Insulation system for floating marine structure

a technology for insulating systems and floating structures, which is applied in the direction of hull parts, vessel construction, transportation and packaging, etc., can solve the problems of sudden decrease in steel temperature between cold lng storage tanks, damage to cofferdams, and brittle fractures, so as to reduce the boil-off rate (bor) generated, reduce the heat transfer, and reduce the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

[0071]In order to sufficiently understand the present invention, operational advantages of the present invention, and objects accomplished by embodiments of the present invention, the accompanying drawings showing embodiments of the present invention and contents described in the accompanying drawings should be referred.

[0072]Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. Like reference numerals proposed in each drawing denote like components.

[0073]In the present specification, a floating structure includes a ship and various structures that are used while floating on the sea, including a storage tank for storing LNG and may include an LNG floating, production, storage and offloading (LNG FPSO), an LNG floating storage and regasification unit (LNG FSRU), an LNG carrier, and an LNG regasification vessel (LNG RV).

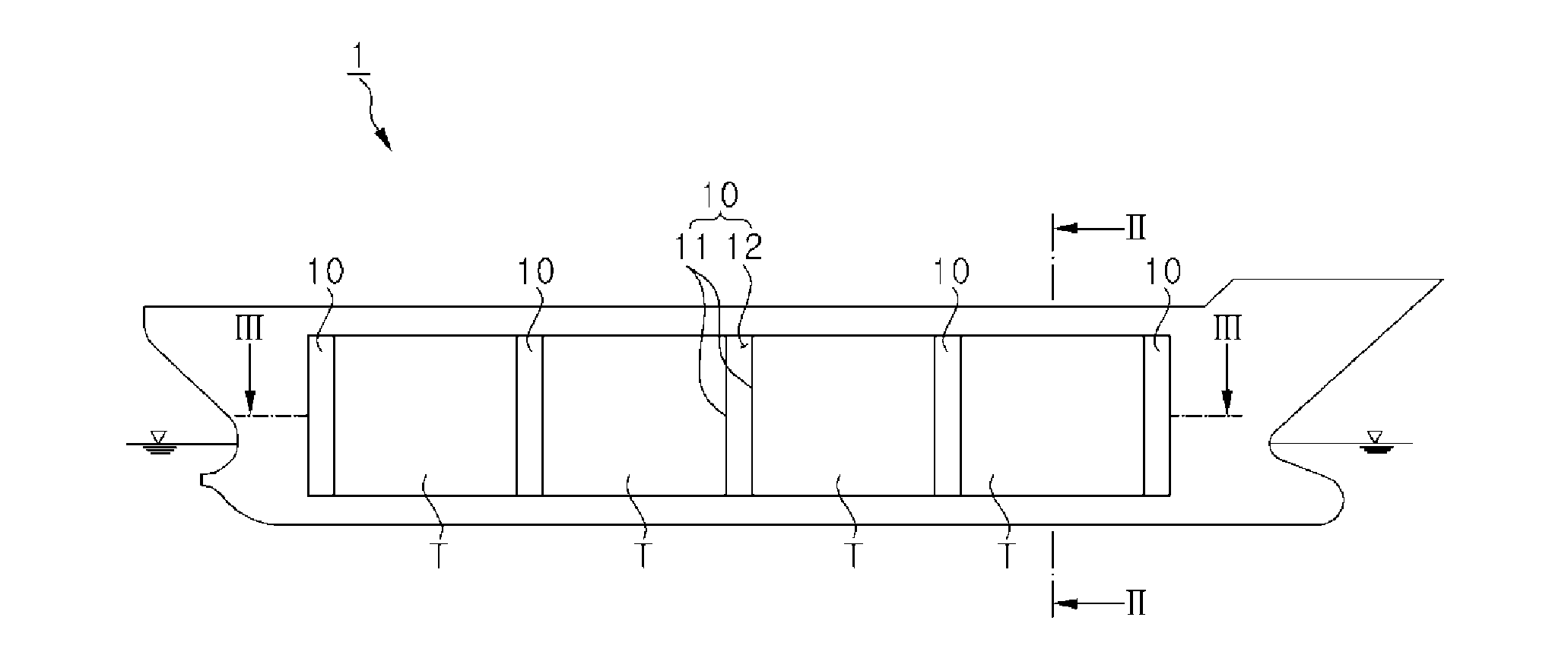

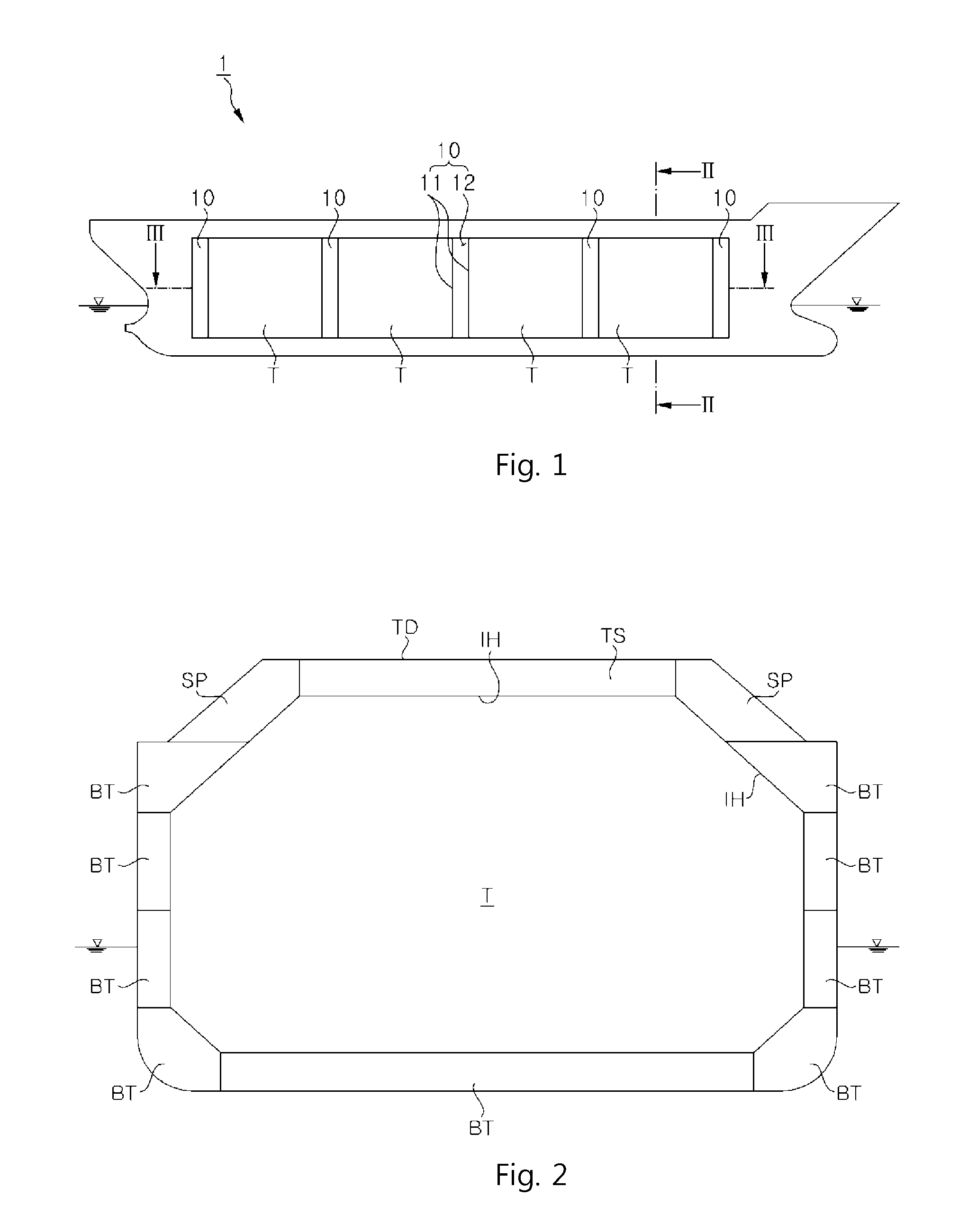

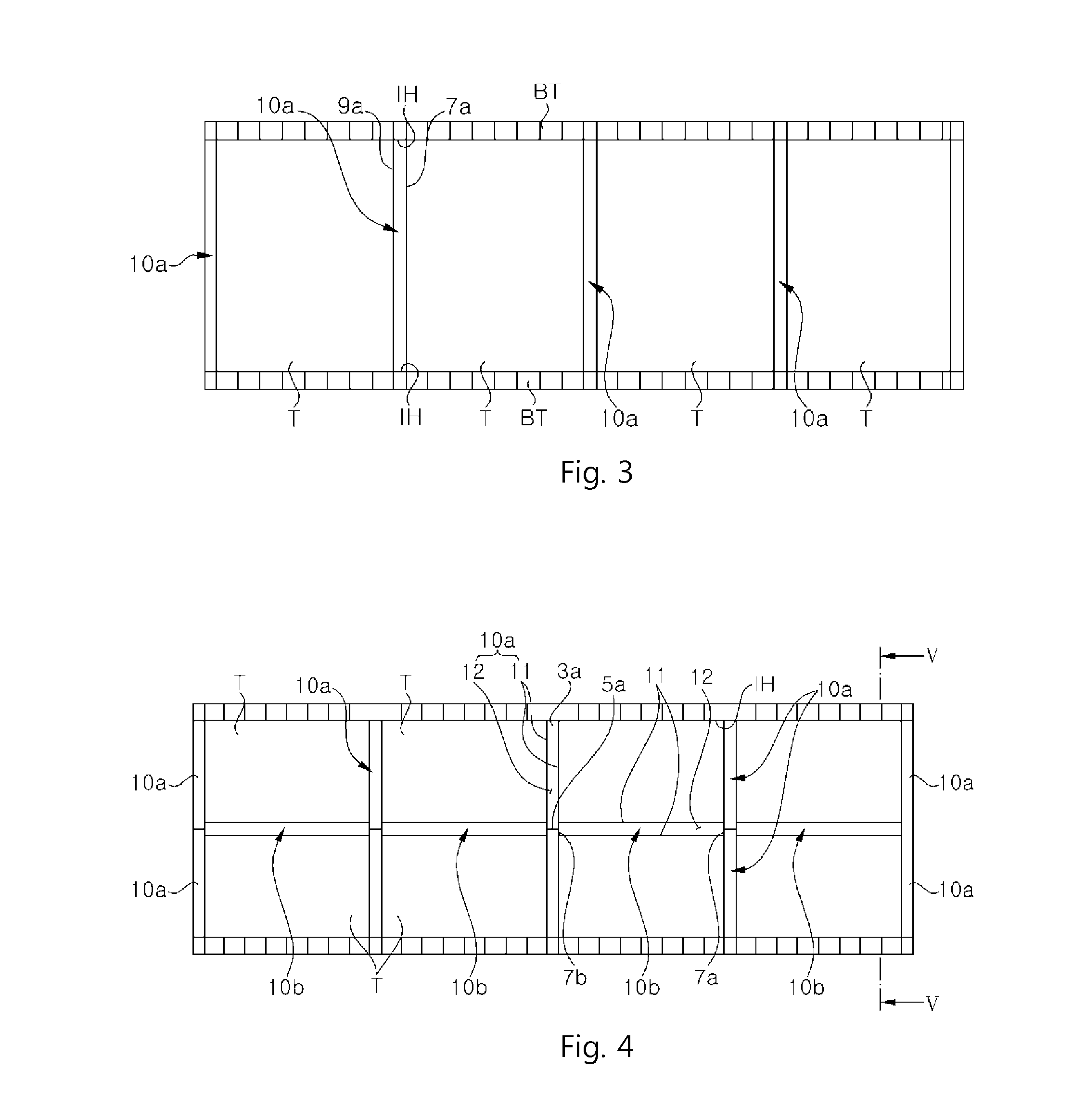

[0074]FIG. 1 is a side view schematically illustrating a state in which a cofferdam is installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com