Independent liquefied gas ship

A liquefied gas ship, independent technology, applied in the direction of the hull, hull bulkhead, hull parts, etc., can solve the problems of large polluted sea area, large loss of fire protection system on board, etc., and achieve the effect of reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

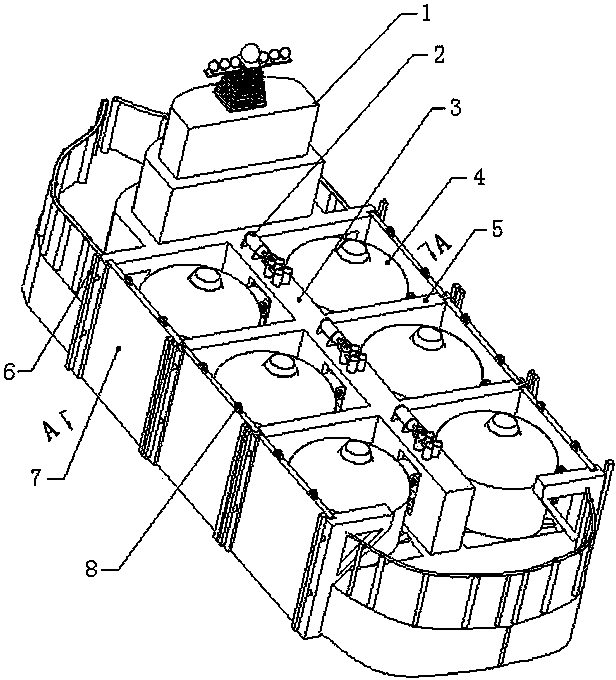

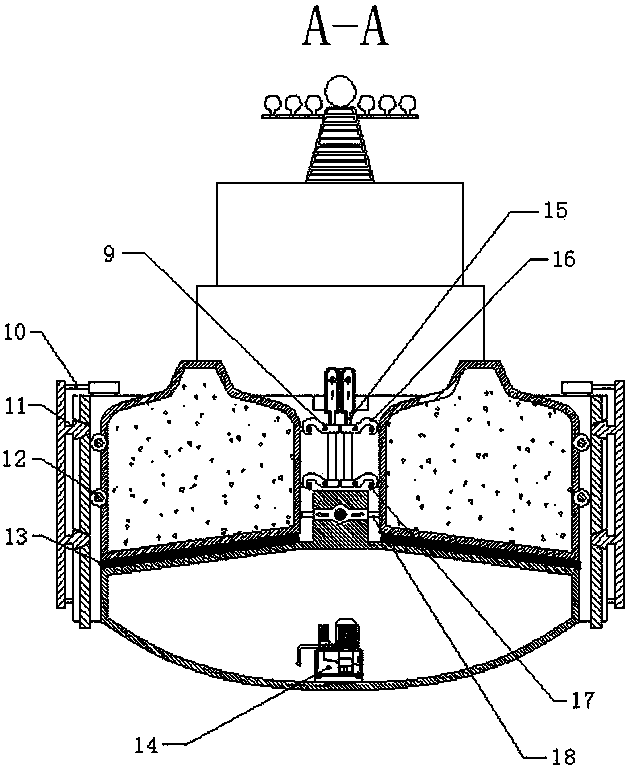

[0013] The independent liquefied gas ship of the present invention includes a hull 1, a hydraulic pump 2, a cantilever beam 3, a storage tank 4, a compartment 5, a connecting rod 6, a release door 7, a hook 8, a rotating shaft 9, a release ejector rod 10, and a release pin 11. Pulley 12, support rail 13, hydraulic pump station 14, hydraulic push rod 15, trip 16, pull ring 17 and push rod 18, six storage tanks 4 are installed on the main deck of the hull 1, and the appearance of the storage tank 4 is The bread has thermal insulation material and steel protective layer to protect the safety and pressure of the tank body. The storage tank 4 is installed on the left and right sides of the cantilever beam 3, which can not only reduce the weight of the tank when it is discarded, but also reduce the weight of the tank when it is discarded. economic loss and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com