Spindle anti-series structure for circular seam back chipping type edge milling machine

An edge milling machine and anti-collision technology, which is applied in milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problem of inability to drill and install positioning pins, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

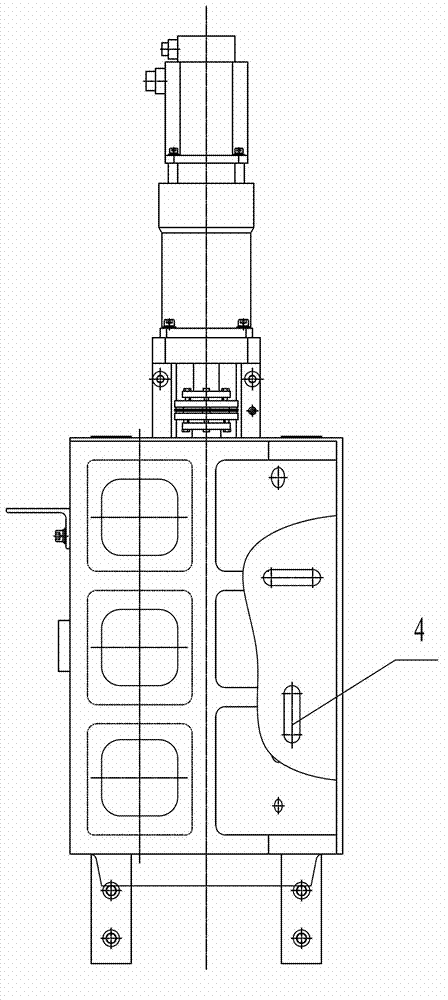

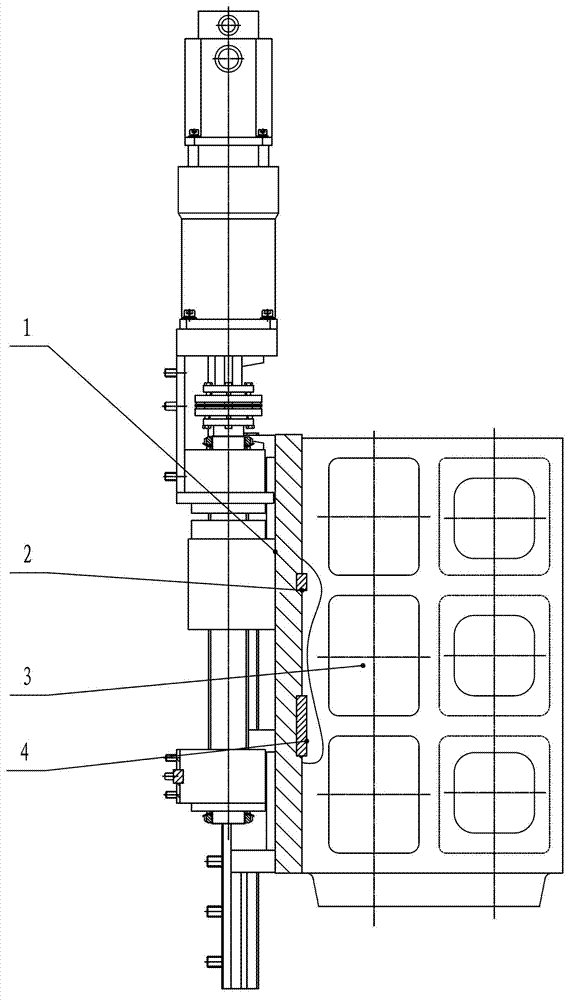

[0010] Such as figure 1 As shown, it includes a horizontal adjustment slide table 1, a horizontal positioning key 2, a main shaft component 3 and a longitudinal positioning key 4.

[0011] The surface of the horizontally adjusting slide 1 is provided with a horizontal keyway, and the corresponding position of the main shaft seat bottom surface of the main shaft part 3 is provided with a longitudinal keyway, the horizontal positioning key 2 is installed in the horizontal keyway, and the longitudinal positioning key 4 is installed in the longitudinal keyway. After the main shaft seat of the main shaft part 3 is connected with the horizontal adjustment slide table, the horizontal positioning key 2 prevents the main shaft seat of the main shaft part 3 from moving vertically, and the longitudinal positioning key 4 prevents the main shaft seat from moving la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com