Qualified medium barrel dilute medium water complementing system and method used for dense-medium coal preparation

A technology of heavy medium coal preparation and water replenishment system, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of increasing coal ash content in products, adverse effects on production and product quality control, and difficulty in ensuring recovery rate, etc. Achieve the effect of reducing magnetic separation loss, ensuring liquid level and density, and reducing dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

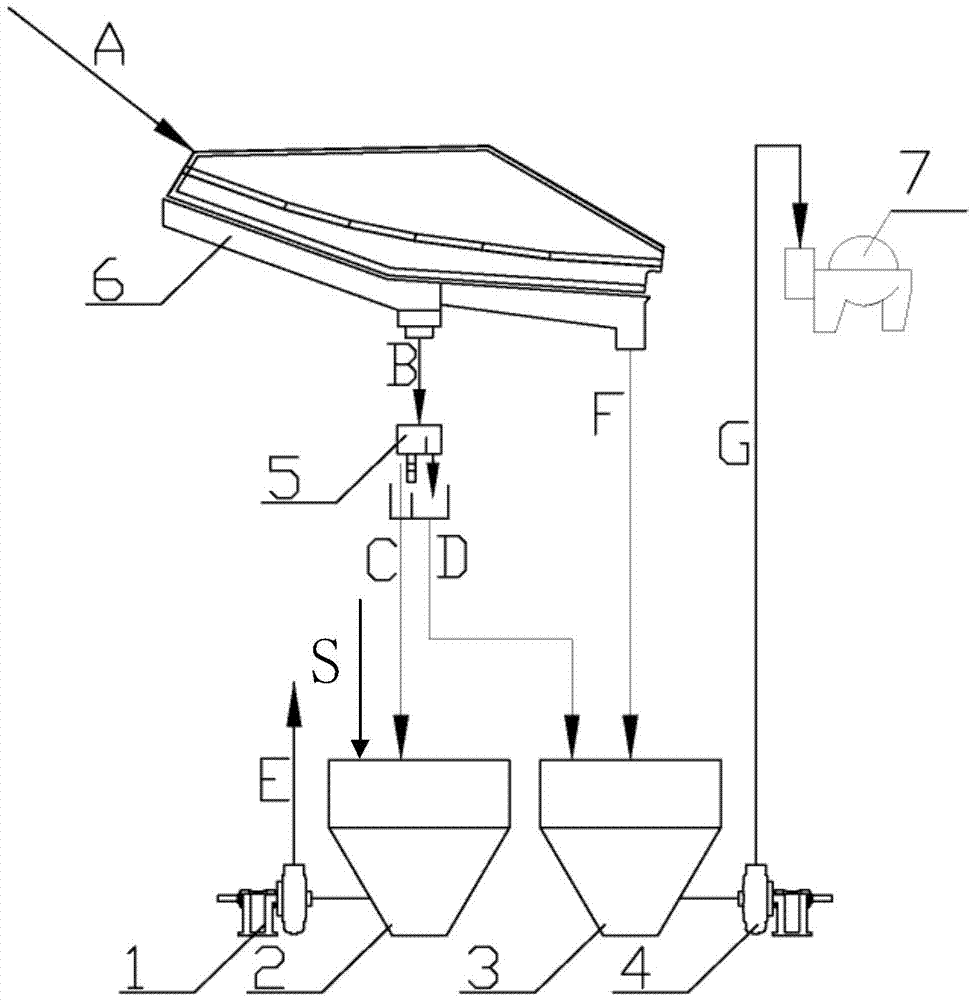

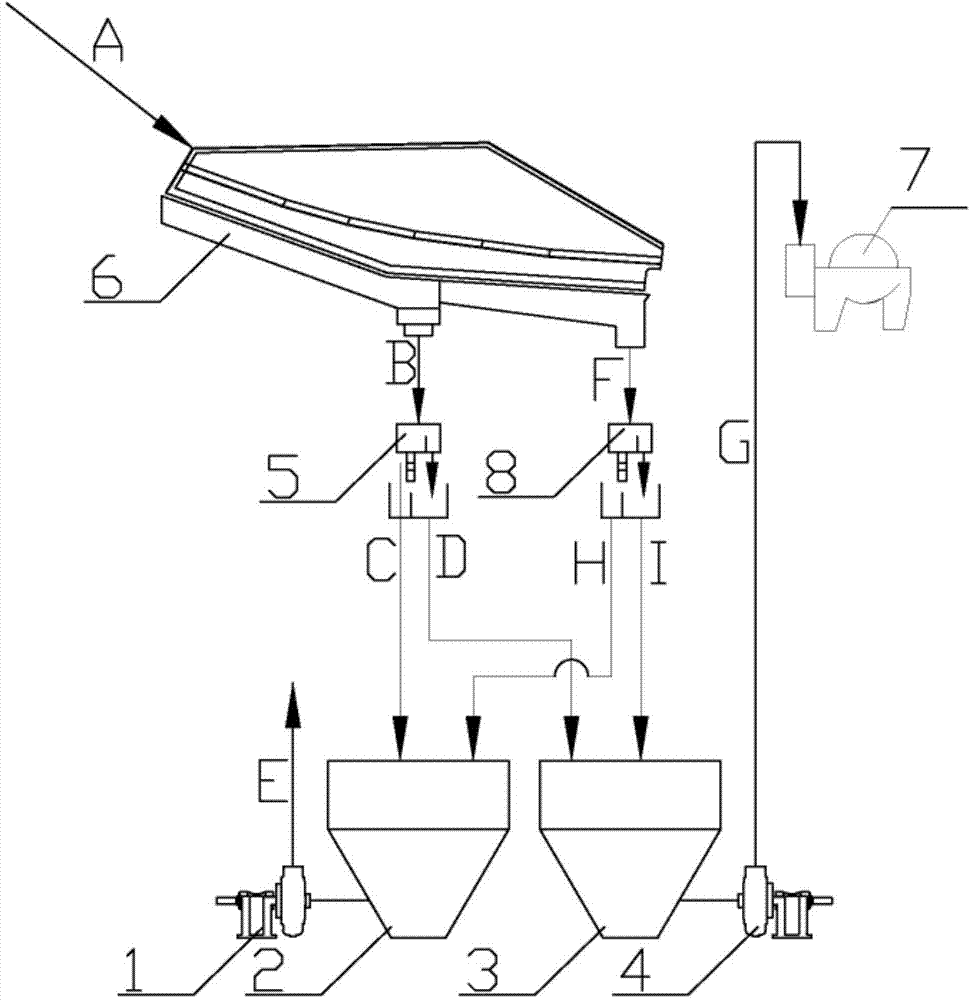

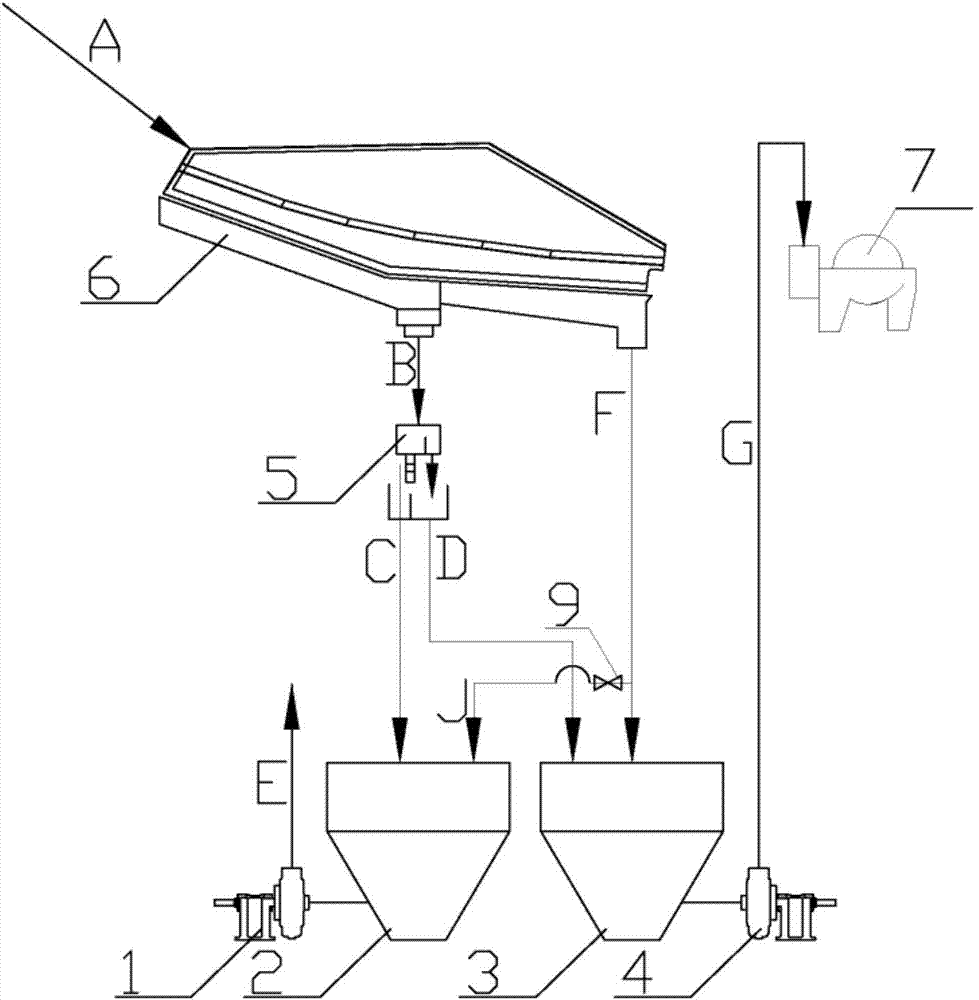

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] figure 1 It shows a typical flow chart of dense medium coal preparation water replenishment process in the field. After the raw coal is sorted by dense medium, the product and dense medium suspension enter the medium separation sieve 6 through path A, and the medium separation sieve 6 separates the heavy medium After sorting, the medium carried by the product is removed, and the general separation and separation section and the thinning section are carried out in the figure 1 Among them, the left port of the de-mediation screen 6 corresponds to the combined media section, and the right port corresponds to the dilute media section.

[0024] When working, on the one hand, the qualified medium removed from the joint section enters the joint distribution box 5 through pipeline B. If the liquid level and density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com