Sleeve for marine riser

A riser and marine technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of high cost of design, manufacture and installation, dynamic instability, increased drag force of the main pipe, etc., to simplify the manufacturing process and reduce construction costs. cost, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

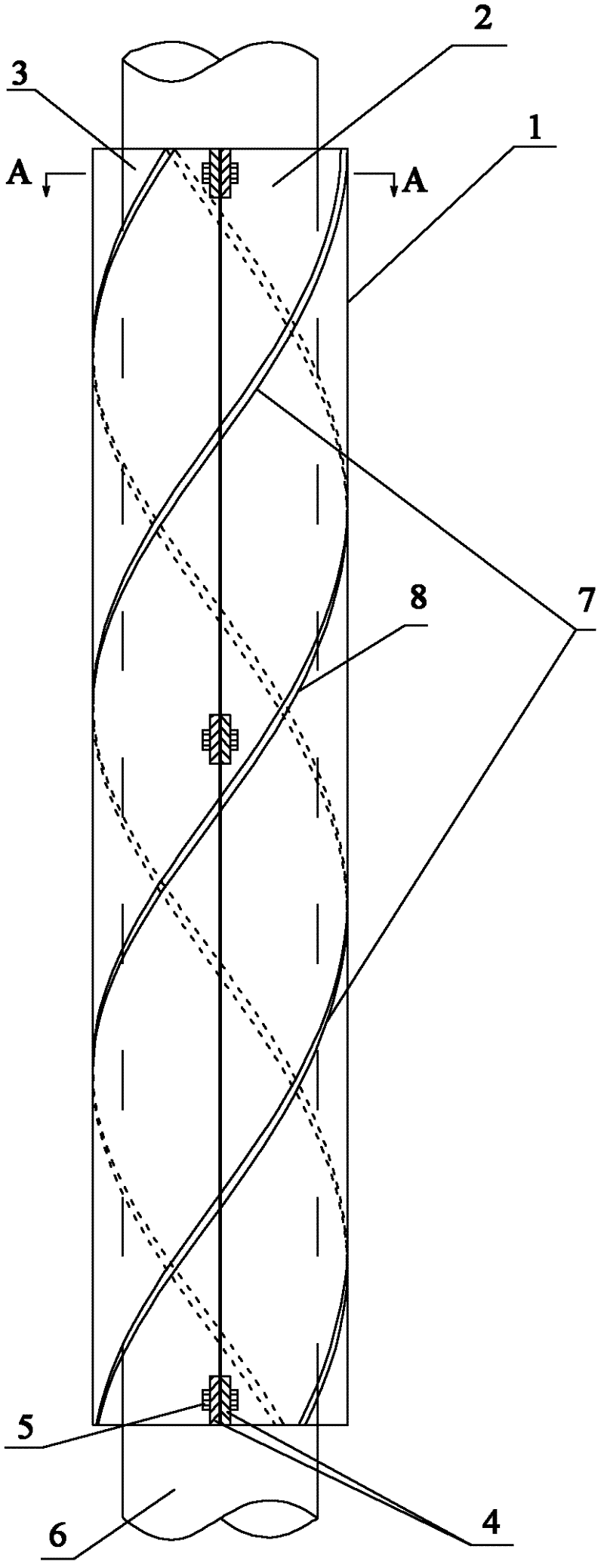

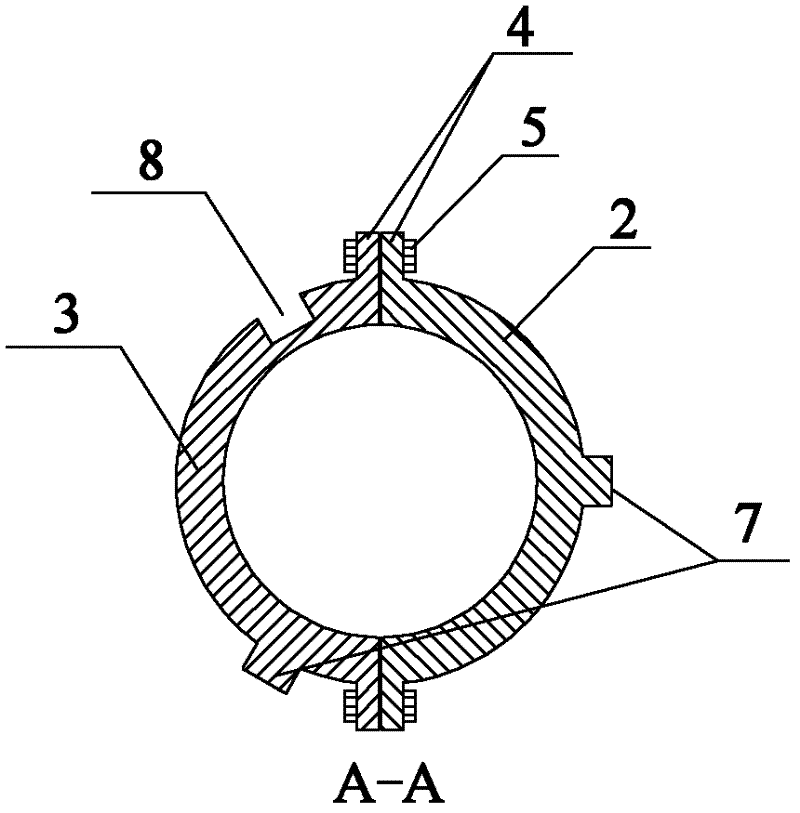

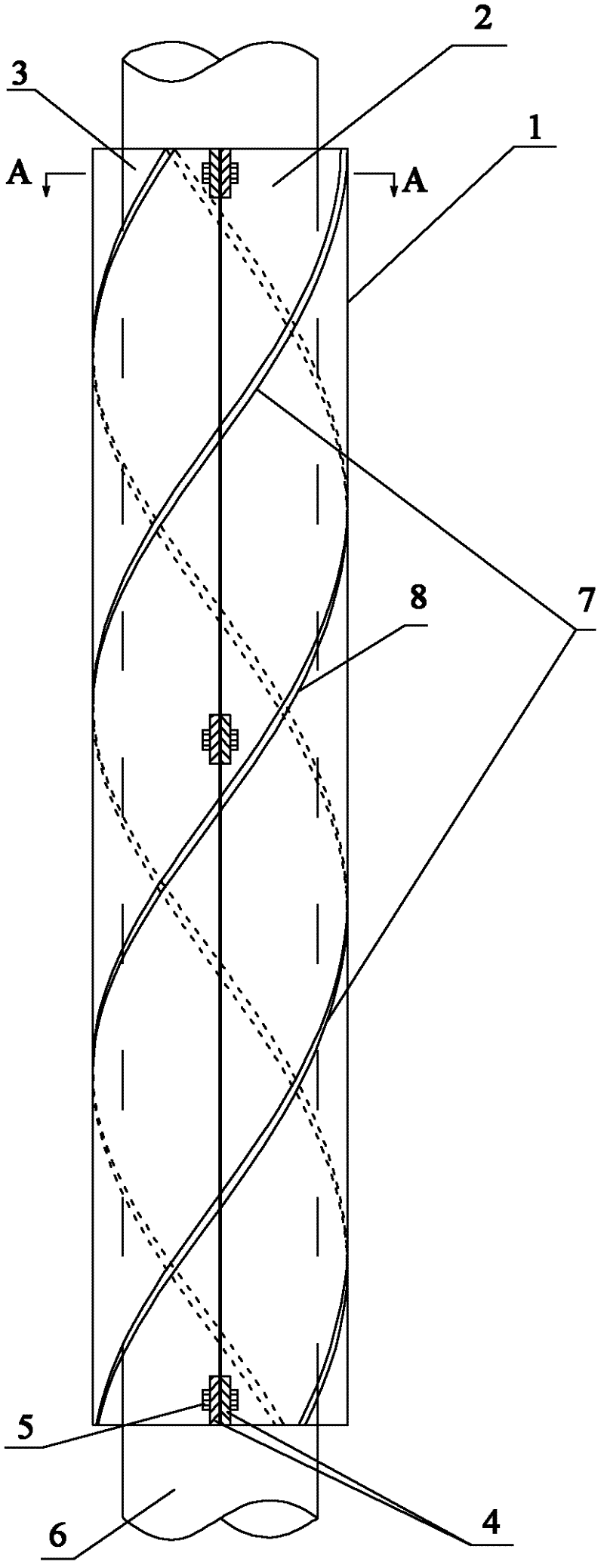

[0014] The invention suppresses the vortex-induced vibration of the marine riser through the method of installing a sleeve with a helical structure at regular intervals on the marine riser. The main steps are as follows:

[0015] (1) According to the outer diameter of the marine riser to be protected, two semi-circular shells with the same size are made, which can be mass-produced through moulds.

[0016] (2) Put the first shell close to one side of the pipeline surface, and connect the other shell with the shell already in place through the position of the eye plate and the rotation direction of the helical structure.

[0017] (3) The two shells are fixed by 6 bolts. Bolts pass through the eye plate to connect the two shells to form a sleeve fixed on the outer surface of the pipeline.

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Front view of a section of a marine riser fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com