Watertight heat insualtion container with improved longitudinal stereo cross angle

An insulated container, watertight technology, applied in the direction of containers, large containers, rigid containers, etc., can solve problems such as insufficient resistance to stretching, damage to the first watertight barrier, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

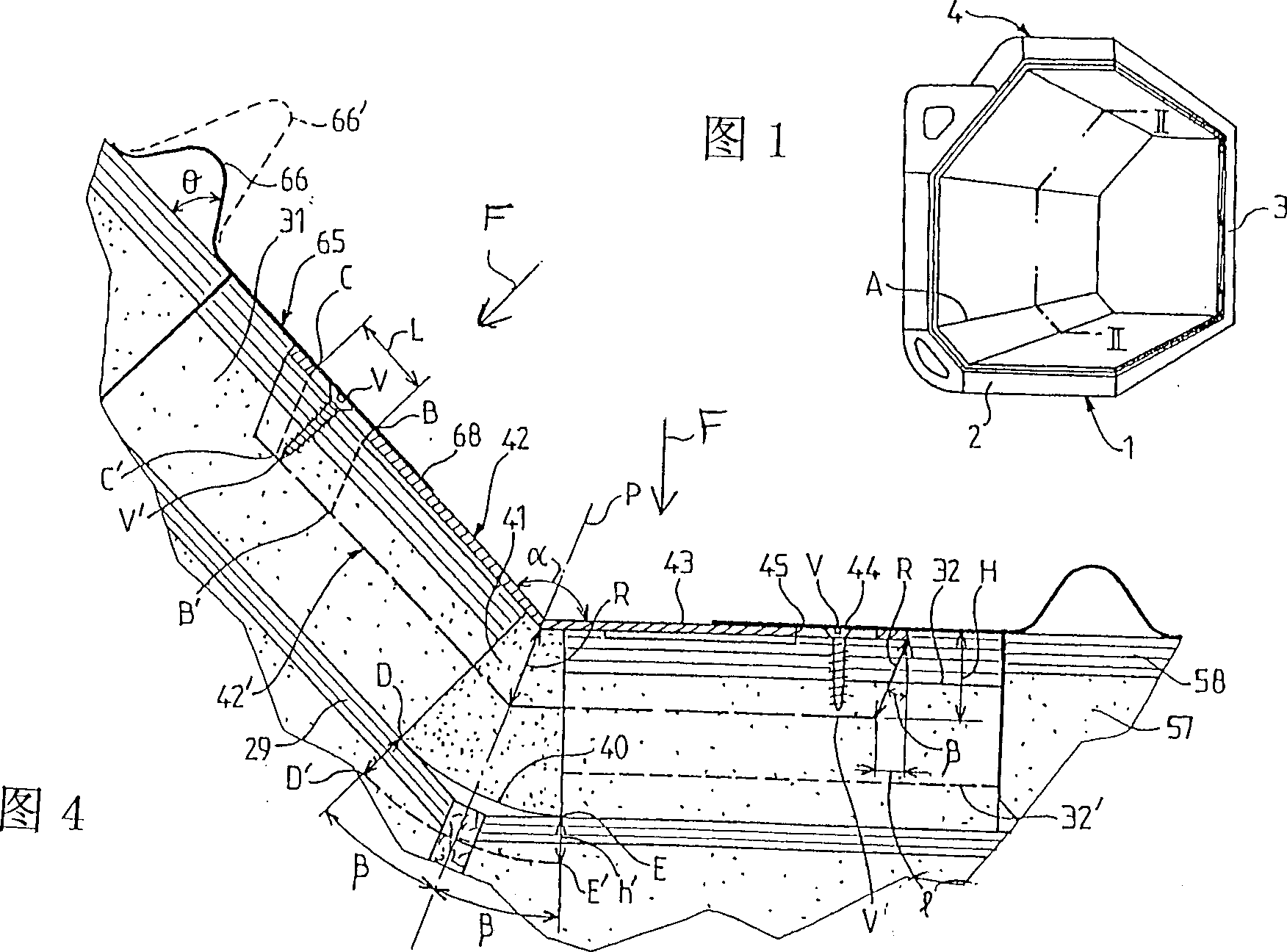

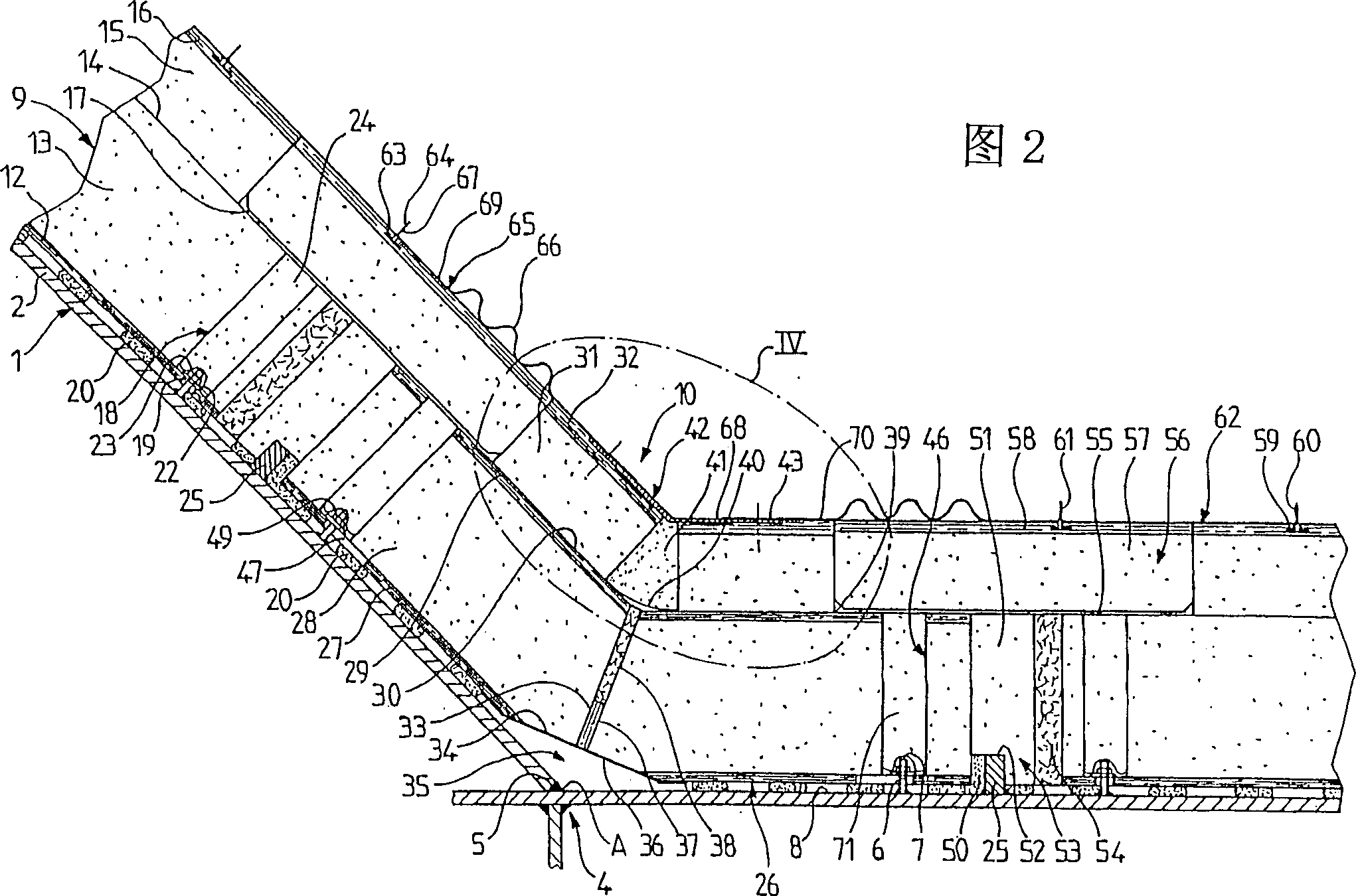

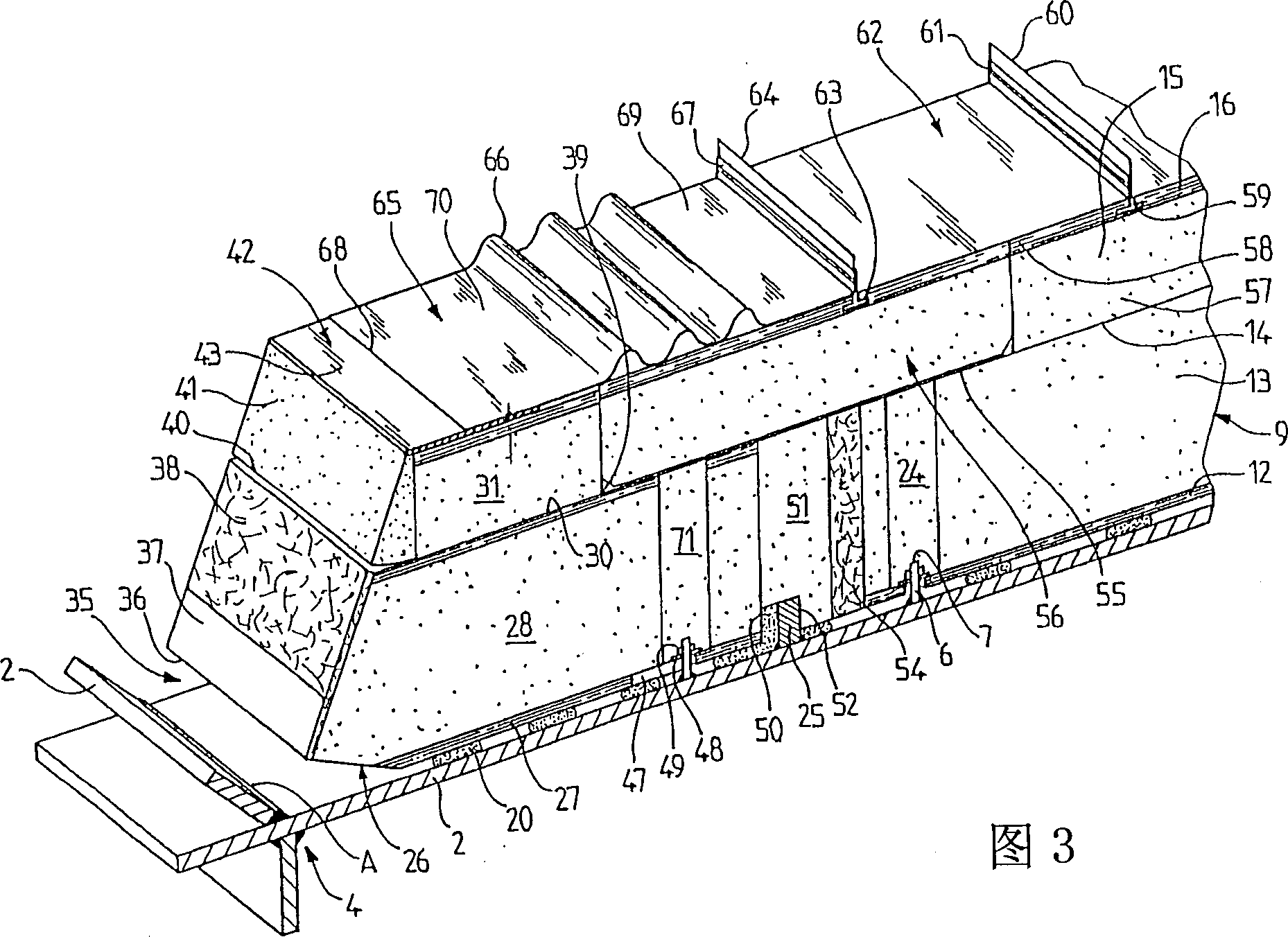

[0029] Figure 1 shows the double hull of a ship in which the container of the invention is built. This double hull wall forms compartments, each compartment being formed by a number of generally flat longitudinal faces 2 welded along their longitudinal edges to generally form a section of cylinder or cone, said longitudinal sides And welded along the transverse partition wall 3 at the longitudinal end of the compartment. The longitudinal faces 2 and transverse partitions 3 of a compartment form the support structure 1 of the container which will be described below. The transverse partition wall 3 is also double-layered. In general, the longitudinal plane 2 is generally conical with a polygonal director curve in the bow part of the above-mentioned ship (not shown) and cylindrical with a polygonal director curve in the rest of the ship ,As shown in Figure 1. Each pair of adjacent longitudinal faces 2 defines a dihedron 4 whose solid intersection angle A substantially coincide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com