Method for adhesively fixing liquid gas adiabatic apparatus by undulance adhesive strip

A thermal insulation device and adhesive strip technology, which is applied to fixed-capacity gas storage tanks, transportation and packaging, and for bulk cargo, can solve the problems of increasing the production cost of shipping liquefied gas tanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

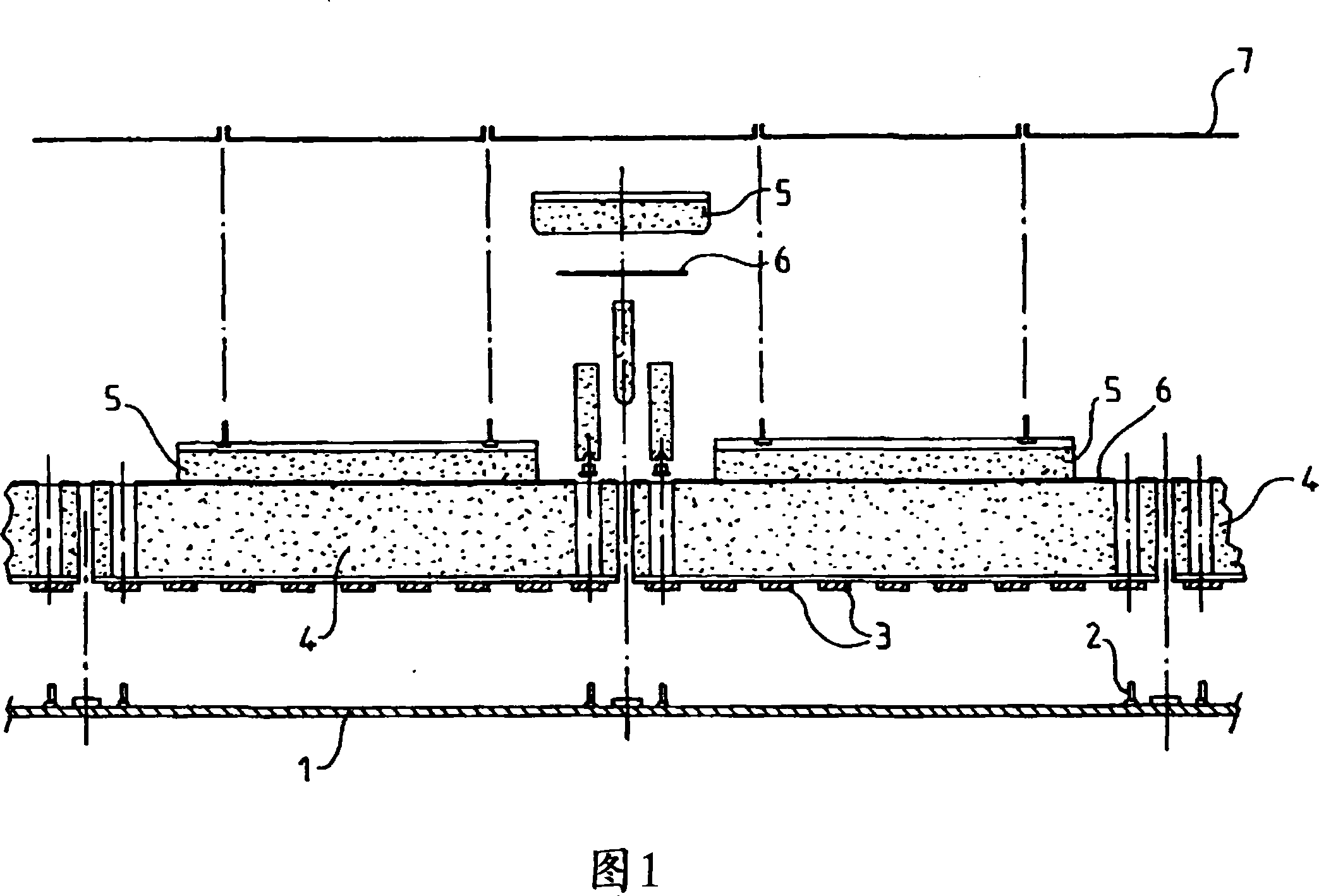

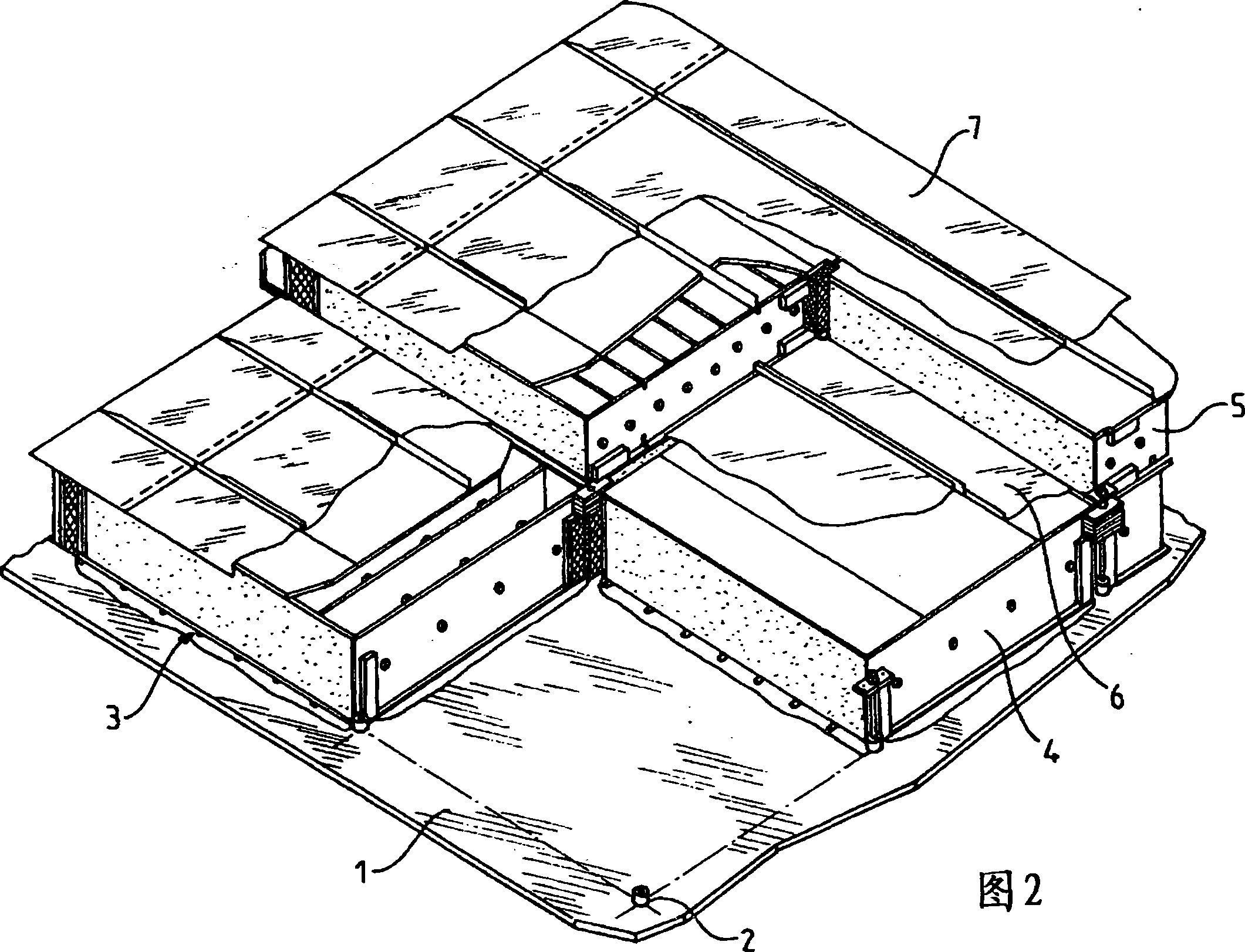

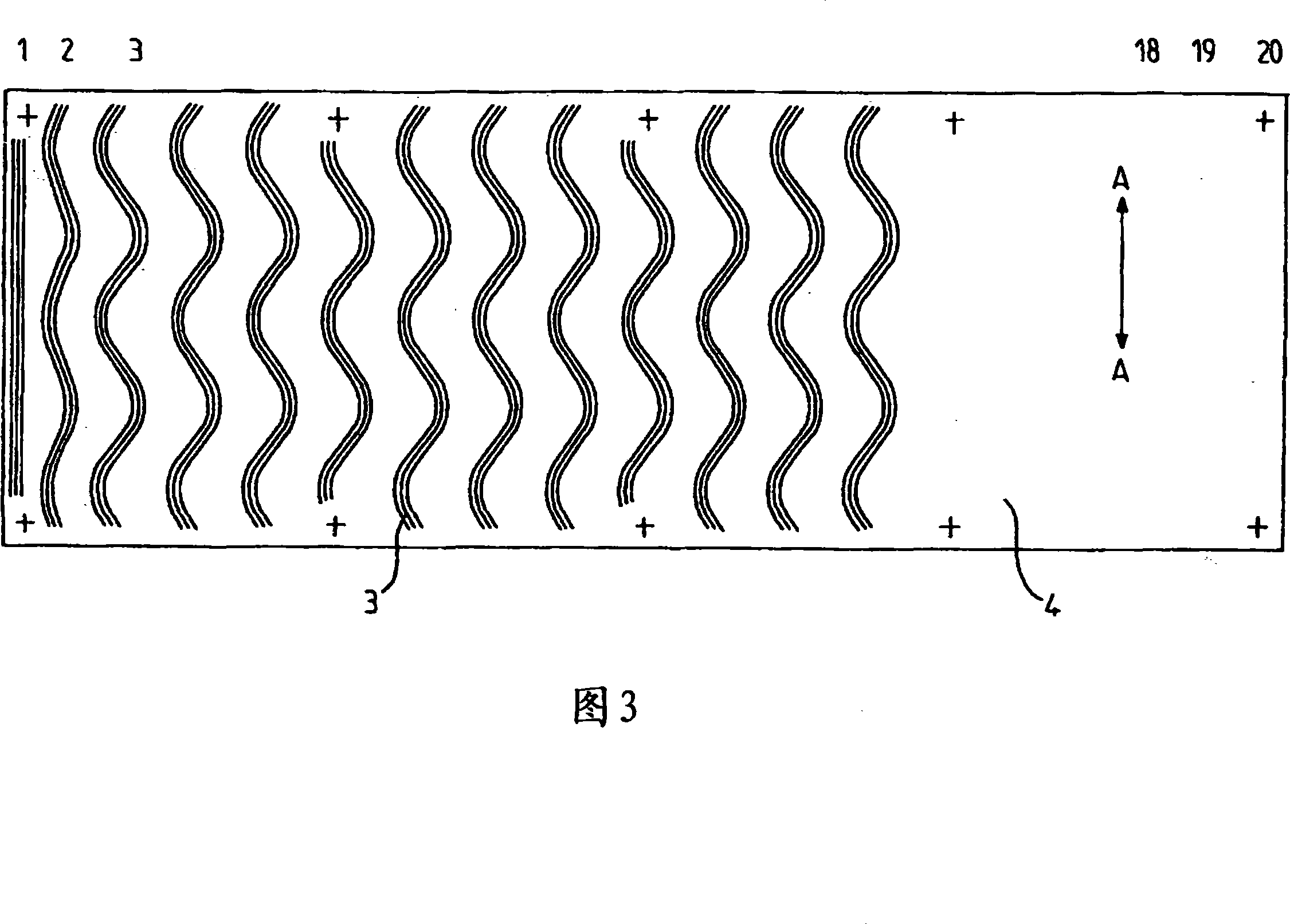

[0022] [22] Referring to Figure 1, it can be seen the inner hull 1 of a ship transporting liquefied gas, to which bolts 2 for holding the second insulation 4 in place during its installation have been secured, these The insulation is made in the form of foam blocks placed on the carrier slats to form a secondary insulation barrier. These second insulating means 4 are fastened to the inner casing 1 by means of adhesive strips 3 which are arranged transversely to the maximum dimension of the second insulating means on the bottom surface of the carrier strips of the insulating means, and the second The heat insulating device 4 is kept in contact with the inner housing 1 during its installation by means of fixing parts cooperating with the bolts 2 . (Note: For the convenience of language description, from now on, regardless of whether the second insulation device is used to be placed on the floor, top surface or side wall of the shell, the bottom surface of the second insulation d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com