Non-oriented electrical steel plate with high magnetic induction and low iron loss and manufacturing method thereof

A technology of grain-oriented electrical steel sheet and a manufacturing method, applied in the field of steel sheet and its manufacturing, can solve the problems of reducing the magnetic induction of the finished steel sheet, increasing the manufacturing cost of the finished steel sheet, and prolonging the production time and delivery cycle of the finished steel sheet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

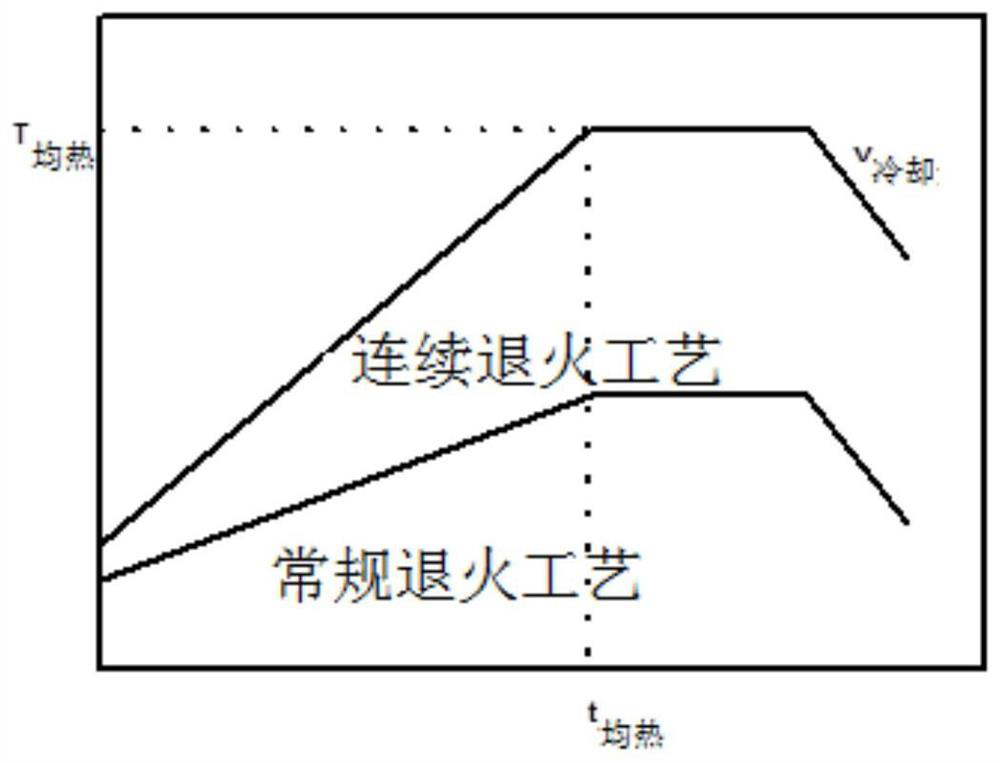

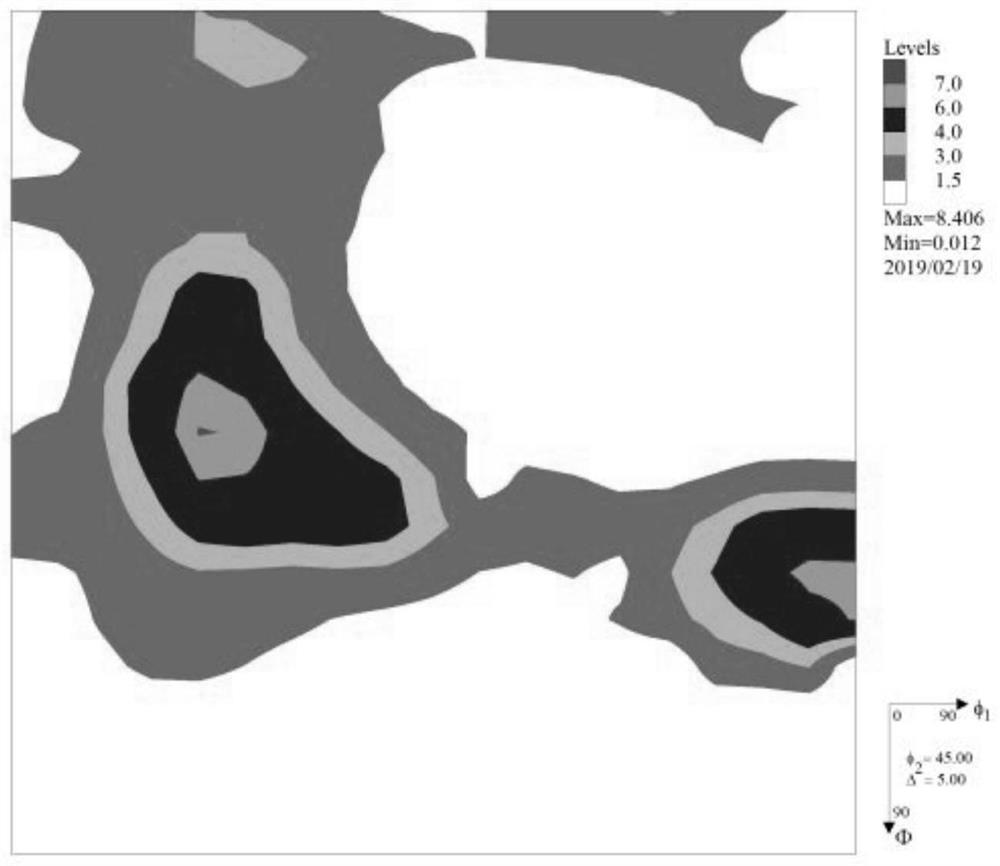

[0065] The non-oriented electrical steel sheet with high magnetic induction and low iron loss and its continuous annealing process described in the present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments of the specification. The scheme constitutes an improper limitation.

[0066] The conventional electrical steel sheets of each comparative example and the non-oriented electrical steel sheets of the embodiments were prepared by the following steps:

[0067] (1) Use molten iron and steel scrap to mix according to the chemical composition shown in Table 1. After smelting in a converter, then RH refining for decarburization and deoxidation alloying.

[0068] (2) After the molten steel is continuously cast, a continuous casting slab with a thickness of 120-250mm and a width of 800-1400mm is obtained.

[0069] (2) Hot rolling.

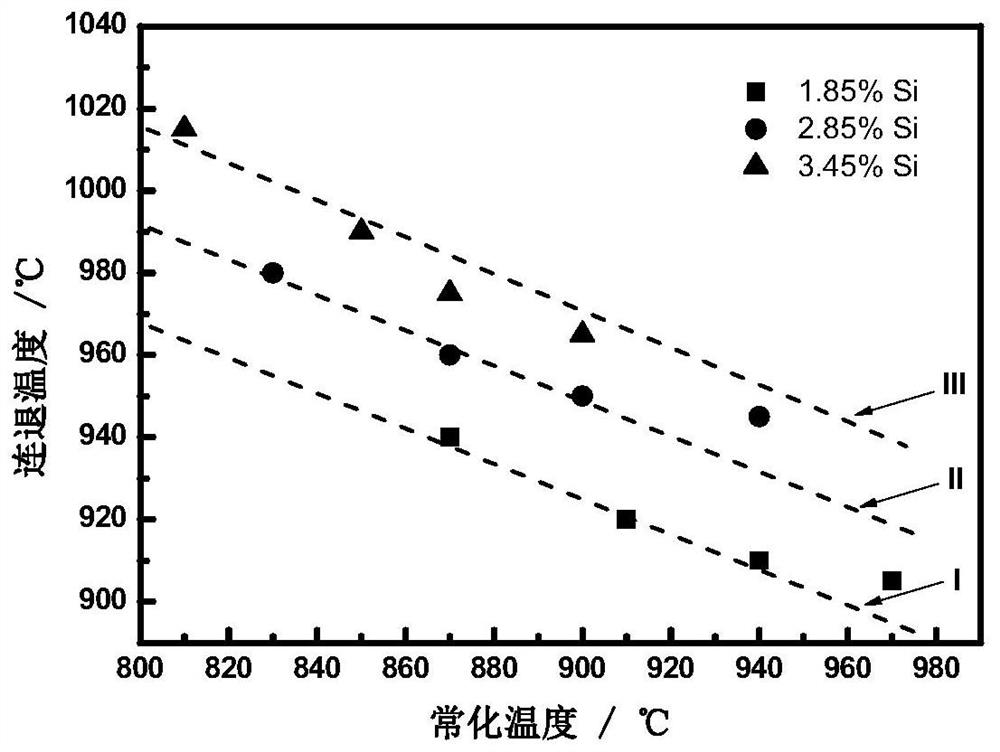

[0070] (3) Normalization: normalization temperature T 常化 =T 居里温度 +(120~1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com