Lightweight acoustic insulation and fire resistant ship compartment wallboard and production method thereof

A lightweight, siding technology, applied in hull bulkheads, chemical instruments and methods, hulls, etc., can solve the problems of poor thermal insulation performance, low sound insulation, heavy weight, etc., and achieve improved fire-resistant separation performance and sound insulation performance. , Reduce the transmission of vibration noise and increase the effect of sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

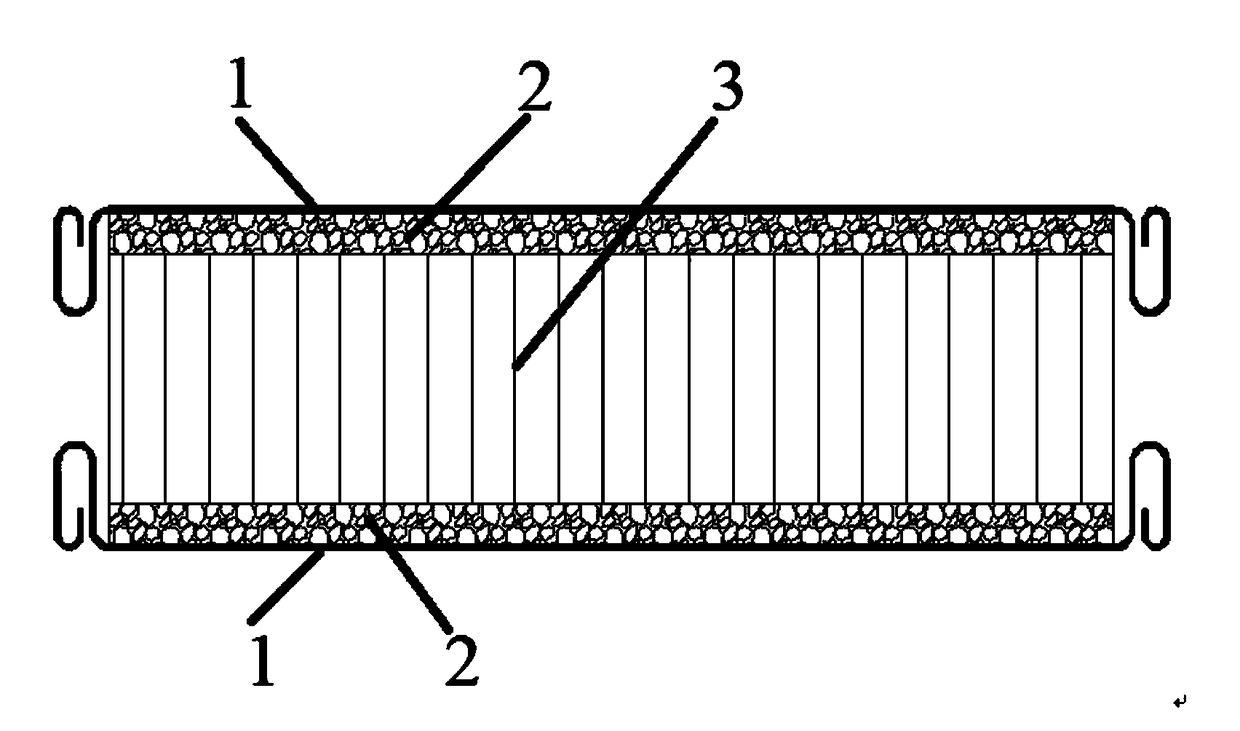

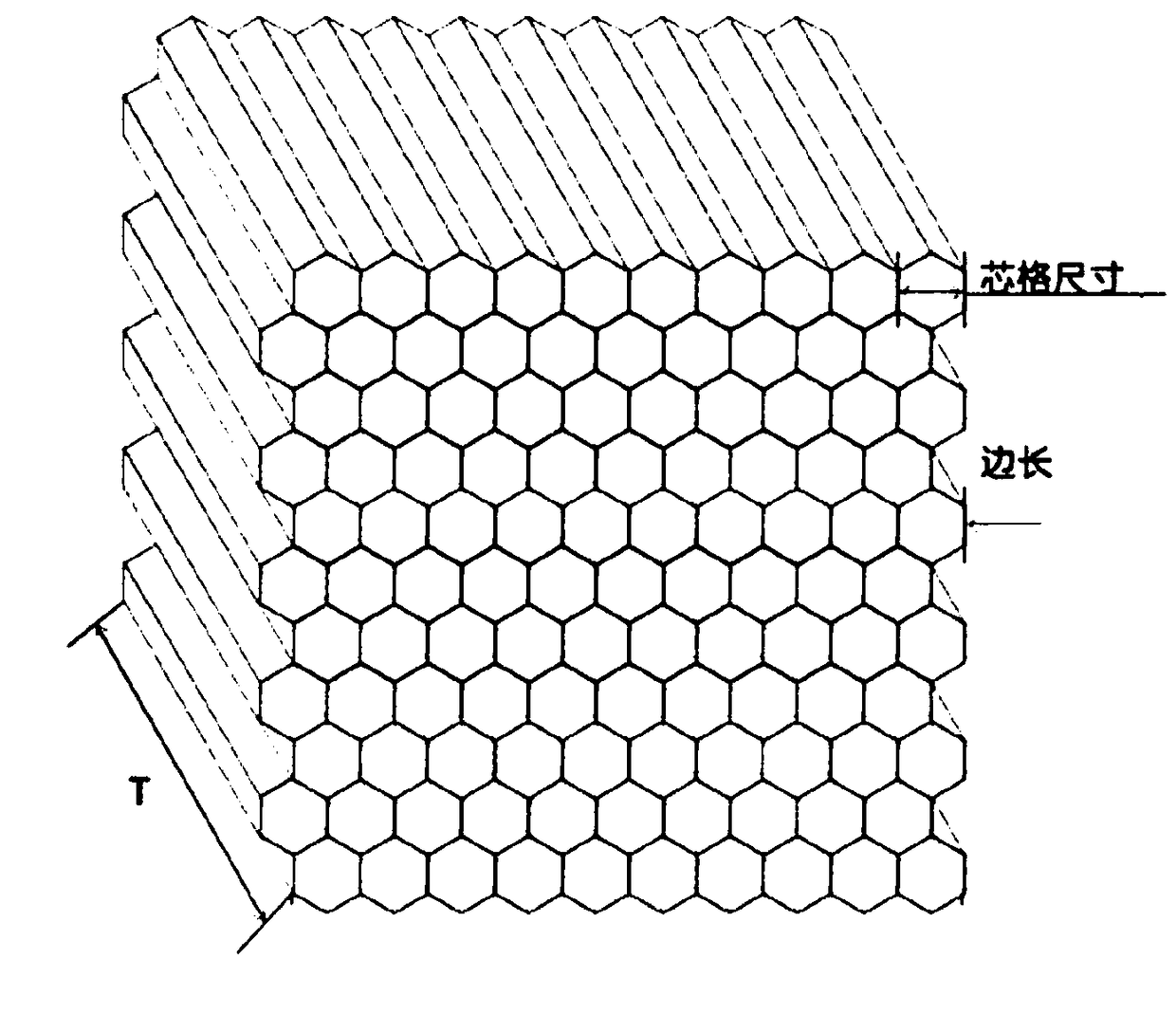

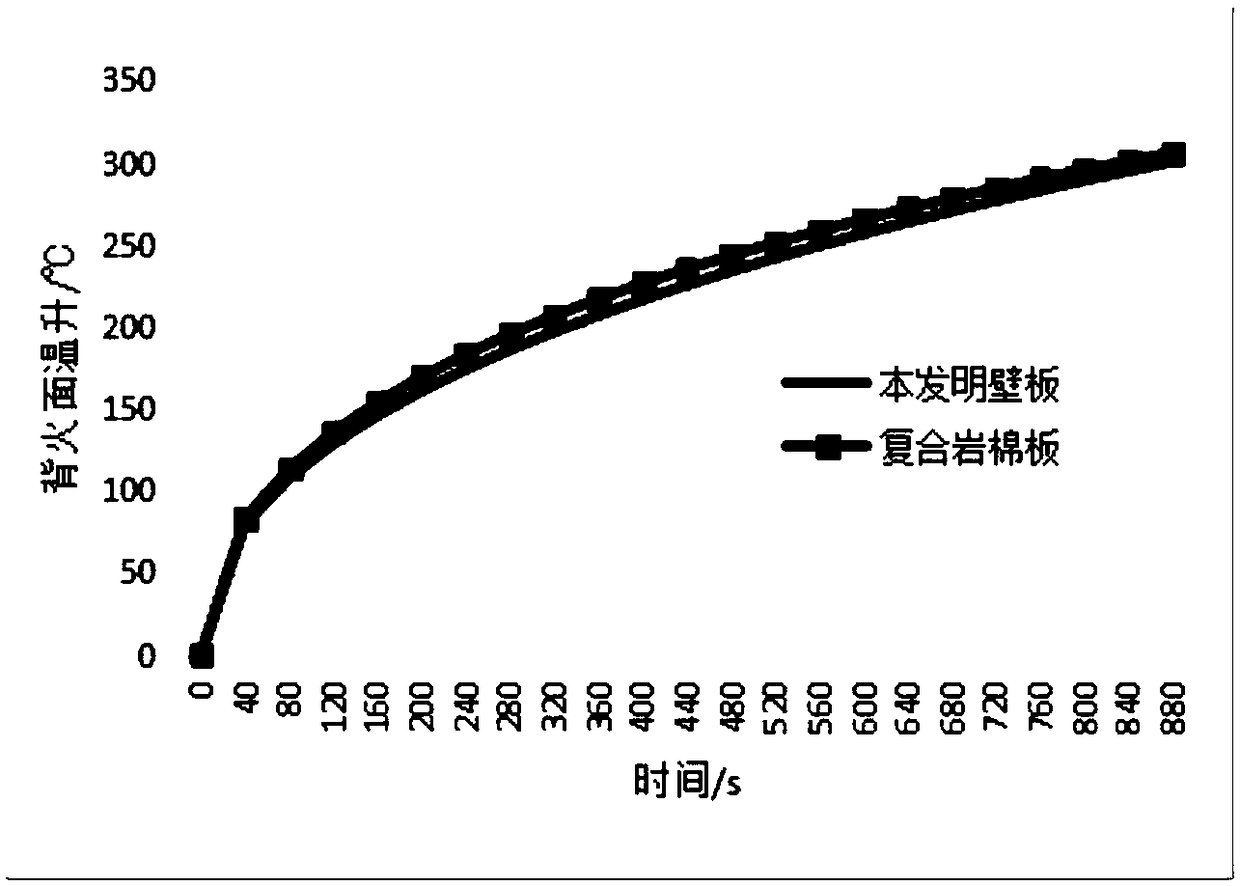

[0034] A light-weight sound-insulating fire-resistant ship cabin wall panel, comprising a five-layer structure, followed by a panel 1, an interlayer heat insulation material layer 2, a supporting core material layer 3, an interlayer heat insulation material layer 2 and a panel 1, such as figure 1 shown. Panel 1 is galvanized steel sheet with a thickness of 0.6mm; the insulation material of interlayer insulation material layer 2 is nano-airgel, the thickness of the airgel layer is 5mm, and the density of the airgel is 180kg / m 3 , the normal temperature thermal conductivity of the airgel is 0.019W / (m.k); the support core material layer 3 is aluminum honeycomb, and the schematic diagram of the aluminum honeycomb structure is as follows figure 2 As shown, the thickness T of the aluminum honeycomb is 30mm, the thickness of the aluminum honeycomb paper is 0.07mm, the cell side length is 12mm, and the density of the aluminum honeycomb is 36kg / m 3 .

[0035] Specifically, the overa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com