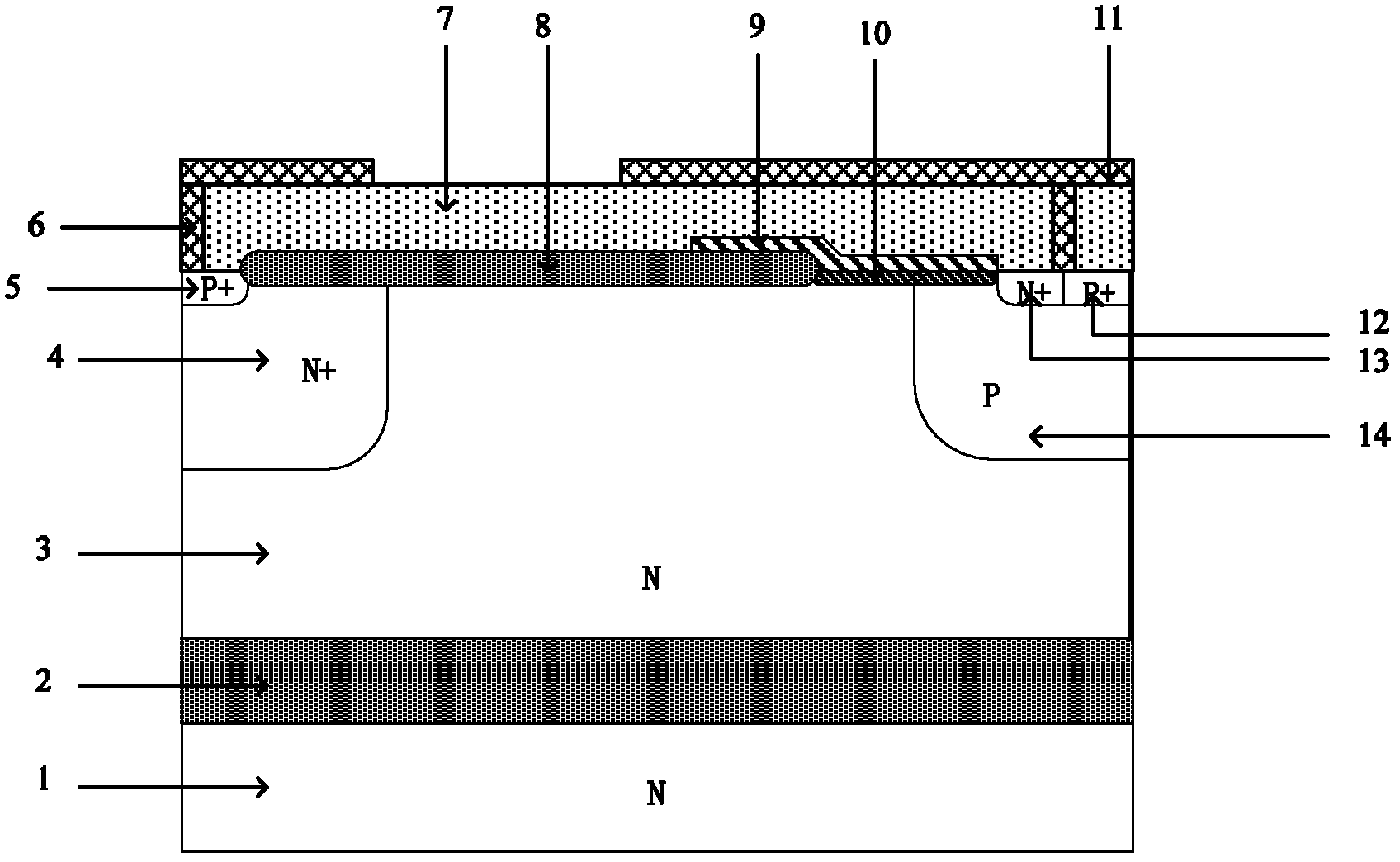

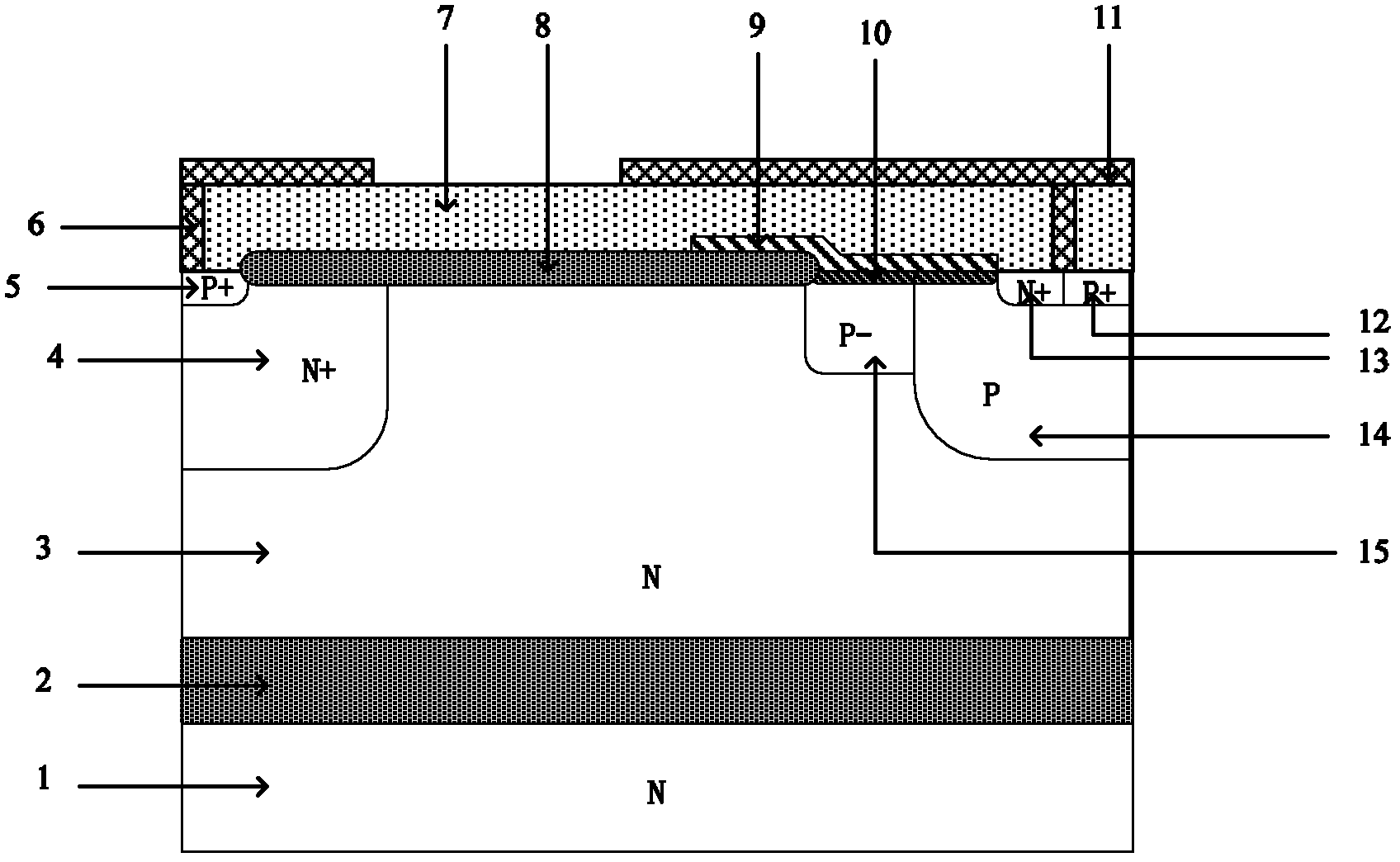

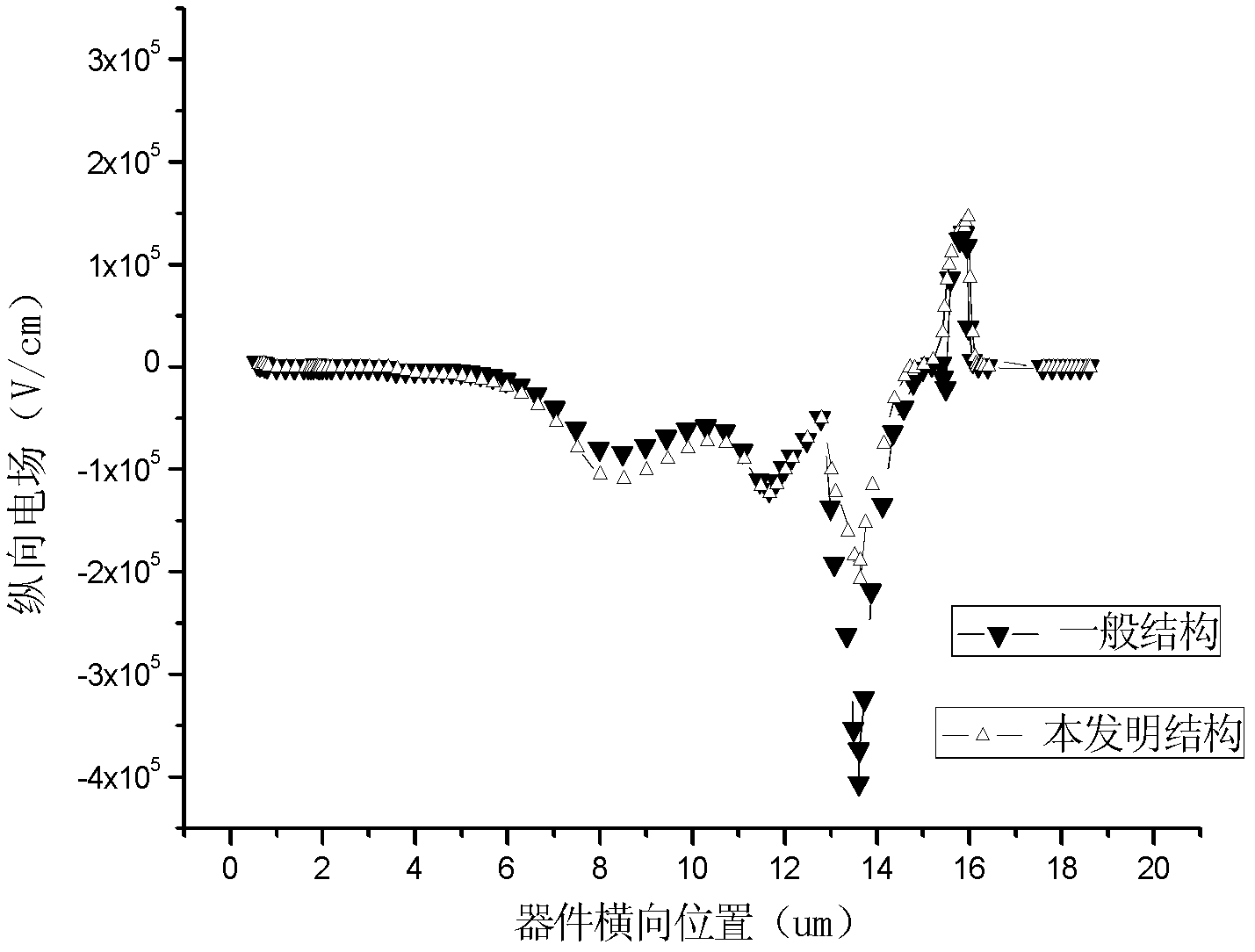

[0021] Attached below figure 2 , the present invention is described in detail, a kind of N-type silicon-on-insulator lateral insulated gate bipolar device, comprising: N-type substrate 1, buried oxygen 2 is arranged on N-type substrate 1, and buried oxygen 2 is provided with The N-type epitaxial layer 3 is provided with an N-type buffer well 4 and a P-type body region 14 inside the N-type epitaxial layer 3, and a P-type anode region 5 is arranged in the N-type buffer well 4, and in the P-type body region 14 An N-type negative region 13 and a P-type body contact region 12 are provided, a gate oxide layer 10 and a field oxide layer 8 are provided on the surface of the N-type epitaxial layer 3, and one end of the gate oxide layer 10 is offset against one end of the field oxide layer 8, The other end of the gate oxide layer 10 extends to the N-type negative region 13 and ends at the N-type negative region 13, and the other end of the field oxide layer 8 extends to the P-type posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com