Vibration damping and noise reducing flexible sandwich plate for ship structure

A technology of vibration reduction and noise reduction, sandwich panels, applied in the direction of hull panels, hulls, hull components, etc., can solve the problem of affecting the performance of anechoic tiles or sound insulation decoupling structures, and the aging of anechoic tiles or sound insulation decoupling structures , Anechoic tile or sound insulation decoupling structure falling off and other problems, to achieve the effect of local pressure bearing capacity and impact energy absorption capacity, small rigidity, and improved vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A flexible sandwich plate for vibration and noise reduction hull structure of the present invention will be further described in detail below with reference to the drawings and embodiments. This description is only a preferred embodiment of the present invention, and does not limit the protection scope of the present invention.

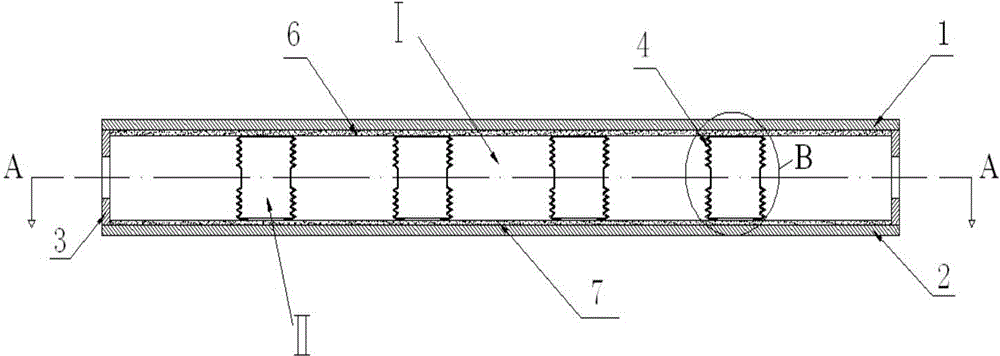

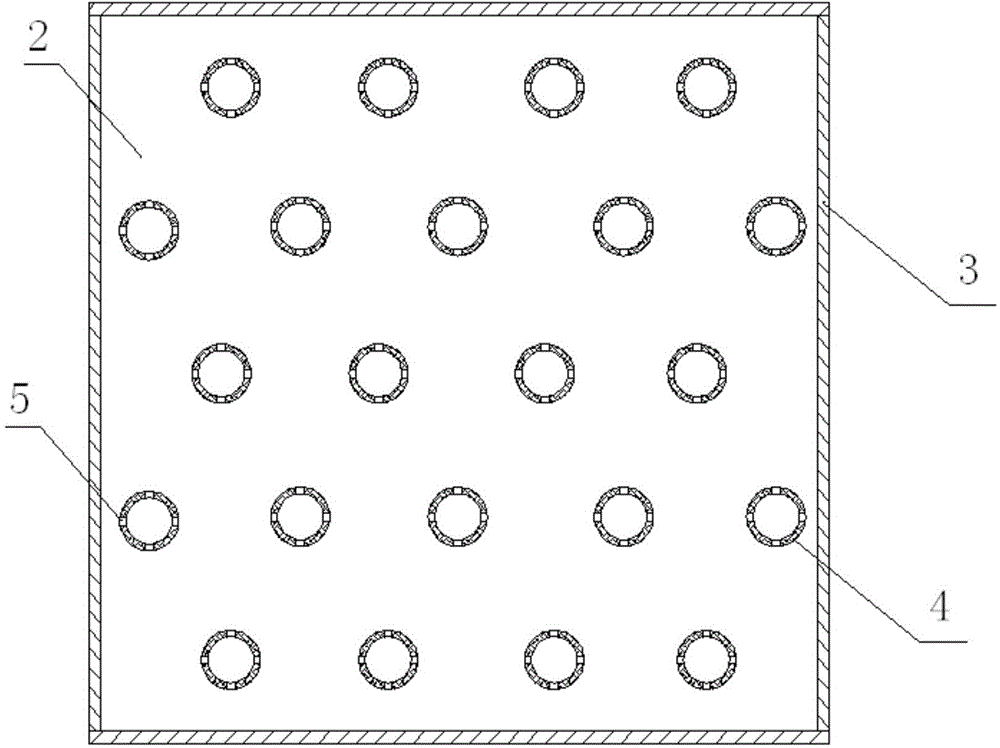

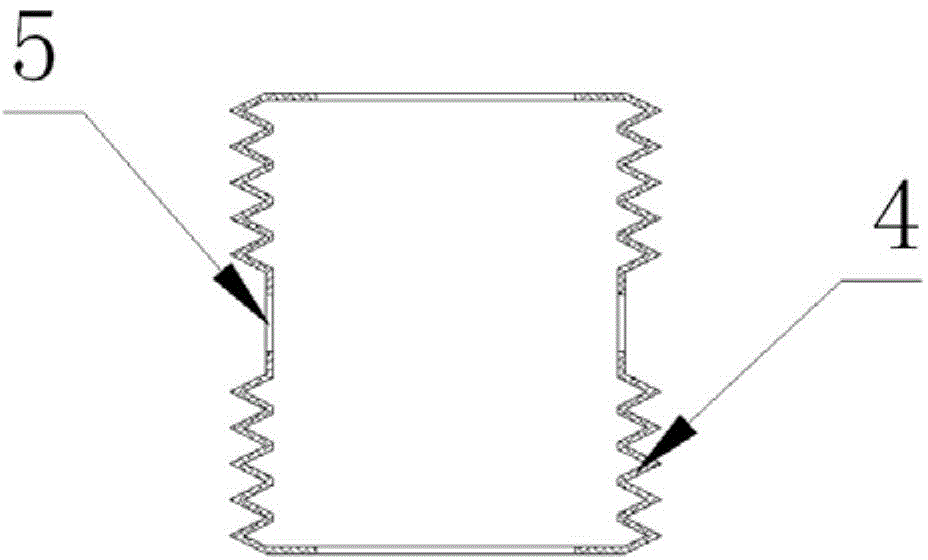

[0028] Such as figure 1 , figure 2 and image 3 As shown, a flexible sandwich panel for vibration and noise reduction hull structure consists of an outer panel 1, an inner panel 2, a frame 3, a flexible interlayer 4, small holes 5, an outer adhesive layer 6 and an inner adhesive layer 7, and a main cavity I and the resonant cavity II; wherein the two open ends of the frame 3 surrounded by four sides are respectively covered and welded by the inner panel 2 and the outer panel 1, and the opposite surfaces of the inner panel 2 and the outer panel 1 are respectively provided with Adhesive layers 6, 7; a flexible interlayer 4 is placed between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com