Split and current collecting interactive assembly manufacturing method for LNG marine polyurethane insulation box

A manufacturing method and technology for LNG ships, which are applied in ship construction, hull, hull paneling, etc., can solve problems such as uneven stress on plywood, poor quality stability, and backlog of components, achieve reliable assembly quality control, reduce equipment investment and , the effect of balancing work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

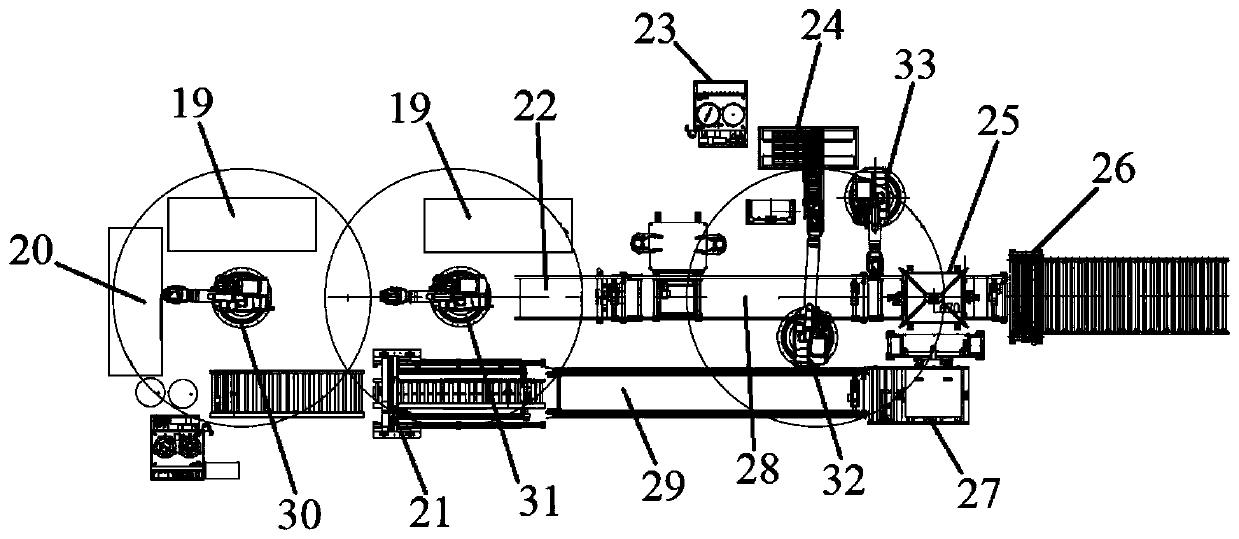

[0047] In this embodiment, a flow diversion and flow collection interactive assembly and manufacturing method suitable for multi-type and large-size LNG marine polyurethane insulation boxes is designed. Taking advantage of the advantages of high efficiency of automation equipment, according to the attribute setting of the processing process, the flow diversion method is used. , The flow-collecting interactive assembly manufacturing method, setting up the material conveying mode of double conveying lines in parallel, arranging multiple assembly stations and assembly special equipment on each conveying line, and connecting each station through an intelligent transmission system to make it It can operate continuously, efficiently and orderly, maximize the functions of each station, improve production efficiency, shorten production working hours, and ensure high-precision product quality requirements.

[0048] The diverting and collecting interactive assembly and manufacturing meth...

Embodiment 2

[0116] Polyurethane insulation box is L03 type insulation box or L03+ type insulation box.

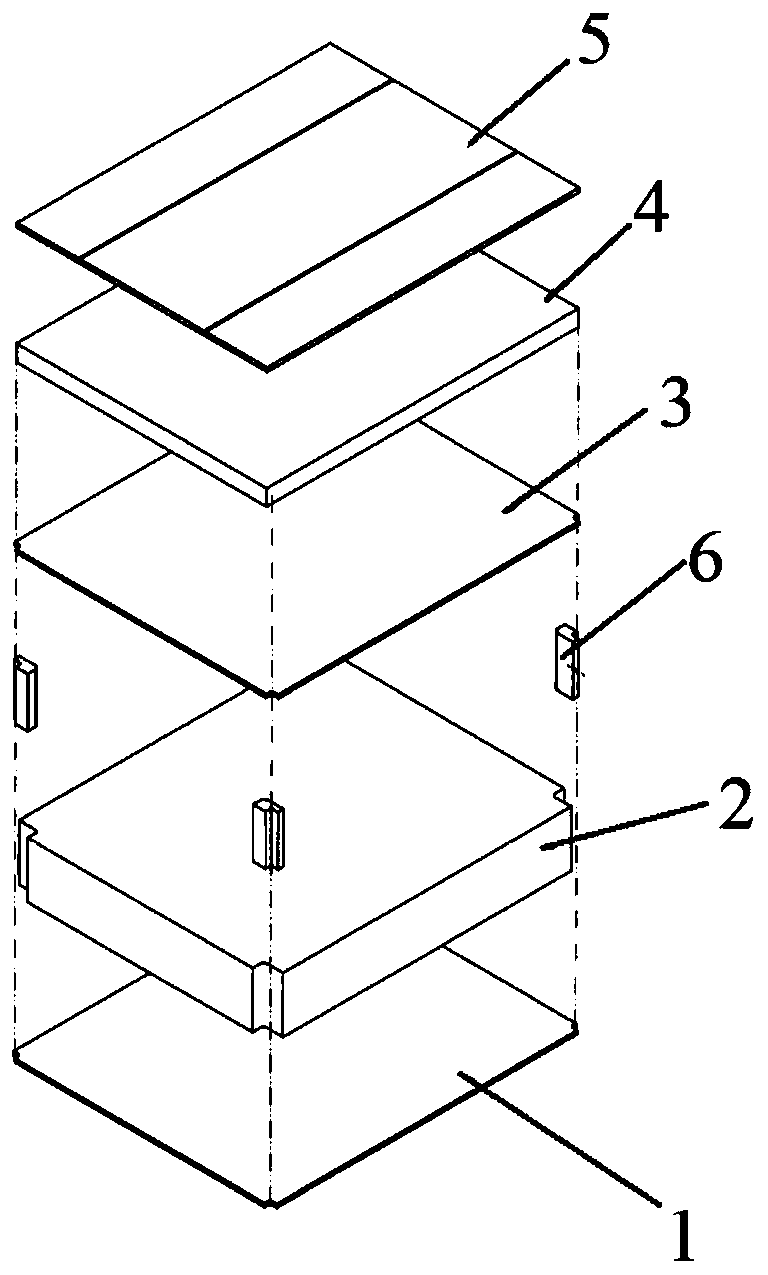

[0117] like figure 1 As shown, the L03 type insulation box includes the bottom plywood 1, the bottom polyurethane board 2, the middle plywood 3, the top polyurethane board 4, the top plywood 5 and four layers respectively arranged on the bottom polyurethane board 2. Wood splints at the four corners 6.

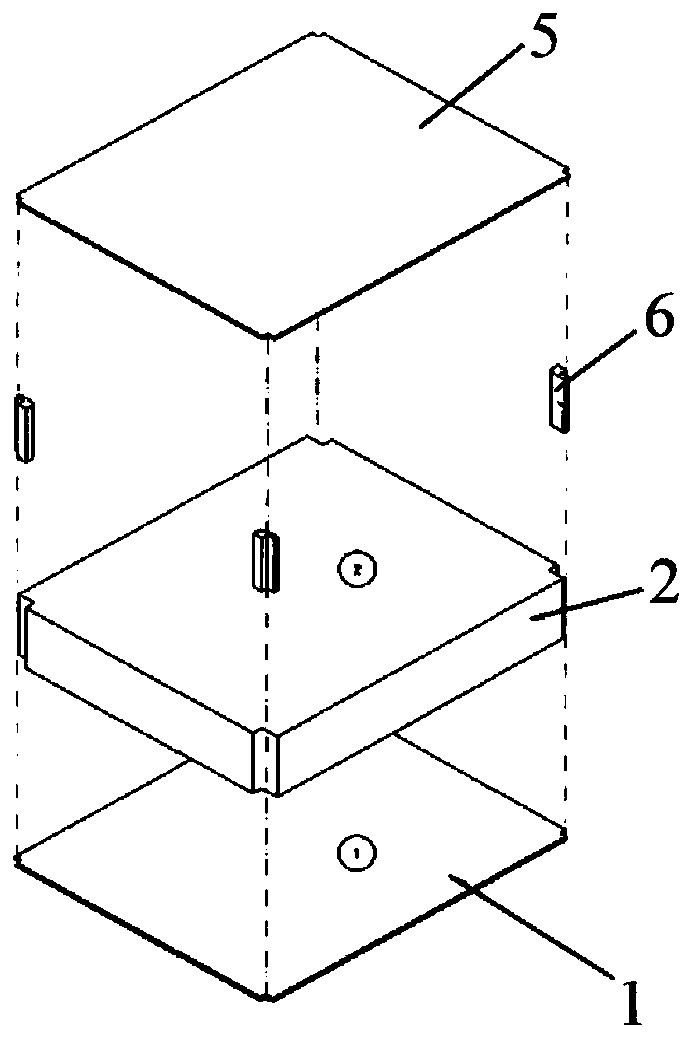

[0118] like figure 2 As shown, the L03+ type insulating box includes a bottom plywood 1, a bottom polyurethane board 2, a top plywood 5 and four wooden splints 6 respectively arranged at the four corners of the bottom polyurethane board 2, which are laminated together from bottom to top.

[0119] The manufacturing method for the flow diversion and flow collection interactive assembly of the polyurethane insulating box for LNG ships includes the following processes:

[0120] (1) Code scanning process, scan the corresponding code of the polyurethane board or plywood, and input it into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com