Gas blowing protective device used during stainless steel sheet pulse laser welding and welding process

A technology of blowing protection and pulsed laser, which is applied in laser welding equipment, welding/welding/cutting items, welding equipment, etc. It can solve the problems of reducing the energy transfer efficiency of lasers and deteriorating the welding performance of laser beams, and achieves good surface gloss, Solve the oxidation problem and promote the effect of convective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

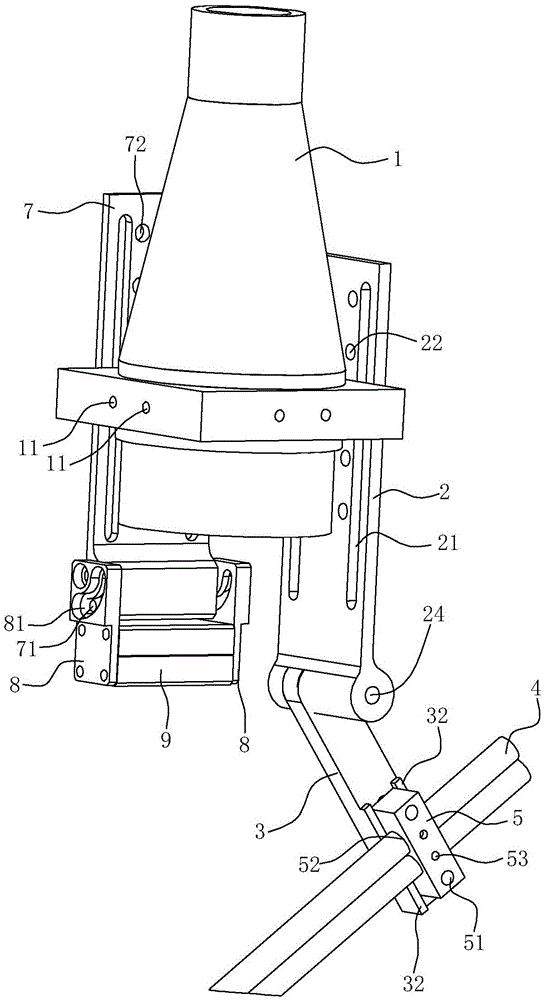

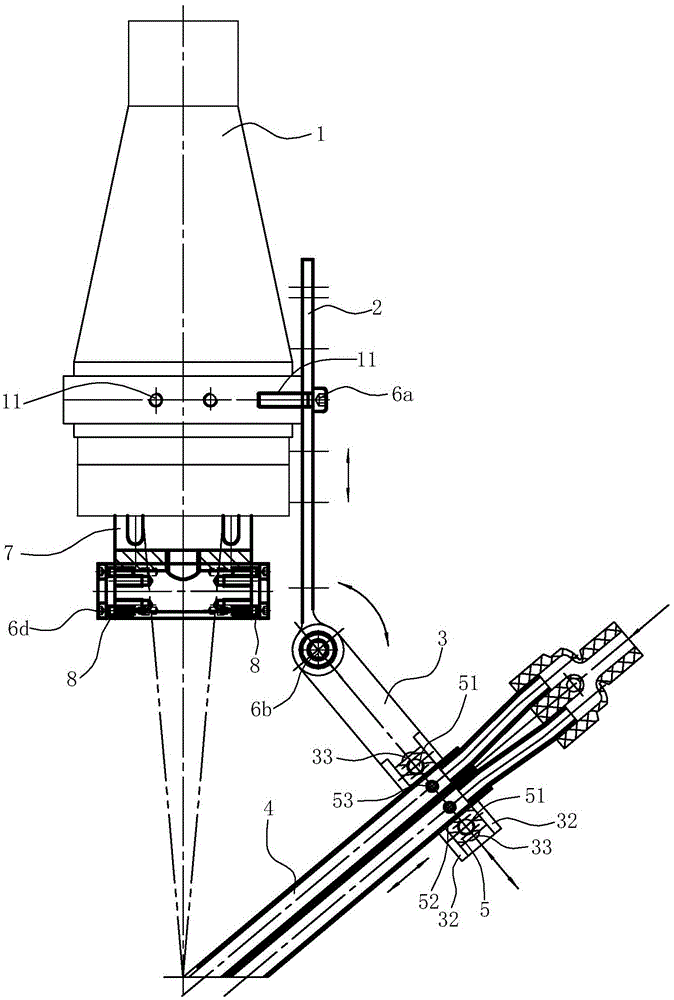

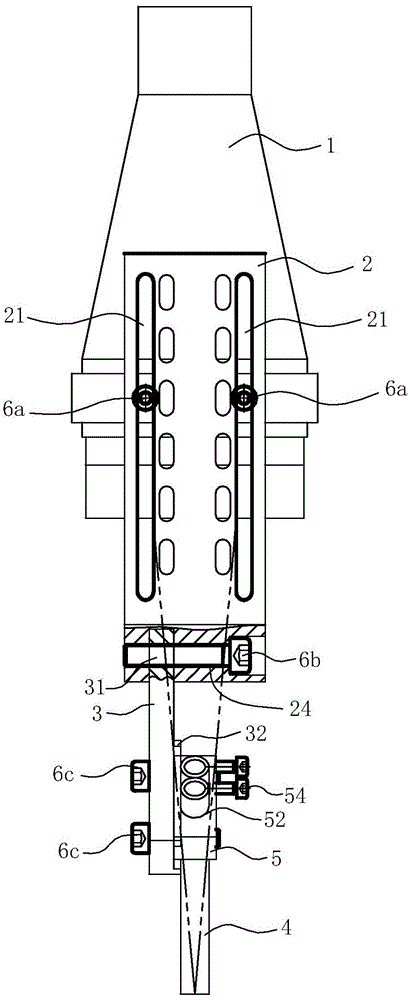

[0028] Such as Figure 1-10As shown, it is a preferred embodiment of the gas blow protection device for pulsed laser welding of thin plate stainless steel of the present invention.

[0029] A thin-plate stainless steel pulse laser welding blowing protection device, including a side blowing protection part installed on the collimation and focusing head 1, the side blowing protection part includes a first adjustment plate 2, a rotating rod 3, a slider 5 and a side The air blowing pipe 4 and the first adjustment plate 2 are fixed on the side wall of the collimating and focusing head 1 and the upper and lower positions relative to the side wall of the collimating and focusing head 1 are adjustable.

[0030] Such as image 3 As shown, the first adjusting plate 2 adopts the following structure to be fixed to the side wall of the collimating and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com