High-heat-conductivity high-corrosion-resistance cast aluminum alloy and preparation method thereof

A casting aluminum alloy, high corrosion resistance technology, applied in the field of aluminum alloy, can solve the problems of unfavorable corrosion resistance improvement, achieve the effect of improving shape and distribution, high strength, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

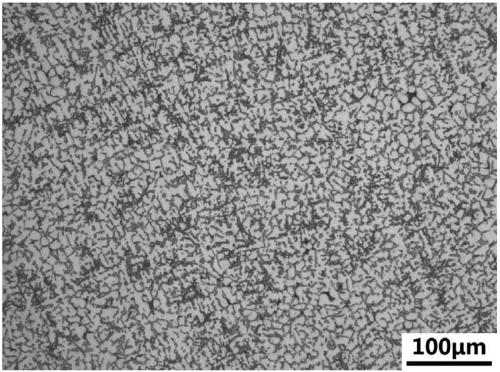

[0063] Example 1 Al-7Si-0.6Fe-0.5Zn-0.05B-0.15Sr-0.2RE alloy

[0064] In this example, B, Sr and RE components are compounded on the basis of Comparative Example 2, wherein RE is mixed rare earths containing Ce and La (Ce / La mass ratio is 6 / 4). The raw materials used in formulating alloys include: industrial pure aluminum, pure zinc, Al-Si, Al-Fe, Al-B, Al-Sr and Al-RE master alloys. The material composition percentage is: Si: 7%, Fe: 0.6%, Zn: 0.5%, B: 0.05%, Sr: 0.05%, RE: 0.2%, and the balance is Al.

[0065] The alloy melting and preparation process and its parameters are as follows:

[0066] (1) Melting aluminum alloy at high temperature. The specific steps are:

[0067] According to the composition ratio requirements, first weigh industrial pure aluminum, Al-Si, and Al-Fe intermediate alloy raw materials, melt the aluminum alloy containing Si and Fe, the melting temperature is 730 ° C, stir for 20 minutes, and let it stand to cool down to 700 ° C.

[0068] (2) alloyi...

Embodiment 2

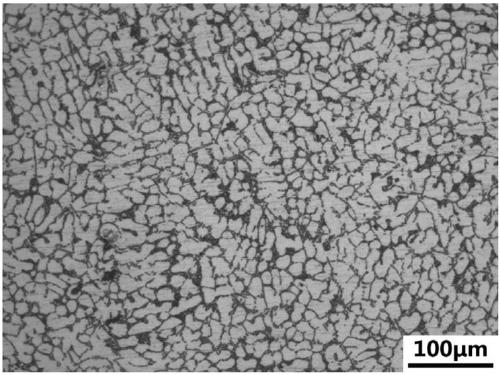

[0078] Example 2 Al-9Si-0.6Fe-0.6Zn-0.3Co-0.1B-0.15Sr-0.2RE alloy

[0079] The alloy system of this embodiment is that the element Co is added on the basis of the alloy composition in the embodiment 1, and the composition of other elements is the same, the difference is that the content of each component is different.

[0080] The raw materials used for formulating alloys include: industrial pure aluminum, pure zinc, Al-Si, Al-Fe, Al-Co, Al-B, Al-Sr and Al-RE master alloys, wherein RE is mixed rare earth containing Ce and La ( The Ce / La mass ratio is 6 / 4). The composition percentage of the material is: Si: 9%, Fe: 0.6%, Zn: 0.6%, Co: 0.3%, B: 0.1%, Sr: 0.15%, RE: 0.2%, and the balance is Al.

[0081] The specific smelting process of this embodiment is similar to that of Embodiment 1. The difference is that the Co element is added, and the processing parameters are different.

[0082] The alloy melting and preparation process and its parameters are as follows:

[0083] (1) ...

Embodiment 3

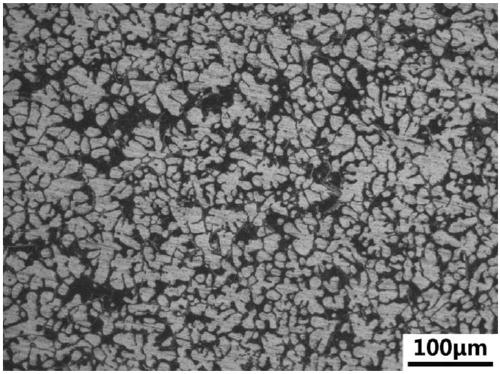

[0095] Example 3 Al-7Si-0.6Fe-0.5Zn-0.2Co-0.05B-0.15Sr-0.2Ce alloy

[0096] The alloy system of this embodiment is similar to the composition of alloy elements in embodiment 2, the difference is that the RE element is Ce, and the content of each component is different. The raw materials used for formulating alloys include: industrial pure aluminum, pure zinc, Al-Si, Al-Fe, Al-Co, Al-B, Al-Sr and Al-Ce master alloys. The composition percentage of the material is: Si: 7%, Fe: 0.6%, Zn: 0.5%, Co: 0.2%, B: 0.05%, Sr: 0.05%, Ce: 0.2%, and the balance is Al.

[0097] The alloy smelting and preparation process of this embodiment is similar to that of Embodiment 2. The difference is that the processing parameters are different.

[0098] The alloy melting and preparation process and its parameters are as follows:

[0099] 1) High temperature melting aluminum alloy

[0100] According to the composition ratio requirements, first weigh industrial pure aluminum, Al-Si, Al-Fe and Al-Co ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com