Patents

Literature

66results about How to "Reduce media consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

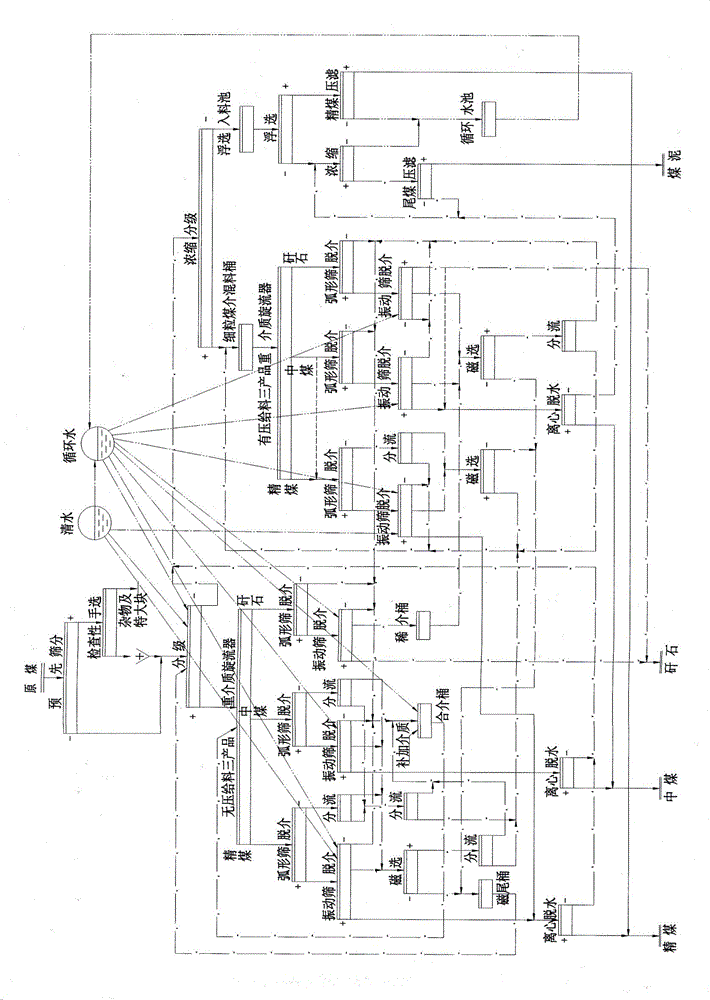

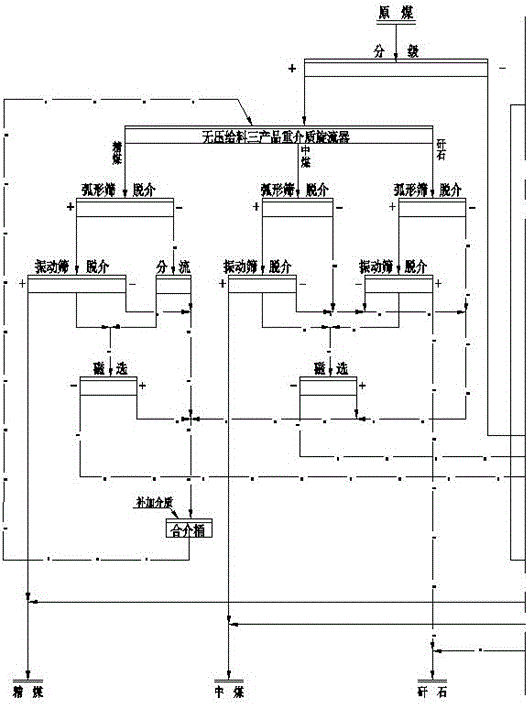

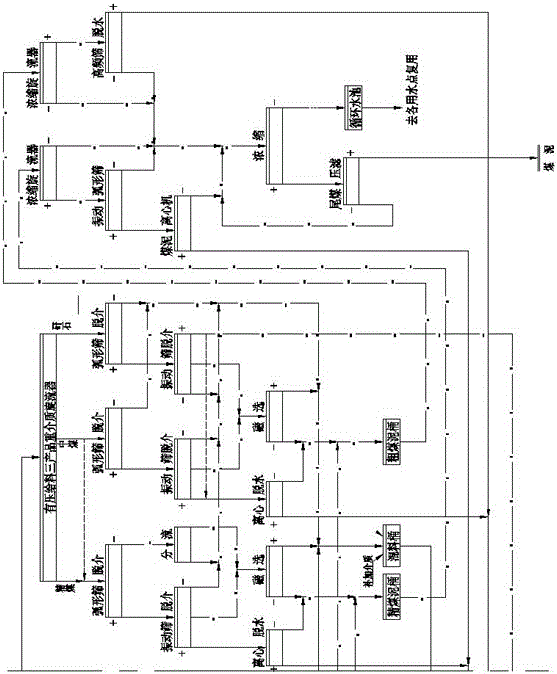

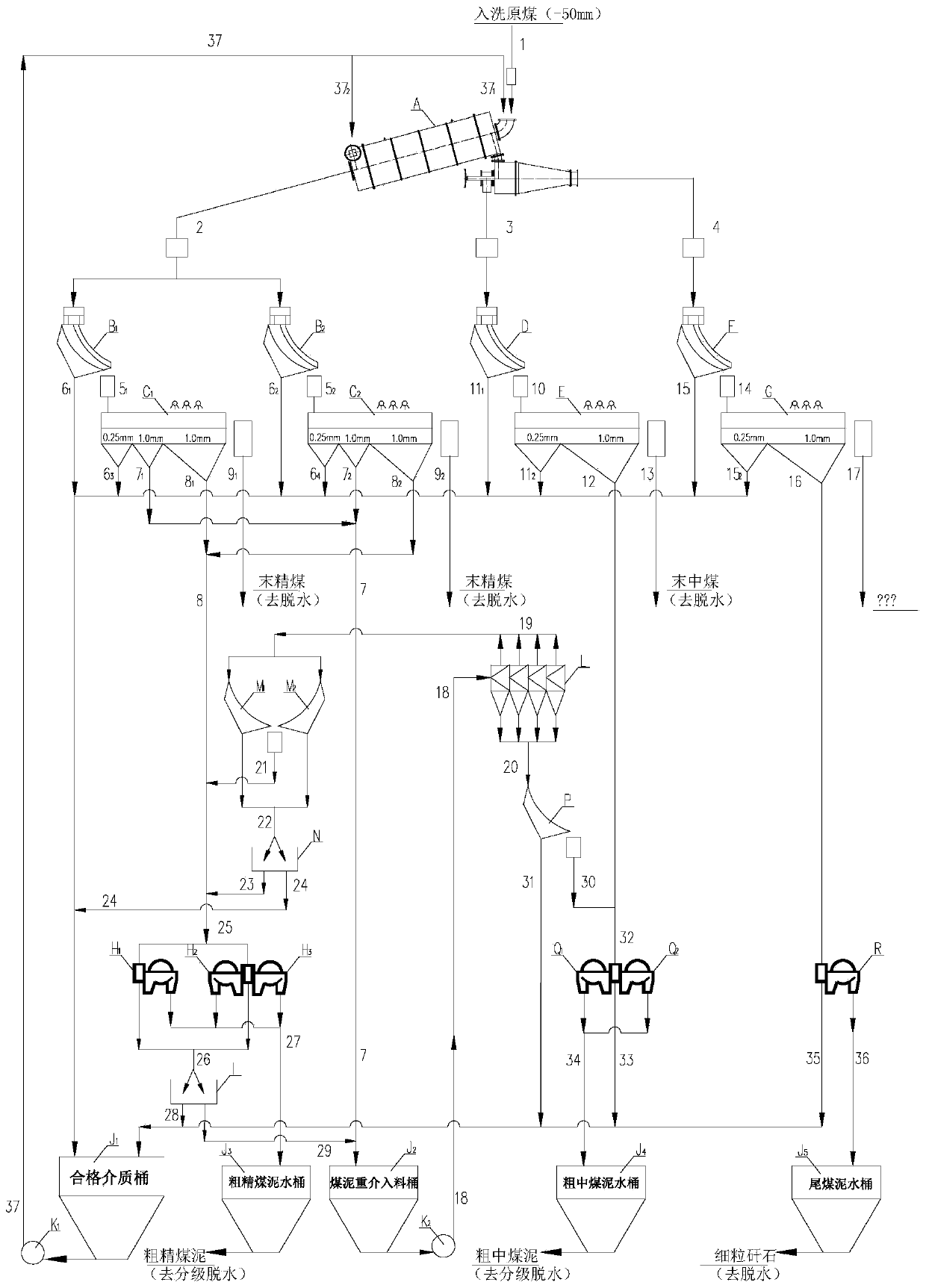

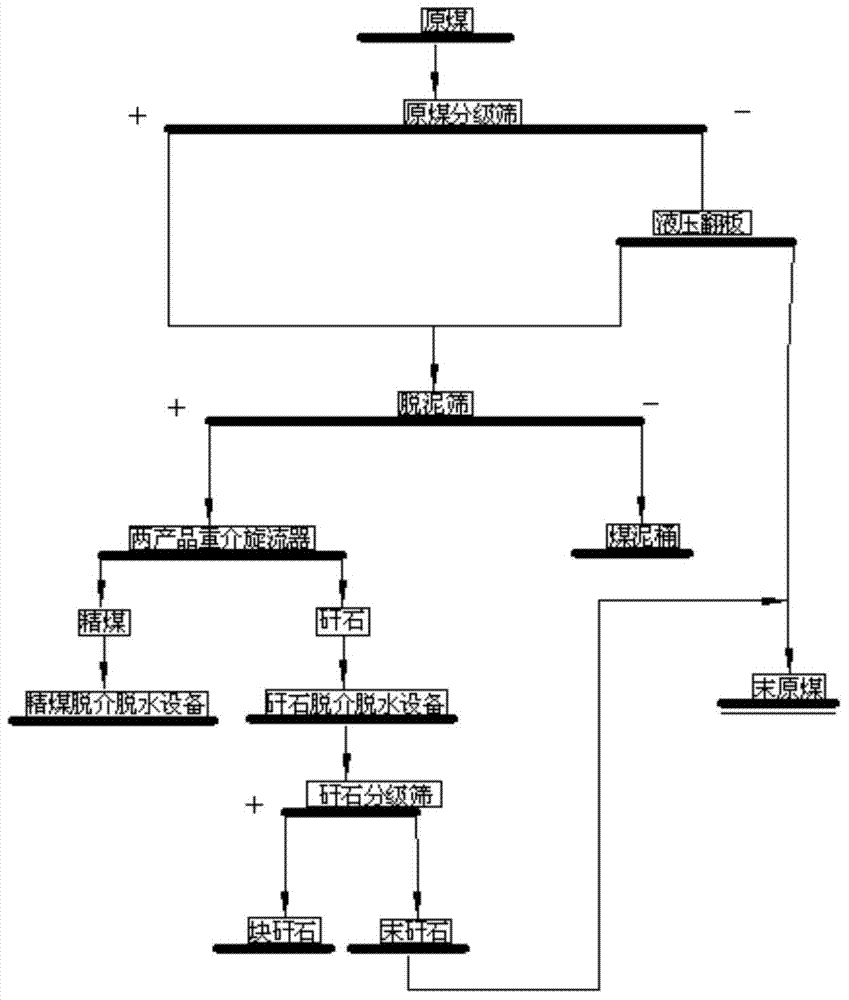

Wide-grain-grade double-dense-medium process for separating all coarse coal slime

The invention discloses a wide-grain-grade double-dense-medium process for separating all coarse coal slime. The wide-grain-grade double-dense-medium process includes that raw coal is preliminarily sieved, manually picked and graded, then oversize products can be used as coarse grain coal, the coarse grain coal is fed into a non-pressure tri-product dense-medium cyclone to be separated, undersize products are concentrated and graded and then are dehydrated in an underflow manner to be used as fine grain coal, the fine grain coal is fed into a pressure tri-product dense-medium cyclone to be separated, and excess flow is fed into a flotation filter-press system, so that the coal slime can be separated; qualified suspension liquid of a fine grain coal dense-medium separating system is provided by coarse grain clean coal of a coarse grain coal separating system, lower branches of coarse grain middling coal primary-section medium removing equipment and branches of coarse grain clean coal and coarse grain middling coal magnetic separation concentration; dilute suspension liquid of coarse grain gangue products and dilute suspension liquid of middling coal and gangue products of a fine grain coal system are treated together; magnetic separation tailings are used as wetting water or primary spray water for grading screens. The wide-grain-grade double-dense-medium process has the advantages that the fine grain coal dense-medium system has a medium automatic generating function, all the coarse coal slime can be efficiently separated by dense media, the suspension liquid is circulated in a closed-loop manner, the separation efficiency is high, the products are flexible in structure, and the production and operation costs are low.

Owner:TANGSHAN BRANCH COAL SCI ACAD

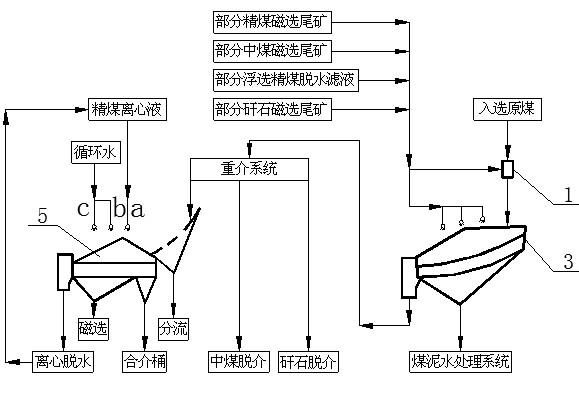

Coal slime treatment process for deslimed dense-medium coal separation

Disclosed is a coal slime treatment process for deslimed dense-medium coal separation. In the process, part of coal slime including magnetically separated clean coal tailings, magnetically separated middling coal tailings, magnetically separated gangue tailings and dehydrated filtrate of floatation separated clean coal is used as flush water for a wet-process classifying screen or a desliming screen and used as spray water for the same, and clean coal centrifugate is used as the primary spray water for a clean coal medium drainage screen. On the premise of guaranteeing feed concentration in floatation separation, work load of a concentrator can be lowered (by 20-40%), higher separation precision in gravity separation operation is maintained, better separation effect can be achieved in thecrude slime separation link and the fine slime flotation link, the recovery rate of crude particles in centrifugate is increased while medium consumption of coal separation plants is reduced, primaryinvestment, floor area and processing cost for deslimed dense-medium coal separation plants are decreased, product quality is improved, and higher economic benefit can be achieved.

Owner:CHINA UNIV OF MINING & TECH

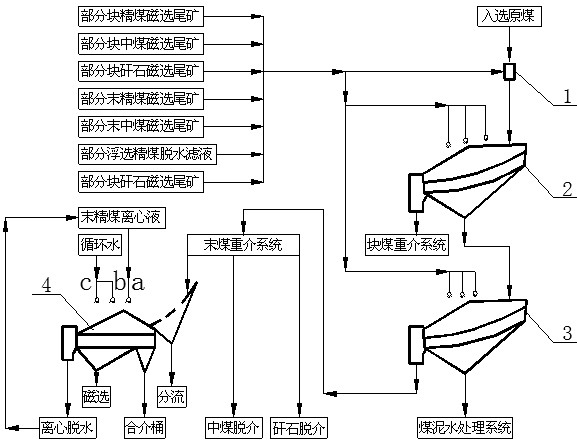

Steam coal all-grade selected and simplified heavy medium separation process

The invention discloses a steam coal all-grade selected and simplified heavy medium separation process. The process comprises classification; separation of coarse-particle coals; separation of fine-particle coals; medium and water removal of coarse-particle products; circulation, recovery and replenishing of coarse-particle coal mediums; medium and water removal of fine-particle products; and circulation, recovery and replenishing of fine-particle coal mediums. Coal slime is separated and recovered; after raw coals are classified, oversize products serve as the coarse-particle coals to enter a non-pressure three-product heavy medium cyclone for separation, and undersize products serve as the fine-particle coals to enter a pressure three-product heavy medium cyclone for separation; and after magnetic-separated tailing is concentrated, dehydrated and recovered, concentrate coal and medium coal products are doped. The coarse-particle coals are separated by the heavy-medium cyclone, so that the high-density separation of low-density suspension is realized, the separation density is reduced, the medium consumption is effectively reduced, and the wet mud removing link before separation of the fine-particle coals in a conventional process is saved; and the process is wide in application range, simple, convenient for operation, high in separation efficiency, flexible in product structure, low in production operation cost, low in capital investment and accordant with national environment protecting requirements.

Owner:TANGSHAN BRANCH COAL SCI ACAD

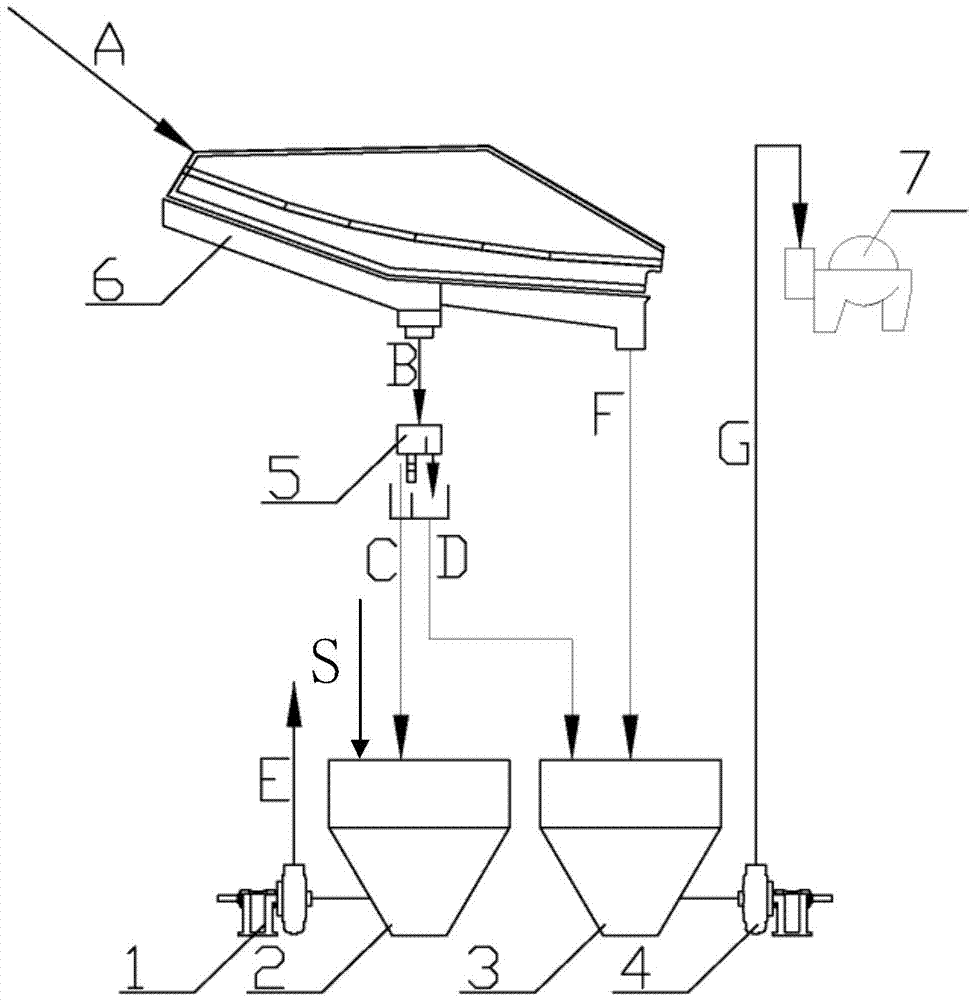

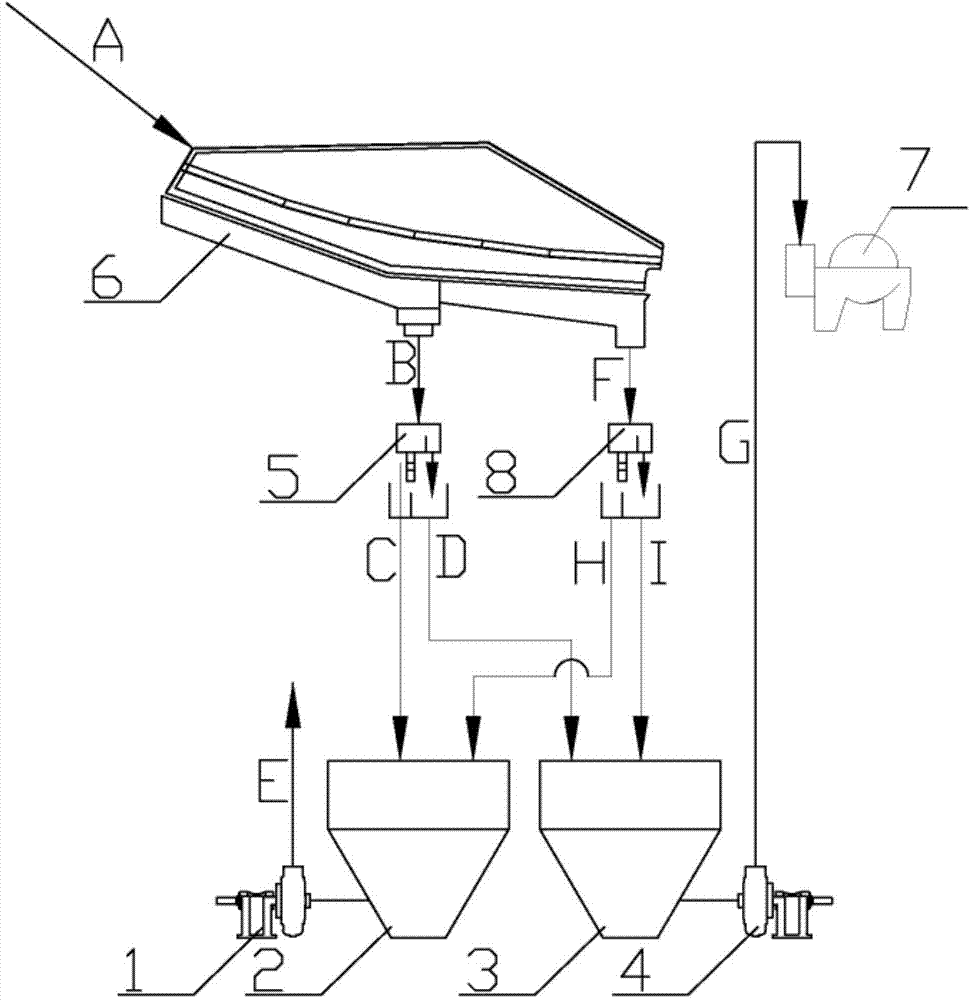

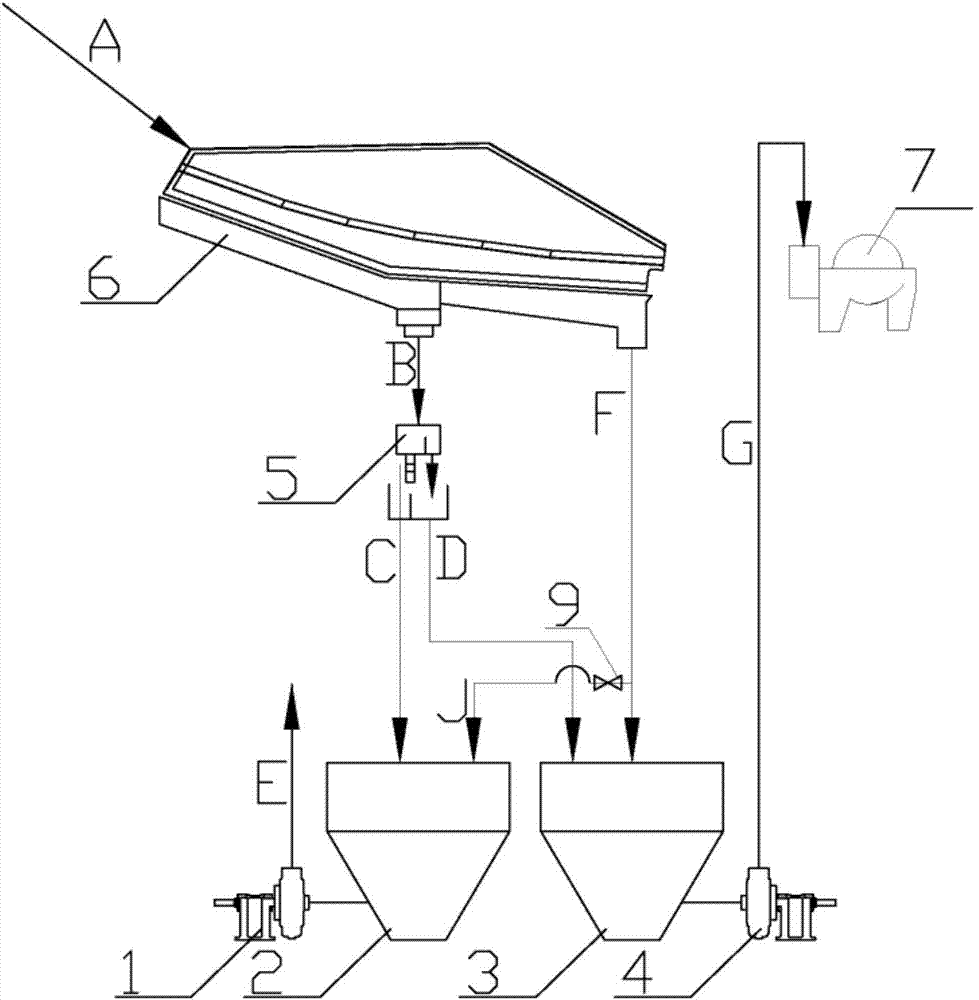

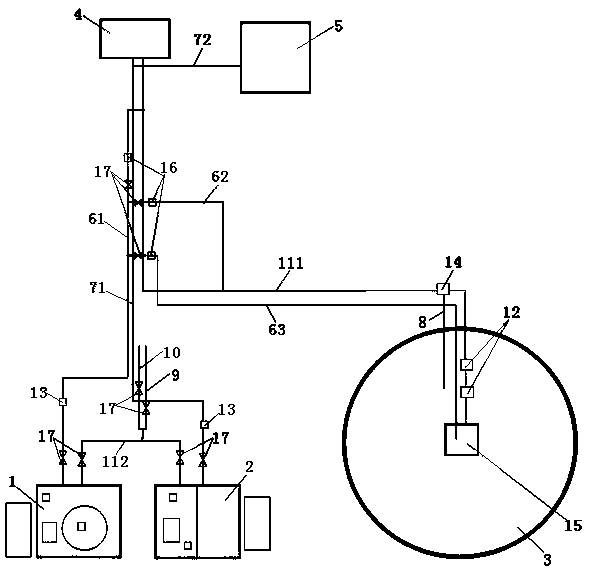

Qualified medium barrel dilute medium water complementing system and method used for dense-medium coal preparation

ActiveCN104289304AReduce distractionsLiquid level stabilityWet separationMagnetic separatorEngineering

The invention discloses a qualified medium barrel dilute medium water complementing system used for dense-medium coal preparation. The system comprises a dilute medium flow guide device, a dilute medium barrel, a dilute medium pump, a detection module and a control module. The dilute medium flow guide device is connected with a qualified medium barrel and leads dilute media into the qualified medium barrel; the dilute medium barrel is connected with a medium drainage screen and holds the dilute media removed from the medium drainage screen; one end of the dilute medium pump is connected with the dilute medium barrel, and the other end of the dilute medium pump is connected with a dilute medium magnetic separator; the detection module is installed on the qualified medium barrel and is used for detecting the density and the liquid level of dense-medium suspension liquid in the qualified medium barrel and sending density and liquid level parameters to the control module; the control module is installed on the dilute medium flow guide device and is used for controlling the dilute medium flow guide device to start and / or stop introducing the dilute media into the qualified medium barrel according to the density and liquid level parameters of the dense-medium suspension liquid in the qualified medium barrel. The invention further discloses a qualified medium barrel dilute medium water complementing method. By means of the qualified medium barrel dilute medium water complementing system and method, stability of the liquid level and the density of the dense-medium suspension liquid in the qualified medium barrel is guaranteed in dense-medium coal preparation.

Owner:CHINA SHENHUA ENERGY CO LTD +1

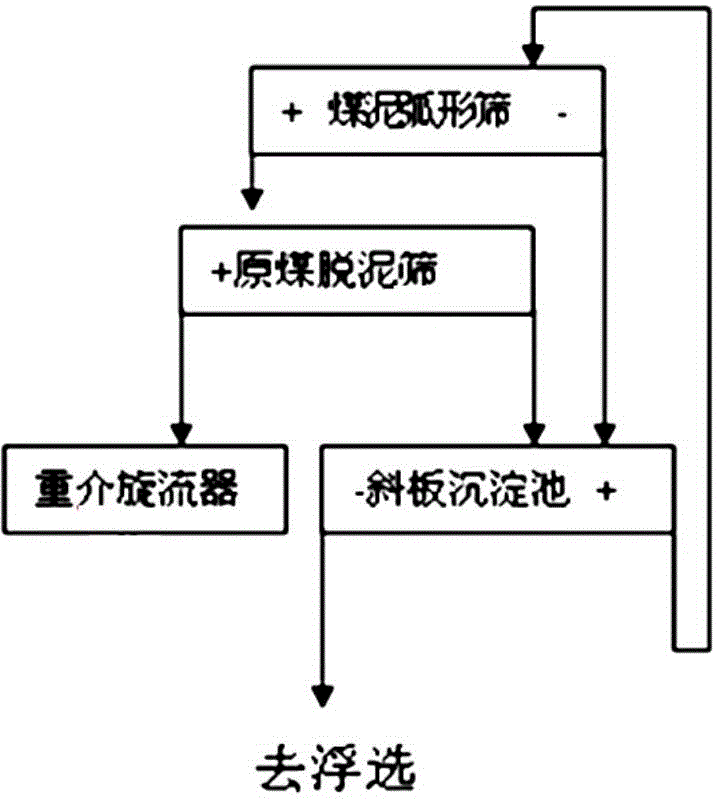

Dense medium coarse slime sorting device and sorting process

InactiveCN104084293ASorting process is reasonableHigh recovery rateWet separationOre concentrateProcess engineering

The invention provides a dense medium coarse slime sorting device and a sorting process. Four rows of water spraying nozzles of a raw coal desliming screen of the sorting device are arranged, and the size of screen cuts is 1 mm. Two rows of water spraying nozzles are formed in a fine coal slime vibration arc desliming screen, and screen bars are prismatic. The height of an overflow weir of a TBS sorting machine can be adjusted. A dense medium hydrocyclone is adopted for a main washing process; according to the auxiliary washing process, coal slime sequentially passes through a conical inclined plate settling pond, the TBS classifying hydrocyclone, the TBS sorting machine, an ore concentration arc desliming screen, a clean coal magnetic tail barrel, a concentration hydrocyclone set, the fine coal slime vibration arc desliming screen and a fine coal slime centrifugal machine to obtain clean coal, the fine coal slime is floated to obtain the fine coal, and the rest is tailing. The sorting device enables the dense medium coal selecting process to be further optimized. After the coarse coal slime is separated from a dense medium main washing system, the coarse coal slime sorting process is more reasonably, and the recovery efficiency of the tail fine coal is obviously improved; as a coarse coal slime sorting system is improved, the content of ash in the coarse coal slime is lowered, the dense medium main washing sorting density and the sorting precision are effectively improved, and the effect of dense medium main washing is ensured.

Owner:DUSHI COAL DRESSING POWER PLANT OF SICHUAN DAZHU COAL & ELECTRICITY GRP

Titanomagnetite and ilmenite separation technology

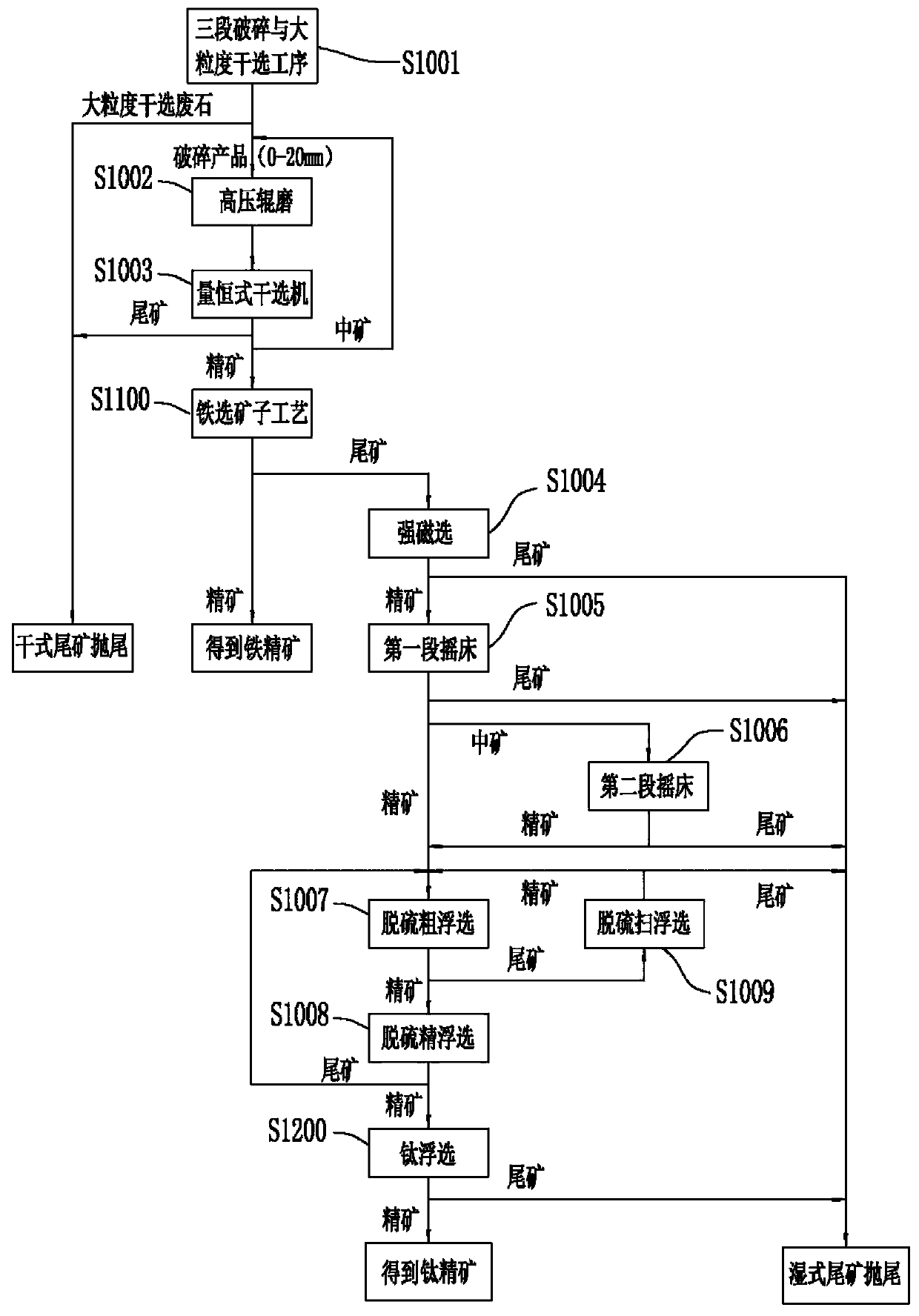

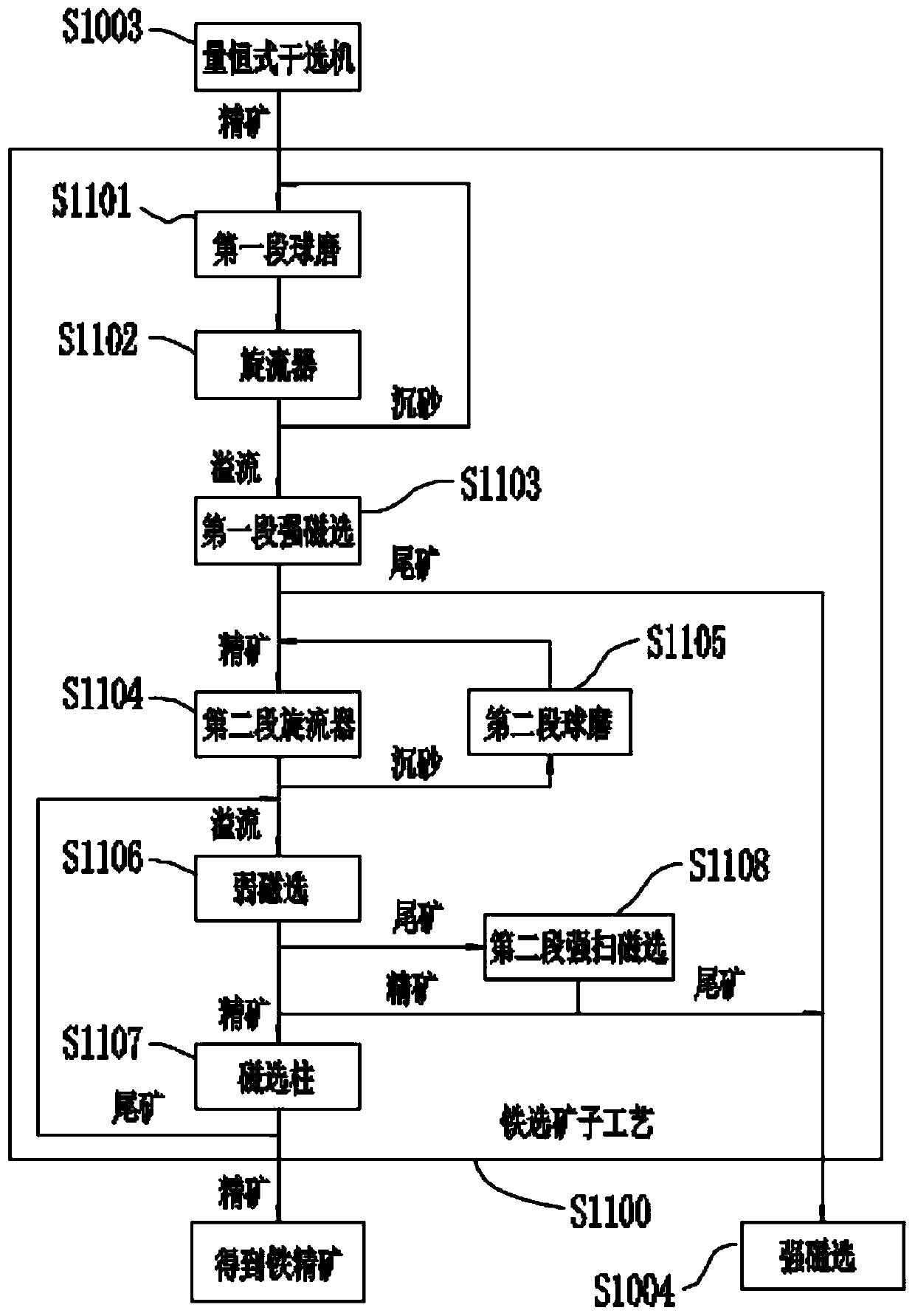

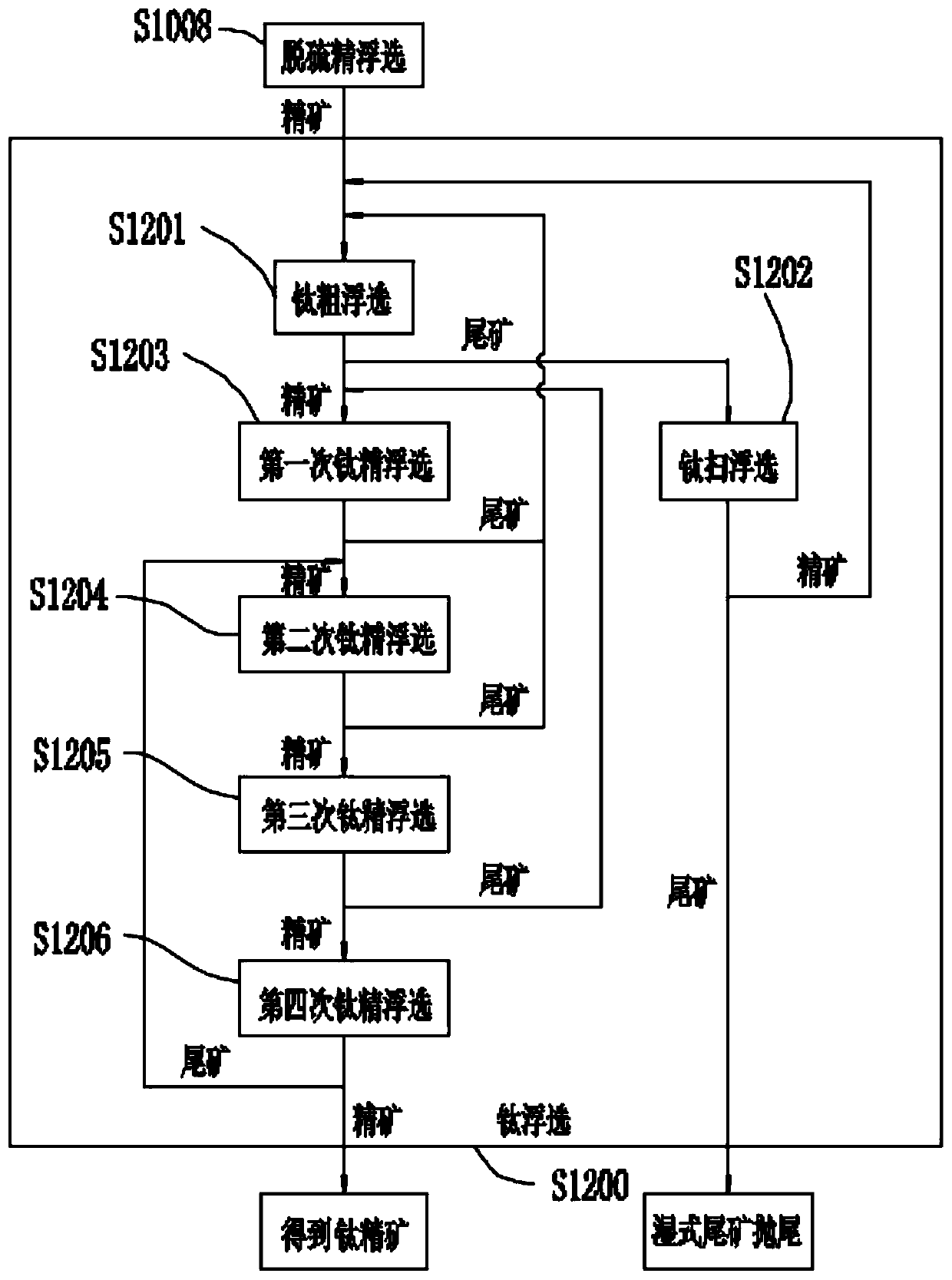

The invention belongs to the technical field of mineral separation, and provides a titanomagnetite and ilmenite separation technology. The titanomagnetite and ilmenite separation technology comprisesthe steps of three-stage crushing and large-particle-size dry separation process conducting, high-pressure rolling and fine grain dry separator closed circuit conducting, iron separation sub-process conducting, strong magnetic separation, two-stage table conducting, desulfurization rough flotation, desulfurization sweeping flotation, desulfurization fine flotation and titanium flotation. Through large-particle-size dry separation in the three-stage crushing and large-particle-size dry separation process and a fine grain dry separator in a high-pressure rolling and fine grain dry separator closed circuit, waste stones with the productivity of 68% are thrown away through two-stage dry separation, therefore, the treatment amount of subsequent ore grinding and grading operation is greatly decreased, energy consumption and medium consumption are reduced, and the cost is reduced; and desulfurization treatment is conducted through desulfurization rough flotation, desulfurization sweeping flotation and desulfurization fine flotation. The titanomagnetite and the ilmenite with the low iron and titanium content are treated through the technology, and therefore iron concentrate and titanium concentrate with the high grade can be obtained.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

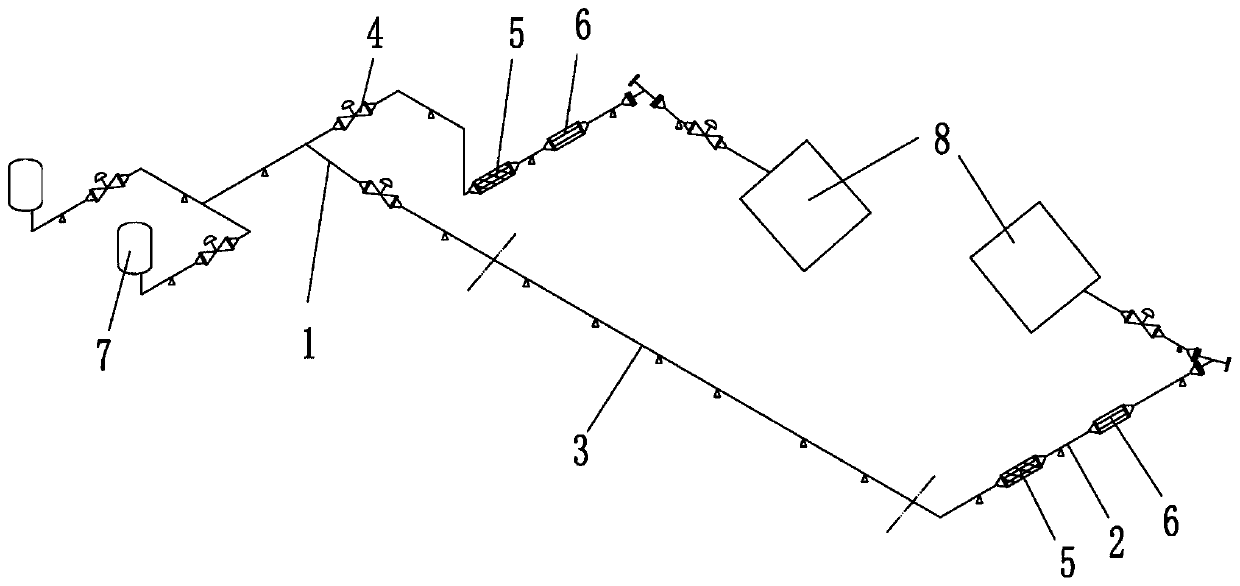

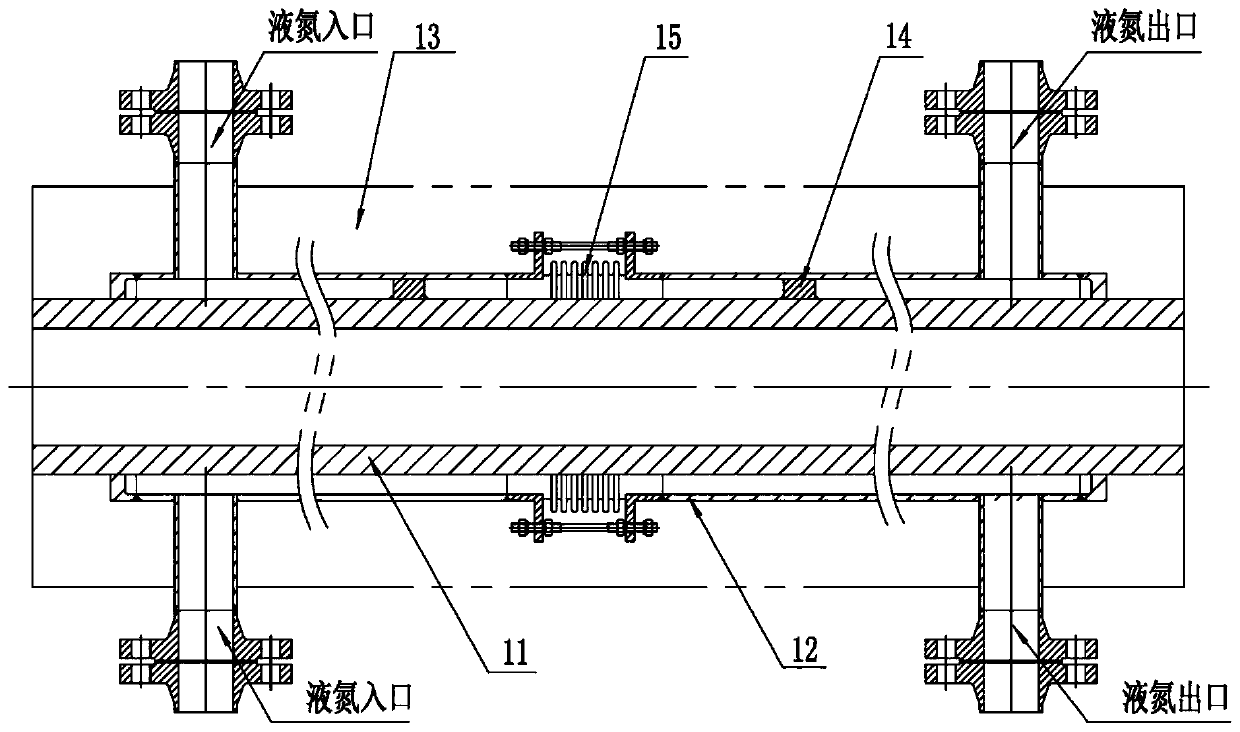

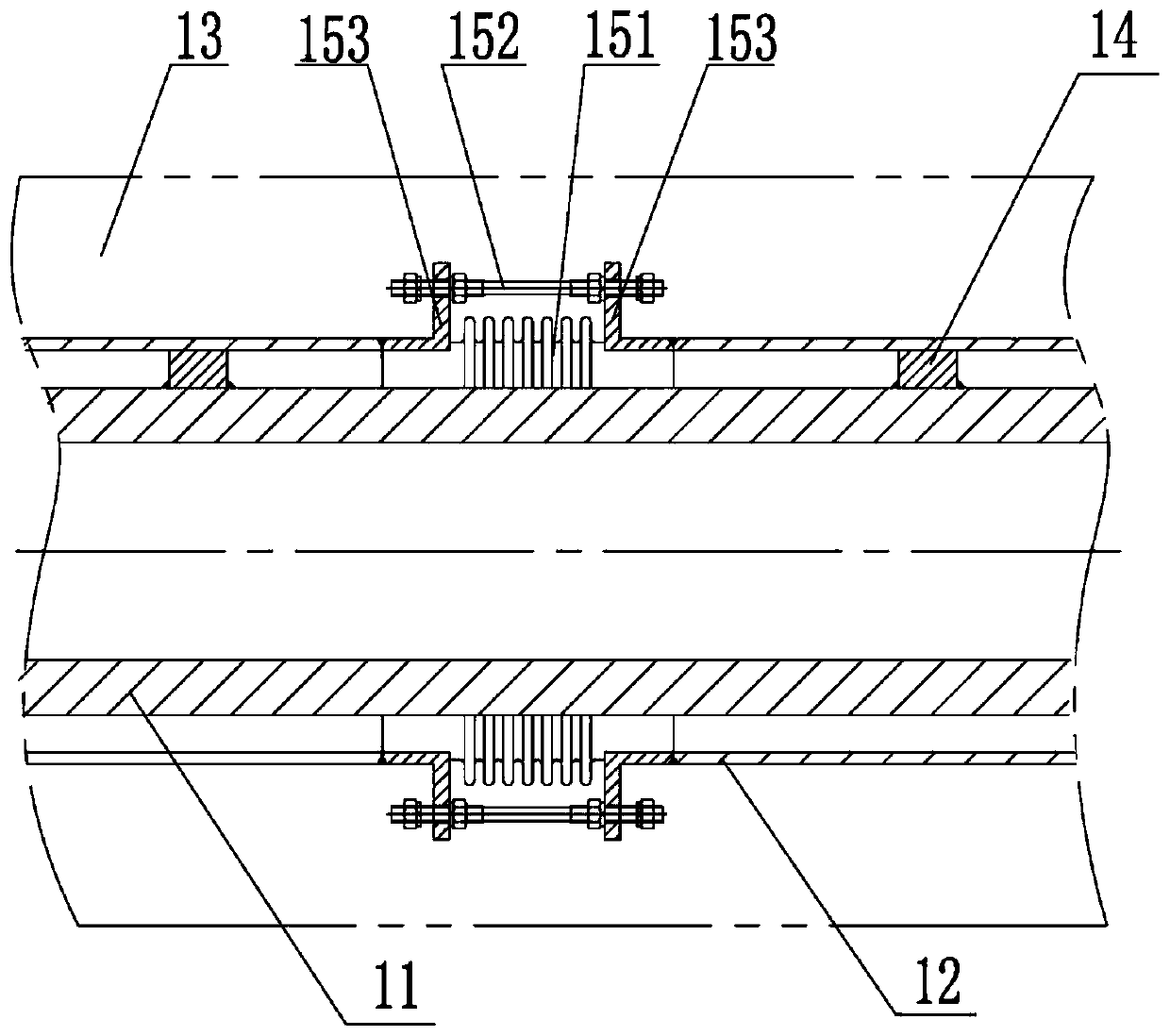

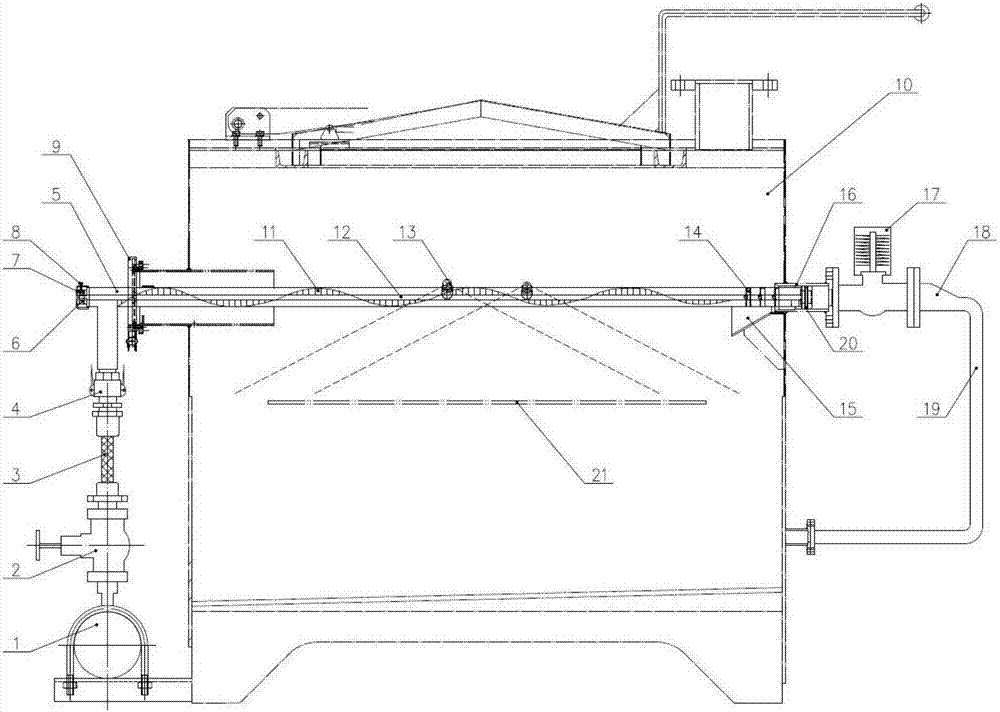

Low temperature pipeline system

ActiveCN109707946AImprove cooling effectReduce usageThermal insulationPipe heating/coolingEngineeringHigh pressure

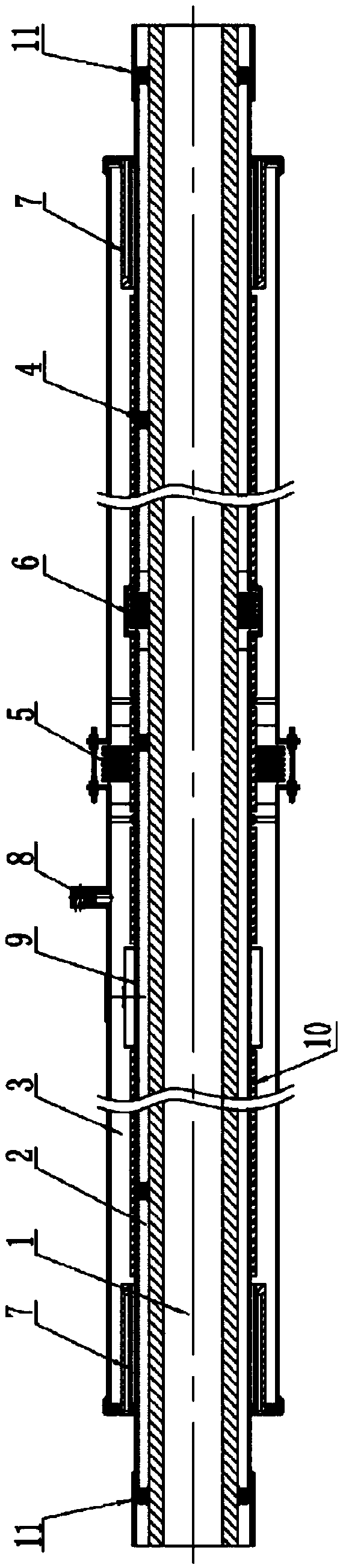

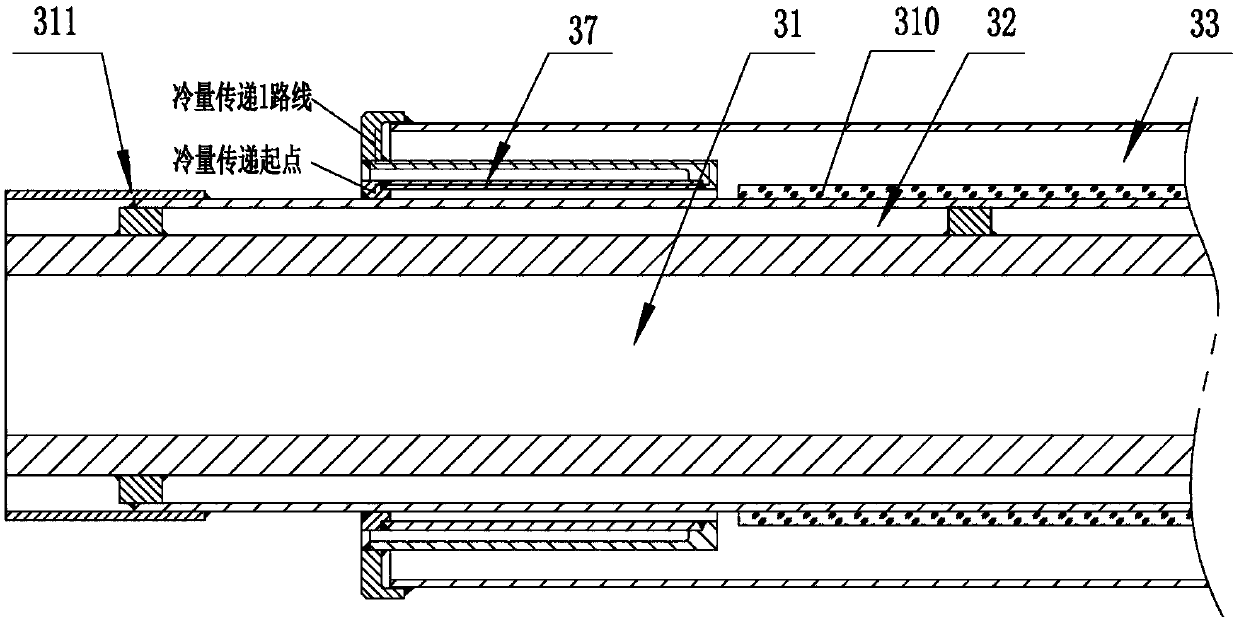

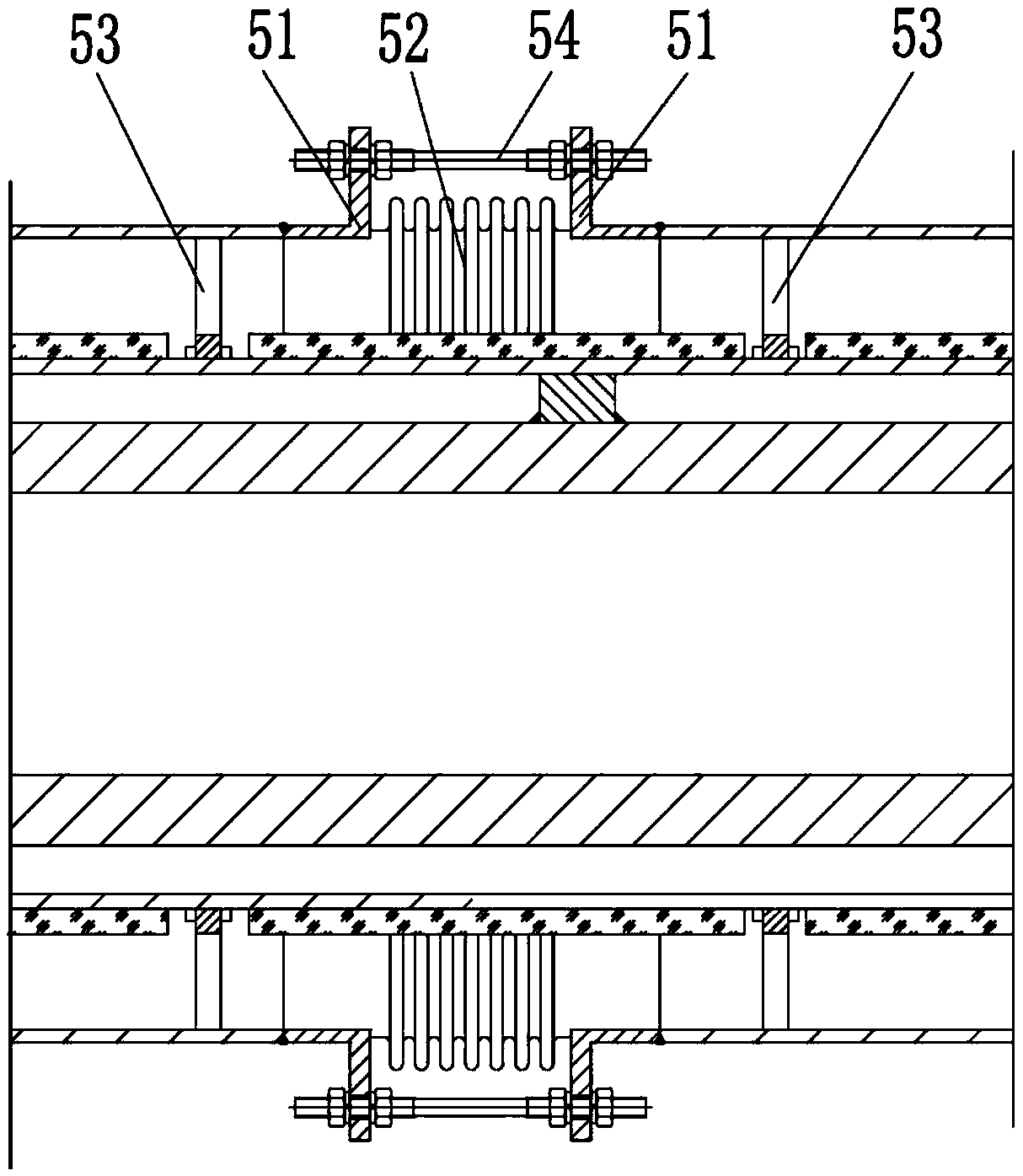

The invention relates to a low temperature pipeline system. The problems that during pipeline precooling of existing pipeline systems, resources are wasted, and safety accidents are liable to occur are solved. The system comprises a high-pressure interlayer pipeline unit and a high-pressure vacuum pipeline; the high-pressure interlayer pipeline unit comprises a first high-pressure interlayer pipeline, a second high-pressure interlayer pipeline, a valve, a flow meter and a filter; one end of the first high-pressure interlayer pipeline is connected with a high-pressure storage tank; the other end of the first high-pressure interlayer pipeline is connected with one end of the high-pressure vacuum pipeline and testing equipment; the other end of the high-pressure vacuum pipeline is connected with the testing equipment through the second high-pressure interlayer pipeline; the high-pressure vacuum pipeline comprises an inner layer conveying pipe, a middle precooling pipe, an outer layer vacuum heat insulation pipe, a first support frame, a first flexible connection assembly and a second flexible connection assembly; and the first high-pressure interlayer pipeline and the second high-pressure interlayer pipeline are of the same structure and each comprise an inner conveying pipe, a middle precooling pipe, an outer cladding layer, a third support frame and a third flexible connection assembly.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

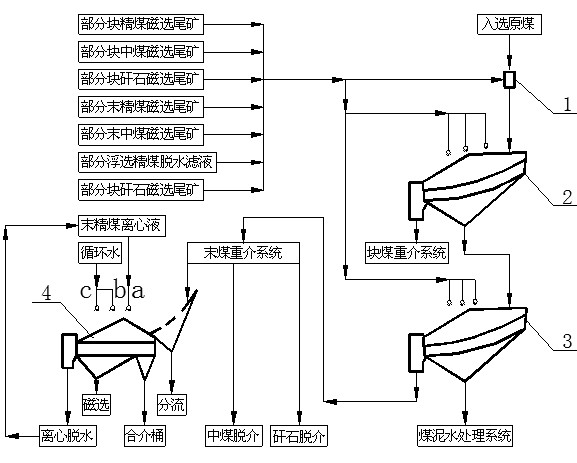

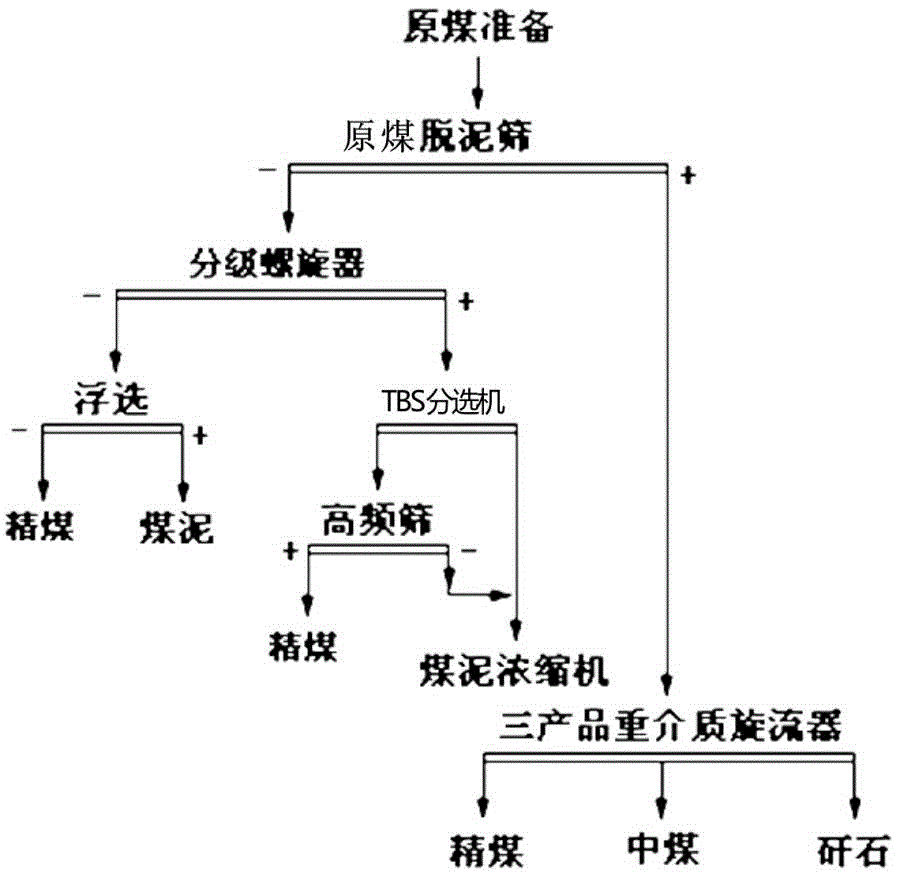

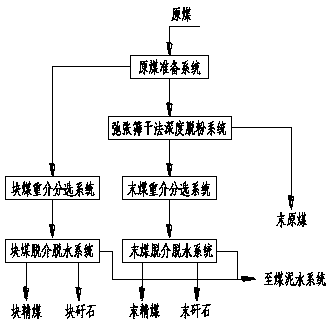

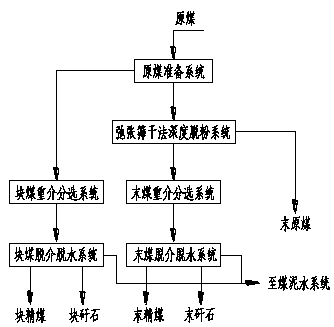

Steam coal dense medium separation process capable of effectively reducing slime content

InactiveCN109999991AReduce the number of running unitsReduce operating loadWet separationWater treatment systemSeparation system

The invention discloses a steam coal dense medium separation process capable of effectively reducing slime content. The process comprises a raw coal preparing system, a fine coal dry method deep finesremoval system, a block coal dense medium separation system, a fine coal dense medium separation system, and a slime water treatment system. The relaxation sieving dry method deep fines removal process is adopted in 3 mm raw coal grading, the fine-particle-size dry method screening is adopted for enabling the slime amount in the subsequent fine coal washing process link is greatly reduced, the running load of the slime water system is effectively relieved, the secondary slime amount is reduced, the clean coal water is reduced, the commercial coal quality is further improved, meanwhile, due toreduction of the slime content, stability of the fine coal medium circular system is ensured, medium consumption is reduced, the running number of slime water treatment devices is reduced, and production cost is reduced.

Owner:COAL IND JINAN DESIGN & RES

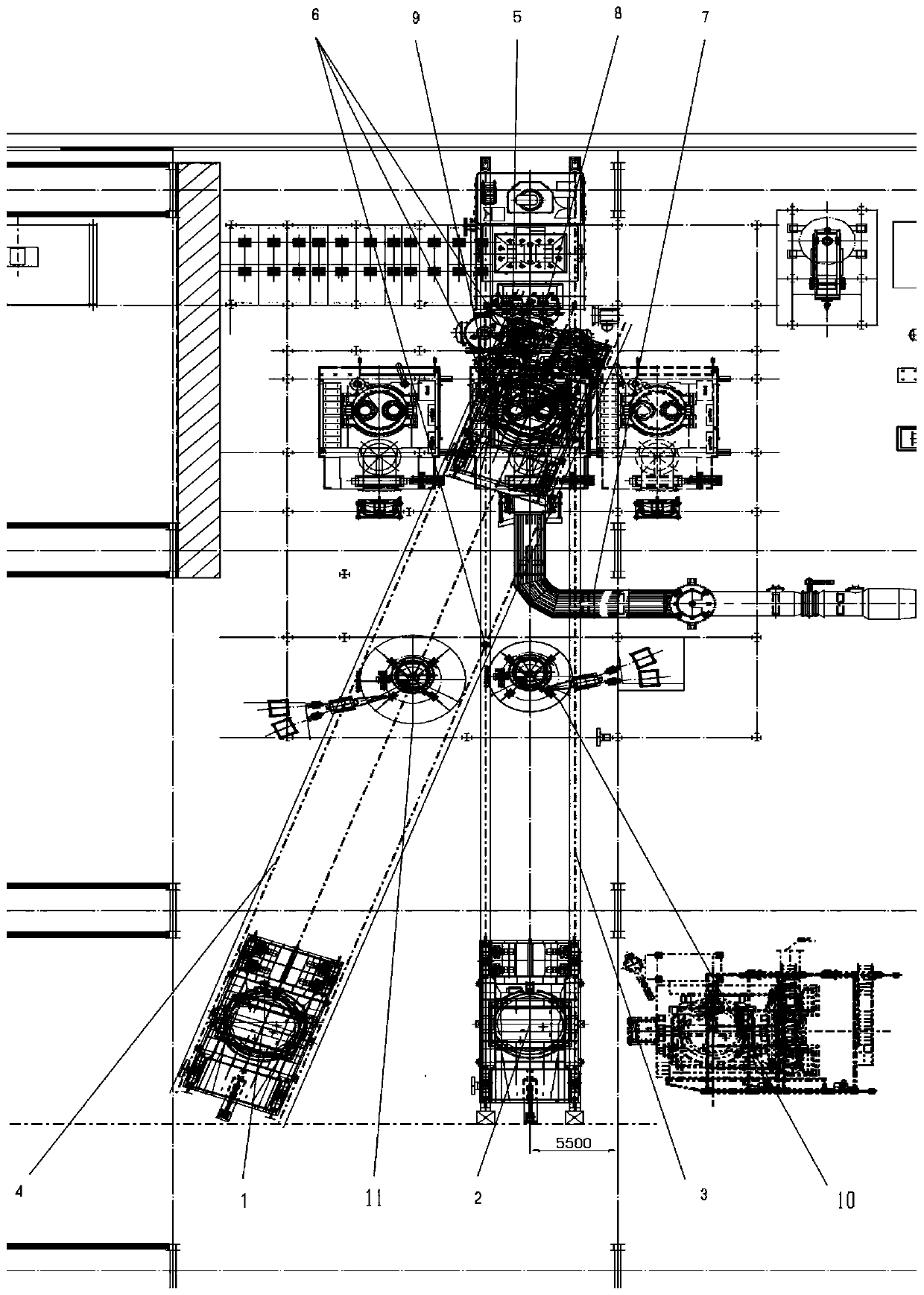

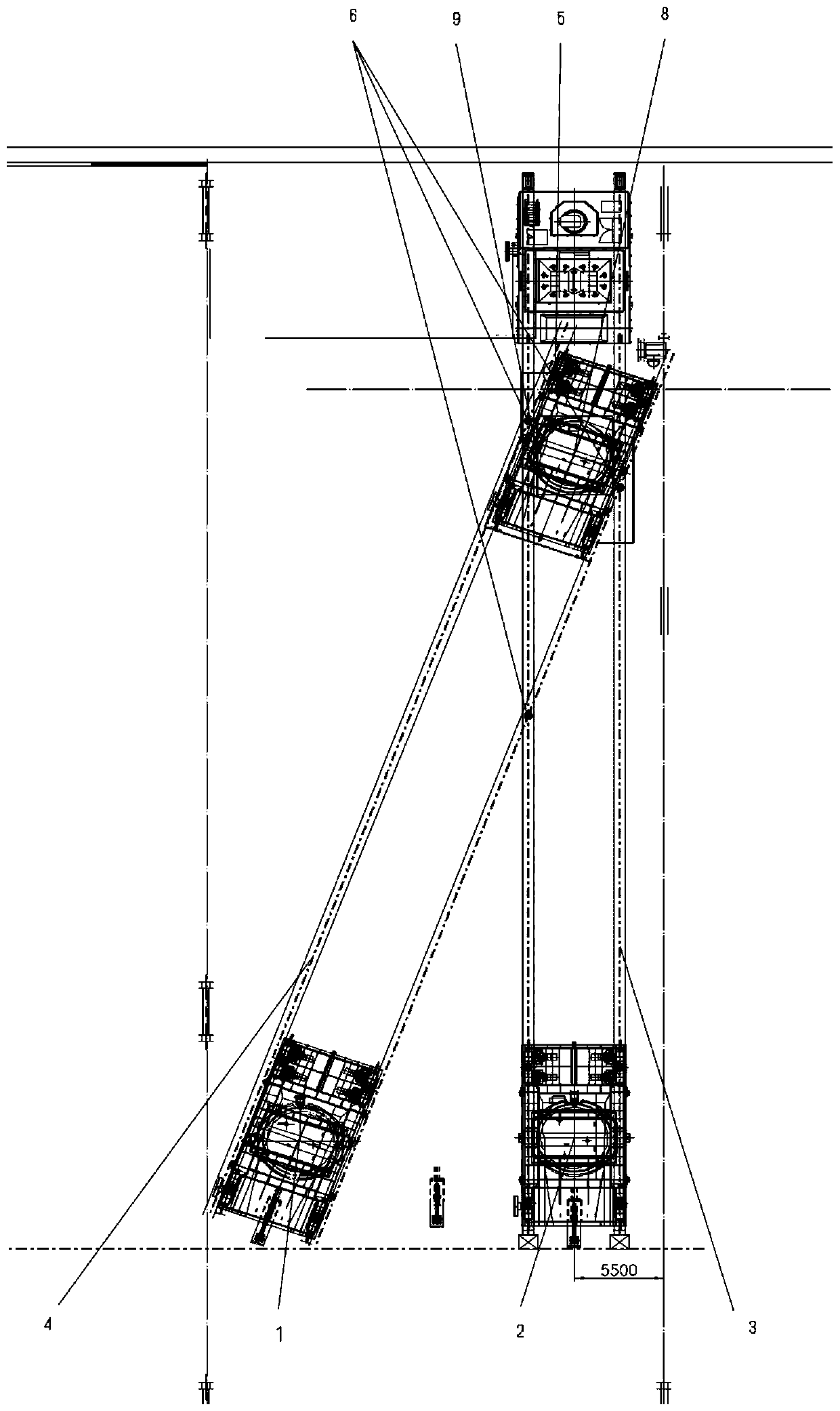

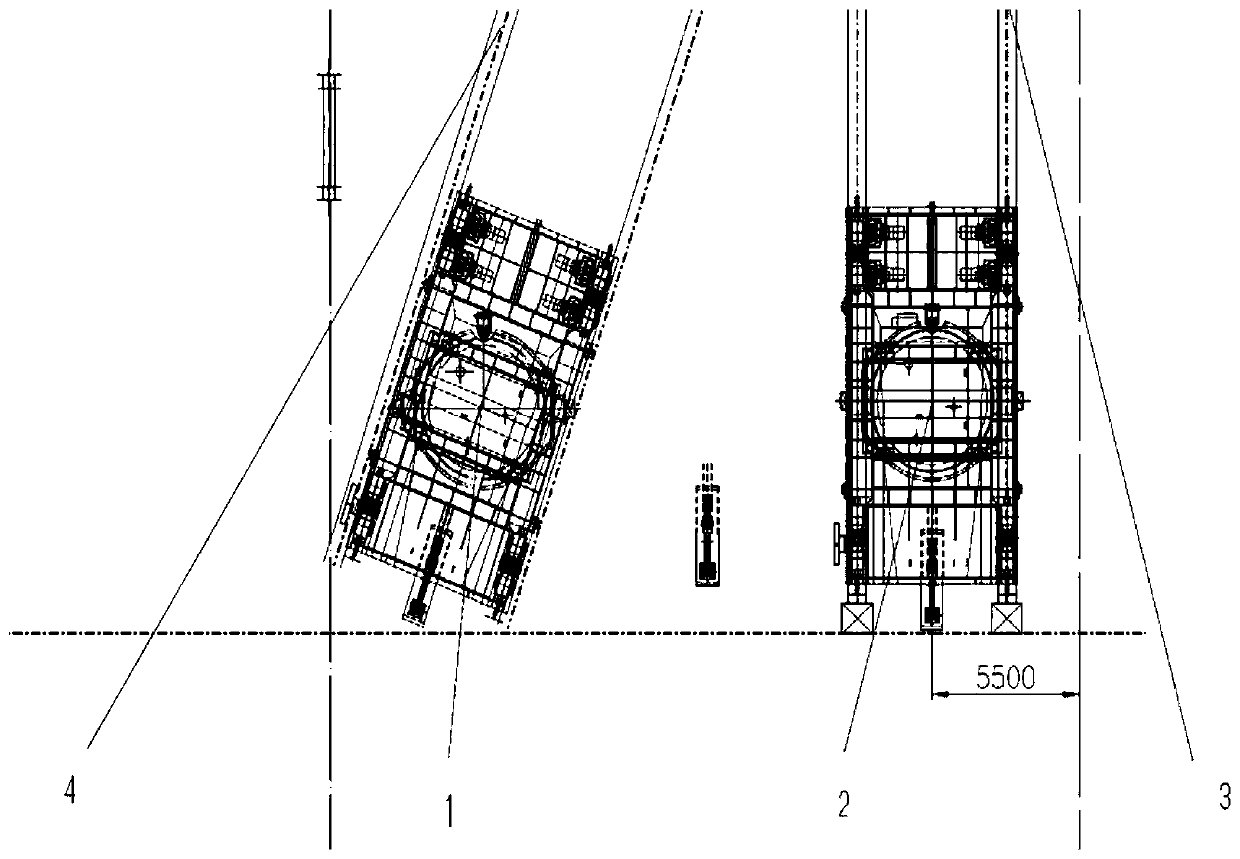

Single-station RH process arrangement method for rail crossing of two molten steel vehicles

InactiveCN110257592AComposition is stableStable temperatureMelt-holding vesselsSteelmakingMetallurgy

The invention discloses a single-station RH process arrangement method for rail crossing of two molten steel vehicles, and belongs to the technical field of steelmaking RH vacuum treatment. The method involves a buggy ladle system, a rail device and a jacking system. Two molten steel vehicles cross rails are designed, a steel ladle of molten steel to be treated are conveyed by one rail to reach a treatment position, the molten steel begins to be treated, after the treatment is finished, the steel ladle is transported to a continuous casting span bull ladle by the molten steel vehicle on the rail; a steel ladle is arranged on the molten steel vehicle on the other rail in advance, and when a buggy ladle is not at the treatment position, the molten steel vehicle on the other rail is driven to the treatment position for molten steel treatment; and in the process, two molten steel car transport tracks are subjected to cross operation and continuous operation is carried out, and the two rails have intersections at the molten steel transport line and the RH treatment position, and meanwhile, a transport vehicle on one rail is a special-shaped molten steel vehicle, so that the operations that the molten steel can be treated at the treatment position, a ladle cover can be picked off and hung on, and a stationary ladle is hoisted through a crown block are met. The single-station RH process arrangement method for the rail crossing of the two molten steel vehicles has the advantages that the RH vacancy time can be greatly saved, the influence of cold steel in a RH vacuum tank on molten steel component in the treatment process can be reduced, and the reasonable arrangement of the production organization can be facilitated.

Owner:BEIJING SHOUGANG INT ENG TECH

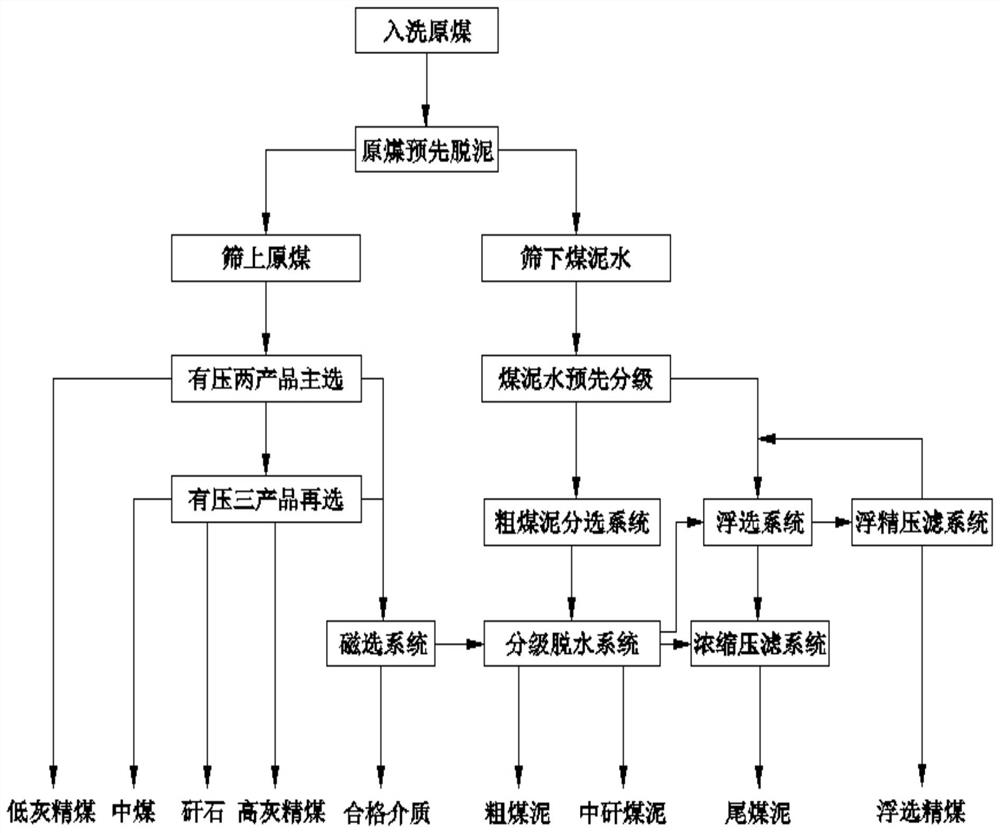

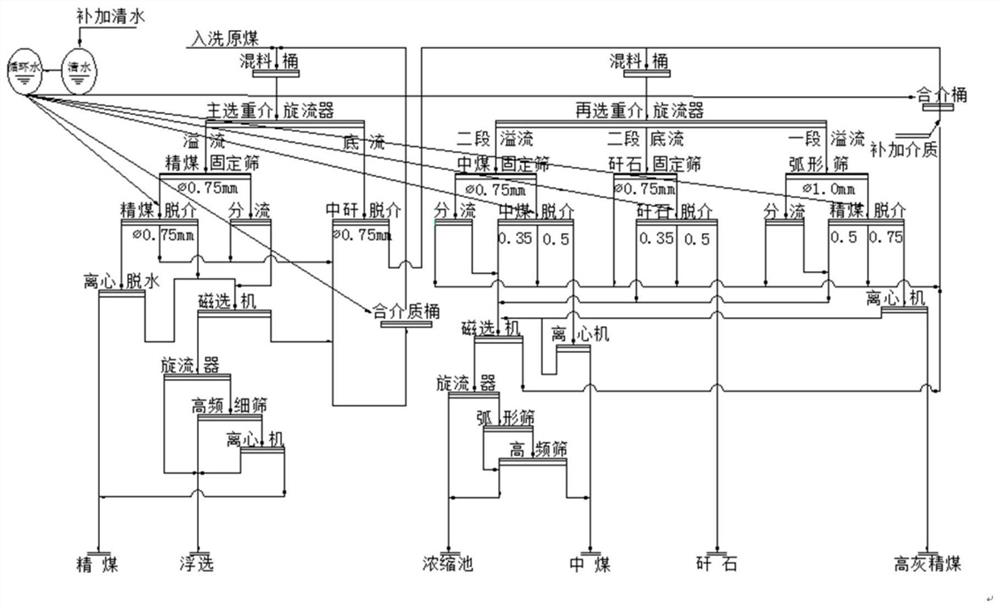

Combined separation process of pressurized two-product and pressurized three-product cyclone

PendingCN112371323AHigh sorting accuracyFlexible product structure adjustmentWet separationProcess engineeringSeparation process

The invention discloses a combined separation process of a pressurized two-product and pressurized three-product dense medium cyclone. The combined separation process comprises the following steps: firstly, desliming washed raw coal in advance to obtain oversize raw coal and undersize slime water; feeding the undersize slime water into a slime water treatment system; feeding the oversize raw coalinto a primary separation system of a first-section pressurized two-product cyclone; separating to obtain a low-ash clean coal and medium gangue mixture; and feeding the medium gangue mixture into a secondary pressurized three-product dense medium cyclone after medium removal, and separating to obtain high-ash clean coal, medium coal and gangue. According to the combined separation process, the dense medium coal is separated into high-ash clean coal and medium coal products again by utilizing the advantages of high separation precision and flexible product structure adjustment of the pressurized three-product cyclone, so that a high-level and high-benefit production system and process taking the pressurized two-product and pressurized three-product dense medium cyclone as main washing equipment are formed, and the investment cost of medium coal re-washing equipment is saved. The combined separation process is particularly suitable for the situation that the medium coal contains part ofhigh-ash clean coal and the clean coal resource is wasted under the condition that the clean coal production index of a coal preparation plant is relatively low.

Owner:XINWEN MINING GROUP

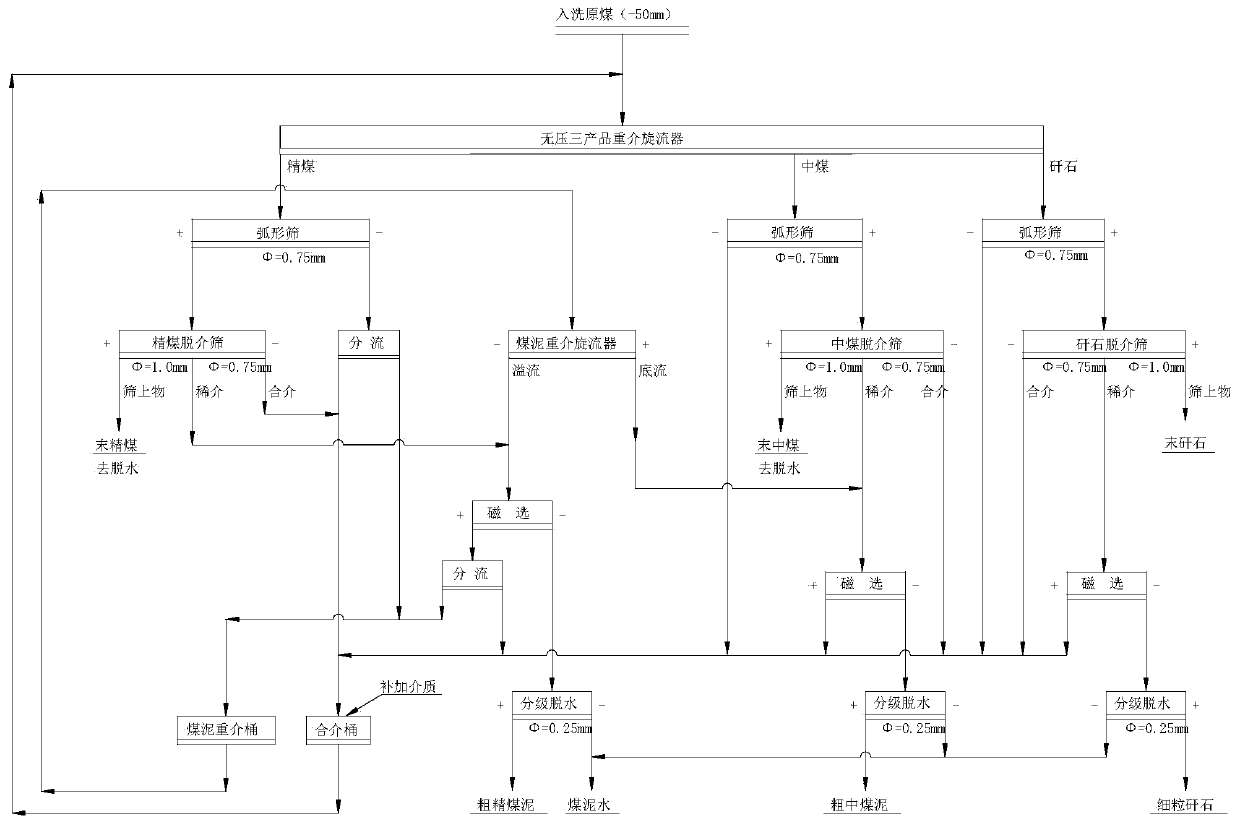

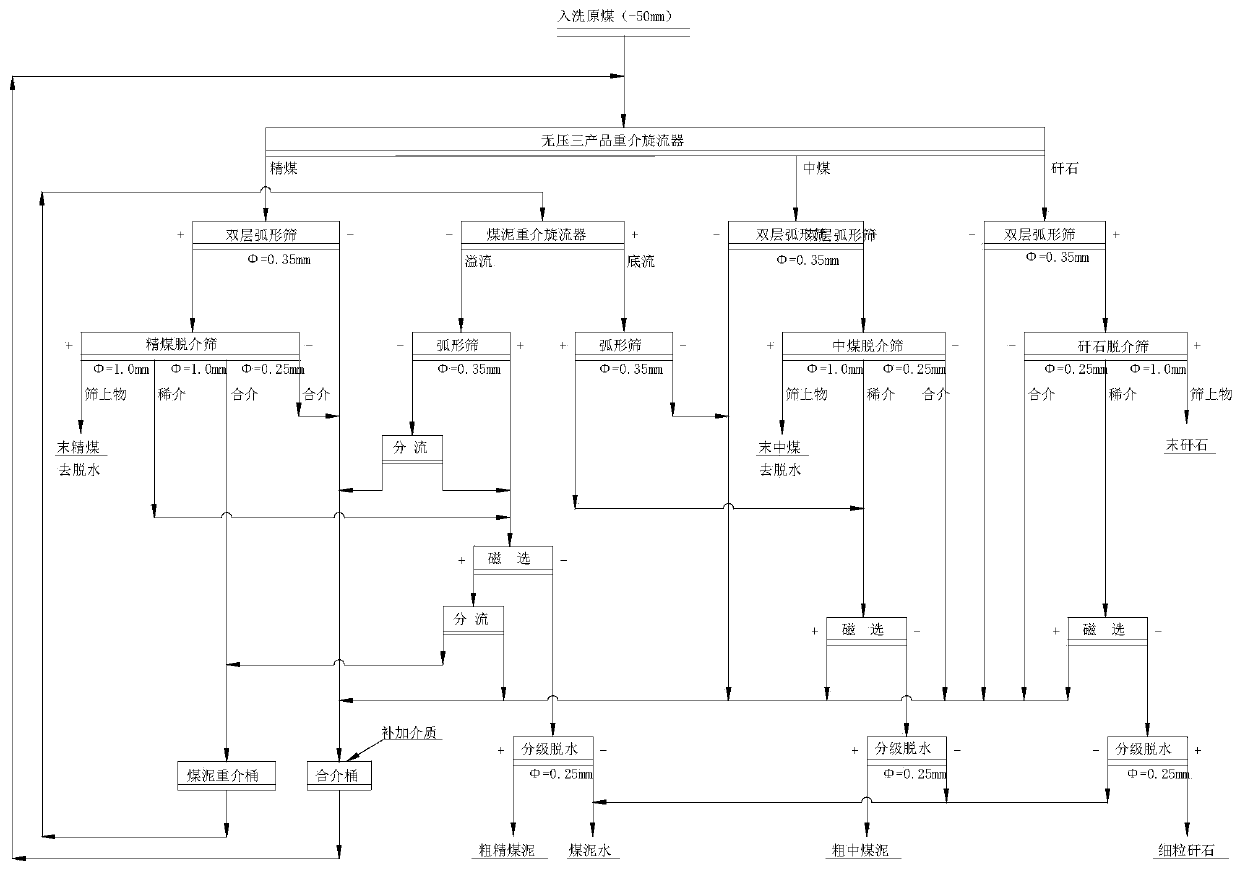

Constant-low-splitting-based non-pressure three-product and slime dense medium separation improved process

ActiveCN111167594AMaintain dynamic balanceImprove stabilityWet separationThermodynamicsMagnetic separation

The invention discloses a constant-low-splitting-based non-pressure three-product and slime dense medium separation improved process. The process specifically comprises the following steps of (a) one-stage separation, (b1) one-stage cleaned coal medium removal, (b2) one-stage middling coal medium removal, (b3) one-stage gangue medium removal, (c) second-stage slime separation, (d1) second-stage cleaned coal medium removal, (d2) second-stage middling coal medium removal, (e1) cleaned coal magnetic separation, (e2) middling coal magnetic separation, (e3) gangue magnetic separation, and (f) one-stage qualified medium blending. The improved process is high in separation efficiency, low in medium consumption, low in operation cost, little in investment, strong in practicability, and remarkablein economic benefit.

Owner:中煤西安设计工程有限责任公司

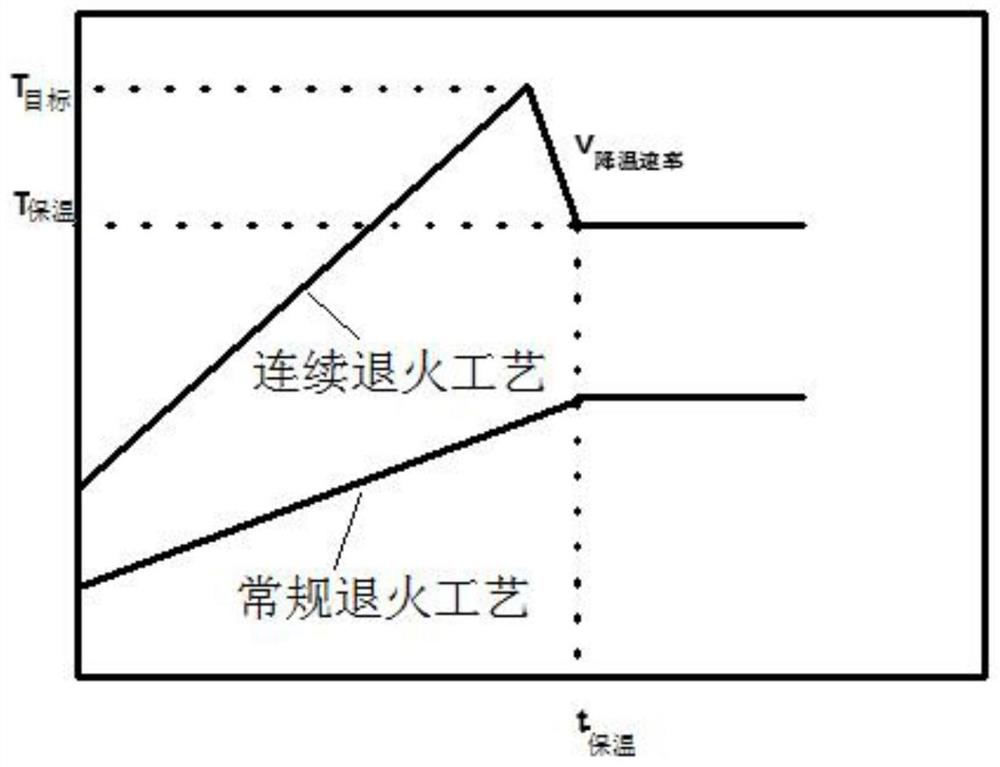

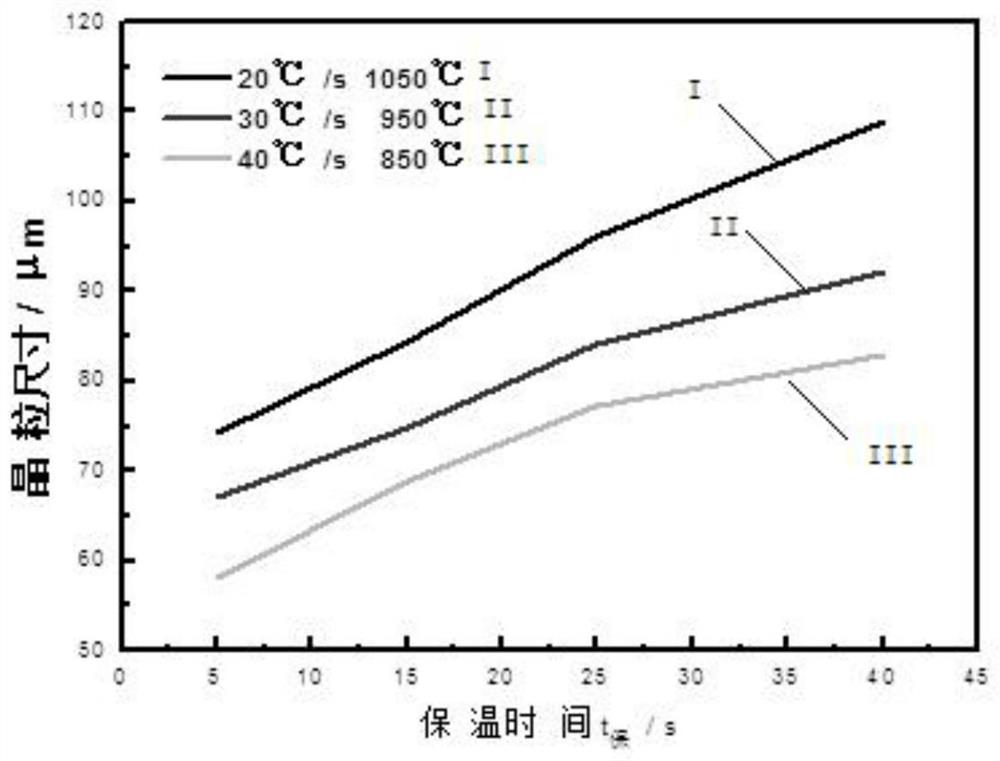

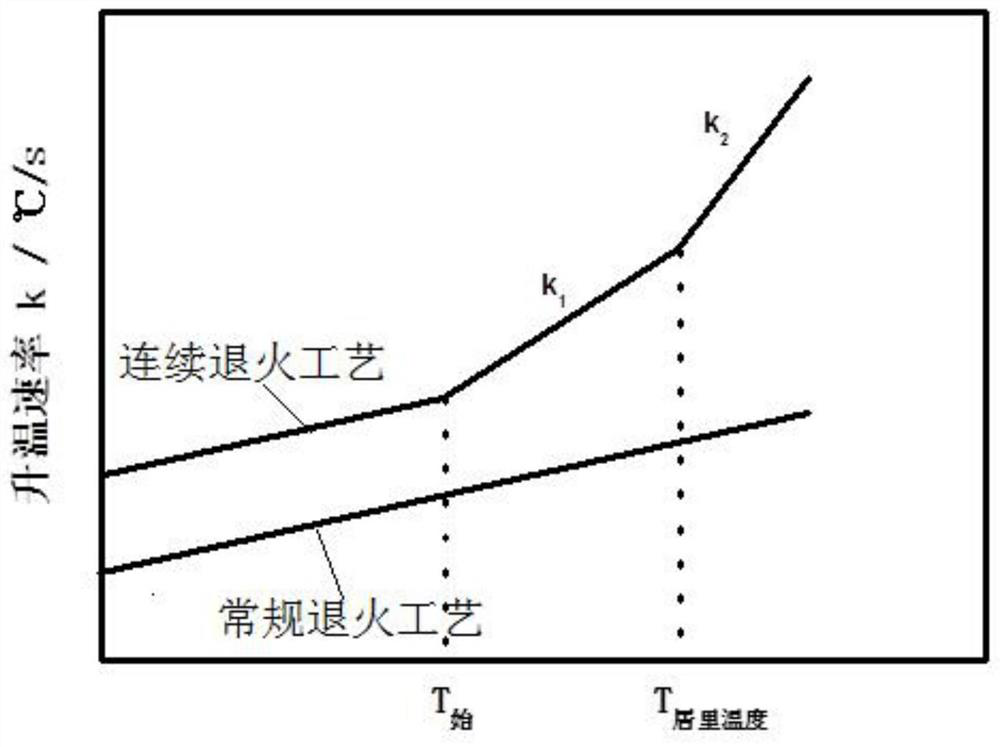

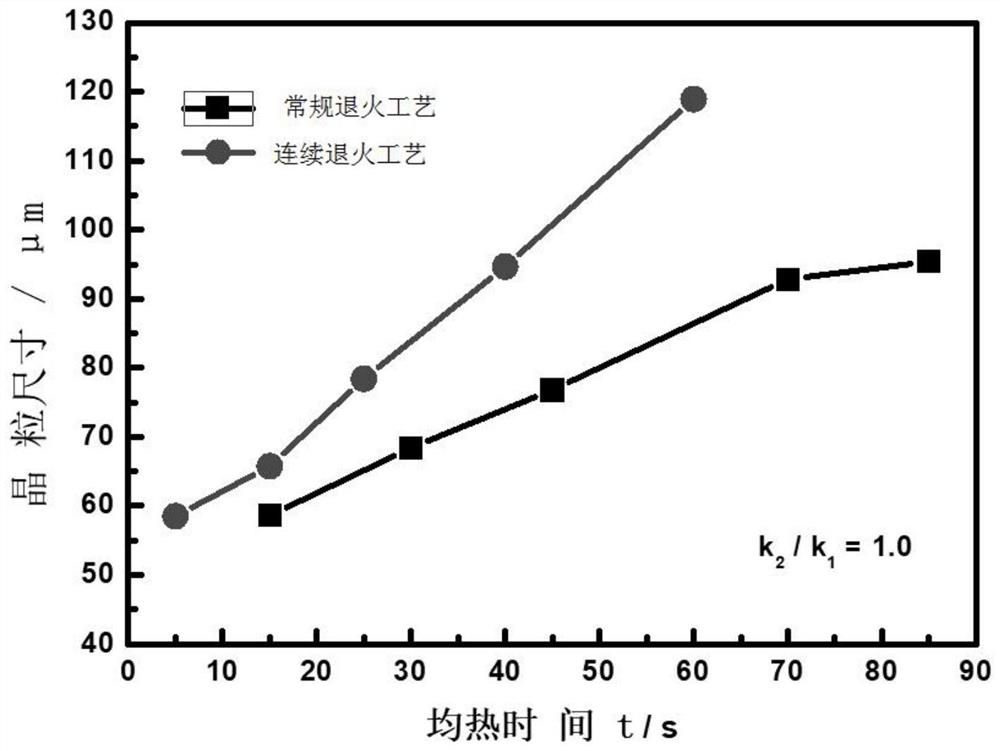

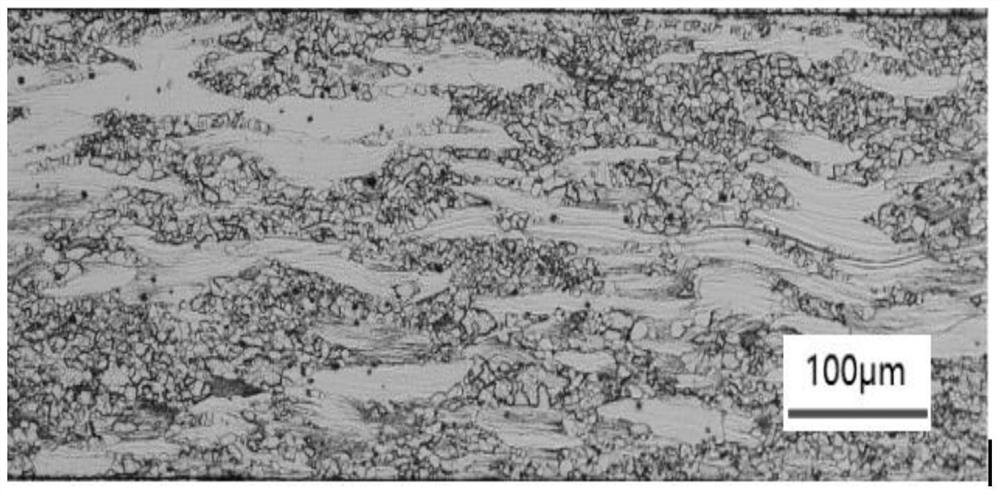

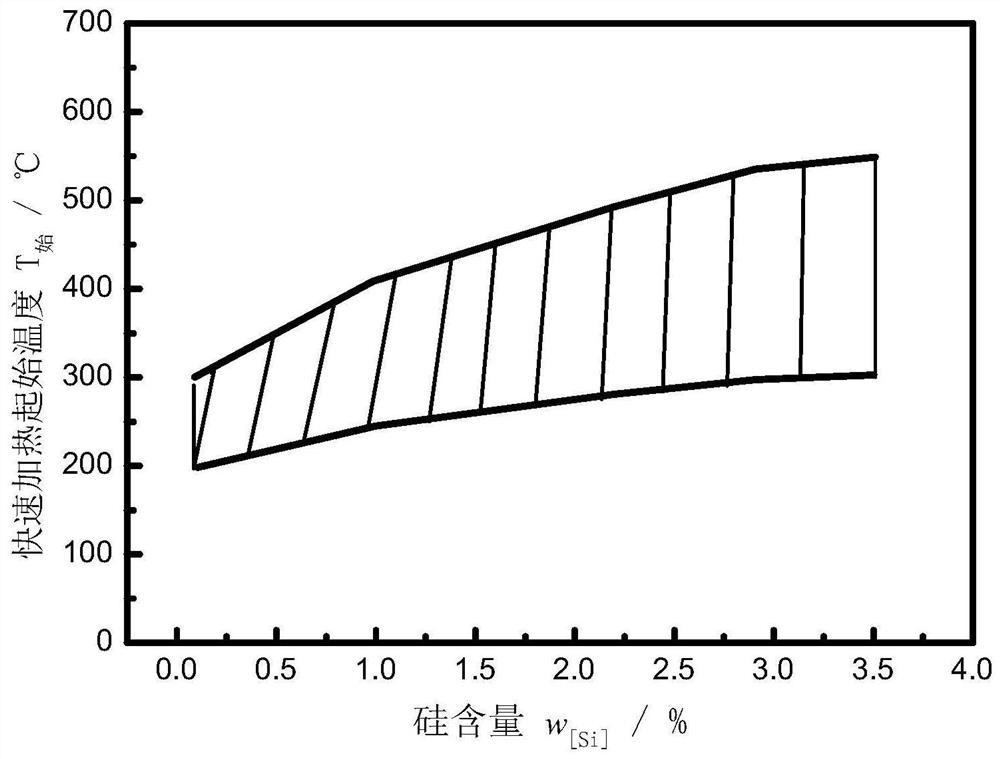

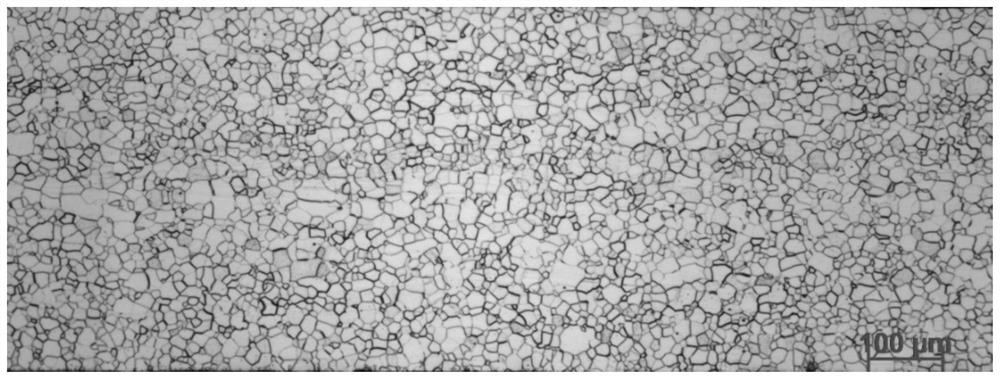

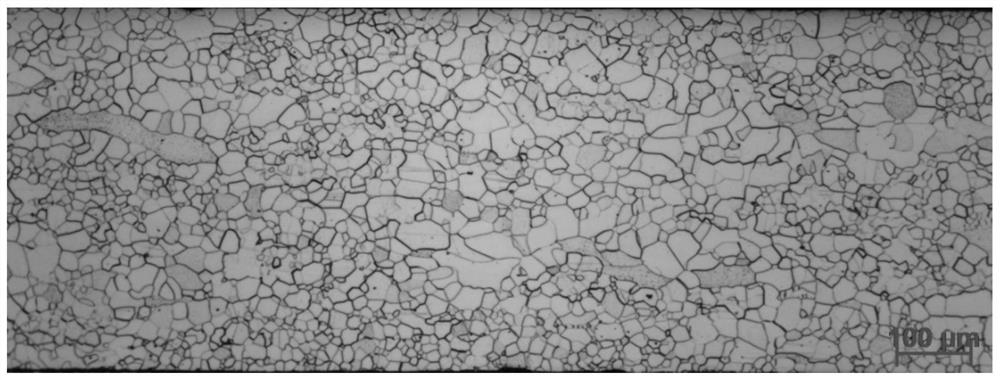

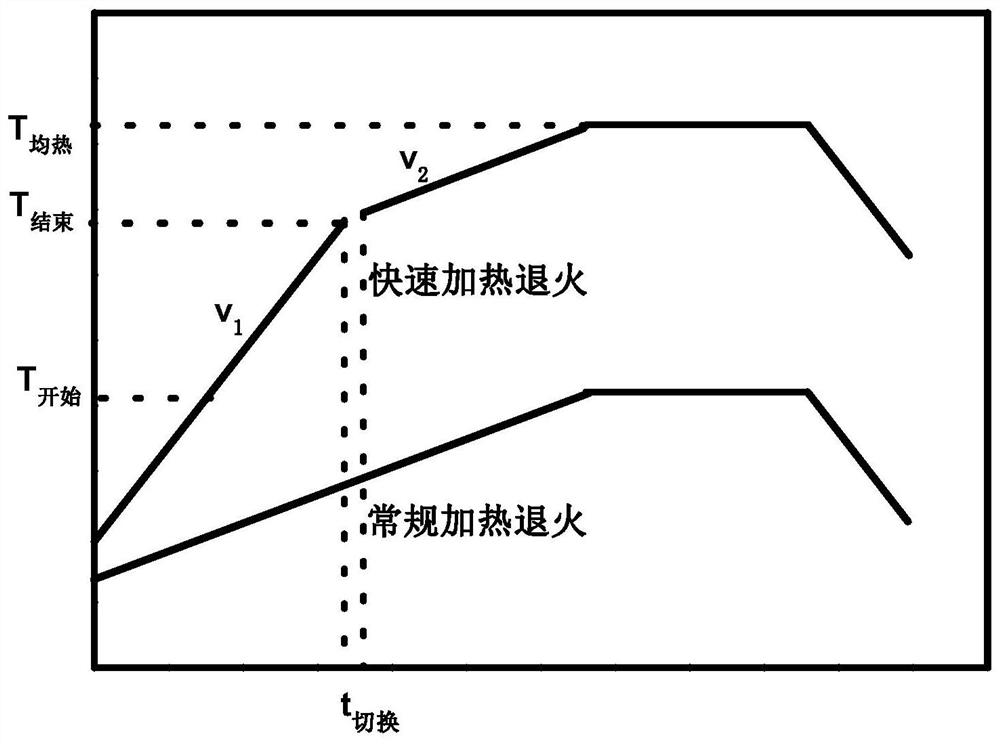

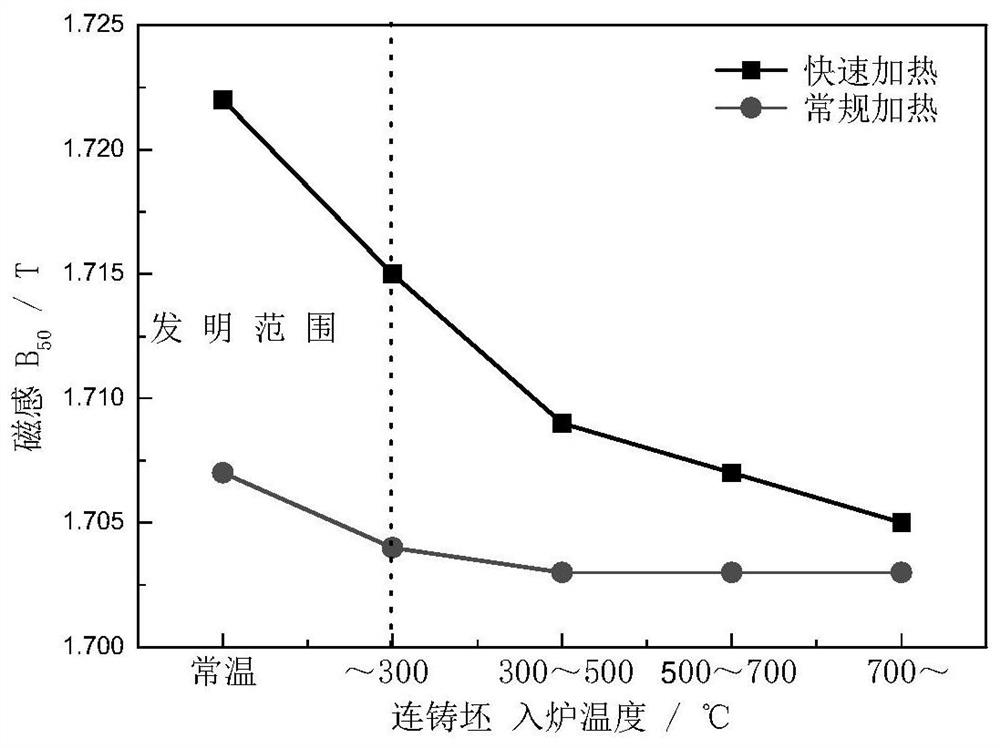

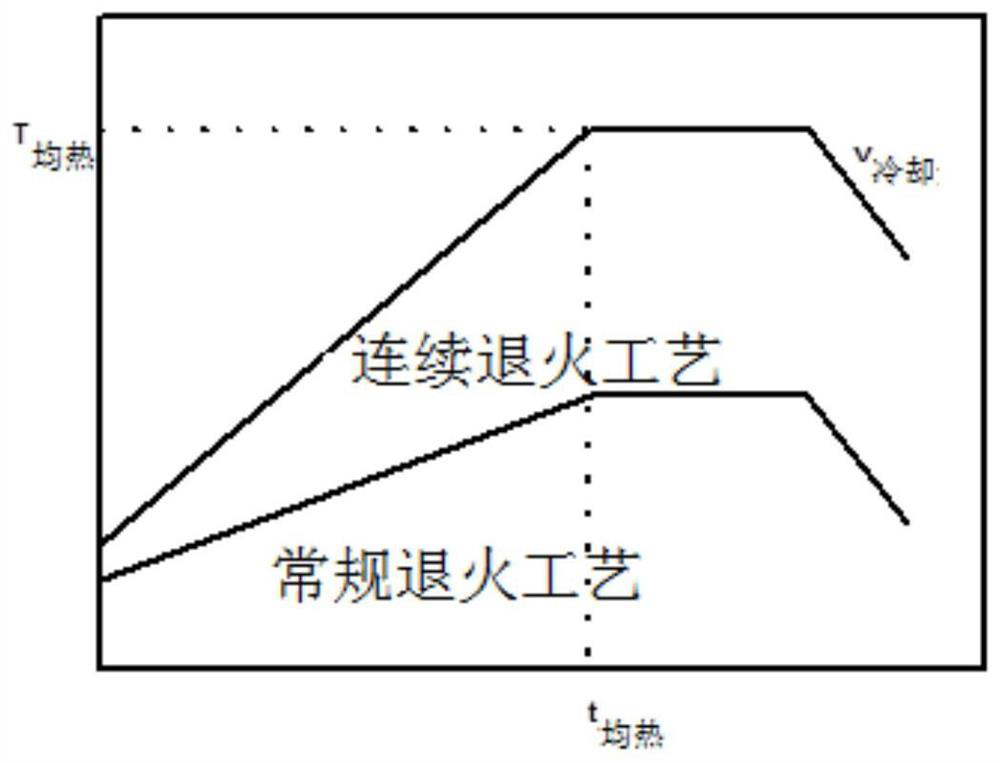

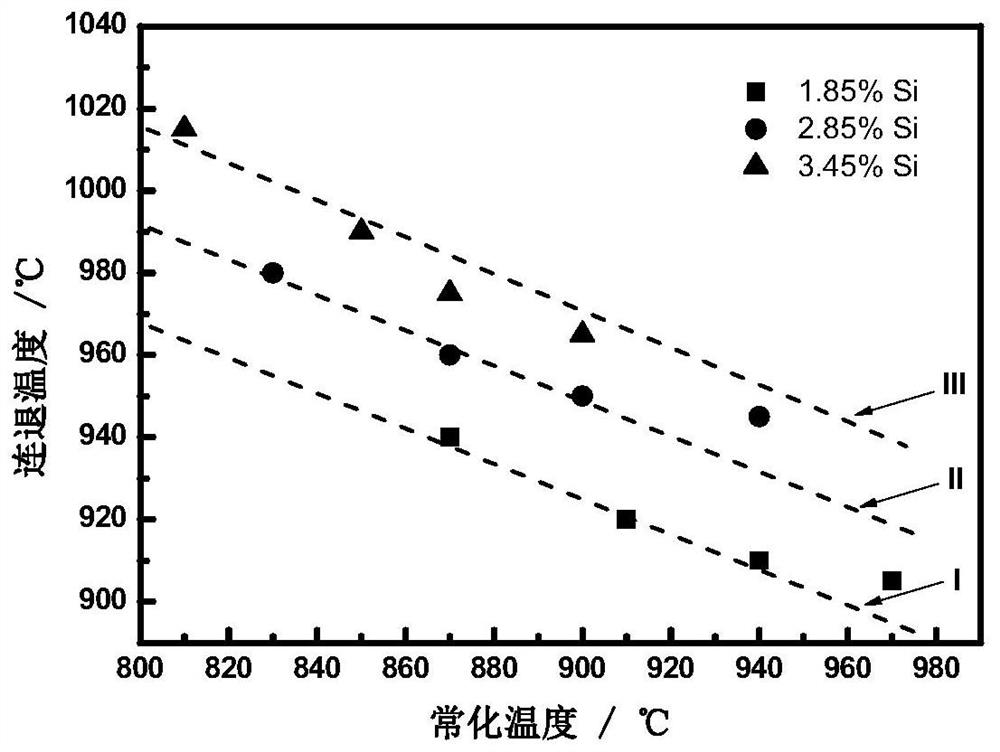

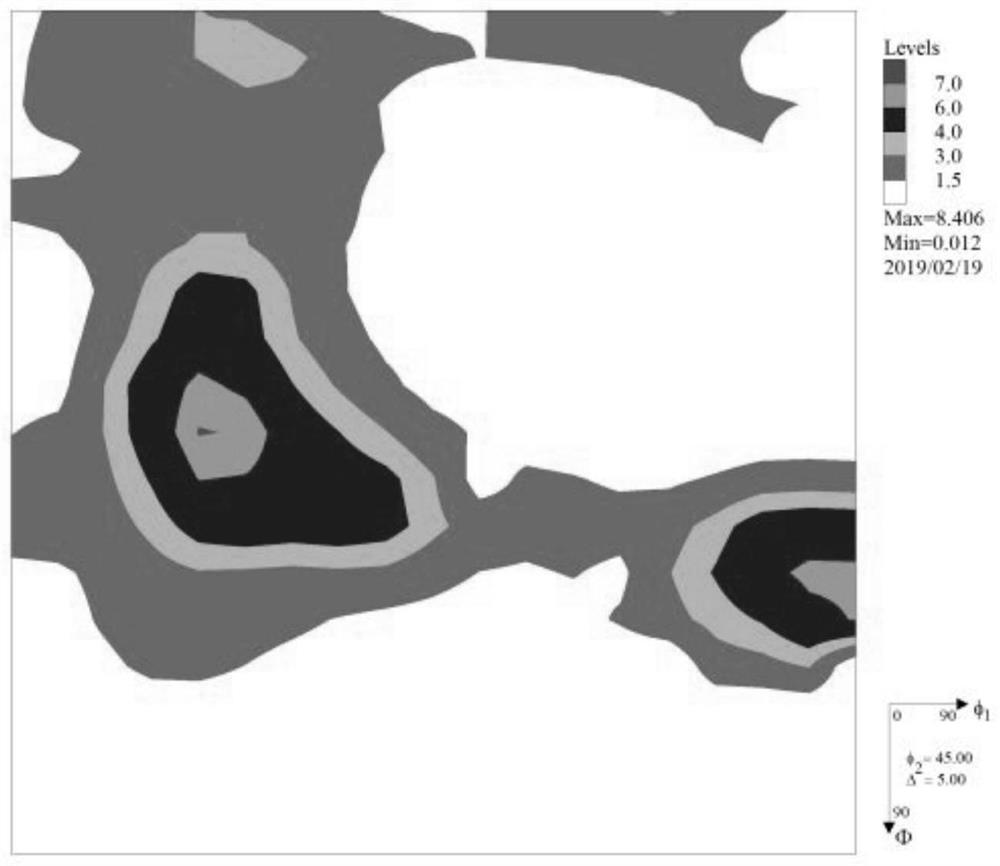

Non-oriented electrical steel plate with extremely-low iron loss and continuous annealing process of non-oriented electrical steel plate

The invention discloses a non-oriented electrical steel plate with the extremely-low iron loss. The non-oriented electrical steel plate is prepared from the chemical elements including, by mass, morethan 0 and less than or equal to 0.005% of C, 1.0%-3.45% of Si, 0.1%-1.2% of Mn, 0.001%-2.0% of Al, 0-0.2% of Cu, 0-0.0015% of Ti, one or both of Sb and Sn with the total content ranging from 0.005% to 0.2%, one or more of Ca, Mg and RE with the total content ranging from 0.0005% to 0.01% and the balance Fe and other inevitable impurities. Besides, the invention discloses a continuous annealing process of the non-oriented electrical steel plate with the extremely-low iron loss. In addition, the invention discloses a manufacturing method of the non-oriented electrical steel plate with the extremely-low iron loss. The method includes the following steps that smelting is performed; casting is performed; hot rolling is performed; normalizing is performed; cold rolling is performed; the continuous annealing process is carried out; and the plate is coated with an insulating coating, so that the non-oriented electrical steel plate with the extremely-low iron loss is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-oriented electrical steel plate with excellent magnetic performance and continuous annealing method thereof

The invention discloses a non-oriented electrical steel plate with excellent magnetic performance. The non-oriented electrical steel plate comprises, by mass, greater than 0 and smaller than or equalto 0.004% of C, 0.1-3.5% of Si, 0.15-2.0% of Mn, 0.1-3.5% of Al, 0.001-0.1% in total of one or both of Sb and Sn, 0.0005-0.01% in total of one or more of Ca, Mg and RE, and the balance Fe and other inevitable impurities. In addition, the invention discloses a continuous annealing process and manufacturing method of the non-oriented electrical steel plate with excellent magnetic performance. The manufacturing method comprises the following steps: smelting and casting, hot rolling, normalizing, cold rolling, implementation of the continuous annealing process, and covering with an insulating coating, thereby obtaining the non-oriented electrical steel plate with excellent magnetic performance.

Owner:BAOSHAN IRON & STEEL CO LTD

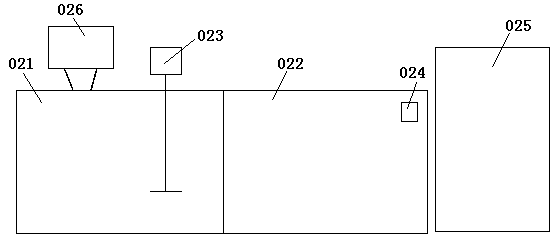

Coal preparation plant slime water intelligent dosing system and dosing method

PendingCN111470583AReduce lossDosage controlWater/sewage treatment by ion-exchangeProcess engineeringEnvironmental engineering

The invention relates to a coal preparation plant slime water intelligent dosing system and dosing method, and belongs to the technical field of coal washing. According to the system, one end of a No.1 slime water feeding pipeline is connected with a concentration tank, and the other end of the No.1 slime water feeding pipeline is connected with a protection box; one end of a first cation dosing pipeline is connected with cation dosing equipment, and the other end of the first cation dosing pipeline is connected with a protection box; one end of a first anion dosing pipeline is connected withanion dosing equipment, and the other end of the first anion dosing pipeline is connected with a first slime water feeding pipeline; one end of a second anion dosing pipeline is connected with the first anion dosing pipeline, and the other end of the second anion dosing pipeline is connected with the first slime water feeding pipeline; one end of a third anionic dosing pipeline is connected with the first anionic dosing pipeline, the other end of the third anionic dosing pipeline is connected with the concentration tank, one end of the second slime water feeding pipeline is connected with theanionic dosing equipment, and the other end of the second slime water feeding pipeline is connected with the cationic dosing equipment.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

High-pressure vacuum sandwich pipeline

InactiveCN109668007ALarge pre-cooling contact areaEnergy savingThermal insulationPipe protection by thermal insulationMolecular sieveHigh pressure

The invention relates to a high-pressure vacuum sandwich pipeline, and the problems of resource waste and safety risk caused by a vacuum interlayer pipeline are solved. The high-pressure vacuum sandwich pipeline comprises an inner-layer conveying pipe, intermediate pre-cooling pipes, external vacuum heat insulation pipes, first supporting frames, first flexible connecting assemblies and second flexible connecting assemblies, wherein pre-cooling medium is arranged in the intermediate pre-cooling pipes; the inner-layer conveying pipe, the intermediate pre-cooling pipes and the external vacuum heat insulation pipes are sequentially arranged from inside to outside and are coaxial, the plurality of external vacuum heat insulation pipes are connected through the first flexible connection assemblies, and the plurality of intermediate pre-cooling pipes are connected through second flexible connecting assemblies; the first supporting frames are multiple, a plurality of first supporting frames are arranged between the intermediate pre-cooling pipes and the inner-layer conveying pipe and are provided with overflowing holes; a heat bridge is arranged at the two ends of the external vacuum heatinsulation pipes, and the heat bridge is of a multi-layer snake-shaped pipe structure; and a vacuumizing connector is arranged on the external vacuum heat insulation pipes, and molecular sieve filling cavities are formed in an inner cavity and are used for filling molecular sieves.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

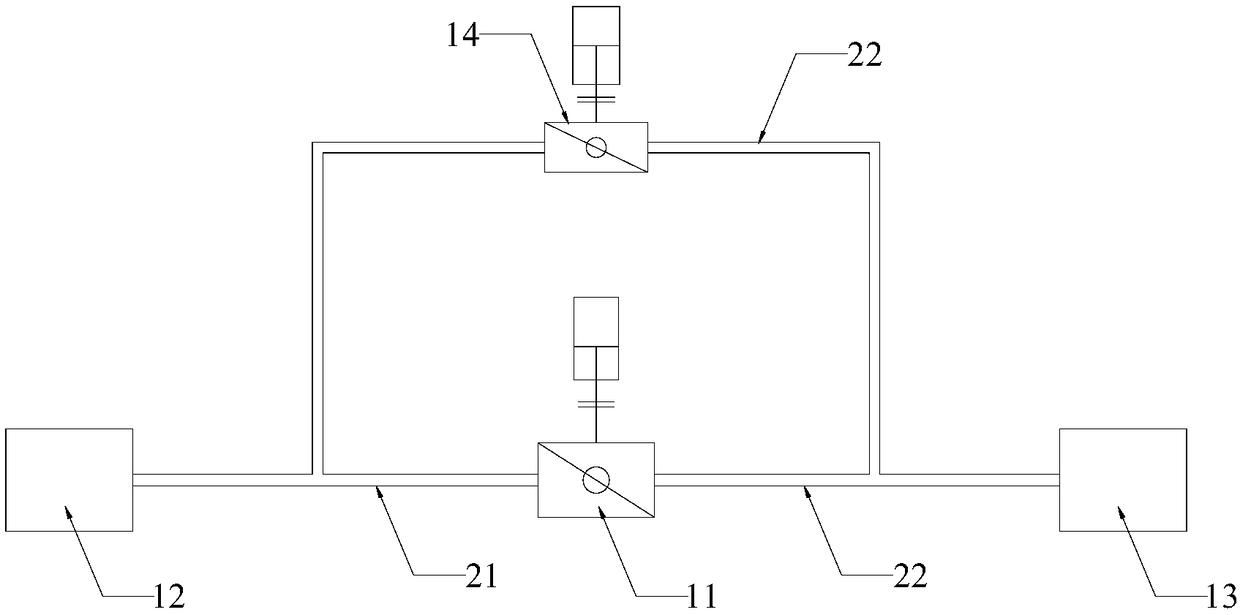

RH vacuum system regulating vacuum device and application

The invention provides an RH vacuum system regulating vacuum device and application. The device includes a vacuum main valve (11), a first pipeline (21), a second pipeline (22), a bypass pipeline (23)and a bypass valve (14), wherein one end of the vacuum main valve (11) is provided with the first pipeline (21) for connection with an RH vacuum refining device, the other end is provided with the second pipeline (22) for connection with a vacuum pump; the first pipeline (21) and the second pipeline (22) are connected through the bypass pipeline (23), and the bypass valve (14) is disposed on thebypass pipeline (23) and forms a parallel connection relationship with the vacuum main valve (11). By vacuuming a vacuum pump side system after RH vacuum treatment, the bypass valve is adopted to balance the vacuum pressure on both sides of the vacuum main valve, the vacuum pump system can be quickly started, the vacuum system emptying time can be shortened, and the consumption of a medium like steam can be saved, and the effect of the RH processing cycle is shortened.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Non-oriented electrical steel plate with excellent magnetic performance and continuous annealing method thereof

The invention discloses a non-oriented electrical steel plate with excellent magnetic performance. The non-oriented electrical steel plate comprises, by mass, greater than 0 and smaller than or equalto 0.004% of C, 0.1-3.5% of Si, 0.1-2.5% of Mn, 0.001-3.5% of Al, 0.001-0.1% in total of one or both of Sb and Sn, 0.0005-0.01% in total of one or more of Ca, Mg and RE, and the balance Fe and other inevitable impurities. In addition, the invention discloses a continuous annealing process and manufacturing method of the non-oriented electrical steel plate with excellent magnetic performance. The manufacturing method comprises the following steps: smelting and casting, hot rolling, normalizing, cold rolling, implementation of the continuous annealing process, and covering with an insulating coating, thereby obtaining the non-oriented electrical steel plate with excellent magnetic performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Coal dressing magnetite powder magnetism strengthening method

The invention relates to a coal dressing magnetite powder magnetism strengthening method, and solves the economic waste problem caused by technical loss in the prior art for the reason that fine-grained magnetite powder is poor in magnetism. The coal dressing magnetite powder magnetism strengthening method comprises the following steps: A. putting magnetite powder in a corundum crucible, then putting in a heating furnace, reducing the pressure until the air pressure in the heating furnace is 0.01-0.1MPa; B. heating the heating furnace to 300-700 DEG C, after 30-60min of heat preservation, stopping heating; C. naturally cooling the heating furnace in air, at the same time, applying a pulsed magnetic field with a frequency of 30-500Hz and a magnetic field strength of 5000-15000oe to the side face of the heating furnace until the heating furnace is cooled to room temperature; and D. taking the magnetite powder for packaging storage. By synergistic effect of heating and the pulsed magnetic field on processing of the coal dressing magnetite powder, the coal dressing magnetite powder material magnetism is strengthened, medium consumption in the coal dressing process can be reduced, and the coal dressing magnetite powder has the advantages of simple process, low strength and low cost.

Owner:HUOZHOU COAL ELECTRICITY GROUP

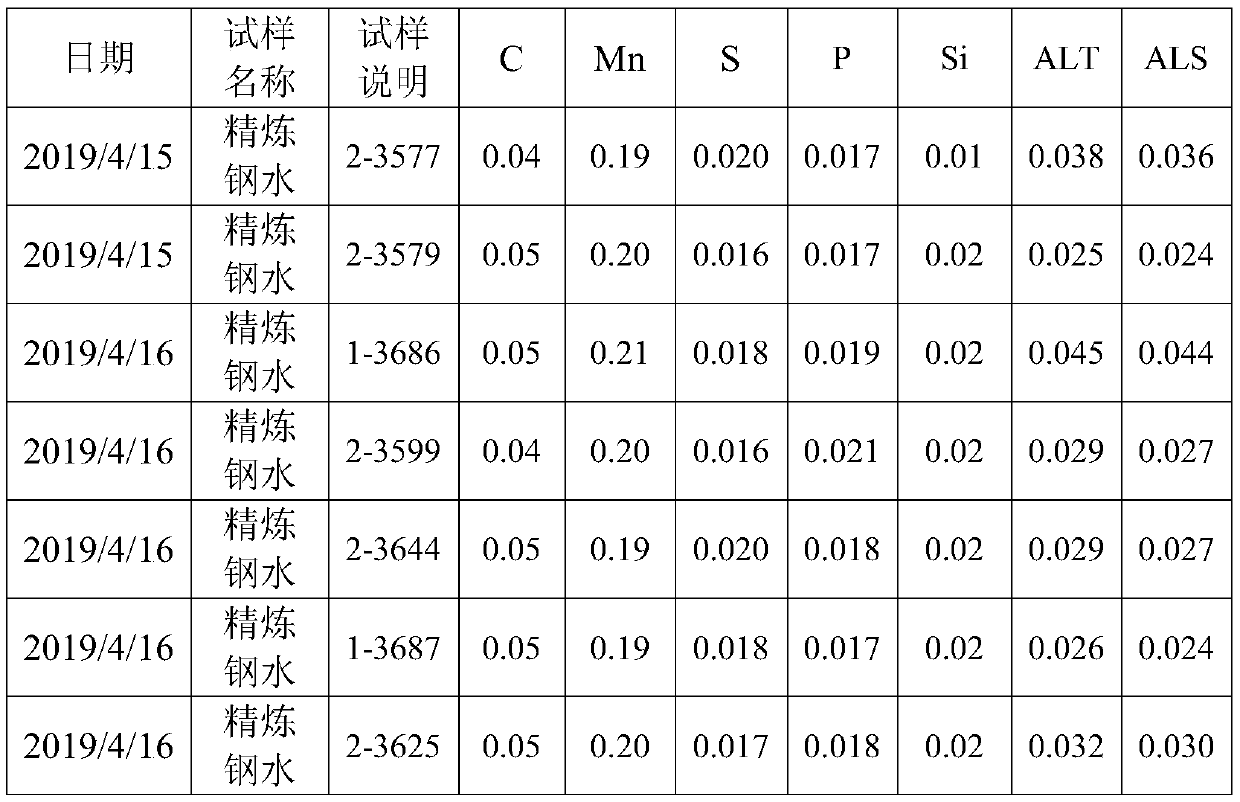

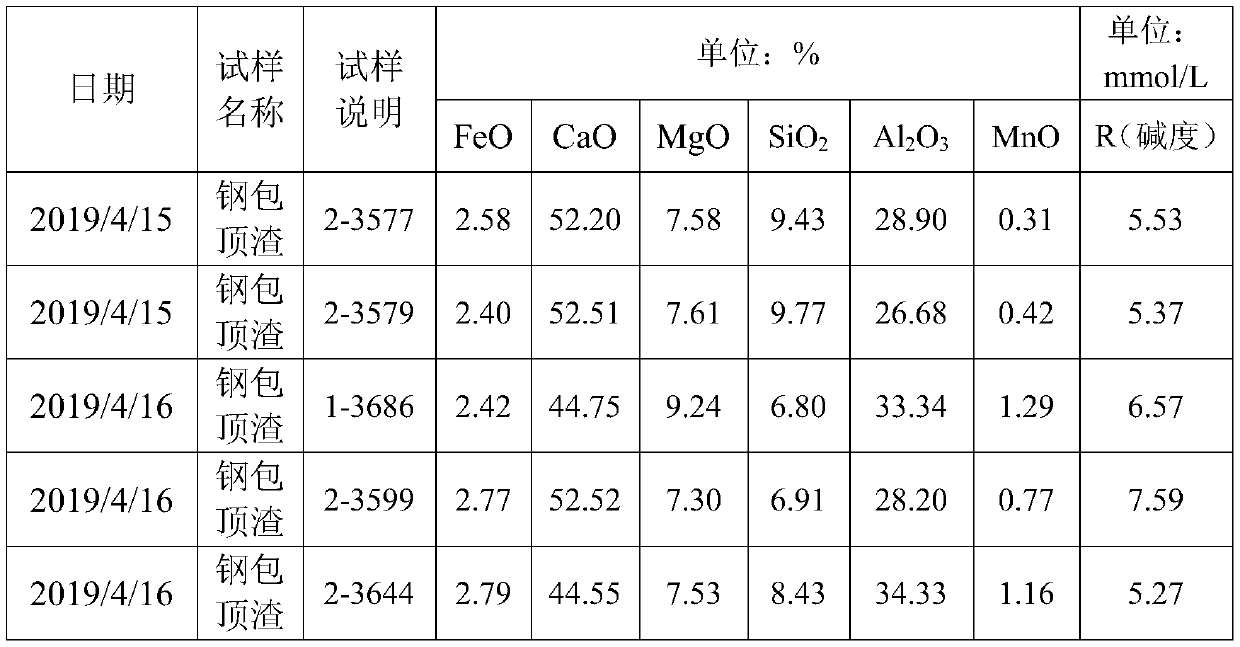

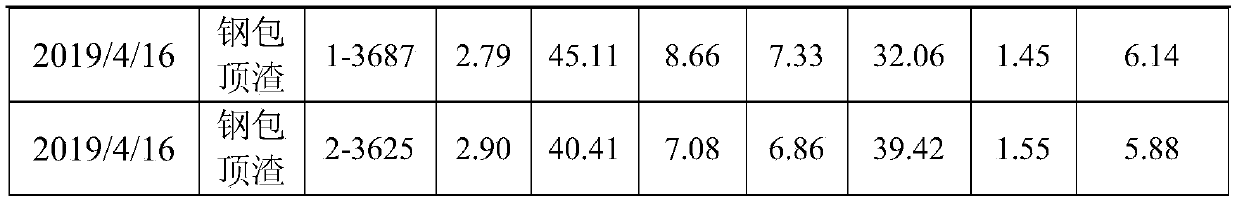

Process of producing SPHC with low cost, short flow and high efficiency

ActiveCN110396637AGuaranteed ingredientsGuaranteed temperatureManufacturing convertersProcess efficiency improvementSlagMolten steel

The invention discloses a process of producing SPHC with low cost, short flow and high efficiency and belongs to the technical field of ferrous metallurgy processes. The process comprises the following steps of a, preparation of molten iron and waste steel; b, converter blowing: feeding the molten iron prepared in the step a into a converter by adopting a "one-ladle through" manner, and adding theprepared waste steel into the converter for blowing; c, refining outside furnace: feeding the molten steel in the converter into a steel ladle to complete the steel tapping process after smelting, rising a temperature by 8-15 DEG C on the basis of the step b while performing deoxidation treatment during steel tapping, adding a carburant, a metal deoxidizing agent, white lime and refining slag along with a steel flow, and then performing top slag recycling treatment, calcium treatment, argon blowing, ladle killing and deslagging to finally obtain refined molten steel; and d, continuous casting. For the process provided by the invention, the treatment process is shortened, consumption of an energy medium can be reduced, the cost is lowered, and indexes of a finally obtained product are easily controlled.

Owner:武安市裕华钢铁有限公司

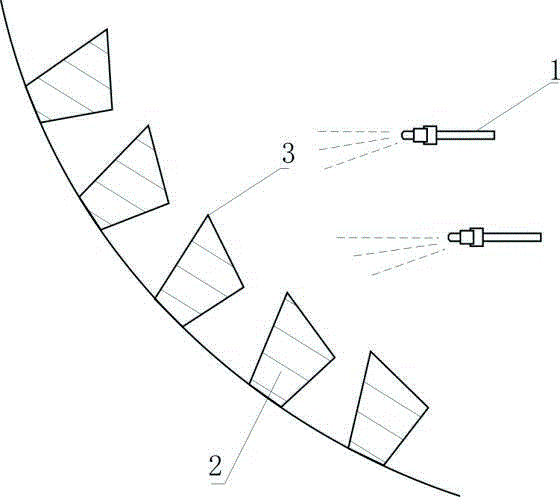

Self-cleaning spraying device with turbine structure

InactiveCN107971277AGuaranteed automatic recyclingRealize fully automatic high-efficiency energy-saving cleaningHollow article cleaningCleaning using liquidsSurface cleaningEngineering

The invention discloses a self-cleaning spraying device with a turbine structure. The self-cleaning spraying device comprises a liquid collecting header pipe, a pump, a spray pipe, a groove body, anda switching valve; the liquid collecting header pipe is connected with the groove body through the pump; one end of the spray pipe is connected with the liquid collecting header pipe through a pipe, and the other end of the spray pipe laterally crosses the groove body and passes through the switching valve and is connected with the groove body through the pipe; nozzles are arranged on the spray pipe; the groove body is internally provided with cleaning liquid; the groove body is used for placing objects to be cleaned, the objects to be cleaned is placed under the nozzles; a brush rod is arranged in the spray pipe in the length direction; the brush rod is provided with a hair brush; one end of the hair brush is connected with a turbine assembly; and the turbine assembly is arranged in the spray pipe. Automatic recycling use of cleaning liquid is ensured, in the self-cleaning process of the spray pipe, the nozzles remain a clean function for the objects to be cleaned, full-automatic high-efficiency and energy-saving cleaning of the nozzles is realized; and the self-cleaning spraying device with the turbine structure can effectively prevent the nozzles from blocking, thereby improvingthe surface cleaning quality, and can be widely used in the field of the surface treatment.

Owner:WISDRI ENG & RES INC LTD

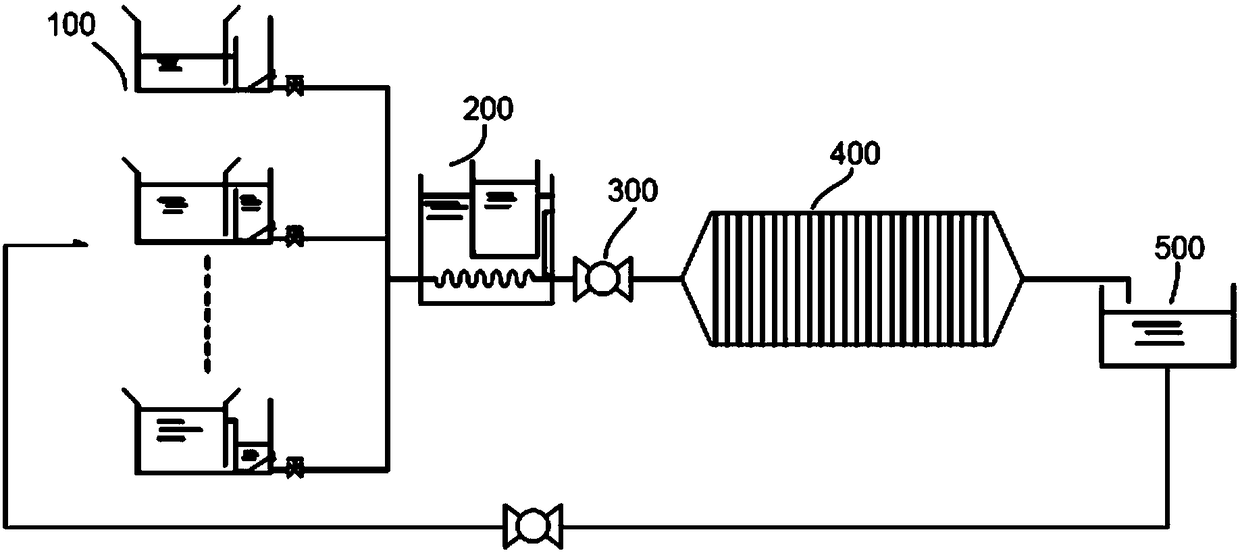

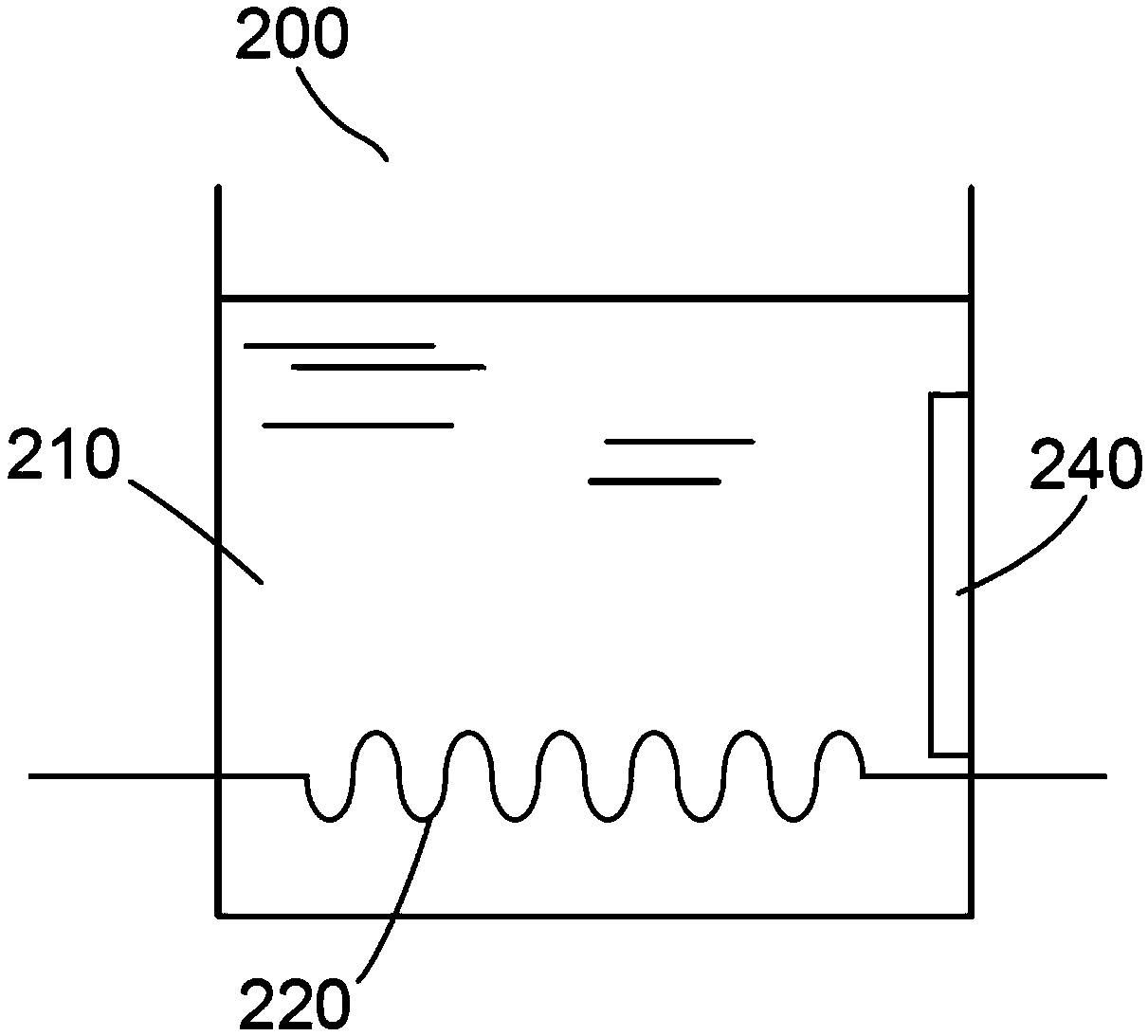

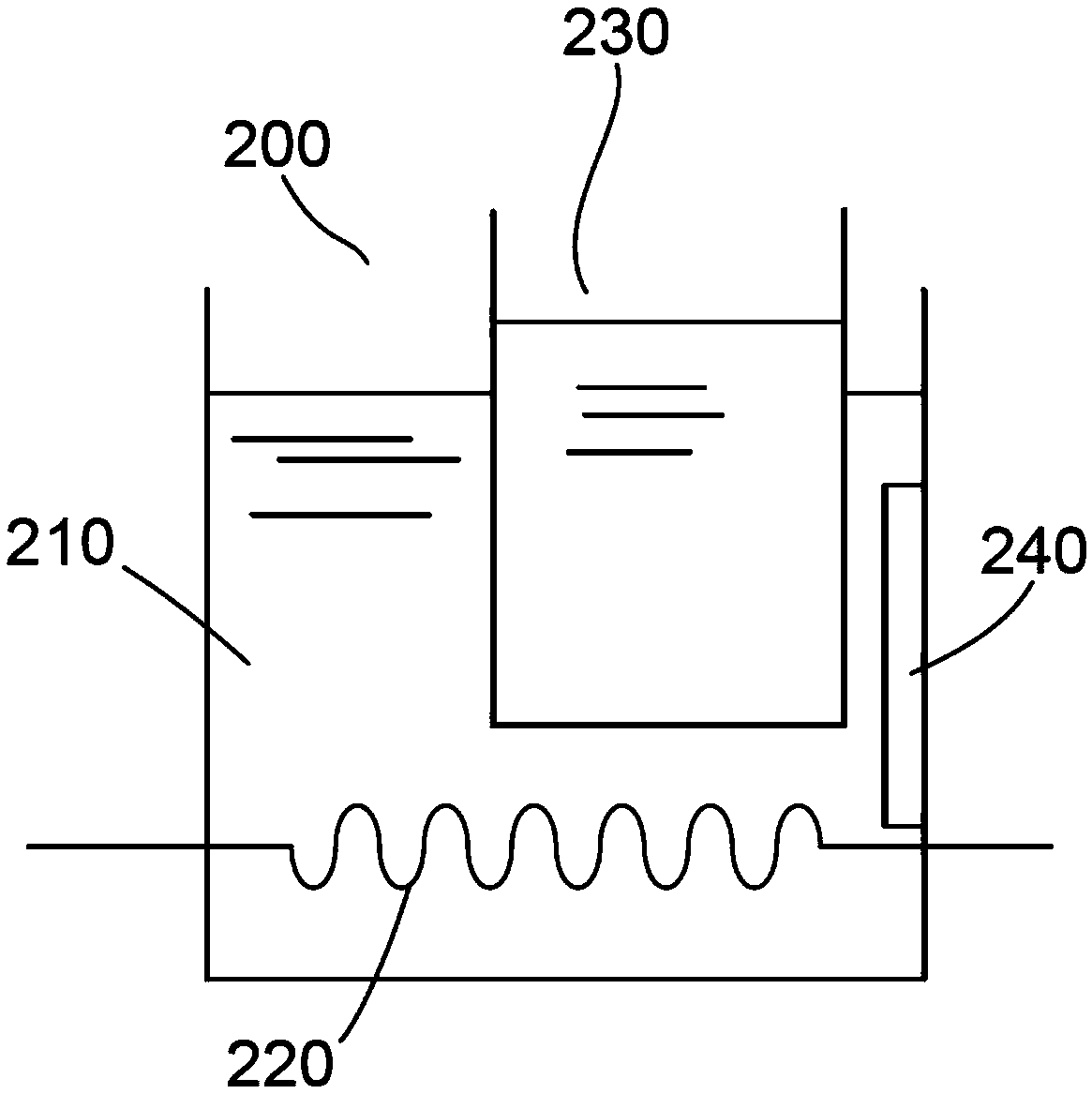

Silicon wafer cutting liquid circulation system and method adopting diamond wire

InactiveCN108793554ARealize recyclingReduce consumption costSpecific water treatment objectivesTreatment involving filtrationWastewaterEngineering

The invention provides a silicon wafer cutting liquid circulation system adopting a diamond wire. The silicon wafer cutting liquid circulation system comprises a collection unit, a heat exchange unit,a filter-press separation unit and a clean liquid recycling unit. By adopting the silicon wafer cutting liquid circulation system, used cutting liquid from which silicon powder particles are separated can be recycled and used as cutting liquid again, and the cutting liquid carrying organic matters is prevented from entering wastewater for treatment, so that the treatment cost of wastewater is lowered, and the environment protection pressure is lowered. Meanwhile, the invention provides a silicon wafer cutting liquid circulation method adopting a diamond wire corresponding to the system.

Owner:SHANDONG DAHAI NEW ENERGY DEV

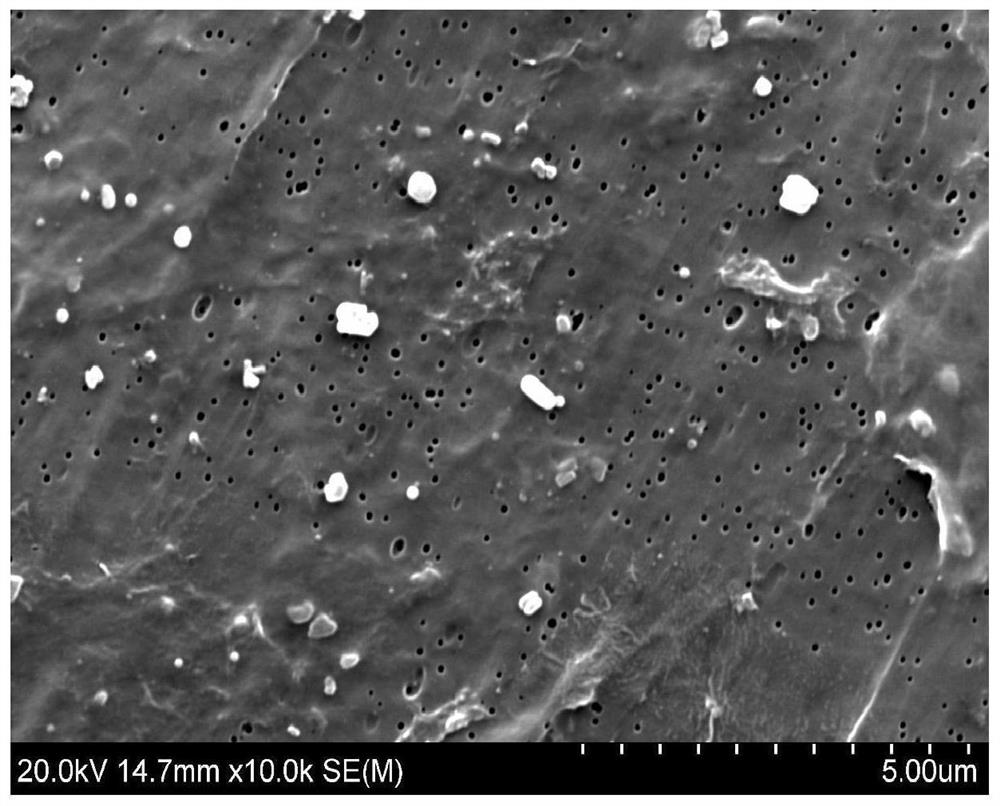

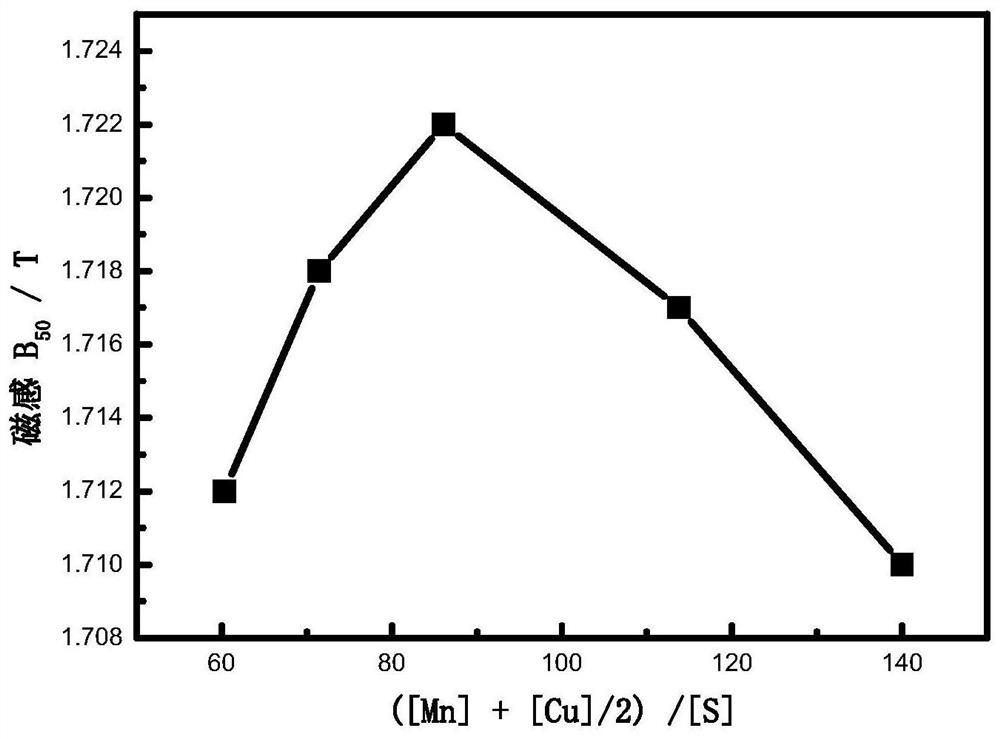

Cu-containing high-cleanliness non-oriented electrical steel plate and manufacturing method thereof

ActiveCN112430780AImprove cleanlinessStrong magnetismInorganic material magnetismFurnace typesElectrical steelContinuous annealing

The invention discloses a Cu-containing high-cleanliness non-oriented electrical steel plate. The Cu-containing high-cleanliness non-oriented electrical steel plate comprises the chemical elements of,by mass, larger than 0 and less than or equal to 0.003% of C, 0.1% to 2.0% of Si, 0.1% to 0.6% of Mn, 0 to 0.004% of S, 0.003% to 0.2% of Cu, 0.1% to 1.0% of Al, and the balance Fe and other inevitable impurities. In addition, the invention further discloses a continuous annealing process of the Cu-containing high-cleanliness non-oriented electrical steel plate. Besides, the invention further discloses a manufacturing method of the Cu-containing high-cleanliness non-oriented electrical steel plate. The manufacturing method comprises the steps of carrying out smelting and casting; carrying outhot rolling; carrying out normalizing; carrying out cold rolling; carrying out the continuous annealing process; and carrying out insulating and coating to obtain the finished non-oriented electricalsteel plate. The Cu-containing high-cleanliness non-oriented electrical steel plate is high in cleanliness and excellent in magnetic performance.

Owner:BAOSHAN IRON & STEEL CO LTD

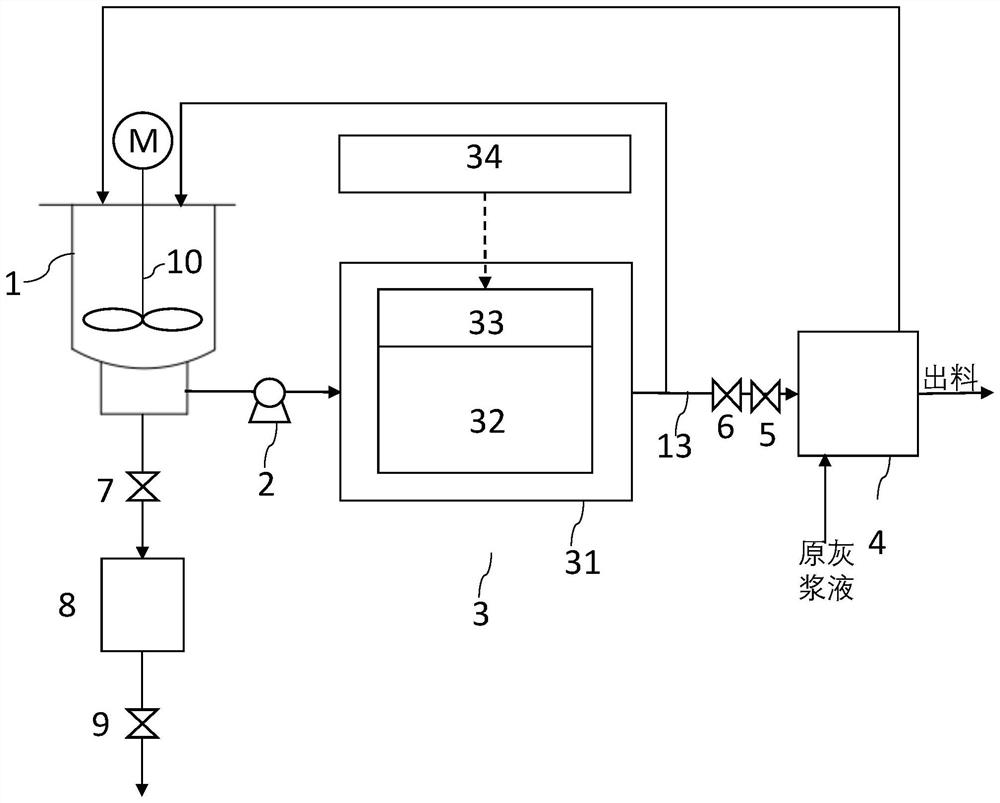

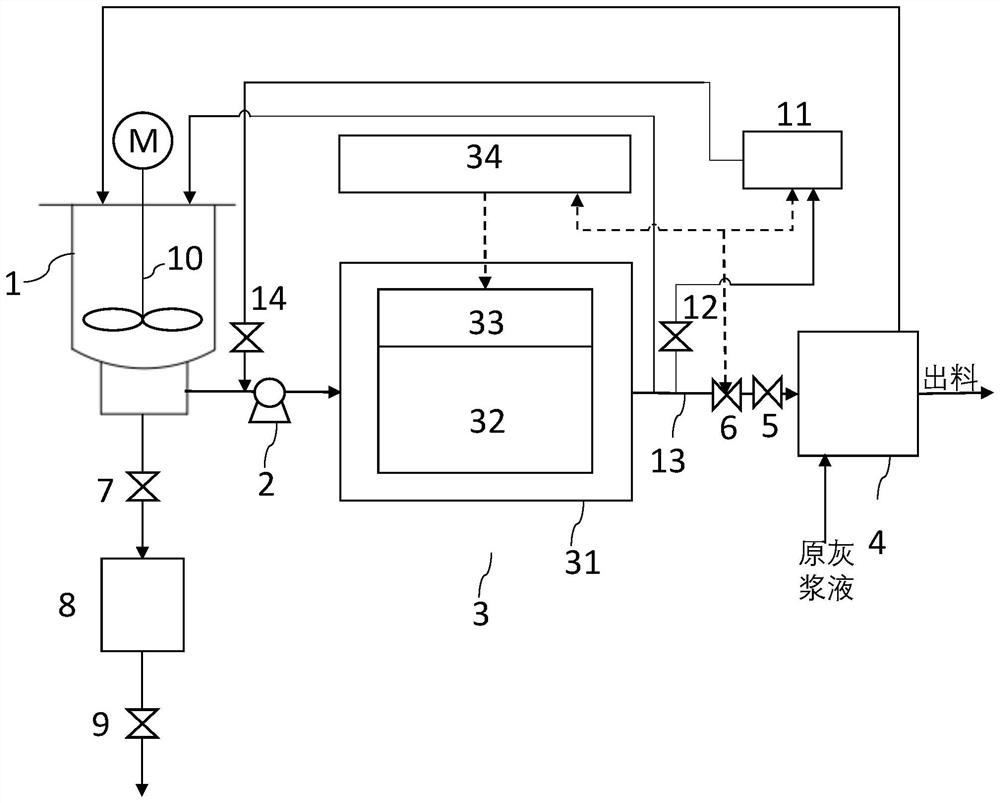

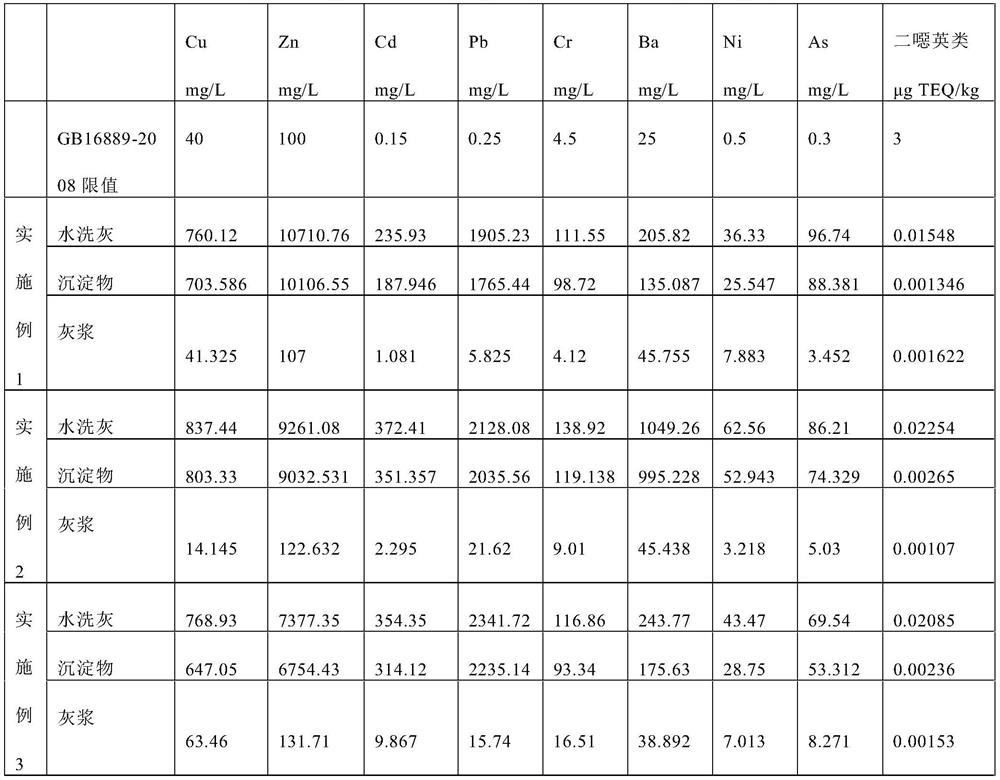

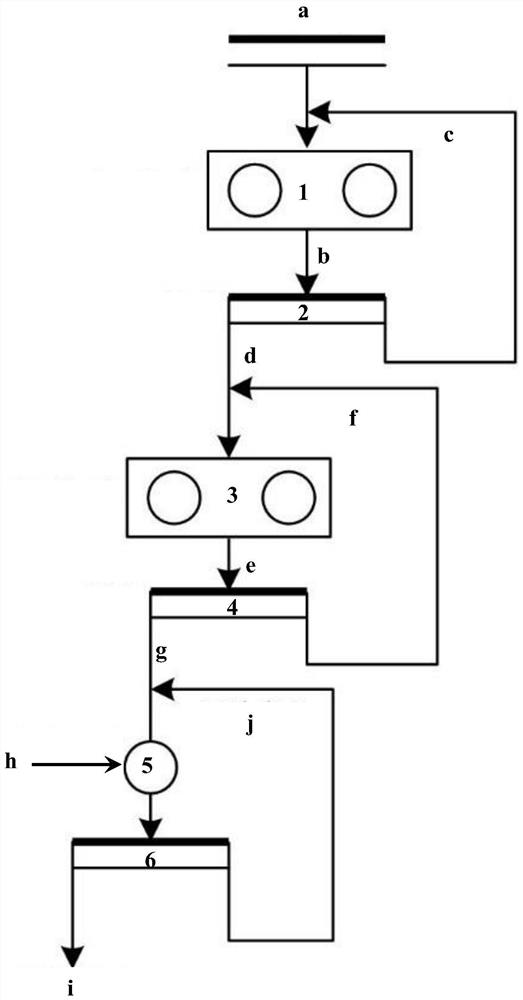

System and method for treating dioxin in incineration fly ash through continuous microwave hydrothermal method

ActiveCN113521637ARealize large batch continuous processingContinuous processingChemical protectionProcess engineeringSlurry

The invention discloses a system and a method for treating dioxin in incineration fly ash through a continuous microwave hydrothermal method. The system for treating dioxin in incineration fly ash through the continuous microwave hydrothermal method comprises a heat exchange device, a buffer stirring tank, a circulating pump and a microwave reaction device. The microwave reaction device comprises a microwave safety shielding unit, a slurry circulating unit, a microwave irradiation unit and a control unit; a feed port of the slurry circulating unit is connected with the buffer stirring tank, and a discharge port of the slurry circulating unit is connected with a heat exchange device; and a circulation loop communicated with the buffer stirring tank is arranged on the pipeline between the microwave reaction device and the heat exchange device. A high-parameter microwave treatment technology is implanted on the basis of traditional hydrothermal method treatment, organic pollutants such as dioxin in the incineration fly ash can be removed, meanwhile, large-scale continuous treatment is achieved, and the incineration fly ash dioxin treatment process is continuous, safe, convenient, reliable in effect, small in occupied area, economical and efficient.

Owner:宝武集团环境资源科技有限公司 +1

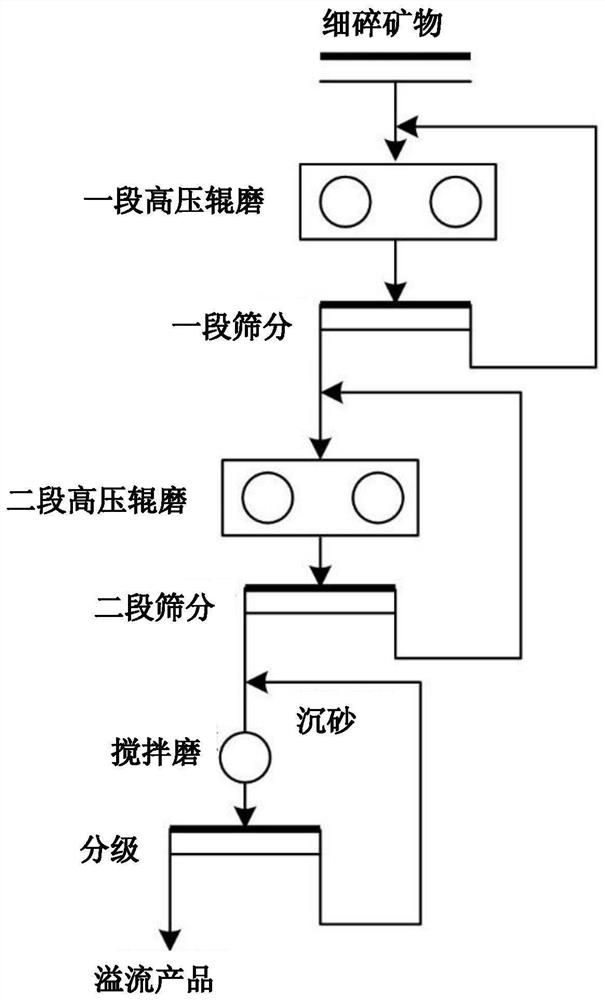

Two-section series high-pressure roller milling-stirring milling short-process grinding system and method

PendingCN113102080AHigh energy consumptionIncrease production costGrain treatmentsProcess engineeringBall mill

The invention discloses a two-section series high-pressure roller milling-stirring milling short-process grinding system and method, and belongs to the field of mineral processing. According to the two-section series high-pressure roller milling-stirring milling short-process grinding system, a first-section high-pressure roller mill is communicated with a first-section vibrating screen, an undersize material outlet of the first-section vibrating screen is communicated with a second-section high-pressure roller mill, the second-section high-pressure roller mill is communicated with a second-section vibrating screen, and an undersize material outlet of the second-section vibrating screen is communicated with a stirring mill; and the stirring mill is connected with a grading device. According to the method, materials crushed and screened by the first-section high-pressure roller mill are crushed by the second-section high-pressure roller mill, and then ore grinding operation is conducted through the stirring mill, so that ball milling operation with high energy consumption and low ore grinding efficiency in a traditional process is omitted, and the energy-saving advantages of the high-pressure roller mill and the stirring mill are fully exerted. The grinding process can be simplified, and meanwhile the grinding efficiency and the treatment capacity can be greatly improved, the ore grinding dissociation effect of the stirring mill is enhanced, the economic benefits of enterprises can be improved, and large-scale industrial operation of the high-pressure roller mill is facilitated.

Owner:NORTHEASTERN UNIV

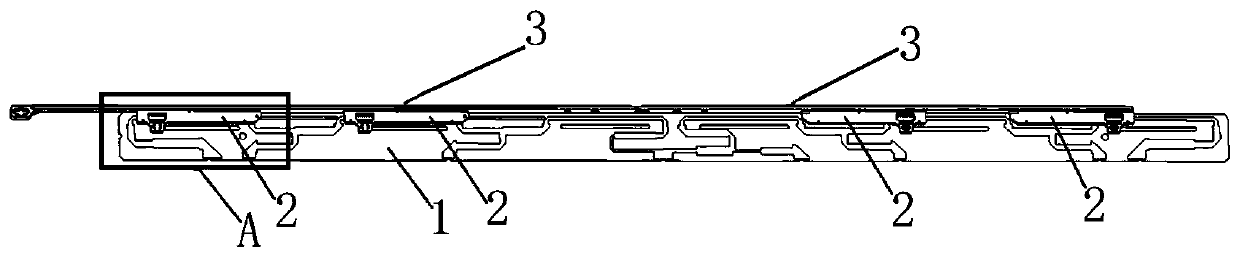

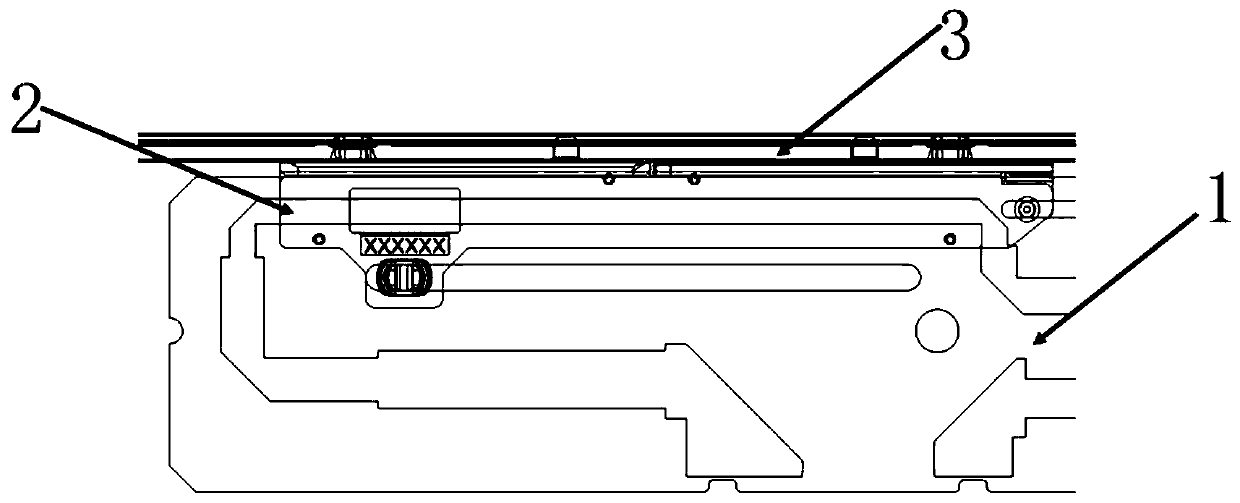

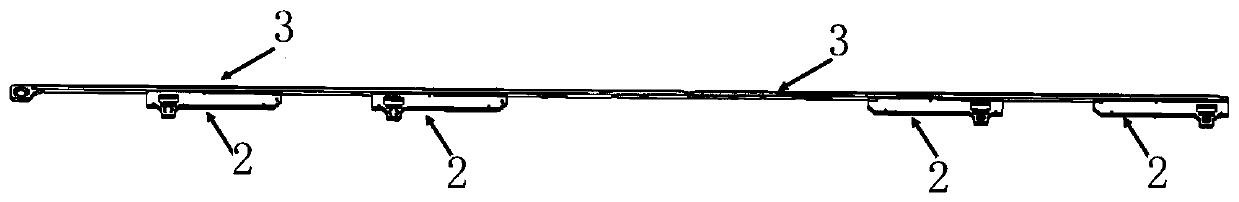

Phase shifter medium structure, phase shifter and base station antenna

The invention relates to the technical field of base station antennas, and discloses a phase shifter medium structure, a phase shifter and a base station antenna. The medium structure is arranged on the carrier plate inside the cavity of the phase shifter and comprises multiple groups of medium components which are arranged at intervals along the length direction of the carrier plate. Each group of medium components are fixedly connected with an inner pull rod. One end of the inner pull rod extends out of the cavity of the phase shifter to be fixedly connected with an outer pull rod. Accordingto the phase shifter medium structure, the phase shifter and the base station antenna, multiple groups of medium components are arranged at intervals so that the medium consumption covering the carrier plate can be reduced and the cost of the phase shifter can be reduced in comparison with a large mass of medium structure at present; besides, the loss of microwave passage can be reduced, the lossof the phase shifter can be reduced and the antenna gain can be improved because of reduction of the medium area; in addition, each group of medium components do not need to be customized for the specific phase shifter, and the medium structure can be applied to other phase shifters so as to improve the applicability of the medium structure.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Copper-sulfur bulk concentrate ore grinding process combining small steel forging ratio with long conical cyclone

InactiveCN105327764AStrong grinding abilityImprove classification efficiencyVortex flow apparatusGrain treatmentsOre concentrateFineness

The invention discloses a copper-sulfur bulk concentrate ore grinding process combining the small steel forging ratio and a long conical cyclone. According to the process, copper-sulfur bulk concentrate is conveyed to grading equipment to be graded through a sand pump, the grading particle size is 0.074 mm, products of -0.074 mm particle size enter a later sorting procedure directly, and sand setting products of +0.074 mm particle size enter a copper-sulfur separating ore grinding machine to be subjected to ore grinding; ore grinding products obtained by conducting ore grinding on the sand setting products enter a pump pool of the copper-sulfur bulk concentrate and then are transferred to the grading equipment to be graded through the sand pump. The products of -0.074 mm particle size enters the later sorting procedure directly, and the sand setting products of +0.074 mm particle size enter the copper-sulfur separating ore grinding machine again to be subjected to ore grinding, and in this way, closed circuit ore grinding is completed by conducting the procedures circularly till ore pulp of required fineness is obtained. Small steel forgings serve as an ore grinding medium of the ore grinding machine. According to the copper-sulfur bulk concentrate ore grinding process combining the small steel forging ratio with the long conical cyclone, the ore grinding efficiency and the grading efficiency can be substantially improved, the investment is low, and the energy consumption is low.

Owner:YUNNAN TIN

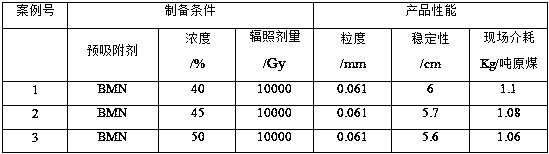

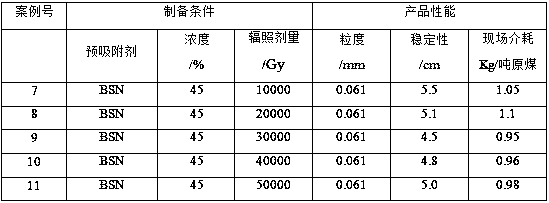

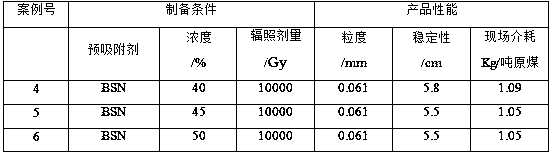

Radiation-grafting-based preparation method for dense medium used for coal preparation

ActiveCN109261342ASolve the problem of large loss and difficult recyclingLarge granularityWet separationHigh concentrationSocial benefits

The invention provides a radiation-grafting-based preparation method for a dense medium used for coal preparation. The dense medium powder uses coarse magnetite powder as a raw material, wet grindingis conducted after the coarse magnetite powder is mixed with a high concentration aqueous solution of sulfonated castor oil (BSN) or castor oil sodium aliphatate (BMN), an acrylic acid aqueous solution is then sprayed for wet grinding to the required particle size, and finally acrylic acid is grafted to magnetite powder through gama ray irradiation to obtain a final product. The increase of the particle size of the magnetite powder has two advantages that 1, the grinding time is reduced in a fine grinding stage, energy is saved, the production cost is reduced, and the method has good social benefits; 2, the magnetite powder relatively large in particle size is easy to recycle, medium consumption is reduced, compared with traditional magnetite powder, the medium consumption can be reduced by 10-20%, and economic benefits are increased for coal preparation plants.

Owner:河南省核力科技发展有限公司 +1

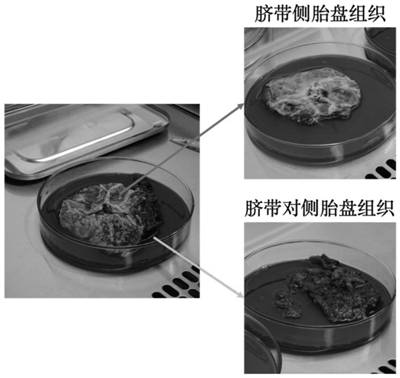

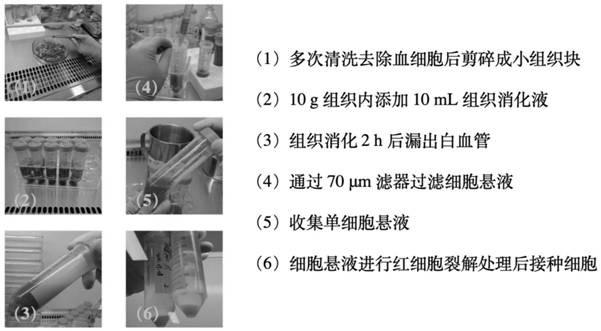

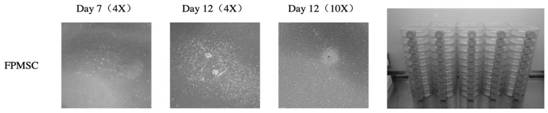

Optimized culture medium, kit and culture method for human placenta-derived mesenchymal stem cells

PendingCN113913375AReduce media consumptionReduce the cost of large-scale cell preparation and productionCell dissociation methodsCulture processLow glucoseMolecular biology

The invention relates to an optimized culture medium, a kit and a culture method for human placenta-derived mesenchymal stem cells, and belongs to the technical field of cell culture. The culture medium comprises DMEM-low glucose, L-glutamine, beta-mercaptoethanol, a KnockoutTM serum substitute, a recombinant human FGF2 protein, a recombinant human FGF4 protein, a recombinant human PDGFAB protein, a recombinant human EGF protein, a recombinant human VEGF165A protein, a recombinant human HGF protein, a recombinant human TGF-beta 1 protein, nicotinamide mononucleotide and non-essential amino acids. By the optimized culture medium, the in vitro amplification efficiency of the placenta-derived MSC can be maximally improved, the difference between batches of cells is reduced, the clinically relevant cell quantity in a shorter time range is reached, and good phenotype consistency and three-line differentiation potential in multiple generations can be maintained.

Owner:北京吉中科生物技术有限公司

Non-oriented electrical steel plate with high magnetic induction and low iron loss and manufacturing method thereof

InactiveCN112143962AImprove electromagnetic performanceImprove applicabilitySteel platesElectrical steel

The invention discloses a non-oriented electrical steel plate with high magnetic induction and low iron loss. The non-oriented electrical steel plate comprises, by mass, 0.001-0.004% of C, 1.6-3.5% ofSi, 0.1-1.0% of Mn, 0.15-2.0% of Al, 0-0.002% of Ti, 0.003-0.2% in total of one or both of Sb and Sn, and the balance Fe and other inevitable impurities. In addition, the invention discloses a continuous annealing process and manufacturing method of the non-oriented electrical steel plate with high magnetic induction and low iron loss. The manufacturing method comprises the following steps: smelting and casting, hot rolling, normalizing, cold rolling, implementation of the continuous annealing process, and covering with an insulating coating, thereby obtaining the non-oriented electrical steel plate with excellent magnetic performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Dense-medium and low-density separation process

The invention discloses a dense-medium and low-density separation process applicable to dense-medium and low-density separation which facilitates coal separation, and relates to the technical field of mineral separation (dense-medium coal separation). The dense-medium and low-density separation process comprises the steps that an oversize product obtained by a raw coal classifying screen and screen underflow which does not pass a hydraulic turnover plate enter a desliming screen; an oversize product obtained by the desliming screen and suspension liquid with the density being 1.35g / cm<3>-1.55g / cm<3> are intensively mixed and then enter a two-product dense-medium cyclone to conduct low-density separation; clean coal obtained by the low-intensity separation becomes a clean coal product after passing through a clean coal de-medium and dewatering device; gangue obtained by the low-intensity separation enters the classifying screen after passing through the de-medium and dewatering device, an oversize product becomes a gangue product, and screen underflow is mixed into pulverized raw coal. The dense-medium and low-density separation process has the advantages of reducing the density of the suspension liquid according to the actual production situation, carrying out dense-medium cyclone low-density separation, being beneficial to efficient recycling of media, reducing the consumption of the media, meanwhile, due to the fact that the separated pulverized gangue is mixed into the pulverized raw coal according to the actual situation, stabilizing the homogenization production of the pulverized raw coal, optimizing the control over the calorific value of the pulverized raw coal, and achieving the maximization of production and economic benefits of the pulverized raw coal.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com