Method for designing die molded surface for forming groove-shaped part

A technology of mold surface and design method, applied in the field of grooved parts forming, can solve the problems of high professional knowledge requirements, cumbersome modeling work, and many iterations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

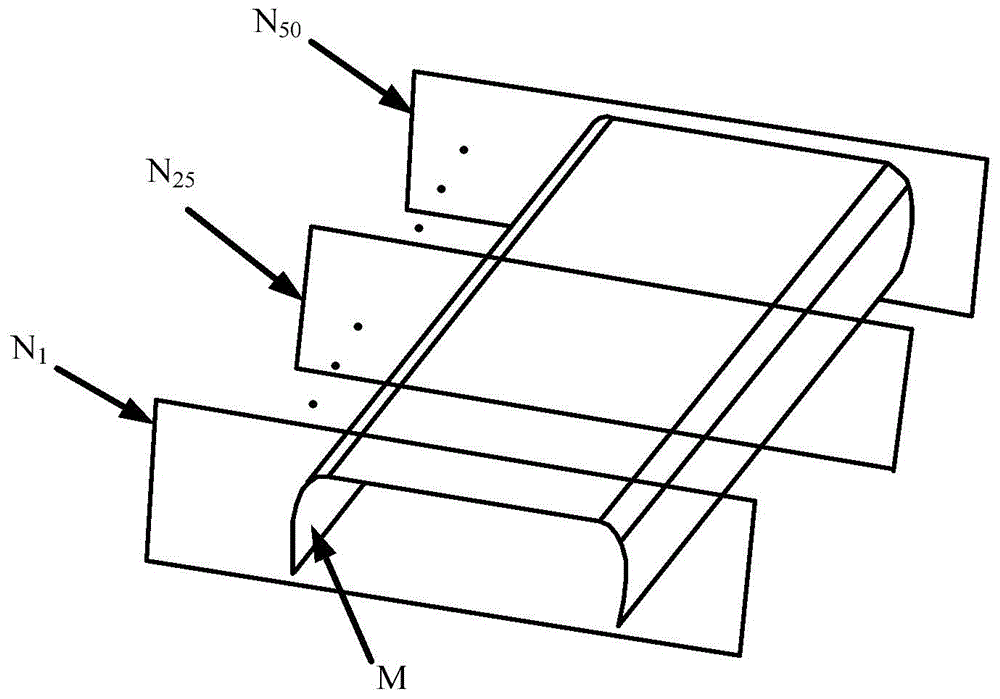

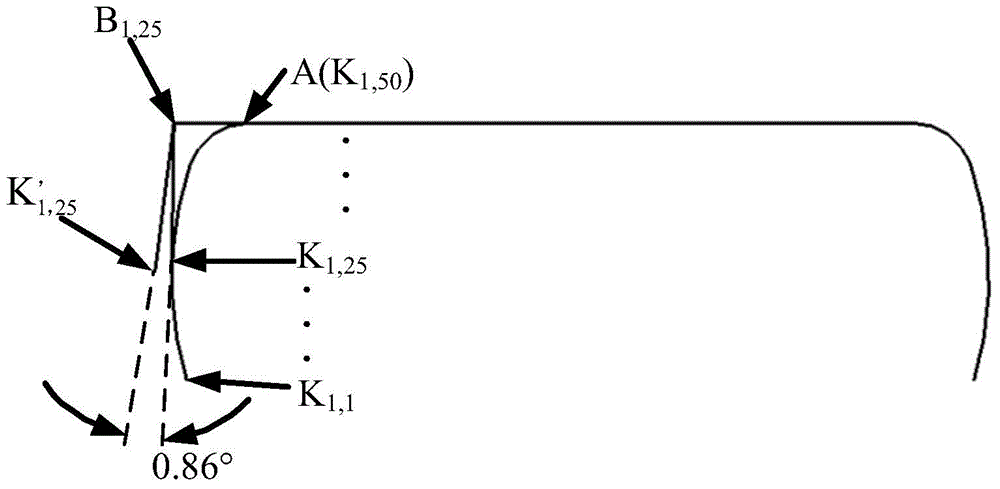

[0041] An embodiment is a method of designing a mold surface for forming a channel.

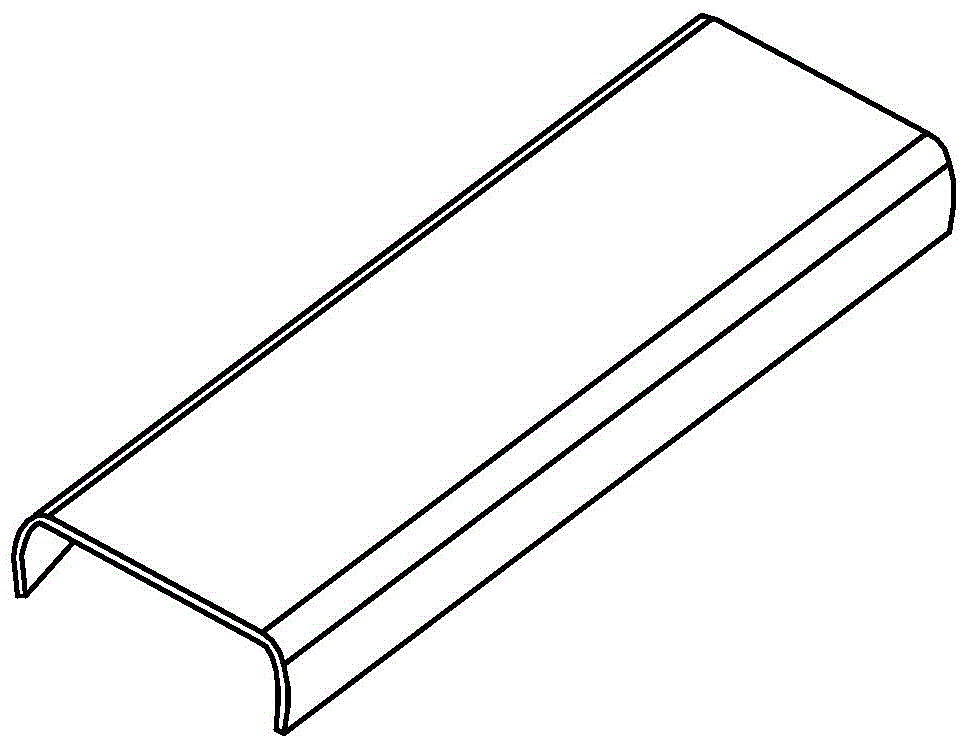

[0042] Such as figure 1 As shown, the cross-section of the composite channel member formed by the mold is concave, and the groove surface of the concave shape is the inner surface.

[0043] The material of the part to be formed is a composite material. The material of the composite groove part is selected as prepreg AS4 / 8552, and the thermal expansion coefficient of the composite fiber direction is a L is 0×10 -6 , the coefficient of thermal expansion in the thickness direction of the composite material a T 32.6×10 -6 , the fiber direction chemical shrinkage coefficient of the composite material is 0, the chemical shrinkage coefficient in the thickness direction of the composite material is 0.0048. The range of forming temperature ΔT is 160°C.

[0044] The length L of the part to be formed is 1000mm, the width of the groove is 300mm, and the height of the two side wall plates is 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com