Pre-pressure device of magnetic force pressure enforcement and micro face ultrasonic electromotor based on this device

An ultrasonic motor and pre-pressure technology, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. To solve the problems of thick size and other problems, it can achieve the effect of low cost, simple pre-pressure device and thin thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

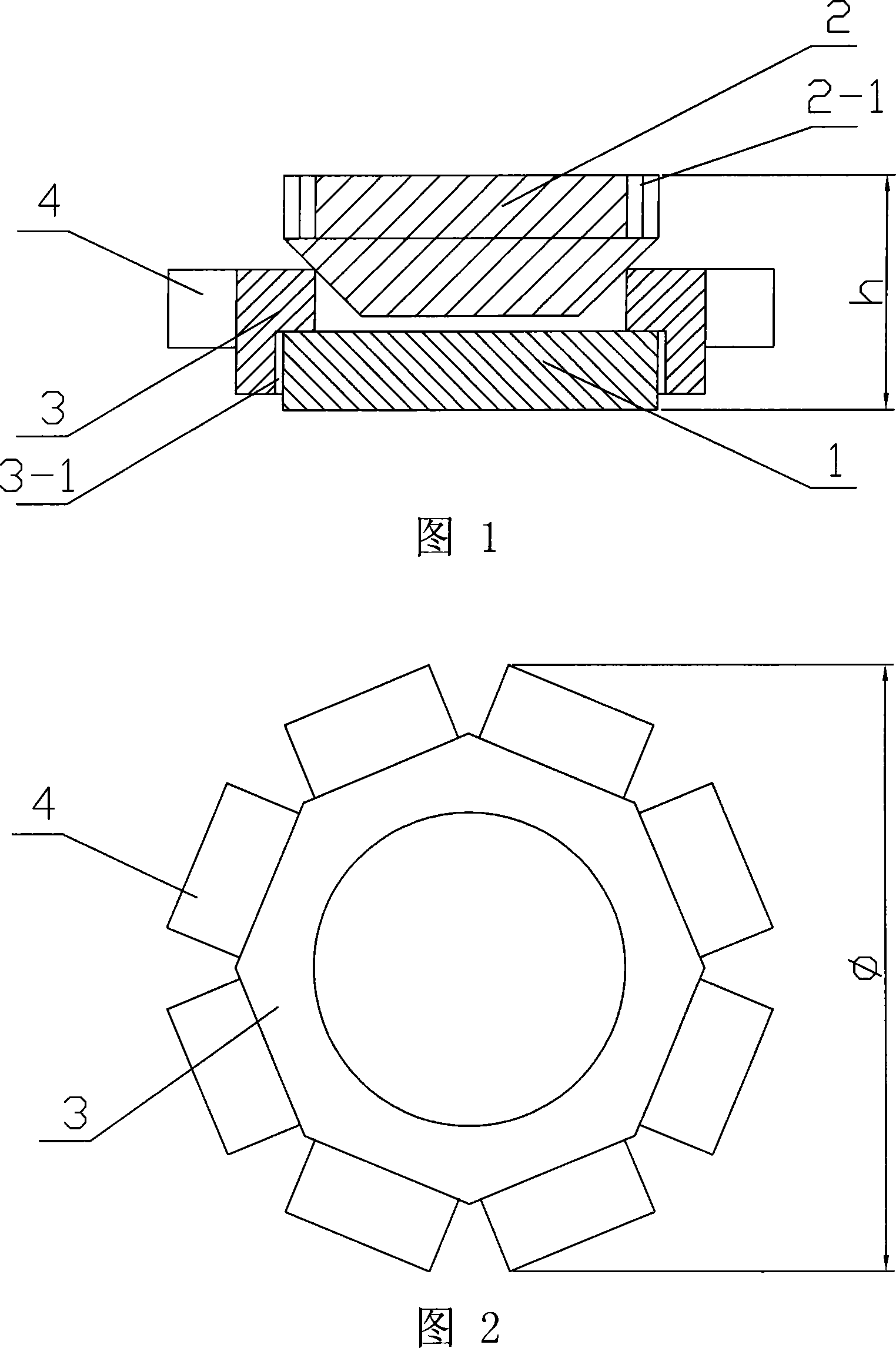

[0007] Specific embodiment 1: This embodiment will be described with reference to Figs. 1 and 2. The magnetically pressurized pre-compression device 1 of this embodiment adopts magnetic steel, and the magnetic steel is a circular sheet. The magnetic steel is a permanent magnetic material such as N35 or N42.

specific Embodiment approach 2

[0008] Embodiment 2: This embodiment will be described with reference to FIGS. 1 and 2. The difference between this embodiment and Embodiment 1 is that the thickness of the disc-shaped magnetic steel is 0.1 mm to 1 mm, and the outer diameter is 1 mm to 4 mm.

specific Embodiment approach 3

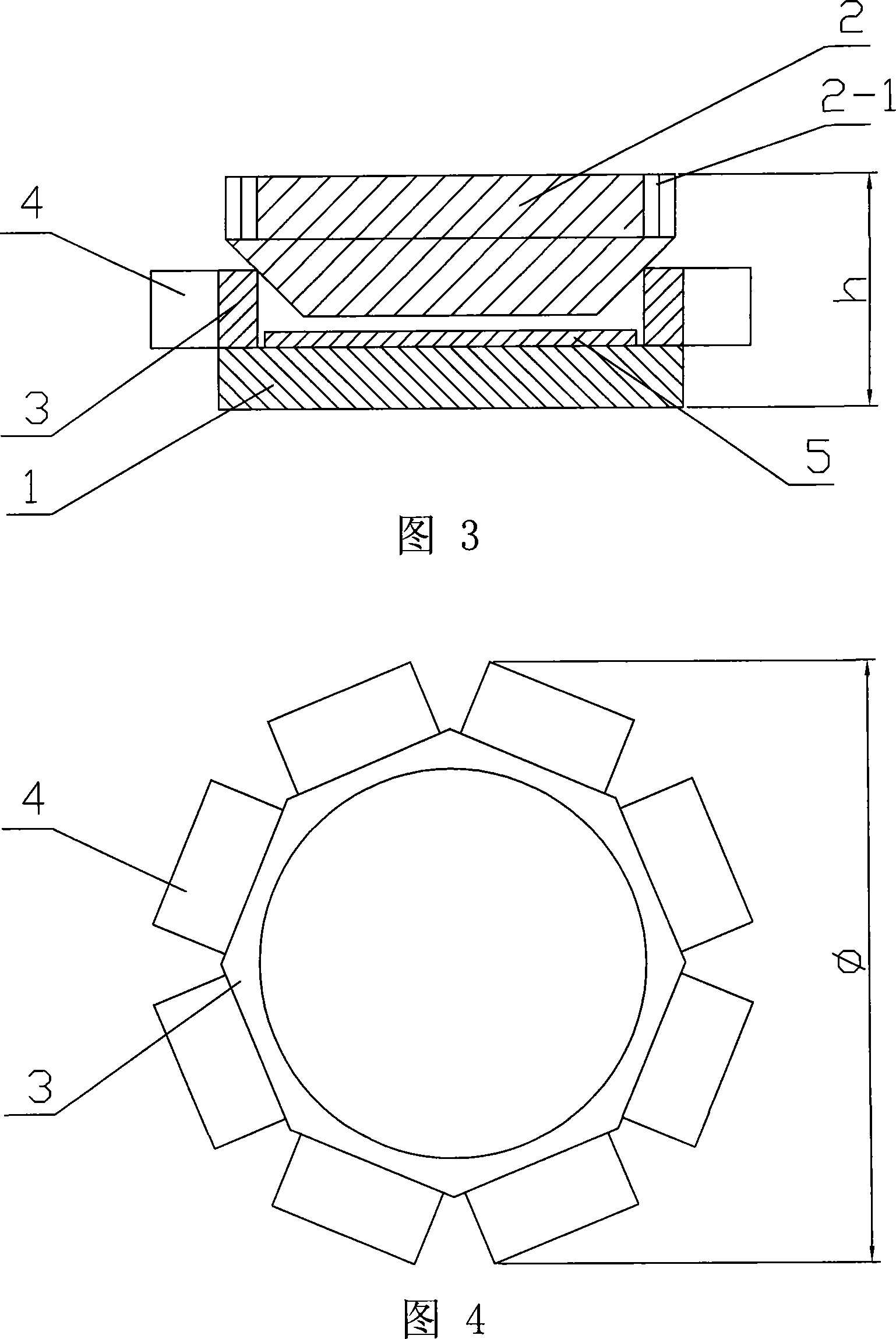

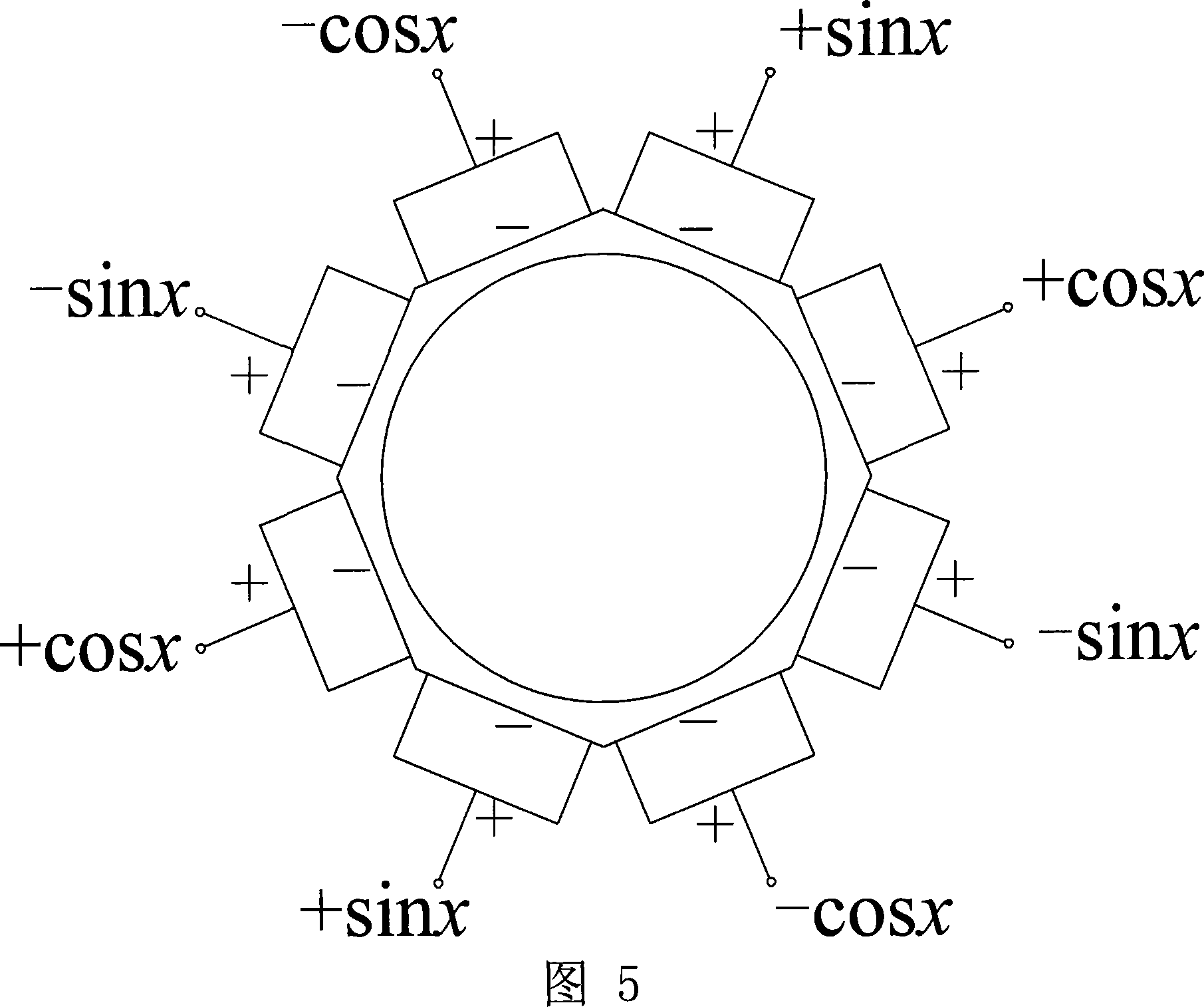

[0009] Specific embodiment three: this embodiment is described with reference to Fig. 1, Fig. 2 and Fig. 5, the miniature in-plane ultrasonic motor using the magnetic pressure pre-compression device of this embodiment is composed of a rotor 2, a stator and a magnetic pre-compression device 1 composition; the magnetically pressurized pre-compression device 1 is fixed at the bottom of the stator; the stator is composed of a metal base 3 and eight piezoelectric elements 4 of the same size, the metal base 3 is a hollow cylinder in the center of the eight Prism tube, the metal base 3 is made of a non-magnetic metal material. A piece of piezoelectric element 4 is fixed on the eight edges of the metal base 3, and four adjacent piezoelectric elements 4 of the eight piezoelectric elements 4 are One group, each group of piezoelectric elements 4 respectively apply sine wave (sin(ωt)), cosine wave (cos(ωt)), negative sine wave (-sin(ωt)), negative cosine wave (-cos(ωt)) ) Of the excitation si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com