Method for lowering noise of ship compartments

A cabin and noise technology, applied in the field of reducing ship cabin noise, can solve problems affecting work efficiency, endangering human health, etc., and achieve the effect of avoiding a large amount of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. The embodiments do not limit the scope of protection of the invention. Obviously, those of ordinary skill in the art can obtain other embodiments without creative work. It belongs to the protection scope of the present invention.

[0022] A method to reduce the noise in the cabin of a ship, using the following steps in the ship design stage:

[0023] 1). Separate the living cabin from the flue, and arrange the cabins with high noise requirements away from the noise source.

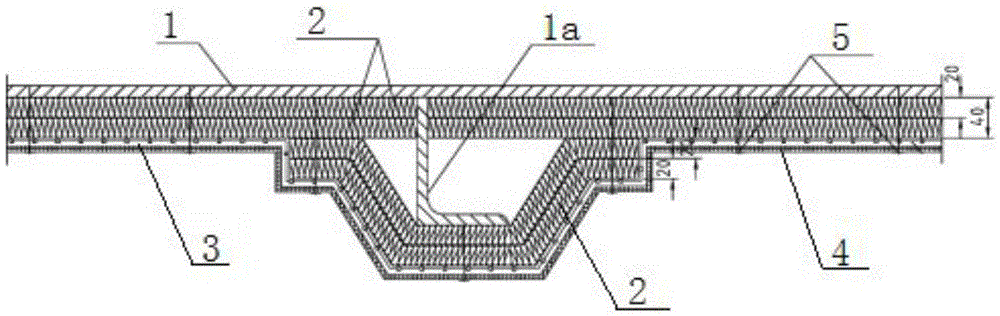

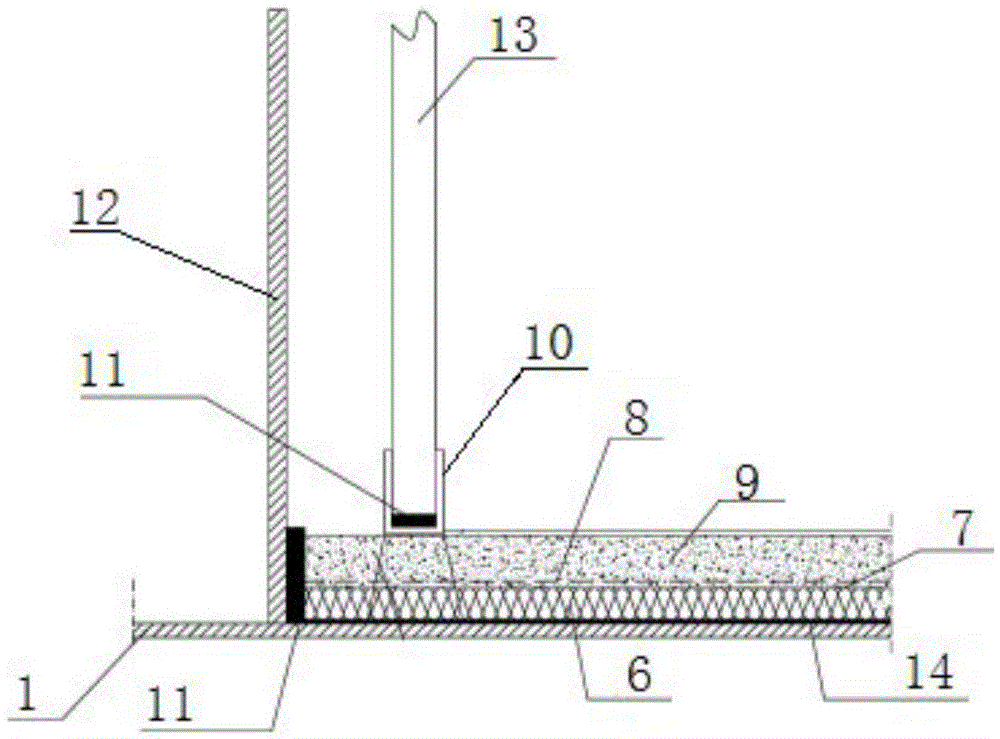

[0024] 2) Steps of laying sound-absorbing materials in the cabin, setting up sound-absorbing structures and applying sound-absorbing treatment measures to environmentally-friendly noise-reducing materials in the cabin, the sound-absorbing structure is as follows figure 1 As shown, it includes mineral wool 2 pasted on the deck or bulkhead 1, the deck or bulkhead is fixed to the L-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com