Heat radiation die set and radiation system applying phase change metal thermal interface material

A heat dissipation module and heat dissipation system technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., can solve the problem of affecting the service life and reliability of electronic components, damaging microelectronic components, and deteriorating the performance of microelectronic components and other problems, to achieve the effects of low cost, avoiding liquid phase leakage, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

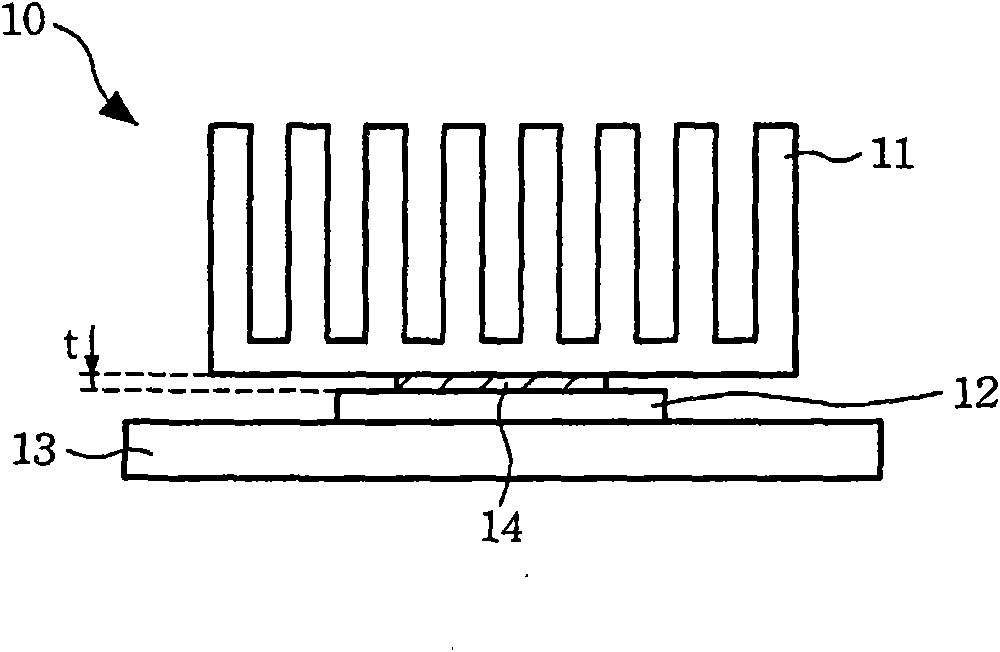

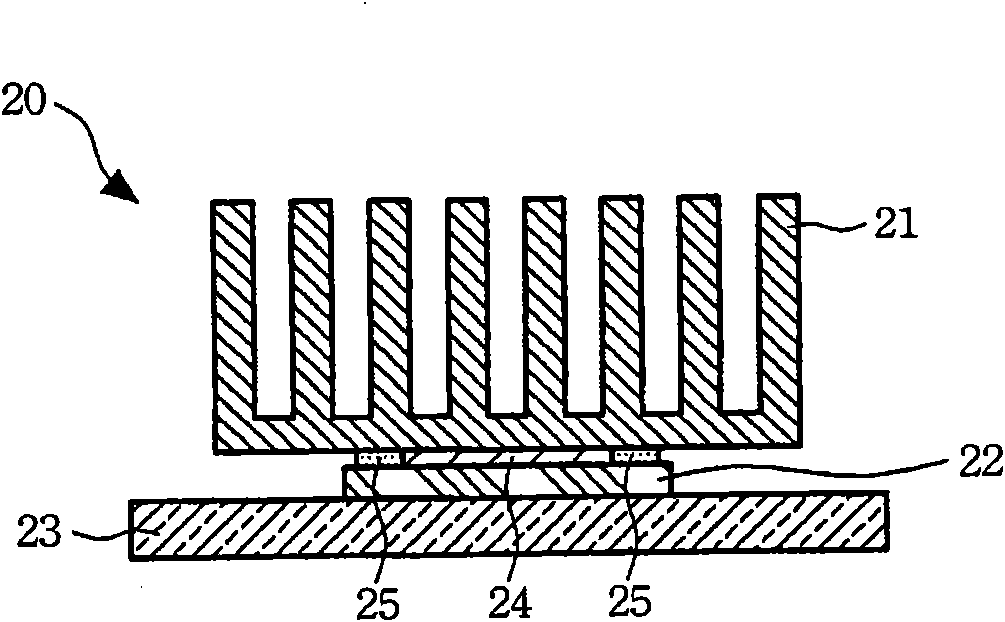

[0046] Please also refer to Figure 3Aand Figure 3B , which are respectively a schematic diagram of the heat dissipation module and a schematic diagram of the bottom surface of the radiator of the present invention. The heat dissipation module 30 of the present invention can quickly transfer the heat generated by an electronic component 32 to the external environment. The heat dissipation module 30 includes a heat sink 31 and a phase-change metal thermal interface material (TIM) 34 .

[0047] The heat sink 31 is disposed above the electronic component 32 , and the bottom surface 311 of the heat sink 31 has at least one groove 312 . The phase change metal thermal interface foil 34 is disposed between the electronic component 32 and the bottom surface 311 of the heat sink 31 as a thermal interface material between the electronic component 32 and the heat sink 31 . Two sides of the phase-change metal thermal interface foil 34 are respectively in contact with the bottom surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com