Explosion venting bulkhead structure with unequal intensity of naval vessel cabin

A strength and cabin technology, applied in the field of strength explosion venting bulkhead structure, can solve the problems of enhancing the destruction power, increasing the number of blast shock waves, and prolonging the action time of quasi-static pressure, so as to avoid the overall damage and improve the residual strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

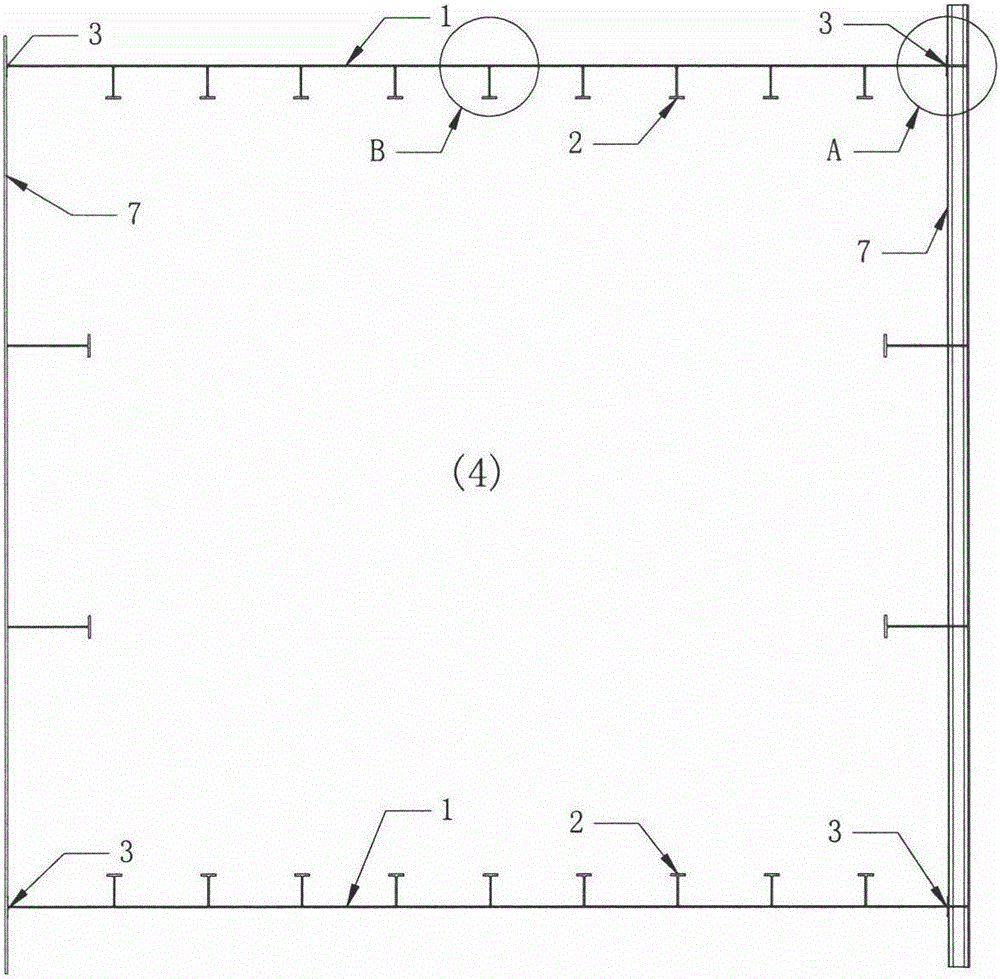

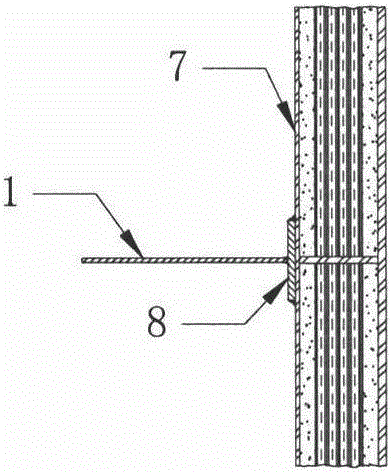

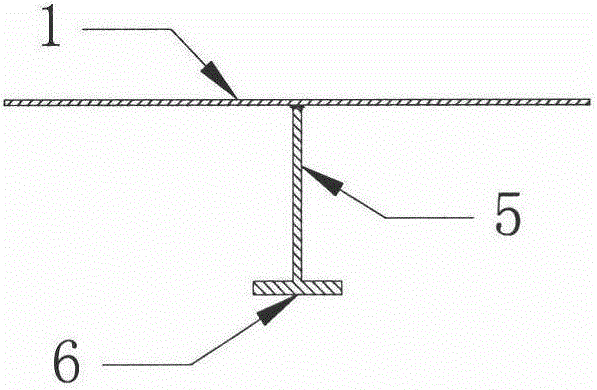

[0024] Example 1: see Figure 1 to Figure 3 , the cabin (4) that needs to be vented adopts two unequal-strength explosion-venting bulkhead structures of the ship cabin according to the present invention, which are connected by the explosion-venting plate (1), the reinforcing rib (2) and the unequal-strength corner connection structure ( 3) Composition. The explosion venting plate (1), the reinforcing ribs (2) and the unequal strength corner connection structure (3) are made of marine steel materials. The reinforcing rib (2) adopts a T profile and is arranged inside the cabin (4) to be vented. The thickness of the web (5) and the face plate (6) of the T profile is greater than that of the explosion venting plate (1). The unequal strength corner connection structure (3) adopts a double plate (8). The thickness of the cladding plate (8) is greater than that of the explosion venting plate (1), and is arranged perpendicular to the explosion venting plate (1) and parallel to the ...

Embodiment 2

[0025] Example 2: see Figure 4 , the structure of this embodiment is basically the same as that of the first embodiment, the difference is that the unequal strength corner connection structure (3) adopts square steel (9), and the wall thickness of the square steel (9) is larger than that of the explosion vent plate ( 1).

Embodiment 3

[0026] Example 3: see Figure 5 , the structure of this embodiment is basically the same as that of the second embodiment, the difference is that the reinforcing rib (2) adopts square steel (10), and the wall thickness of the square steel (10) is larger than that of the explosion vent plate (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com