Device for mounting a tank in a ship

A technology for storage tanks, ships, applied in the field of double-blade pressure tanks, able to solve problems such as known structural limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

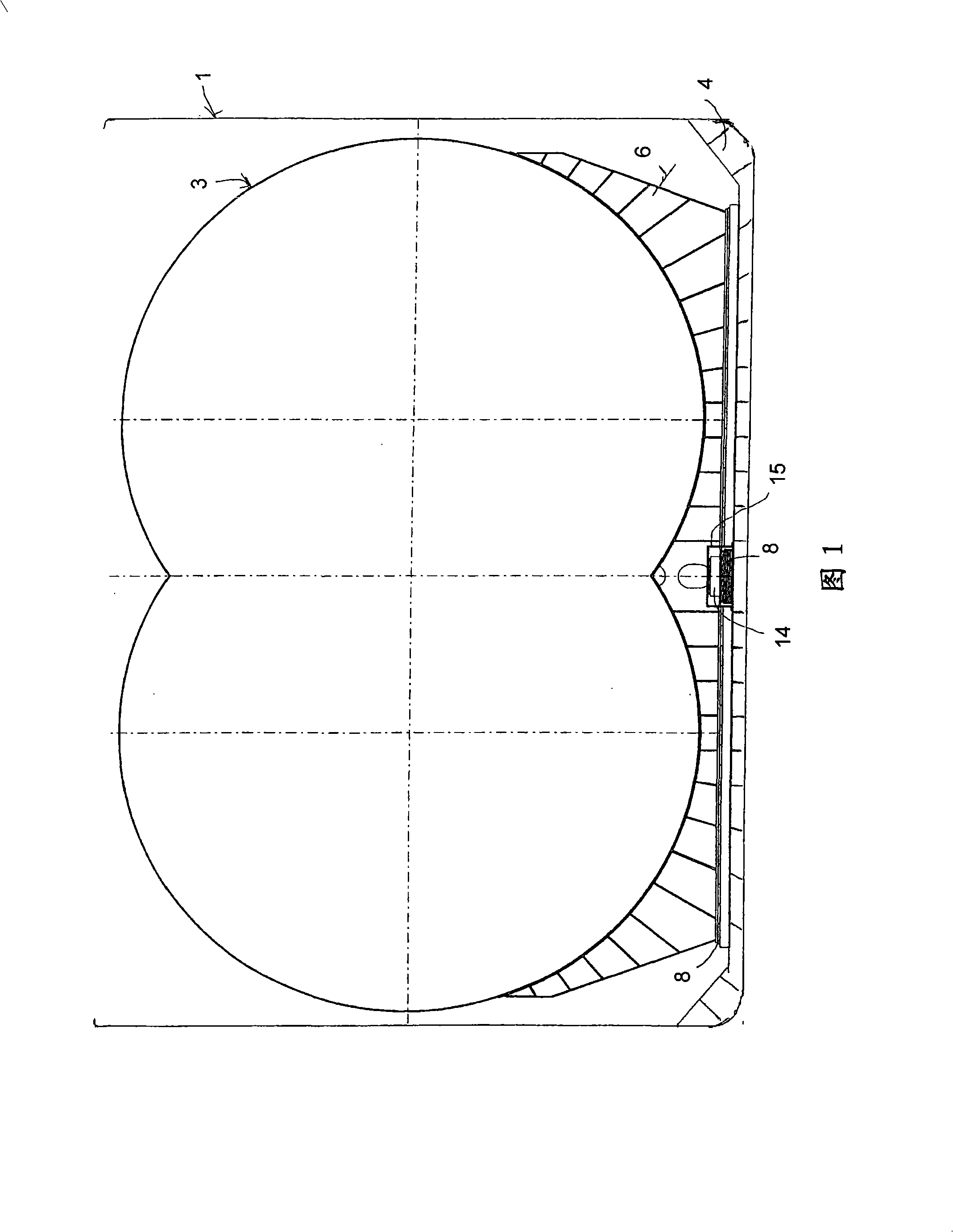

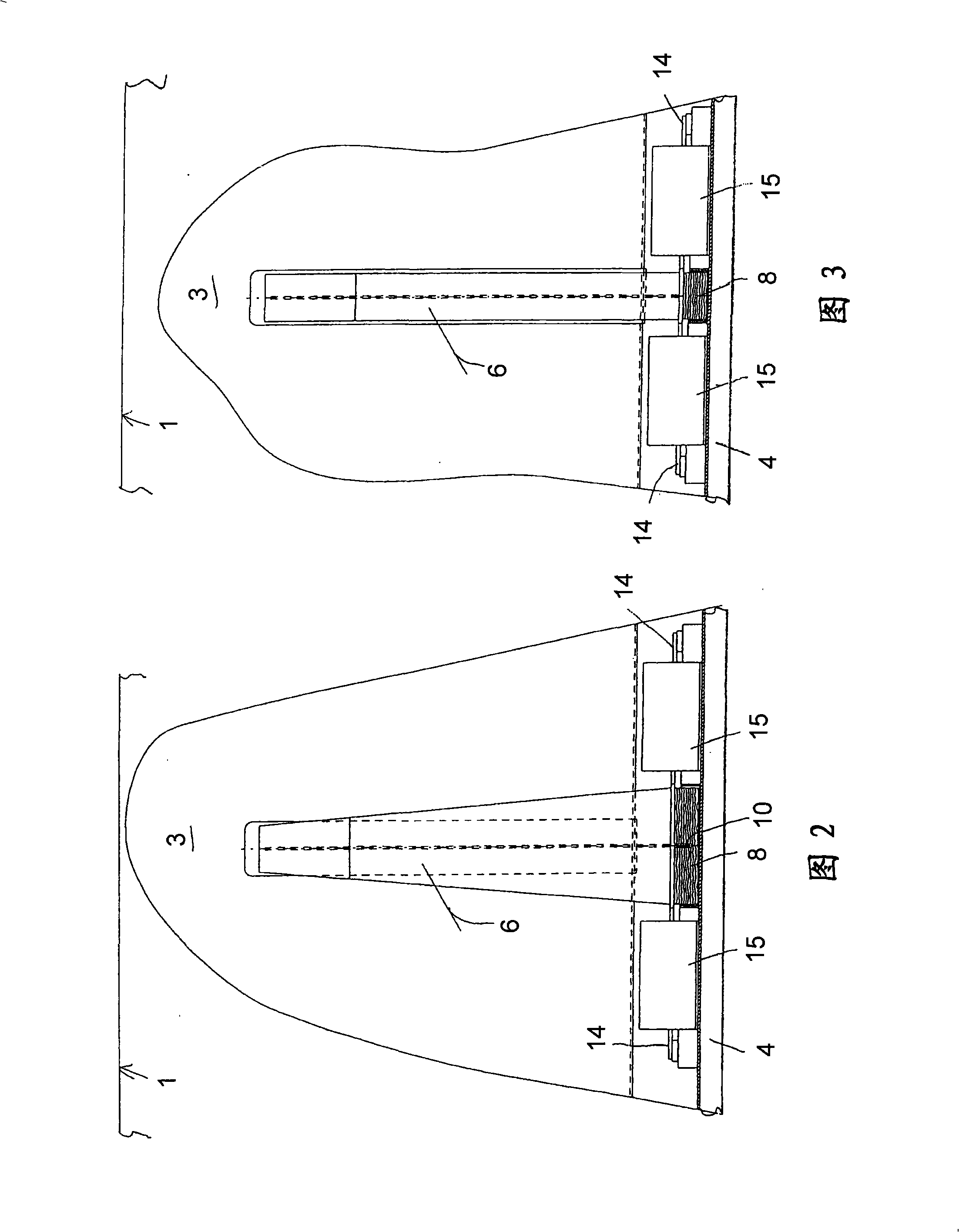

[0023] Figure 1 shows a simplified cross-sectional view of a hull 1 with a device for supporting a bilobed storage tank 3 according to the invention. The section plane shown is perpendicular to the longitudinal axis of the vessel.

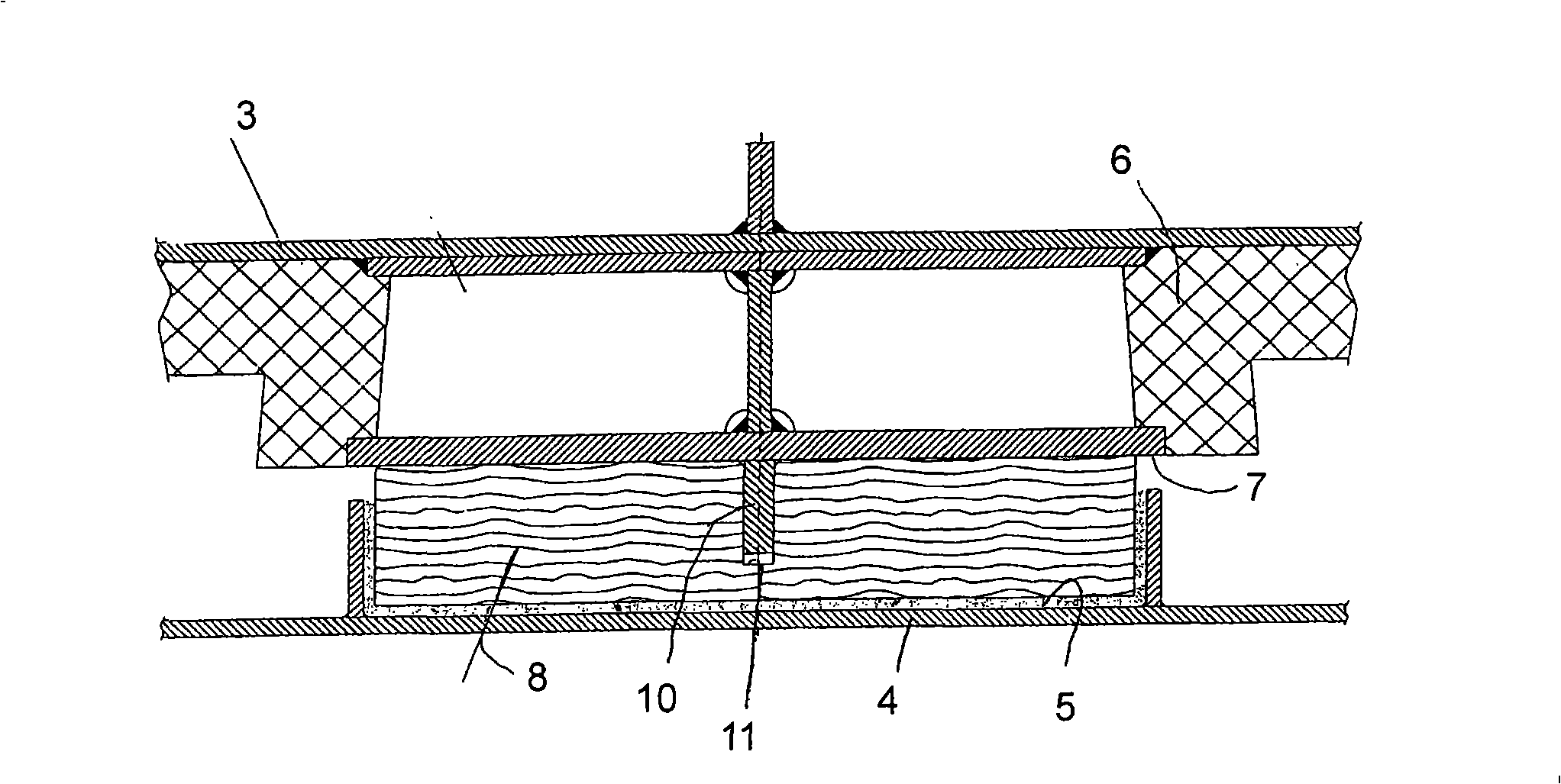

[0024] The double-leaf tank 3 has a cross-section consisting of two arc segments. The storage tank 3 rests on two or more saddles 6, one of which is shown in FIG. 1 . The saddle 6 is firmly connected with the storage tank 3, preferably welded together. The base 4 is arranged in the hull 1 and is firmly connected with the hull. A heat insulating layer 8 is provided between the flat upper side 5 of the base 4 and the flat lower side 7 of the saddle 6 . This insulating layer 8 transfers the weight of the tank and its contents to the base 4 . The thermal insulation layer 8 is preferably at least partially made of laminated sheet material. This insulating layer is firmly connected to the flat lower side 7 of the saddle 6 and slides on the flat uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com