Modularized LED lamp strip and processing method thereof

A technology for LED strips and LED chips, which is applied in lighting and heating equipment, lighting devices, electrical components, etc., can solve the problems of increasing the thickness of LEDs, increasing the difficulty of processing, and increasing the difficulty of processing, so as to reduce production costs and processing efficiency. High, application-perfect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

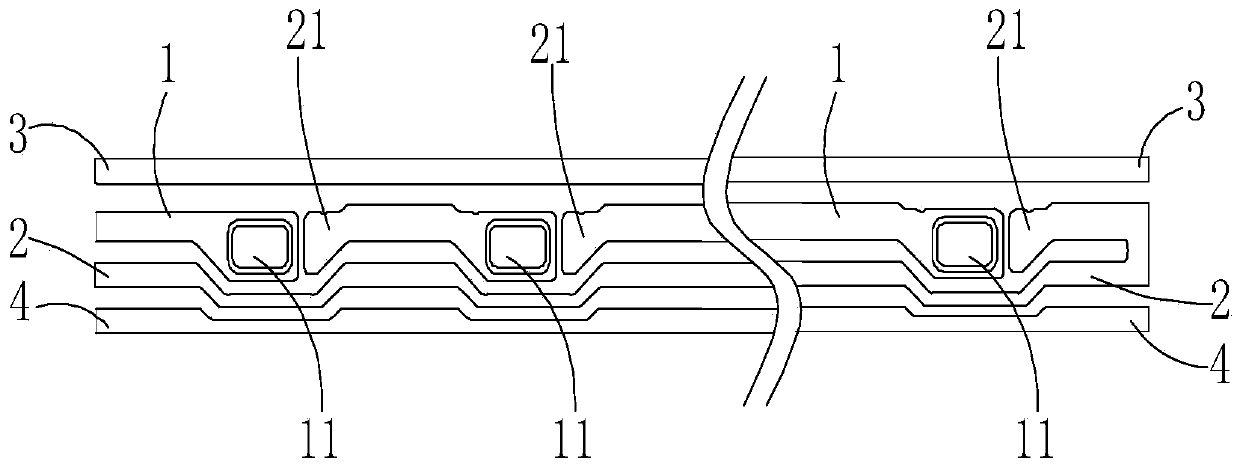

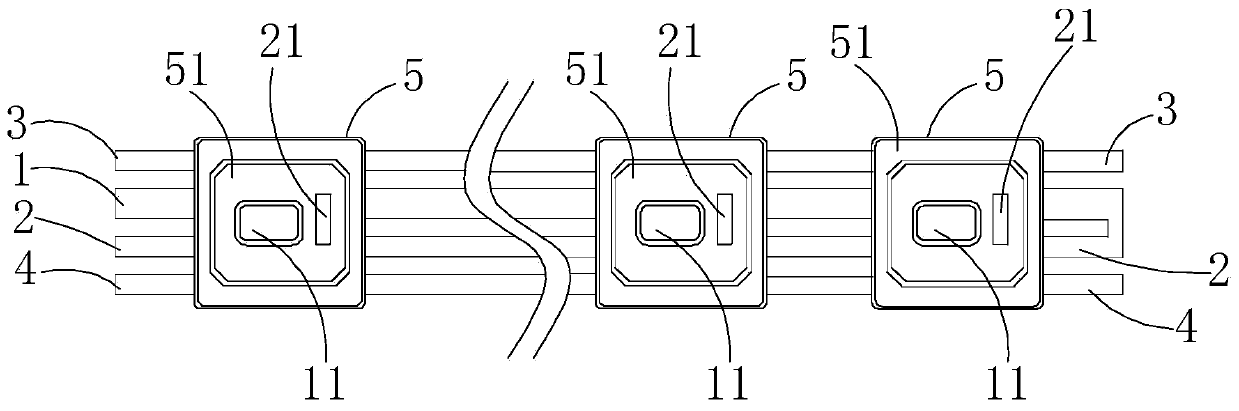

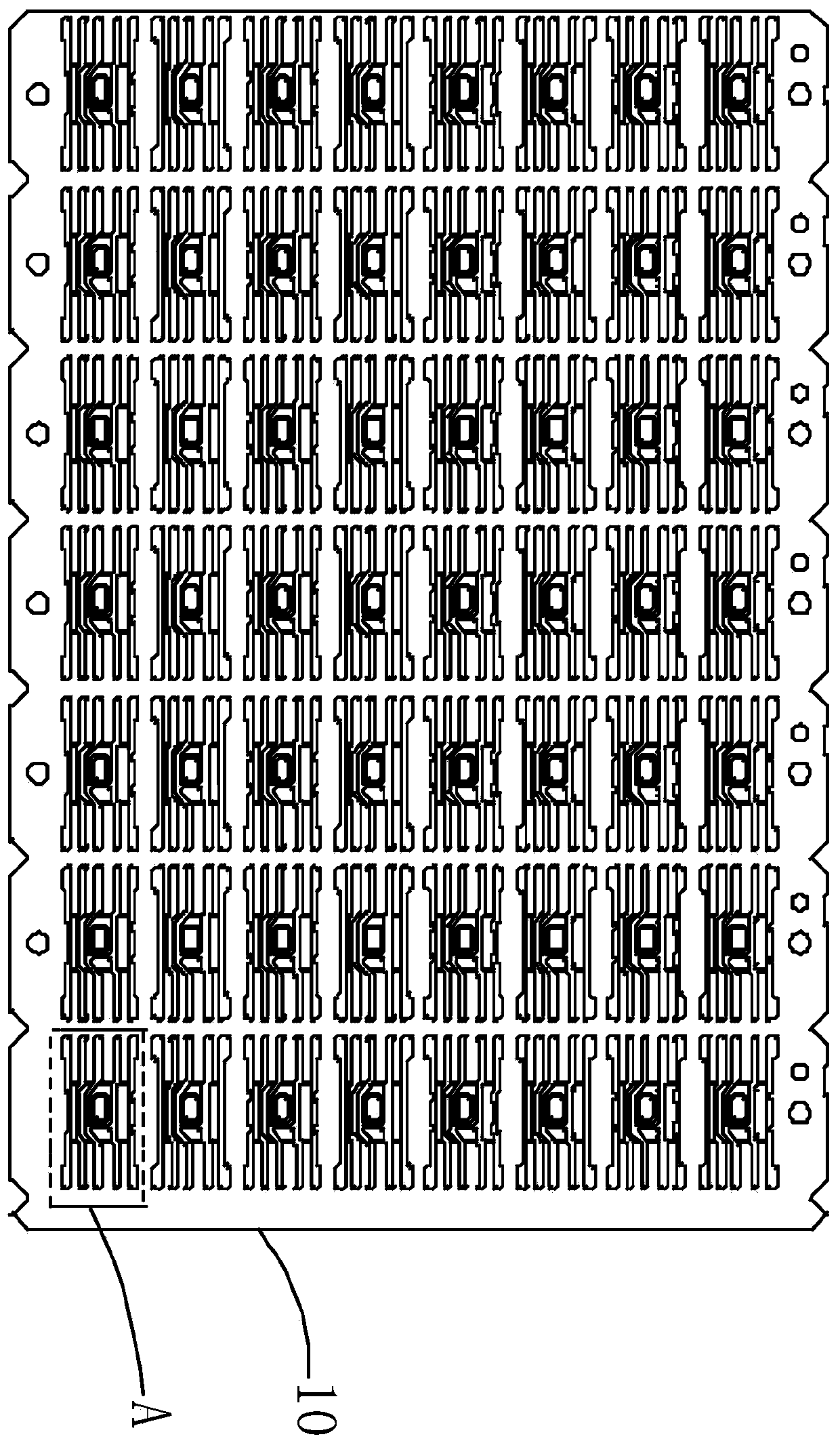

[0029] refer to Figure 1 to Figure 6 The present invention provides a modular patch LED light bar, the positive metal wire 3 and the negative metal wire 4 are correspondingly connected to the input terminal of the rectifier, one end of the positive metal baseline 1 and the negative metal baseline 2 are connected to the electrodes of the LED chip, and the other One end is connected to the output terminal electrode of the rectifier. The positive metal base wire 1, the negative metal base wire 2, the positive metal wire 3, and the negative metal wire 4 are thin flat metal wires such as iron, copper, aluminum, etc. In order to ensure that these thin metal wires have good conductivity and are not corroded, the These iron, copper and aluminum thin metal wires are electroplated with a layer of anti-corrosion conductive layer. In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com