Space truss structure surface slab assembly

a technology of space trusses and surface slabs, which is applied in the direction of girders, instruments, vessel construction, etc., can solve the problems of low dynamic efficiency of processing plates in any type of materials, low productivity, and reduced thickness of hollow grid members, so as to achieve high strength, low cost, and economic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0047]A description of preferred embodiments will be provided with reference to the drawings:

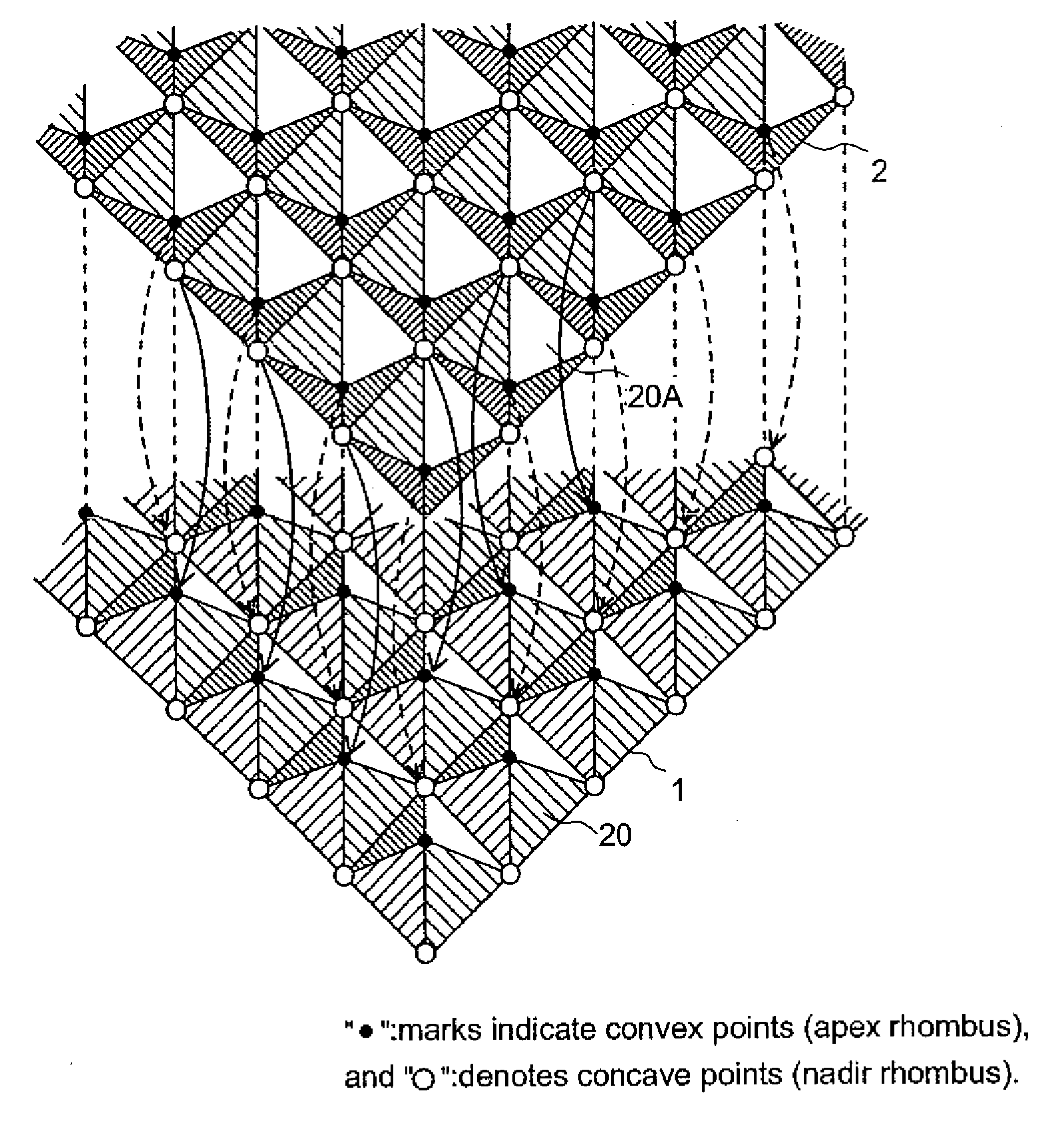

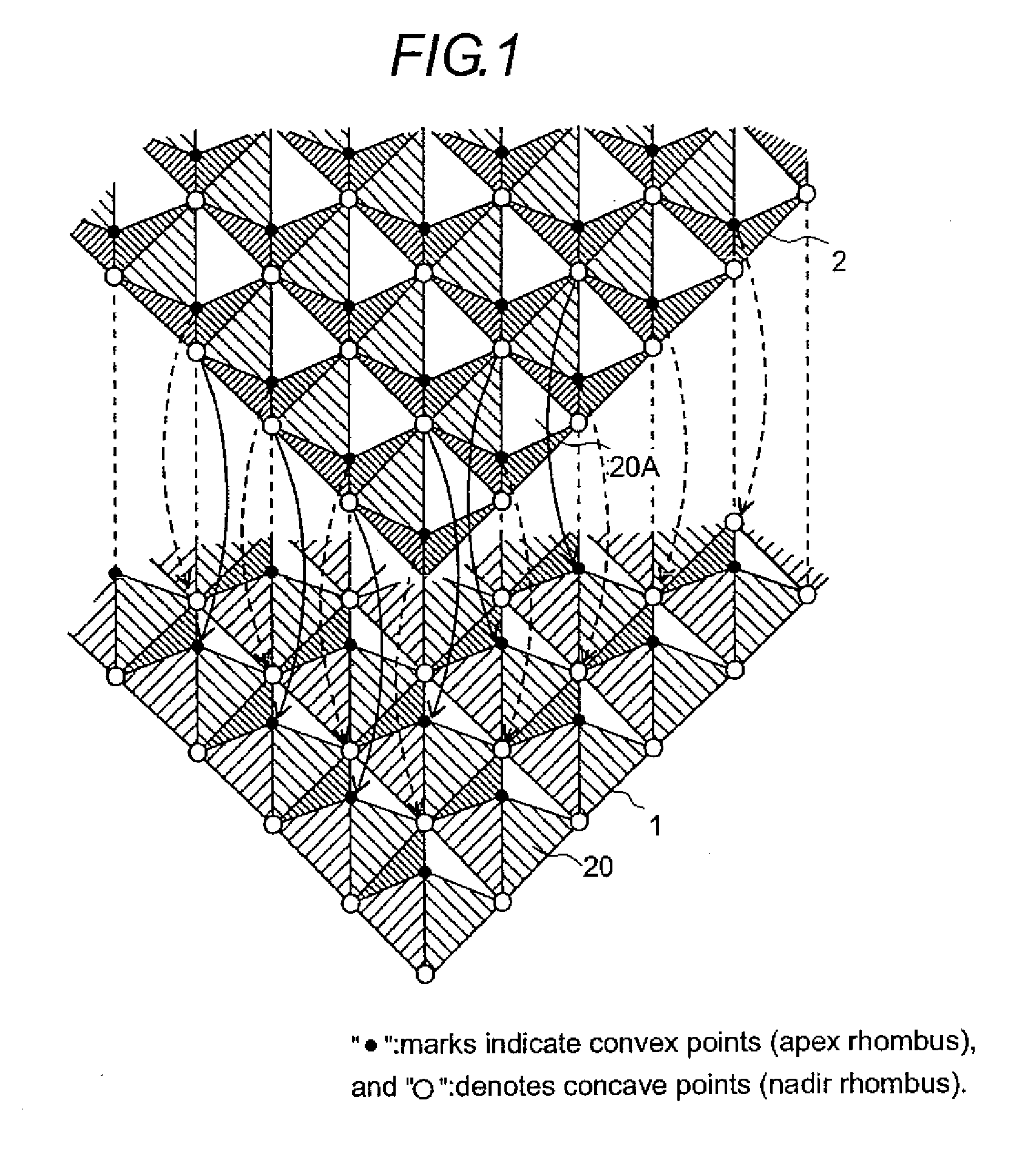

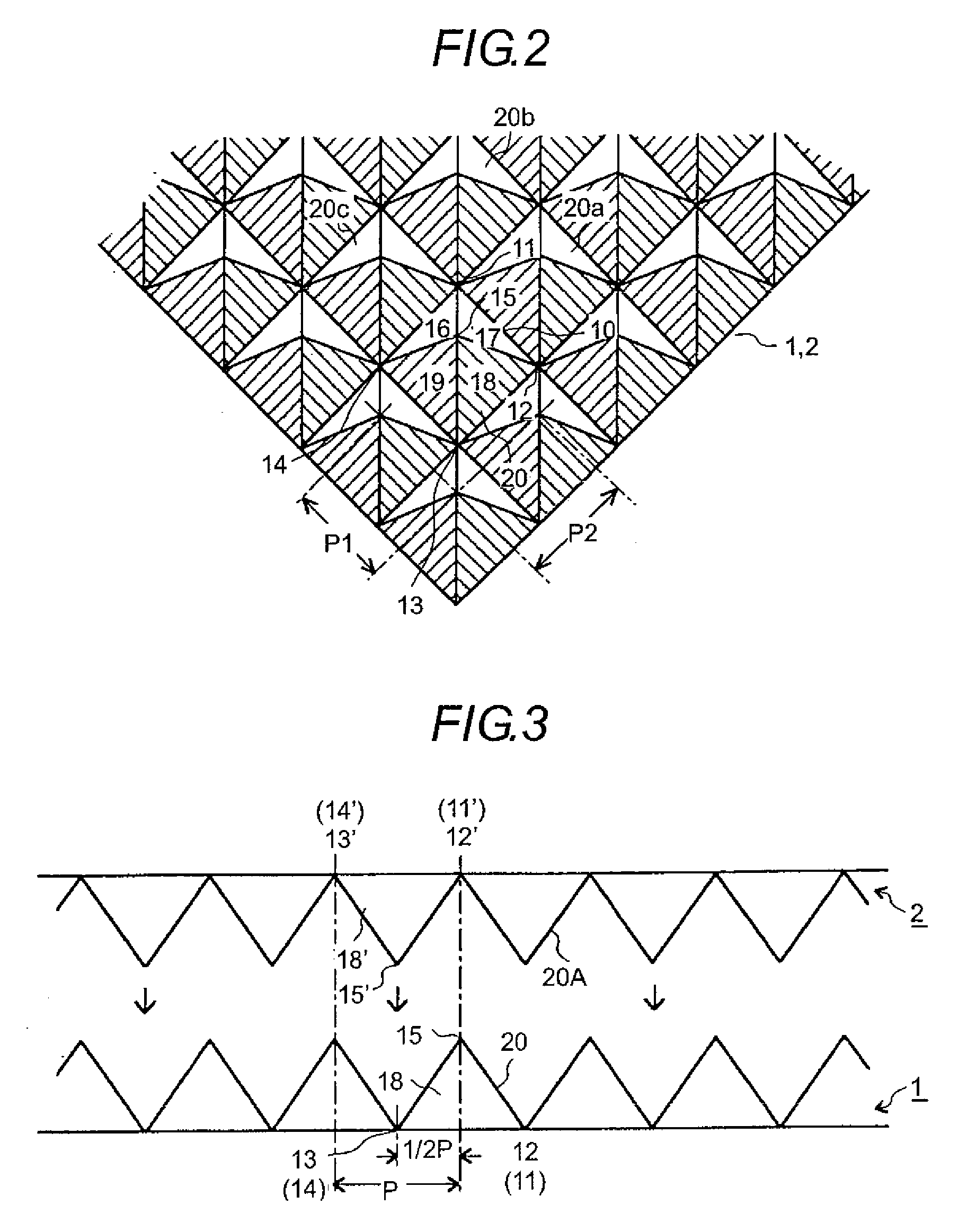

[0048]FIGS. 1 through 4 show a first embodiment of the present invention.

[0049]FIG. 1 shows how to configure a space truss structure surface slab assembly. FIG. 2 provides details of a partial view in FIG. 1. FIG. 3 shows a two-piece set of pyramidal surface slabs prior to assembling. FIG. 4 shows the assembly thereof as a first embodiment.

[0050]In FIG. 1, two pyramidal surfaces 1 and 2 are used to configure the space truss structure surface slab assembly.

[0051]Referring first to FIG. 2, the configuration of the pyramidal surface slabs 1 and 2 will be described. Pyramidal surface slabs 1 and 2 are fabricated from one of sheet material, for example, a metal sheet formed through injection processing by a stamping die. As will be described later, except for the metal sheet, a non-metallic material such as corrugated cardboard, lumber, plywood, plastics and glass can be used as a sheet material....

embodiment 2

[0065]FIGS. 7 through 9 show a second embodiment of the present invention. FIG. 7 shows the details of the pyramidal surface; while, FIGS. 8 and 9 show how to assemble a two-piece set of the pyramidal surface slabs used in the present embodiment.

[0066]To configure a space truss structure surface slab assembly, two pyramidal surface slabs 101 and 102 are used in a manner similar to that shown in FIG. 1. Referring to FIG. 7, the configuration of the pyramidal surface slabs 101 and 102 will be described. The pyramidal surface slabs 101 and 102 are produced from one plate-like material, for example, a metallic plate, by a molding operation using a stamping die.

[0067]As shown in FIG. 7, the pyramidal surface slabs 101 and 102 are delimited by plotting three nadir rhombuses 111, 112 and 113. An apex rhombus 115 is delimited above the center point of a triangle 110, and each of the nadir rhombuses 111, 112 and 113 and the apex rhombus 115 are plotted to form a group of pyramidal surfaces p...

embodiment 3

[0077]FIG. 10 shows an example of a third embodiment in which a pyramidal surface slab containing a hexagonal pyramidal surface is employed. FIGS. 10 through 13 show the details of the third embodiment. FIG. 10 shows how to configure a space truss structure surface slab assembly, and FIG. 11 shows details thereof in a partial view of FIG. 10. FIG. 12 and FIG. 13 show how to assemble a two-piece set of pyramidal surface slabs used in the present embodiment.

[0078]In FIG. 10, two sets of pyramidal surface slabs 1 and 2 are used to configure a space truss structure surface slab assembly.

[0079]Referring to FIG. 11, the configuration of the pyramidal surface slabs 1 and 2 will be described. The pyramidal surface slabs 1 and 2 are produced from one plate-formed material—for example, sheet metal—by a molding operation using a stamping die. As shown in FIG. 11, an apex rhombus 47 is delimited over the center point of a hexagon 40 that is delimited by plotting six nadir rhombuses 41, 42, 43, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com