Tower frame vibration damping device and tower frame comprising same

A vibration damping device and tower technology, applied in the installation/supporting configuration of wind turbines, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problem that turbulence or damping devices cannot suppress the random vibration of tower vortex-induced vibration at the same time , Control the limited power control of the unit, the large space occupied by the cable, etc., to achieve the effect of high construction feasibility, small occupied space, and economical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

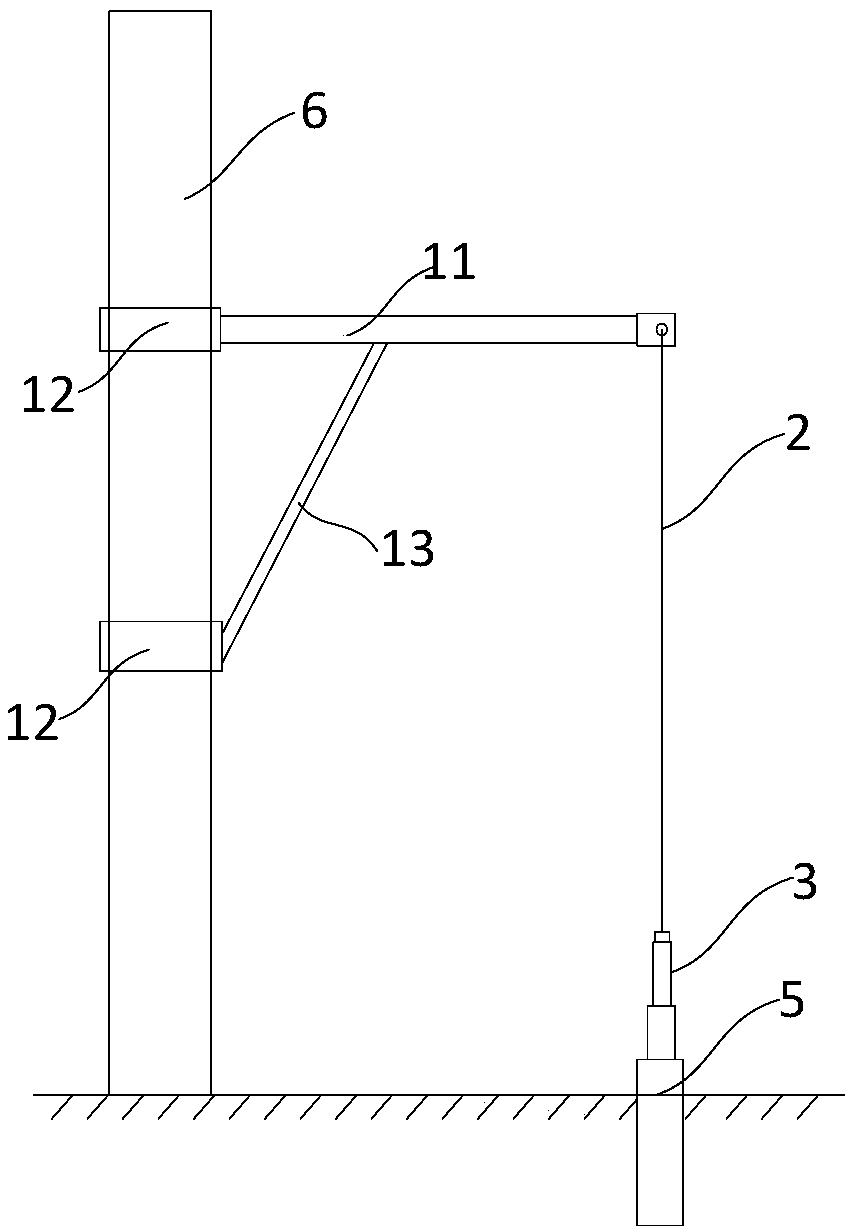

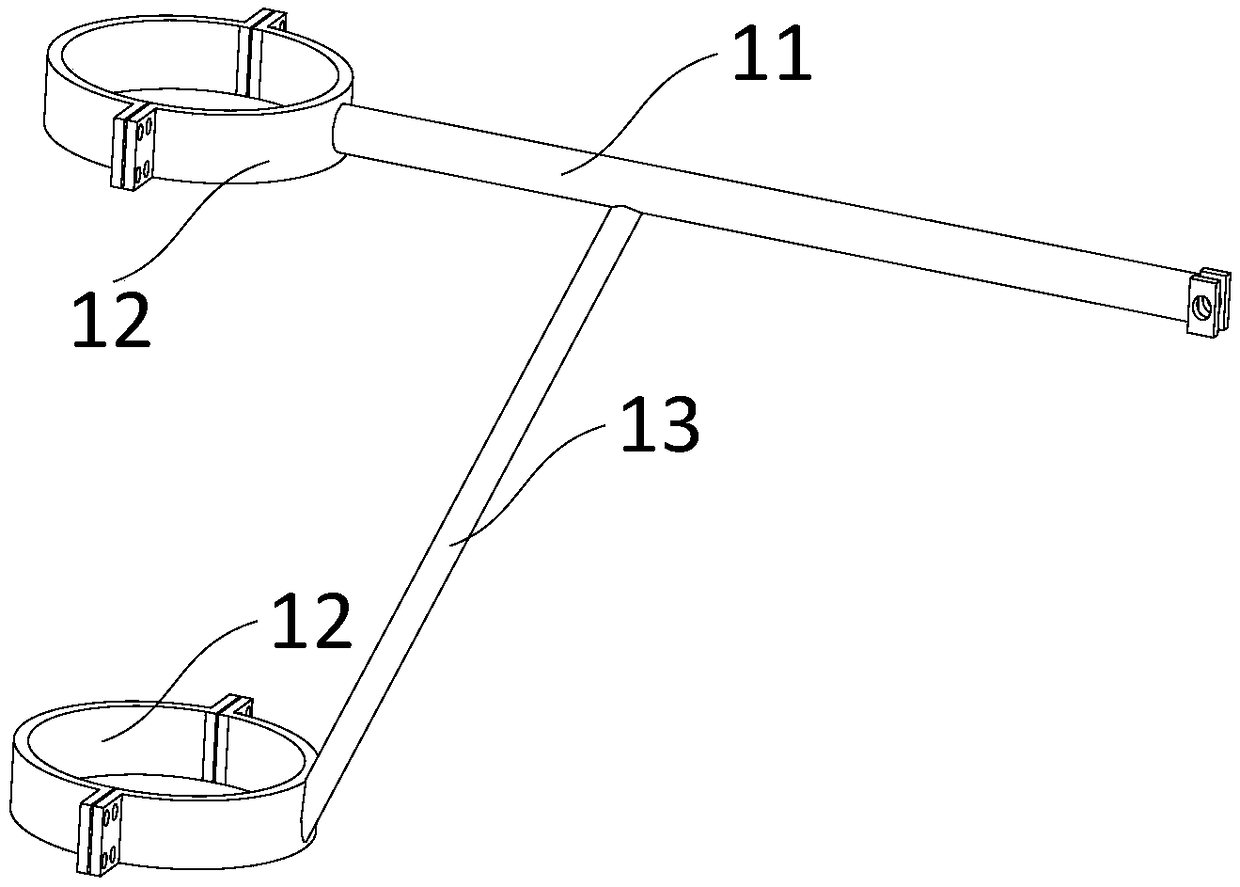

[0046] Such as figure 1 and figure 2 As shown, the present invention provides a vibration damping device for a tower, which includes a support system 1 . The support system 1 includes a support rod 11 and a connecting block 12 . The connecting block 12 is fixedly welded to one end of the support rod 11 . The support system 1 also includes a diagonal brace 13, and the use of the diagonal brace 13 can make the structure of the entire support system 1 stronger. One end of the diagonal strut 13 is fixedly welded with a connecting block 12 , and the other end of the diagonal strut 13 is fixedly welded to a position in the middle of the support rod 11 . As an alternative, other fixed connections can also be used. The tower vibration damping device also includes a cable 2, a damper module 3, and an anchor pile system 5, and the support system 1, the cable 2, the damper module 3, and the anchor pile system 5 are connected in sequence.

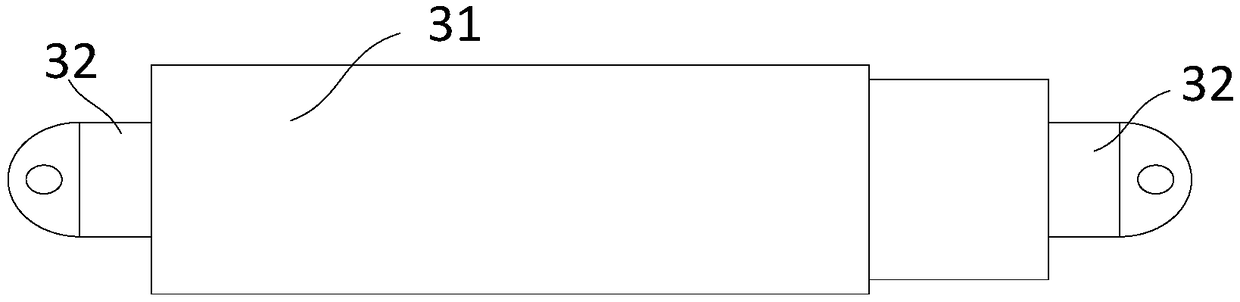

[0047] Such as image 3 As shown, the dampe...

Embodiment 2

[0052] Such as Figure 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference being that: the support system 1 further includes a pulley 14 fixed to one end of the support rod 11 . One end of the cable 2 is bound to the tower 6 , then goes around the pulley 14 , and the other end is connected to the first connecting rod 32 at the other end of the damper module 3 . Adding a pulley 14 at one end of the support rod 11 can avoid the friction between the stay cable 2 and the support rod 11, and the stay cable 2 itself will be deformed due to tension, and the use of the pulley 14 makes the deformation of the stay cable 2 unconstrained , so as to better achieve the effect of suppressing tower vibration.

Embodiment 3

[0054] Such as Figure 4 and Figure 7As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the tower vibration damping device also includes an elastic system 4 . That is, in order to adjust the natural frequency of the entire tower vibration damping device and avoid resonance between the tower vibration damping device and the tower 6 , an elastic system 4 is installed between the damper module 3 and the anchor pile system 5 . The elastic system 4 includes a spring 41 , a barrel 42 , a movable link 43 and a fixed link 44 . The spring 41 is located inside the cylinder 42 , one end of the spring 41 is fixed on the movable connecting rod 43 , the other end of the spring 41 is fixed on the top of the inner wall of the cylinder 42 , and the fixed connecting rod 44 is welded on the top of the outside of the cylinder 42 . In order to achieve a better effect of avoiding resonance between the tower vibration damping device an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com