Patents

Literature

116results about How to "Guaranteed ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

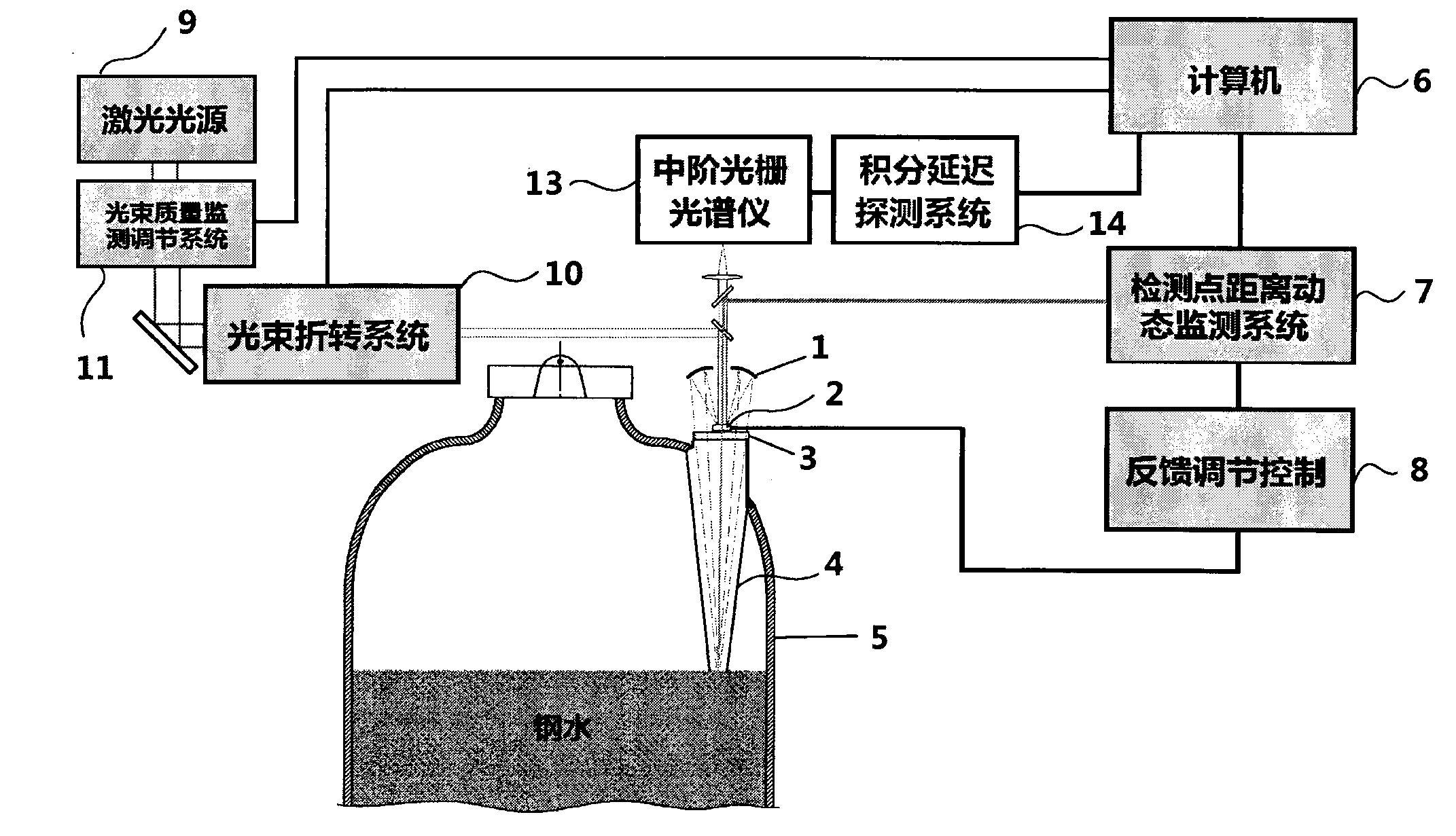

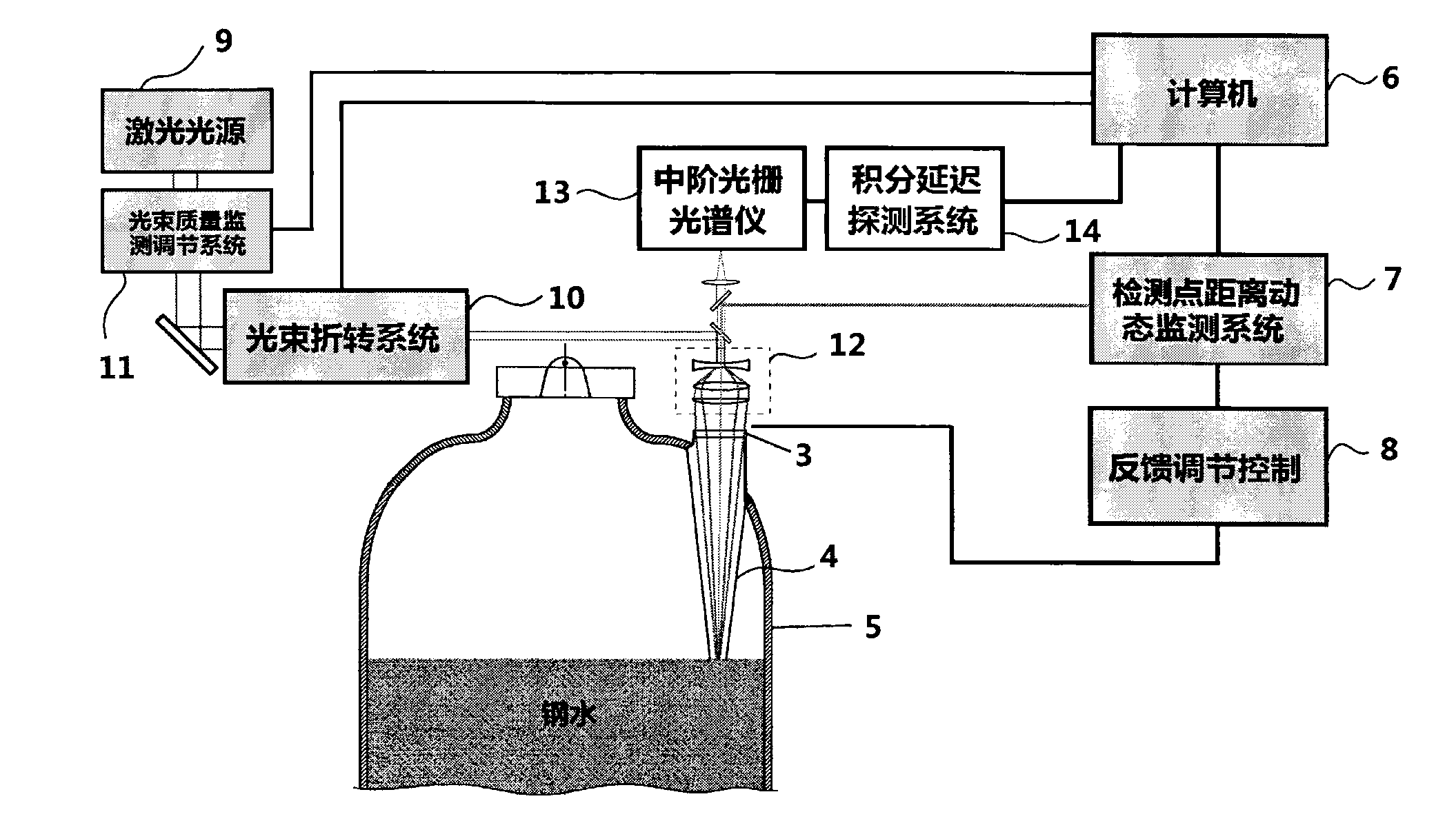

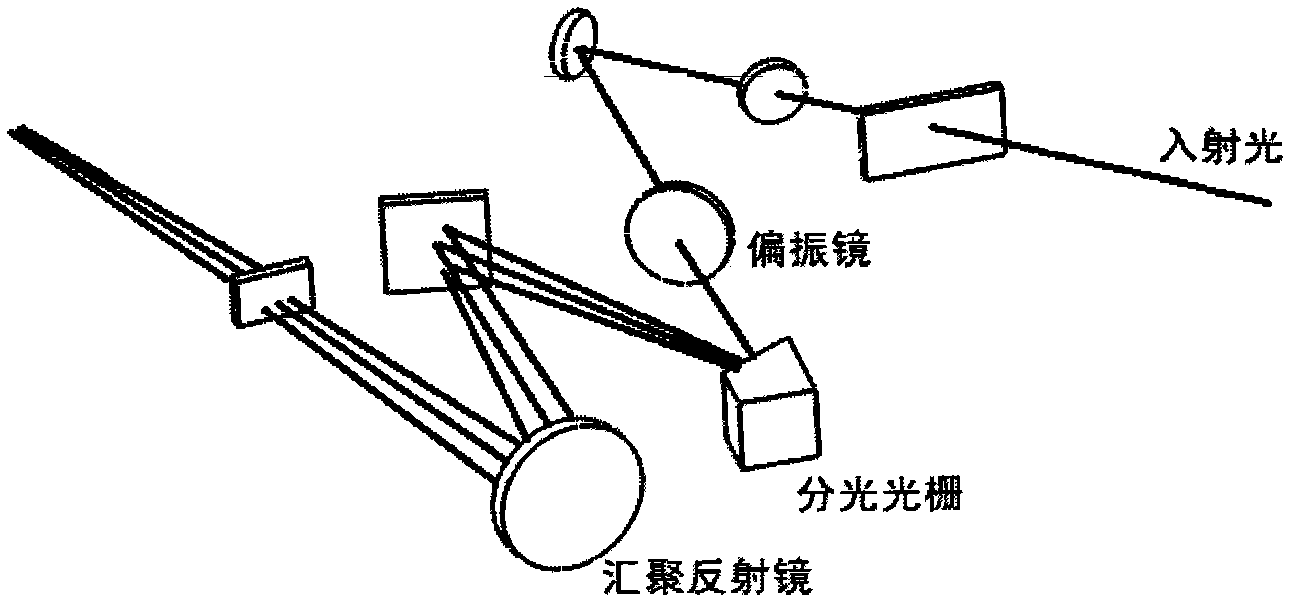

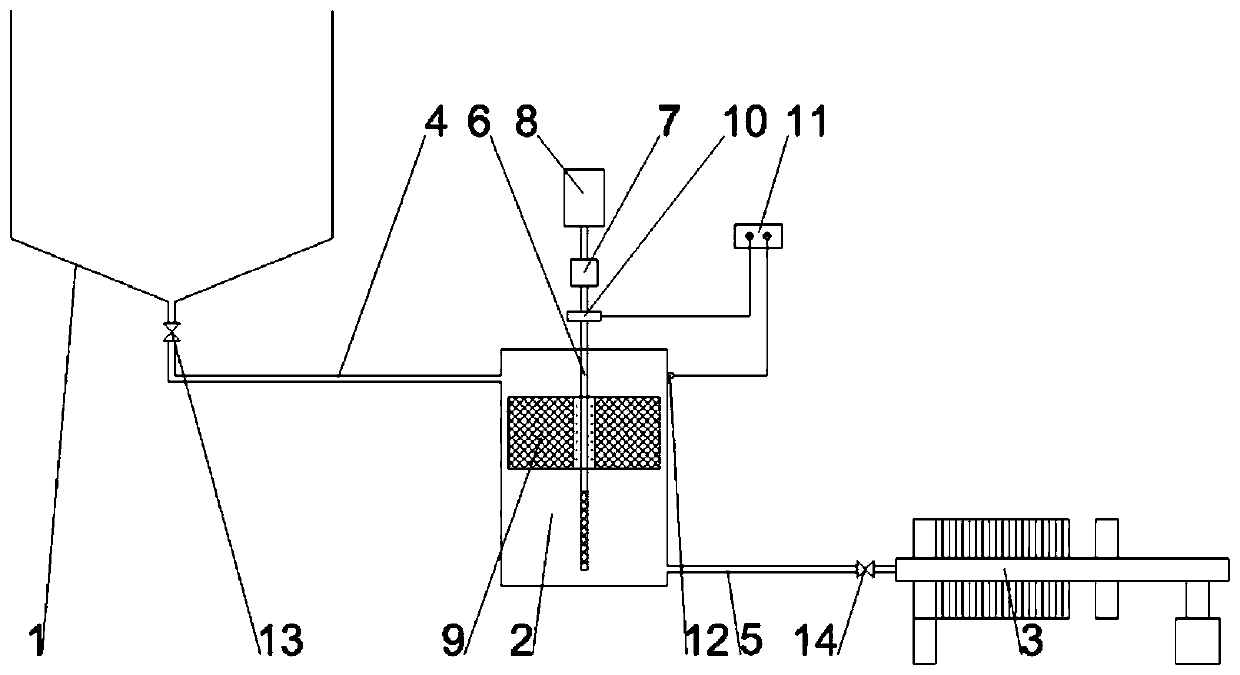

Laser spectroscopy induced component detection system

InactiveCN102841075AThe detection process is simpleDetection speedSpectrum investigationAnalysis by material excitationFeedback regulationDynamic monitoring

Belonging to the technical field of laser detection, the invention relates to a novel laser spectroscopy induced detection system, especially to a molten steel component online detection system, which is obtained by gathering lasers on a molten steel surface and conducting analysis through induced plasma spectroscopy. The laser spectroscopy induced online molten steel component detection system includes: a concave reflecting mirror, a convex reflecting mirror, a window mirror, a casing pipe, a steel furnace, a computer, a detection point distance dynamic monitoring system, a feedback regulation control device, a laser light source, a light beam turning system, an echelle spectrometer, an integral delay detection system, a laser beam quality control system and the like, and can realize accurate detection of manganese, magnesium, sulfur, carbon and other 20 components contained in molten steel. The detection system provided in the invention can realize real-time detection of molten steel components, reduce the smelting cost, and save resources.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI +1

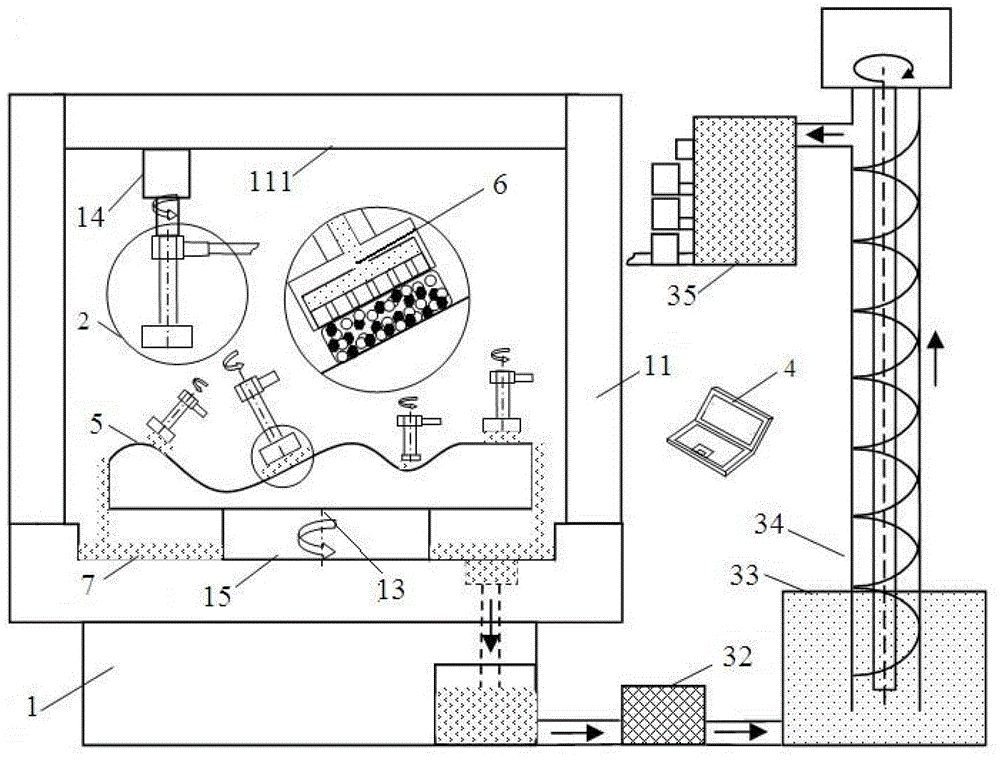

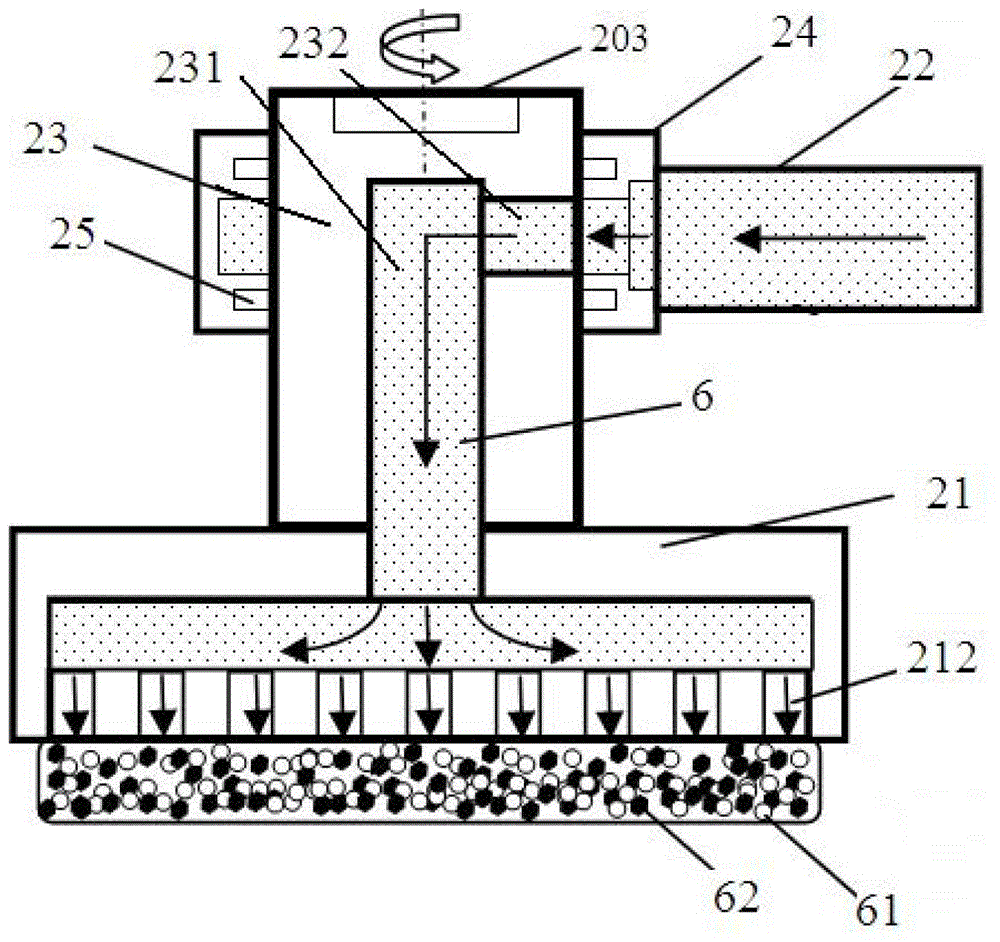

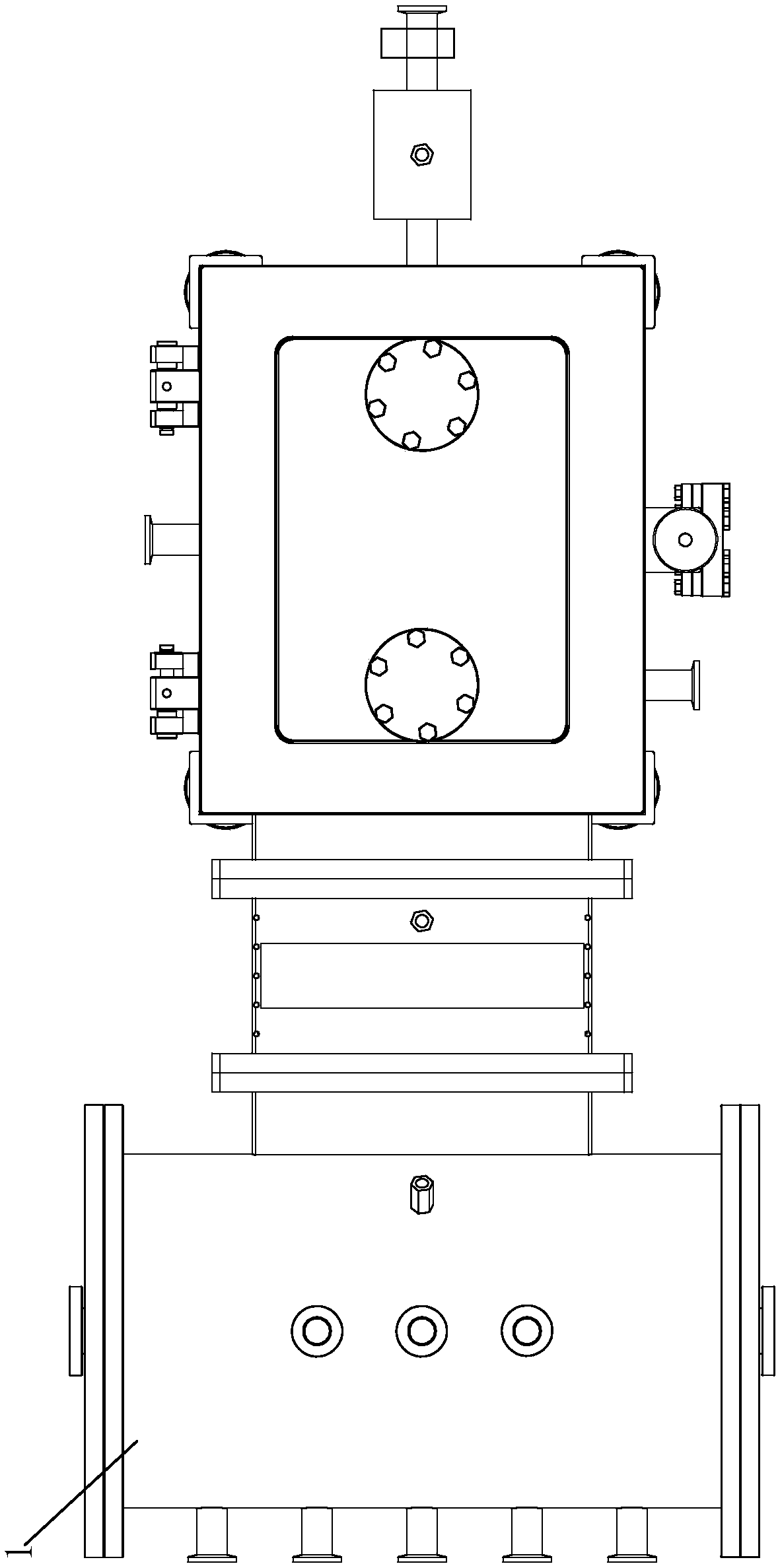

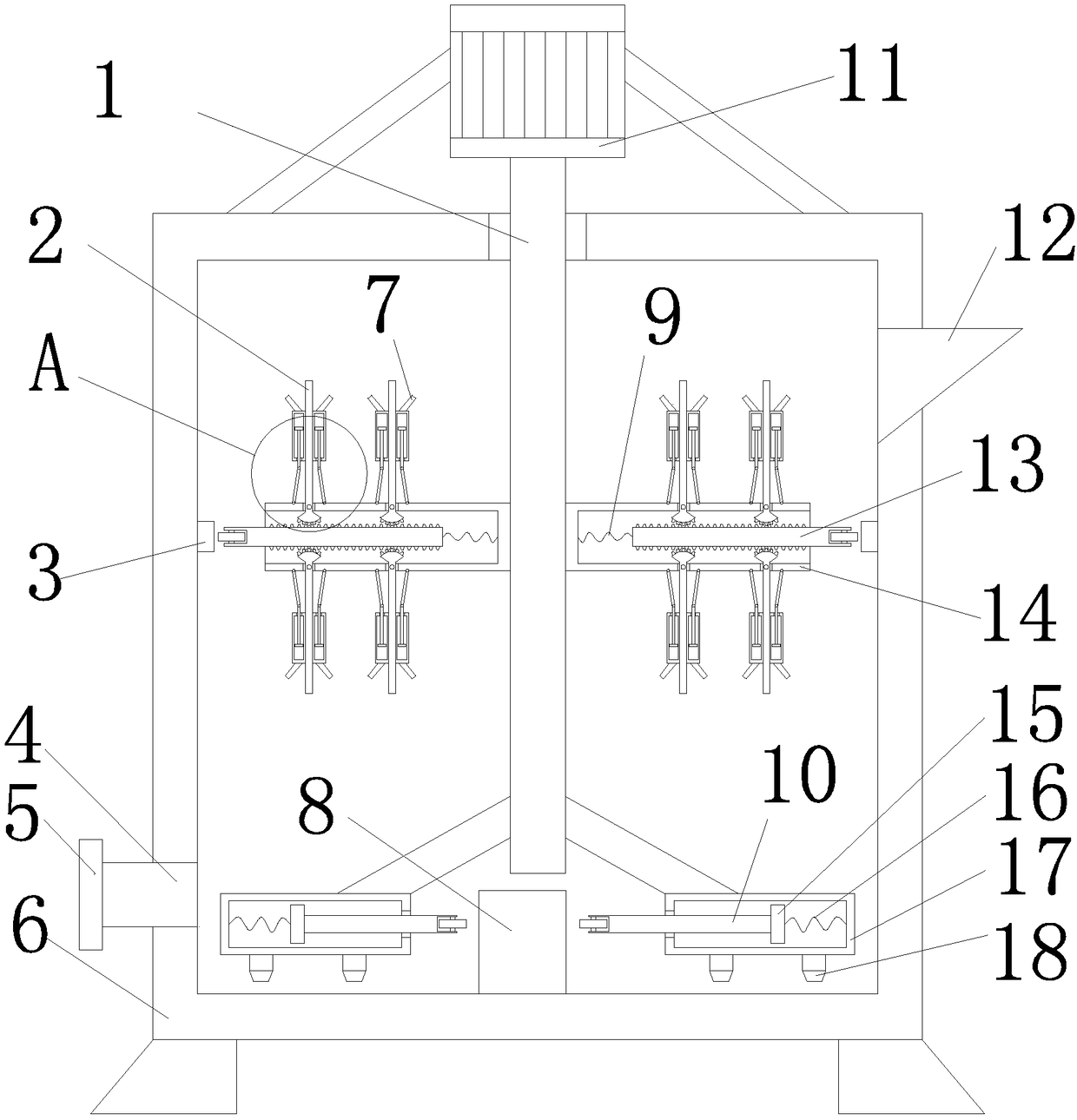

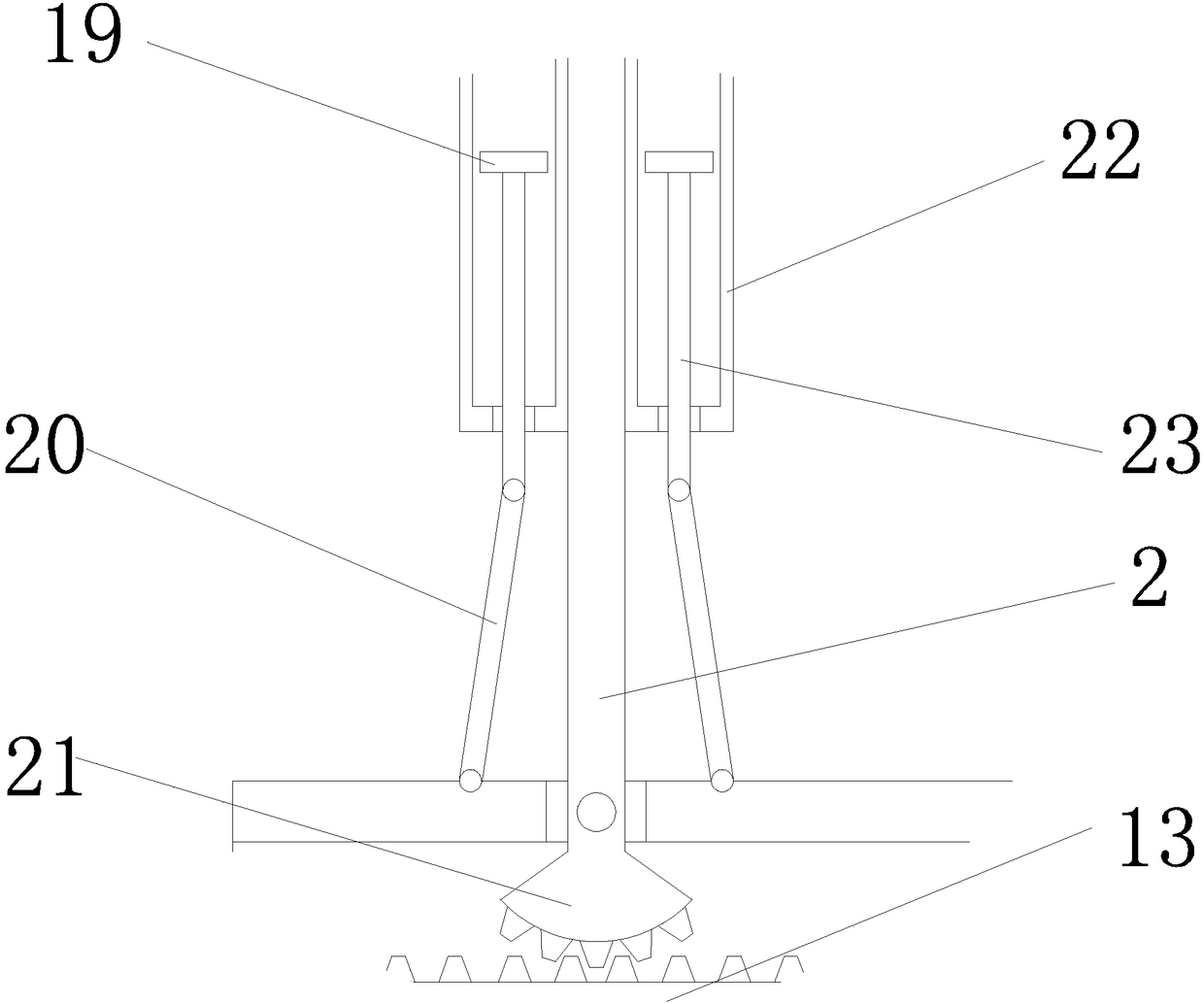

Machining device based on non-Newtonian fluid shear thickening mechanism polishing method

ActiveCN103331685ARealize multi-pose transformationRemovablePolishing machinesEngineeringPortal frame

A machining device based on a non-Newtonian fluid shear thickening mechanism polishing method comprises a workbench, a polishing tool system, an abrasive fluid circulation device and a computer control module, wherein the polishing tool system is installed on a portal frame of the workbench, an inlet of the abrasive fluid circulation device is communicated with an abrasive backflow opening in the workbench, and the workbench, the polishing tool system and the abrasive fluid circulation device are respectively connected with the computer control module. The machining device has the advantages that the application range is wide, the size of machined workpieces is not limited, the structure of the device is simple, the device is controlled easily, a computer controls the operation track of the device, the polishing process of non-Newtonian fluid abrasive fluid and the surfaces of the workpieces can be controlled effectively, a non-Newtonian fluid abrasive fluid circulation system is adopted, and the functions of removing abrasive dust, purifying, recycling, transporting and storing the abrasive fluid, and adjusting performance are achieved.

Owner:ZHEJIANG UNIV OF TECH

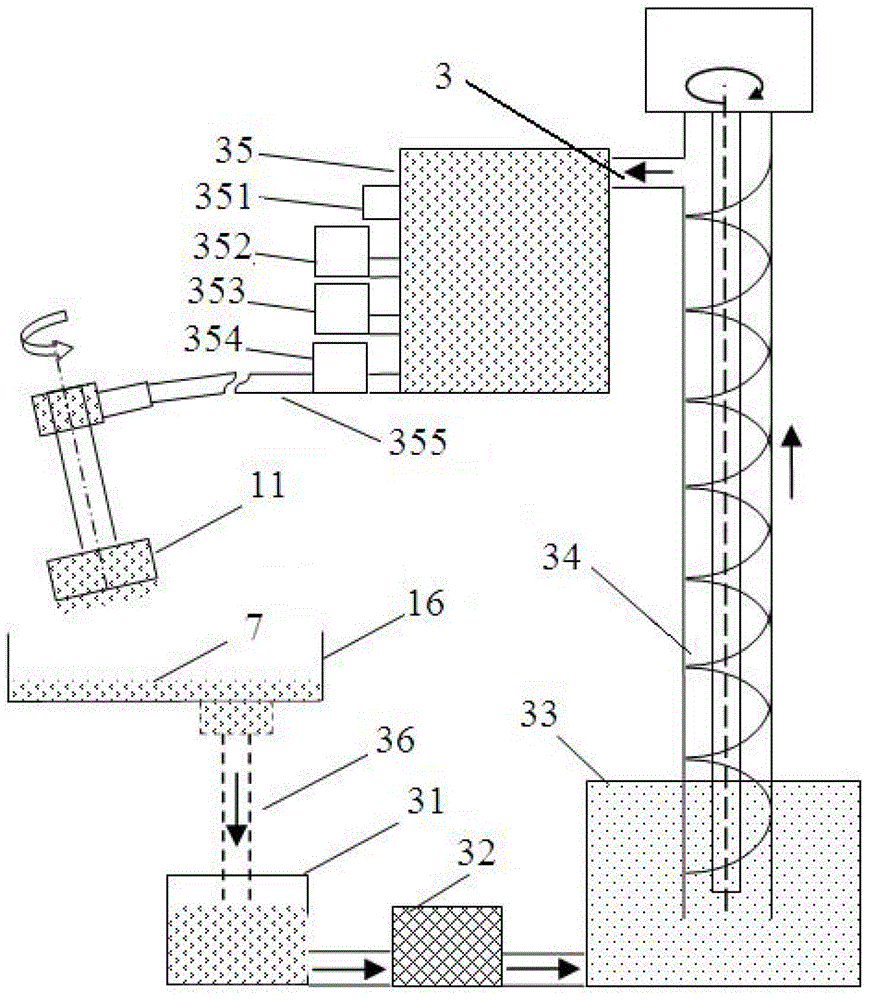

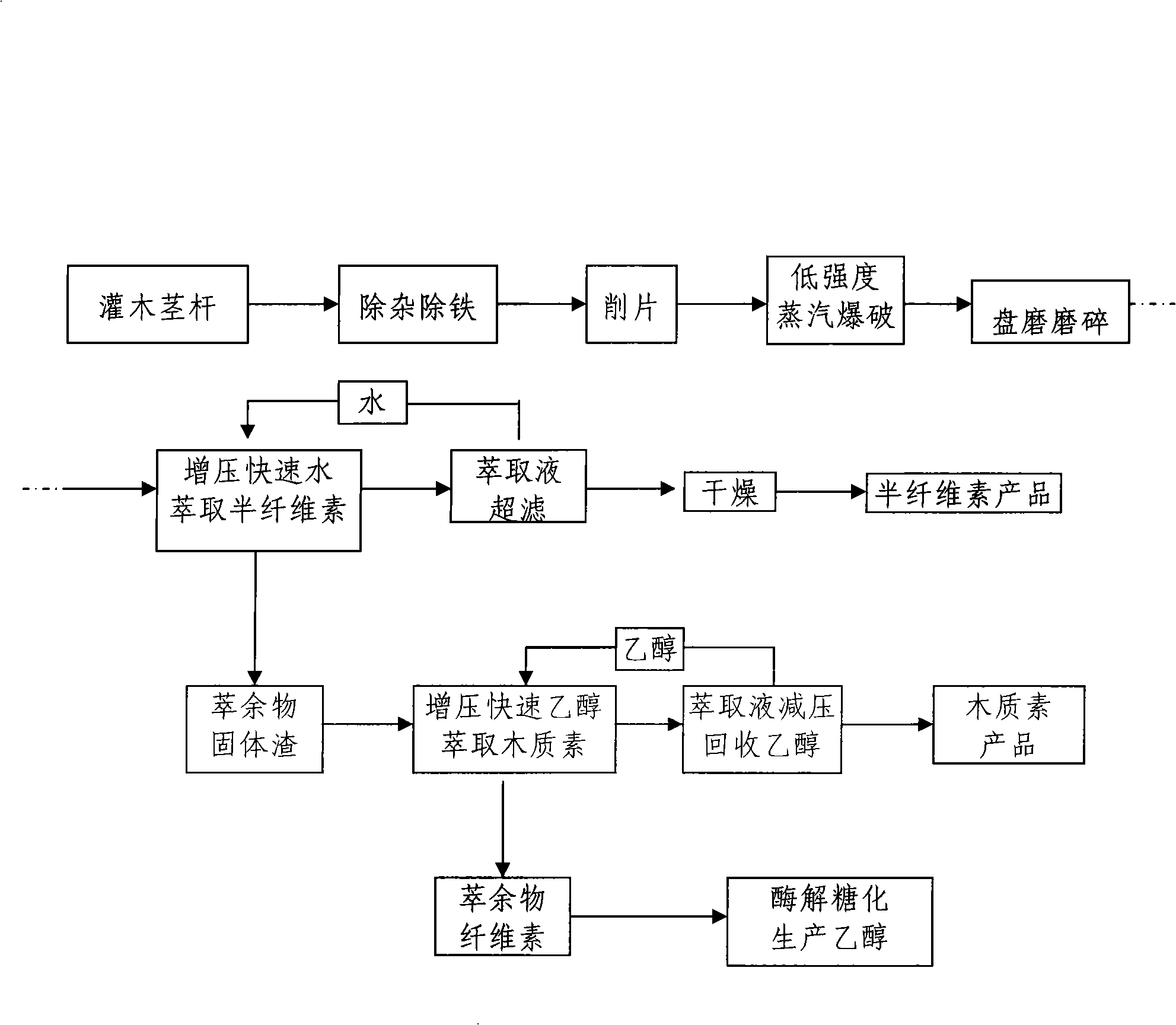

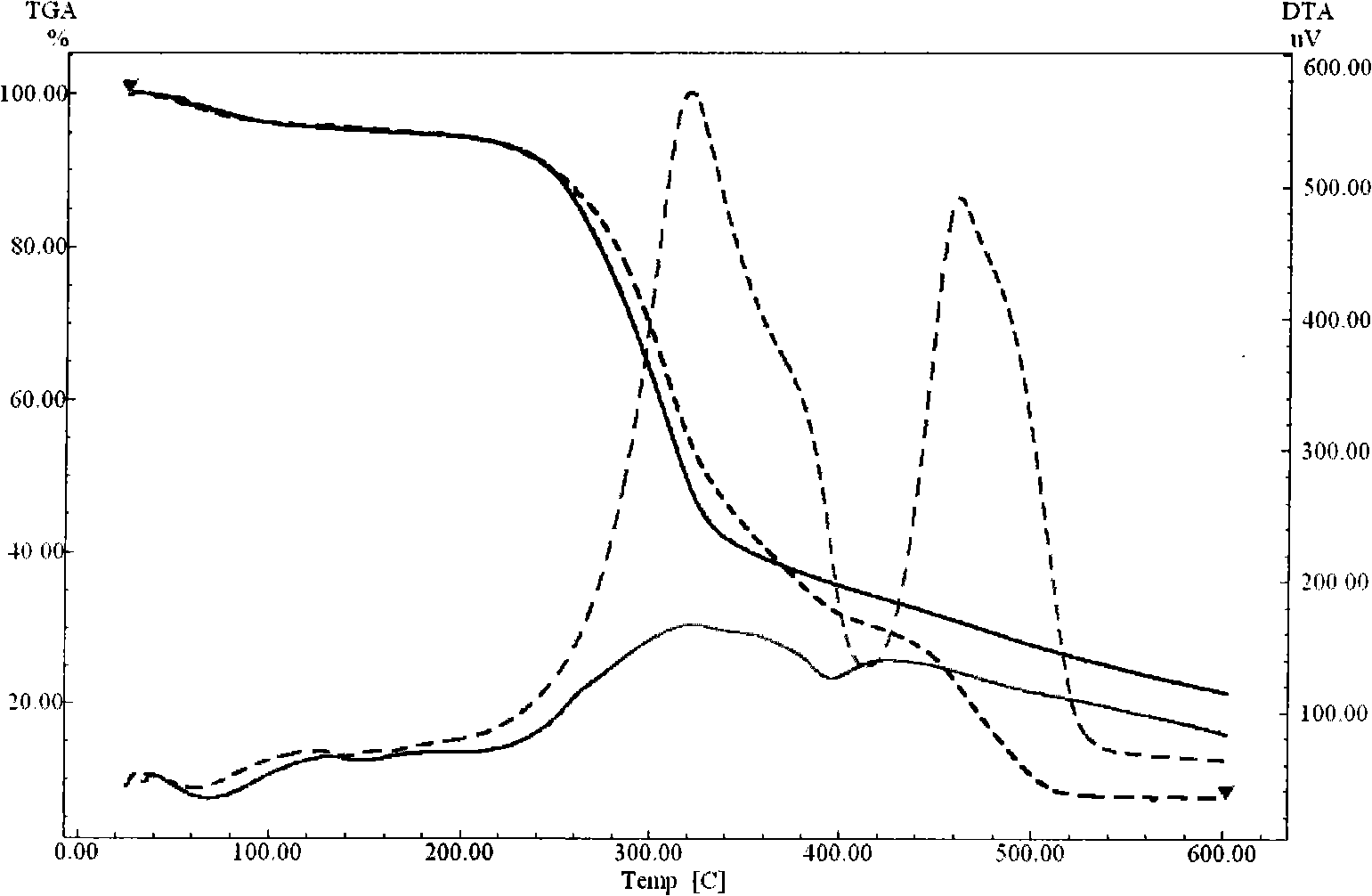

Method for separating main ingredients of arboret stalk by low-intensity steam explosion

InactiveCN101348804ALow equipment requirementsReduce energy consumptionBiofuelsFermentationChemistryPre treatment

The invention relates to a method for separating shrub stalks containing lignocellulose into elementary compositions such as lignin, hemicellulose, cellulose and so on after pretreatment. The method comprises the following steps of (1) low-intensity vapor explosion pretreatment, wherein the vapor explosion pressure is between 0.5 and 1.2 MPa and the pressure maintaining time is between 20 and 150 seconds; (2) extraction and separation of the hemicellulose;(3) extraction and separation of the lignin; and (4) zymohydrolysis and saccharification of the cellulose. The method utilizes the low-intensity vapor explosion pretreatment to extract and separate the hemicellulose and the lignin, obtains the cellulose and then prepares biological ethanol through zymohydrolysis of the cellulose, can convert carbon from wood biomass of the shrub stalks into useful products to the maximum degree, particularly greatly improves the conversion rate of converting the cellulose into ethanol, reduces the conversion cost, fully utilizes the lignocellulose resources, does not use acid, alkali or sulfur-bearing and chlorine-bearing chemical products during the processing procedure, and is a green and pollution-free separation technology.

Owner:BEIJING FORESTRY UNIVERSITY

Non-magnetic 316L stainless steel and production method thereof

The invention discloses non-magnetic 316L stainless steel and a production method of the non-magnetic 316L stainless steel. The non-magnetic 316L stainless steel is prepared from, by weight, 0.01-0.03of C, 1.0 or less of Si, 2.0 or less of Mn, 0.045 or less of P, 0.002 or less of S, 16.5-17.50 of Cr, 13.5-14.0 of Ni, 2.5-2.7 of Mo, 0.11 or less of N, 0.001-0.003 of B and the balance Fe and otherinevitable impurity elements, Md30 is -170 DEG C--200 DEG C, and delta ferrite is smaller than 0.5%; and steel billet smelting, plate billet heating, plate billet rolling, black coil annealing and pickling, modulation calendering, cleaning and oil removal processes are carried out. The non-magnetic 316L stainless steel has the advantages that the requirements for no magnesium, machining performance and corrosion resistance are all met, harmful elements S and P are controlled, Cr oxidation is restrained, and inclusion is controlled; and annealing demagnetization is not needed, and the non-magnetic stainless steel is obtained and used for electronic product structural parts and stainless steel frames.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

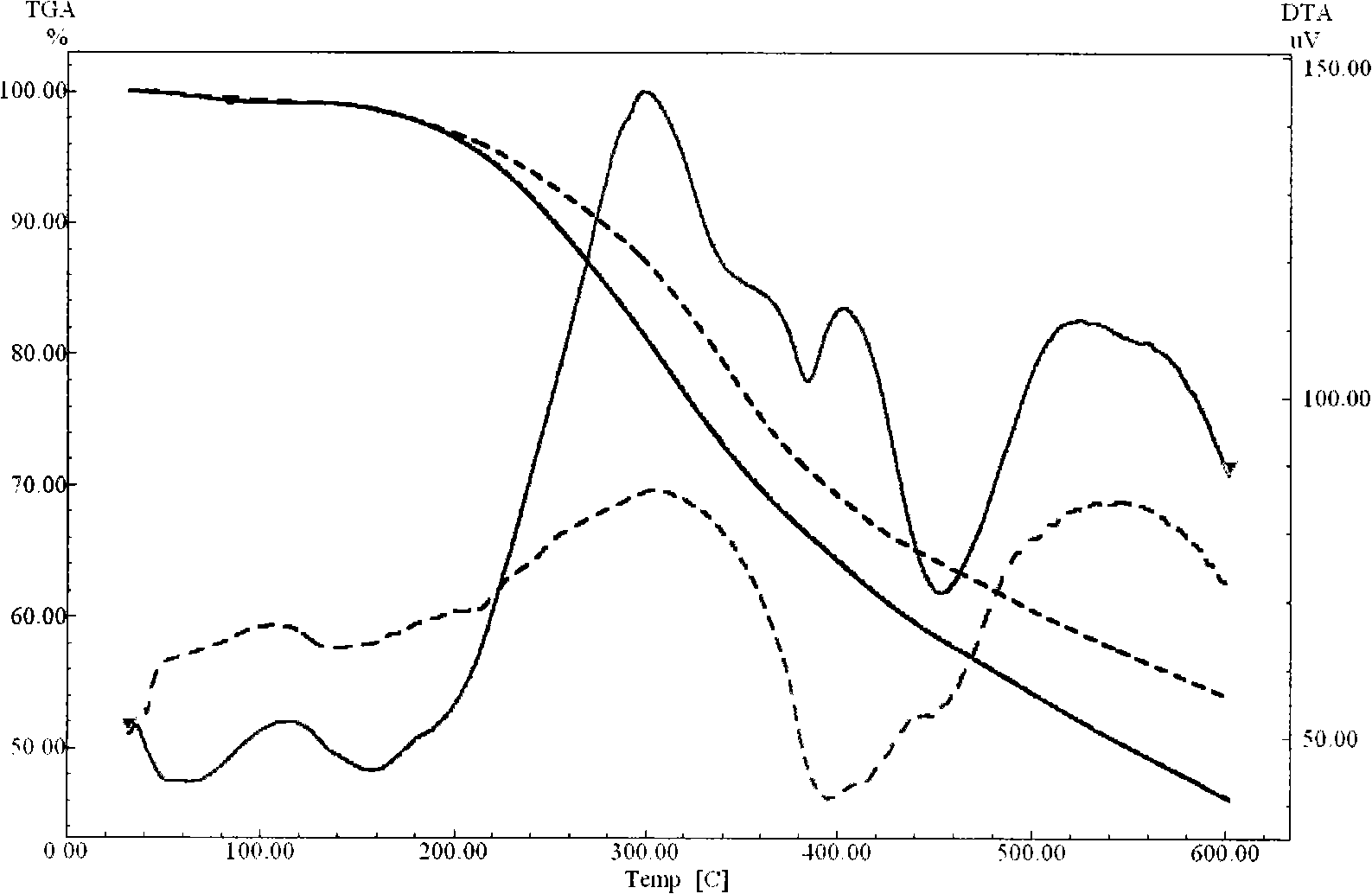

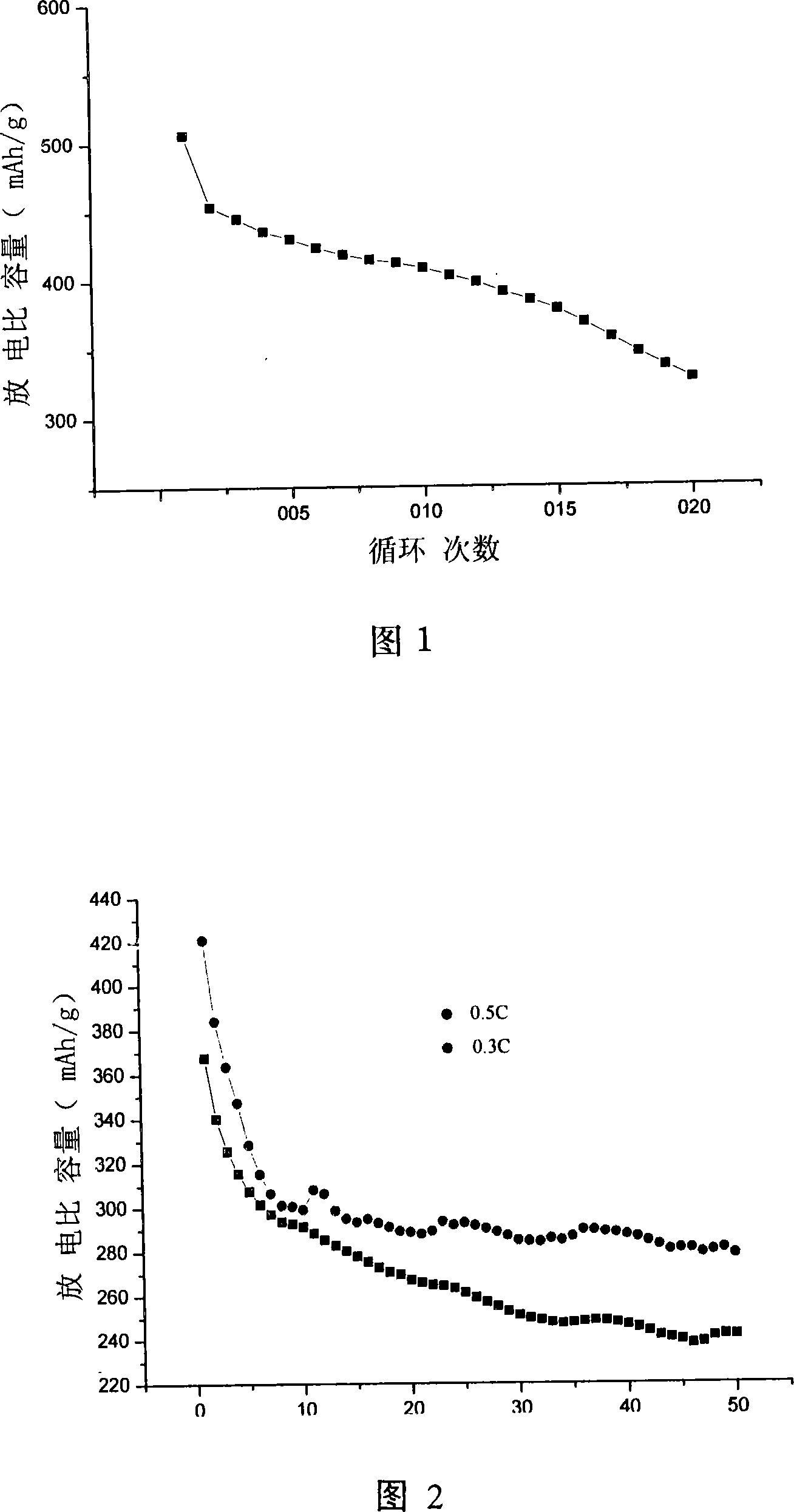

Method for reducing metal and alloy hydroxide gel by hydrogen separated from electrochemistry cathode

InactiveCN101144176APrecise control of ingredientsGuaranteed ingredientsElectrolytic coatingsAlkaline accumulator electrodesPotassiumAlloy

The present invention discloses a method for reducing metal hydroxide gel and metal hydroxide-carbon gel and alloy gel and alloy hydroxide-carbon gel through electrochemical cathodic hydrogen evolution in potassium chloride aqueous solution, and directly further forming and preparing electrode materials of metal and metal-carbon and alloy and alloy-carbon. The electrode prepared by the method can obtain composition of metal: carbon or alloy: carbon with definite proportion, thereby the electrode composition is stable. The tin-carbon gel and tin-cobalt-carbon gel of the present invention is prepared by a definite proportion chemical precipitation method, and overcomes the disadvantage that the coating element content can not be accurately controlled if an electrochemical deposition method is adulterated. The experimental battery consisting of the tin-carbon anode and the lithium sheet cathode prepared with the process has 20 times circulation time and specific capacity of up to 327.4 mAh / g under 0.2 C charging and discharging current; the prepared experimental battery consisting of the tin-cobalt-carbon anode and the lithium sheet cathode has 50 times circulation time specific capacity of up to 278.5 mAh / g under 0.3 C charging and discharging current.

Owner:BEIHANG UNIV

Nutrition fortification biscuit powder capable of reducing blood sugar and method for preparing same

ActiveCN102696710ALower and stabilize blood sugarImprove immunityDough treatmentBakery productsGynostemmaFreeze dry

The invention provides a nutrition fortification biscuit powder capable of reducing blood sugar, which comprises the following raw materials in weight ratio: 1,000g of low-gluten flour, 3-5g of freeze-dried powder of black fungi, 10-15g of freeze-dried powder of yams, 8-10g of freeze-dried powder of hawthorns, 3-5g of freeze-dried powder of balsam pear, 10-15g of freeze-dried powder of pueraria, 8-10g of freeze-dried powder of celery, 1-2g of freeze-dried powder of gynostemma pentaphylla, 10-15g of freeze-dried powder of pumpkins and 3-5g of freeze-dried powder of silkworm chrysalis. A methodfor preparing the nutrition fortification biscuit powder comprises the following steps: soaking all the accessories, drying by adopting the freeze-drying method, grinding, sieving, and stirring uniformly according to proportion to obtain the product. Because the nutrition fortification biscuit powder is prepared by adopting the low-temperature freezing and processing technology, the original components of all the raw materials are guaranteed, and the nutrition fortification biscuit powder has comprehensive nutrition. Because nutritional substances capable of regulating the blood sugar are added, the nutrition fortification biscuit powder is particularly suitable for the patients with diabetes to eat for a long time and has the functions of reducing and stabilizing the blood sugar and improving the immunity of the patients. The patients eating the nutrition fortification biscuit powder can take less or even do not need to take the medicine for reducing the blood sugar, thus the side effects caused by the reason of taking the medicine for a long time to the body of the patients can be reduced.

Owner:临泉县金禾面粉有限公司

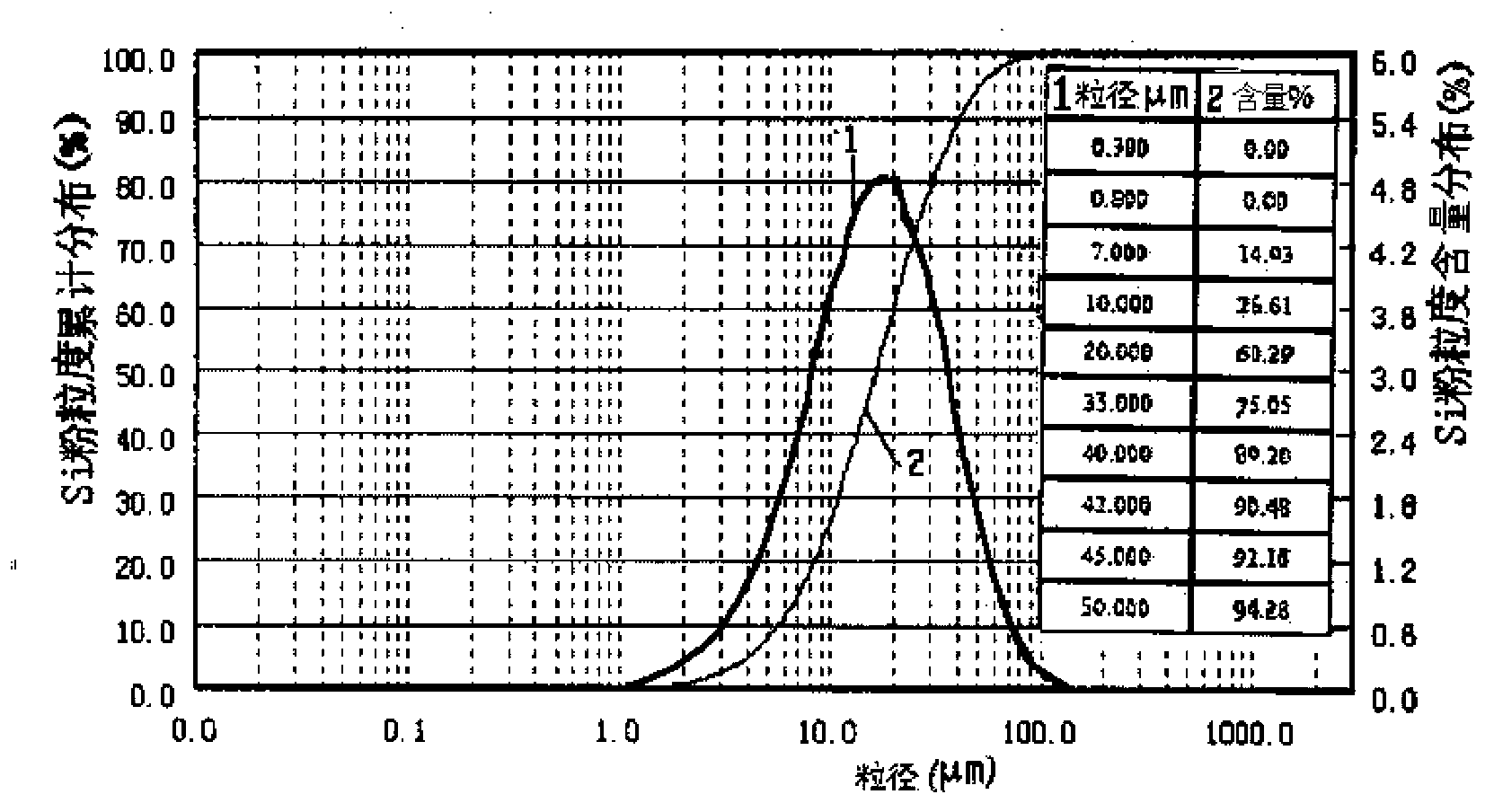

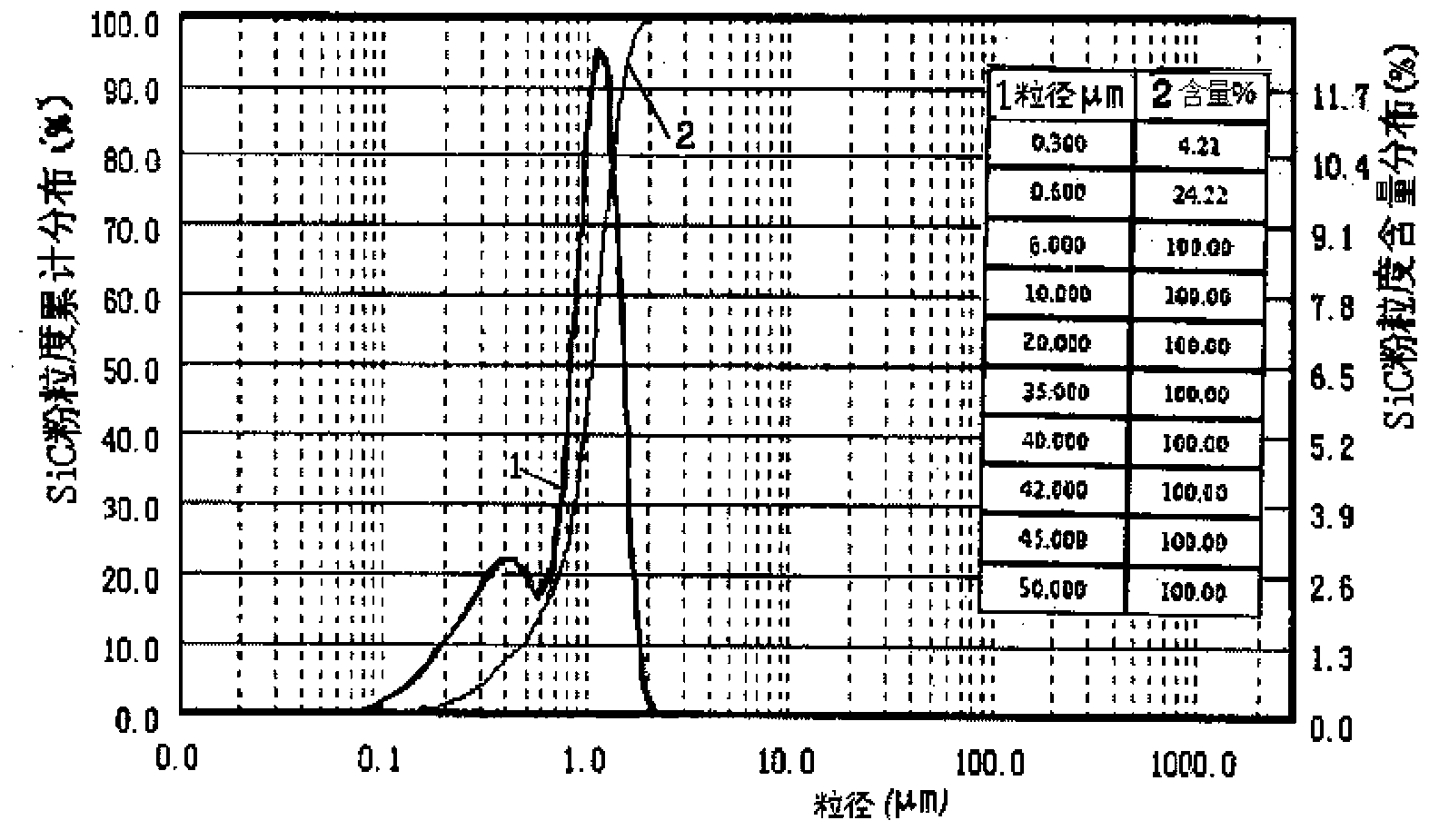

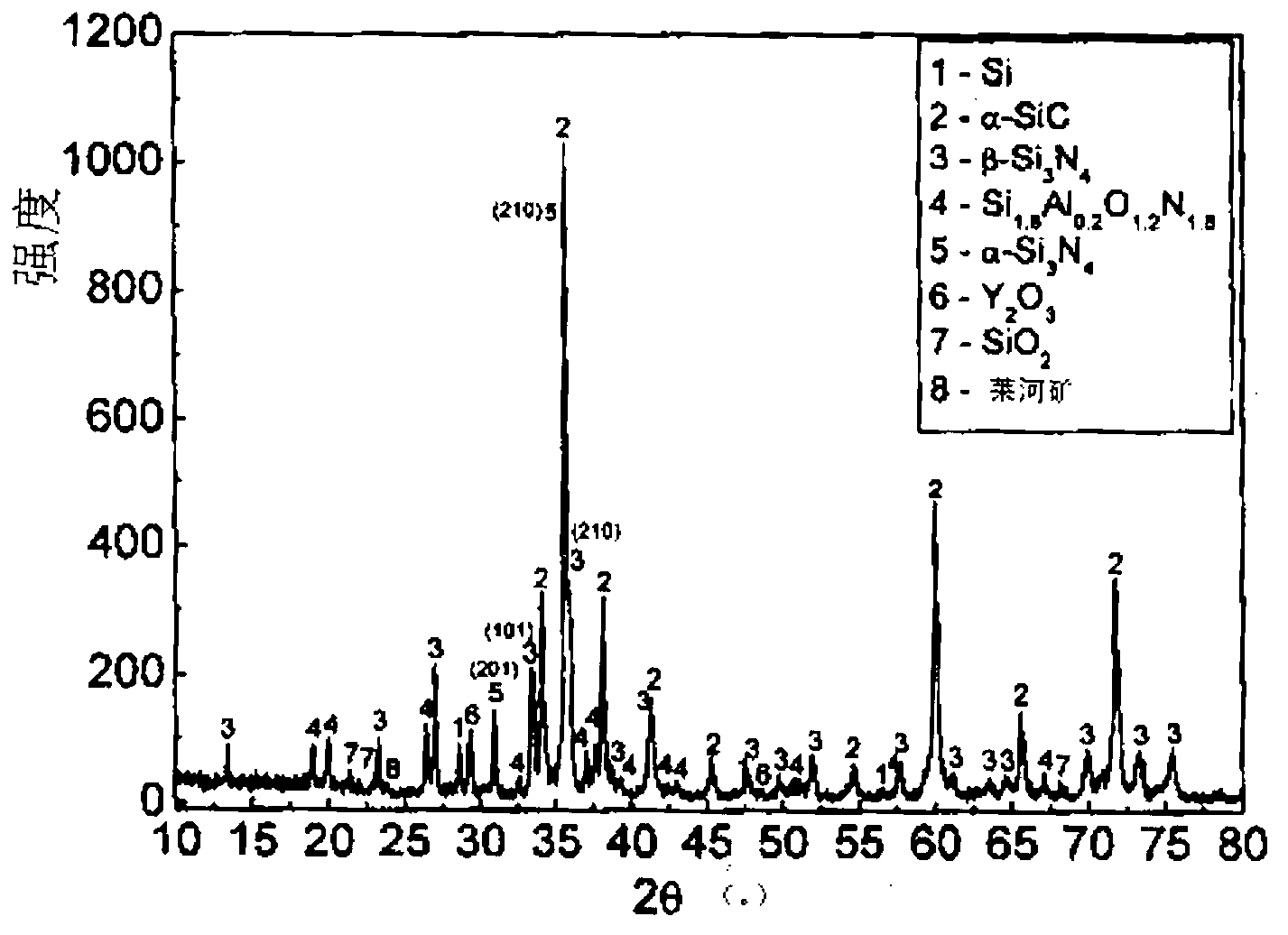

Method for preparing silicon nitride compound silicon carbide ceramic from crystalline silicon cutting waste materials

Owner:NORTHEASTERN UNIV LIAONING

Brown sugar candy and production method thereof

The invention discloses a production method of brown sugar candy, comprising the following steps: 1) cleaning and peeling off fresh ginger, cutting into small blocks to obtain ginger blocks; 2) treating the ginger by grinding and then filtering the serous fluid to obtain ginger juice; 3) mixing the ginger juice, brown sugar, white sugar, isomaltulose alcohol with water and then heating and stirring to gain syrup; 4) drying treatment of the syrup in vacuum to gain dewatering syrup; 5) evenly adding into the dewatering syrup with the atomized menthol to gain mixed syrup; 6) pouring the mixed syrup into a mould for shaping. The invention also simultaneously discloses a brown sugar candy produced according to the method. The brown sugar candy of the invention has the function of regulating and nourishing the stomach, etc.

Owner:ZHEJIANG UNIV

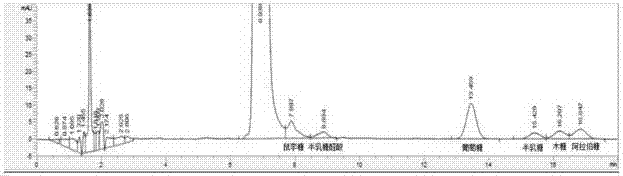

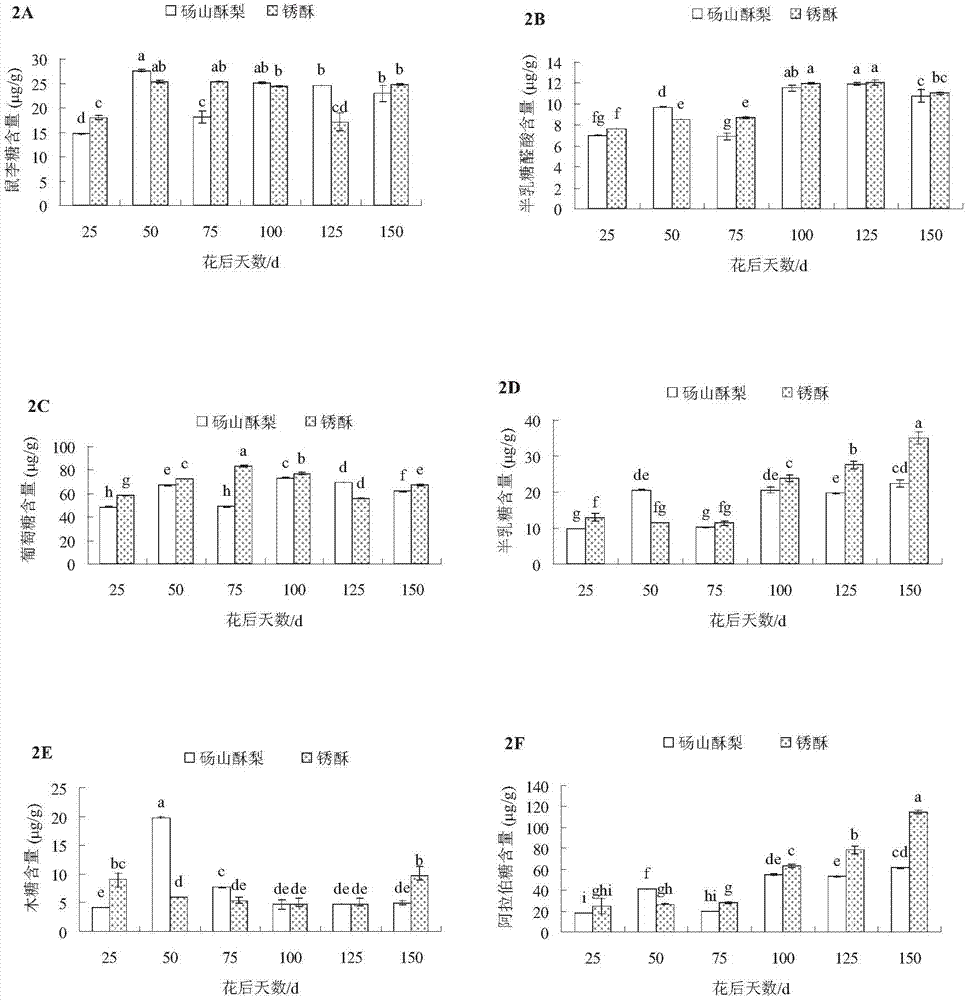

Method for testing content of monosaccharide in polysaccharide in pear peel tissue

InactiveCN104714037AGuaranteed ingredientsImprove extraction efficiencyComponent separationBiological testingPEARTrifluoroacetic acid

The invention relates to a method for testing the content of monosaccharide in polysaccharide in pear peel tissue. The method comprises the following steps: preparing a sample to be tested, namely, weighing a fixed amount of pear peel, extracting with petroleum ether, performing heating extraction to the residues by using deionized water, filtering by using a membrane of 0.45mu m, putting the filtrate into an ampoule bottle, adding trifluoroacetic acid, introducing N2, sealing the tube to react for 0.5-5 hours, adding a NaOH solution and a PMP methanol solution, and uniformly mixing to react; preparing a standard monosaccharide solution, and quantitatively analyzing the content of different monosaccharide components in polysaccharide in the pear peel by using a high performance liquid chromatography method. The change rules of the content of the different monosaccharide components in polysaccharide in the peel in different periods of fruits can be compared. The method is small in sample amount, capable of effectively increasing the extraction rate of the content of the monosaccharide components in polysaccharide, and high in accuracy and repeatability.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Method for heating and melt-cladding TiC reinforced high-entropy alloy coating through high-frequency induction

ActiveCN108118338AImprove toughnessHigh strengthMetallic material coating processesHigh entropy alloysWear resistant

The invention discloses a method for heating and melt-cladding a TiC reinforced high-entropy alloy wear-resistant composite coating through high-frequency induction. An inductor is adopted to heat andmelt-clad mixed powder prepared from Ni-Cr-B-Si, Co-Cr-B-Si, Cu, Al and TiC according to a certain proportion under the protection of argon gas on the surface of low-carbon steel; composition elements are five elements or more, and during a melt-cladding process, a retardation effect of a high-entropy alloy is achieved, and primary Cr7C3 has the characteristic of fine grain size; the AlCoCrCuNi high-entropy alloy coating reinforced by TiC and Cr7C3 is finally formed on a surface of a steel substrate.

Owner:GUANGDONG HECHENG ENVIRONMENTAL ENG CO LTD

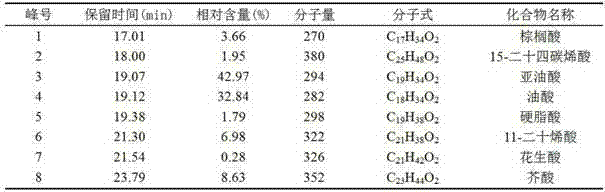

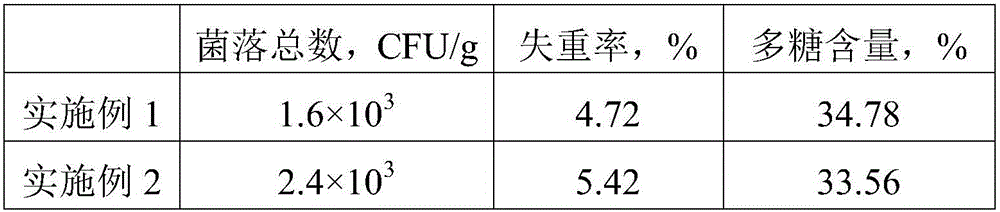

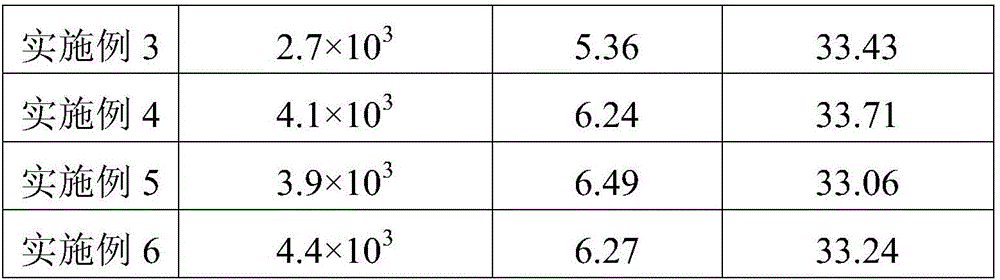

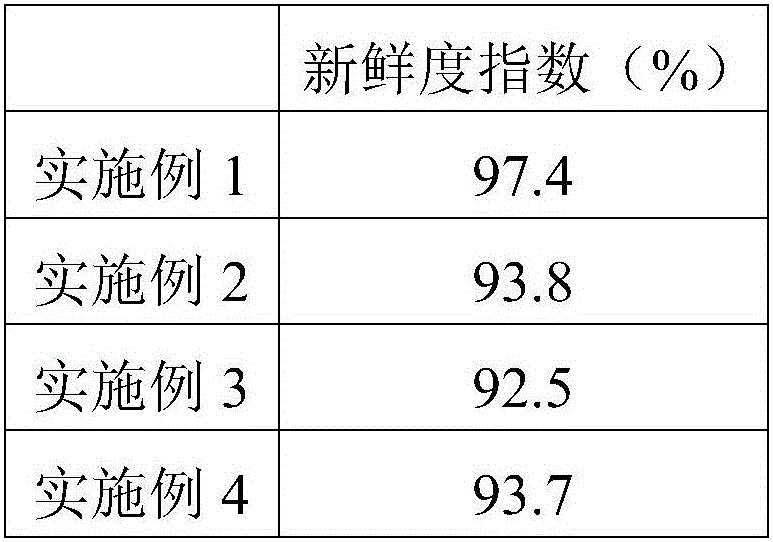

Method for preserving dendrobium officinale

ActiveCN103932355AGuaranteed ingredientsMaintain colorDead plant preservationFood preservationAdditive ingredientToxicology

The invention discloses a method for preserving dendrobium officinale. The method comprises the following steps: removing leaves of picked dendrobium officinale, and washing; precooling, disinfecting and sterilizing the washed dendrobium officinale; draining the disinfected and sterilized dendrobium officinale in an aseptic condition, performing aseptic packaging, and refrigerating. According to the method for preserving dendrobium officinale, the preservation period of the dendrobium officinale can be prolonged to over 6 months, the original ingredients, color and crispness can be effectively maintained, the weight loss ratio is low, and the commercial value of the dendrobium officinale can be guaranteed. Furthermore, the method cannot generate harmful substance residues, and is environment-friendly.

Owner:广南县凌垭原生铁皮石斛科技有限公司

Atomization assisting CVD thin film deposition method

ActiveCN109440083AAdjust gas atmosphereAdjust the atmosphereLiquid/solution decomposition chemical coatingChemical vapor deposition coatingGas phaseRoom temperature

The invention discloses an atomization assisting CVD thin film deposition method. The atomization assisting CVD thin film deposition method is characterized by comprising the following steps that a, an atomization assisting CVD thin film deposition device is designed; b, a plane substrate being about to form a film is placed in an installing hole in a substrate template, then the substrate template is horizontally placed on the upper plate face of a lower lifting plate, and the position of the lower lifting plate is adjusted; d, after a temperature of a reaction area reaches a preset temperature, firstly an atomization source is opened, and is used for atomizing liquid precursors into aerosol precursors, the aerosol precursors are input into a buffering mixing chamber through carrier gas sent out of the atomization source; and e, after the temperature of the reaction area is close to a room temperature or is 45 DEG C or below, the operation that the precursors are input into the buffering mixing chamber through a gas phase matter inflow pipe and an aerosol inflow pipe firstly stops, then a gas sucking pump is closed, finally, a sealing cover is opened, the substrate template is taken out, and finally a substrate is taken down from the substrate template. The thin film deposition method is high in deposition efficiency, reasonable in process arrangement and high in thin film quality.

Owner:CHONGQING UNIV OF TECH +1

Fully-natural plant anti-allergy repair essence and preparation method thereof

PendingCN110974763AImprove allergiesKeep dryCosmetic preparationsToilet preparationsBiotechnologySeparation technology

The invention discloses a fully-natural plant anti-allergy repair essence. The fully-natural plant anti-allergy repair essence comprises the following raw materials: herba portulacae, radix stephaniaetetrandrae, liquorice roots, cactus, oat, herba centellae, herba taraxaci, aloe and essential oil. According to the invention, no chemical component is added, so a formula of the essence is reasonable and environment-friendly; active ingredients in each plant are extracted by adopting a supercritical extraction method, an efficient high-pressure-difference low-temperature continuous extraction and separation technology or a film evaporation and concentration method; and the raw materials are extracted at a low temperature and converted into essence which can be applied, so effective components in the raw materials are kept, the natural activity of plants is given to play and permeates into the skin, and the problems of skin allergy, dryness, elasticity loss and the like are improved.

Owner:广州重生化妆品实业有限公司

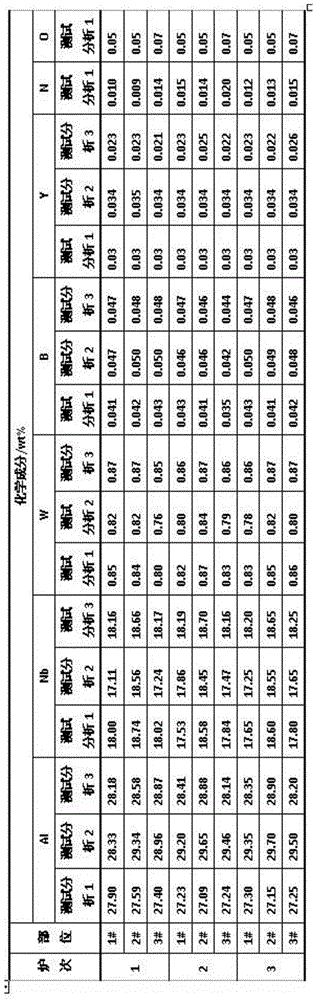

Aluminum-tungsten-niobium three-element intermediate alloy and preparation method thereof

The invention discloses an aluminum-tungsten-niobium three-element intermediate alloy which comprises the following components in percentage by weight: 25-40wt% of W, 20-35wt% of Nb, 0-0.3wt% of microelements and the balance of Al. The invention further discloses a preparation method of the intermediate alloy and a method for preparing a high Nb-TiAl intermetallic compound cast ingot by using the intermediate alloy. By adopting the alloy disclosed by the invention, the phenomenon that the melting current is unstable due to inconsistency of metal single substances in of the melting point is avoided in the intermetallic compound melting process, and the stability of the melting process is improved, and the probability that high-melting-point refractory elements Nb and W form a severe high-density inclusion and segregation defect is effectively reduced, so that the components and uniformity of the high-melting-point refractory element titanium aluminum intermetallic compound are guaranteed due to the invention and application of the intermediate alloy.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

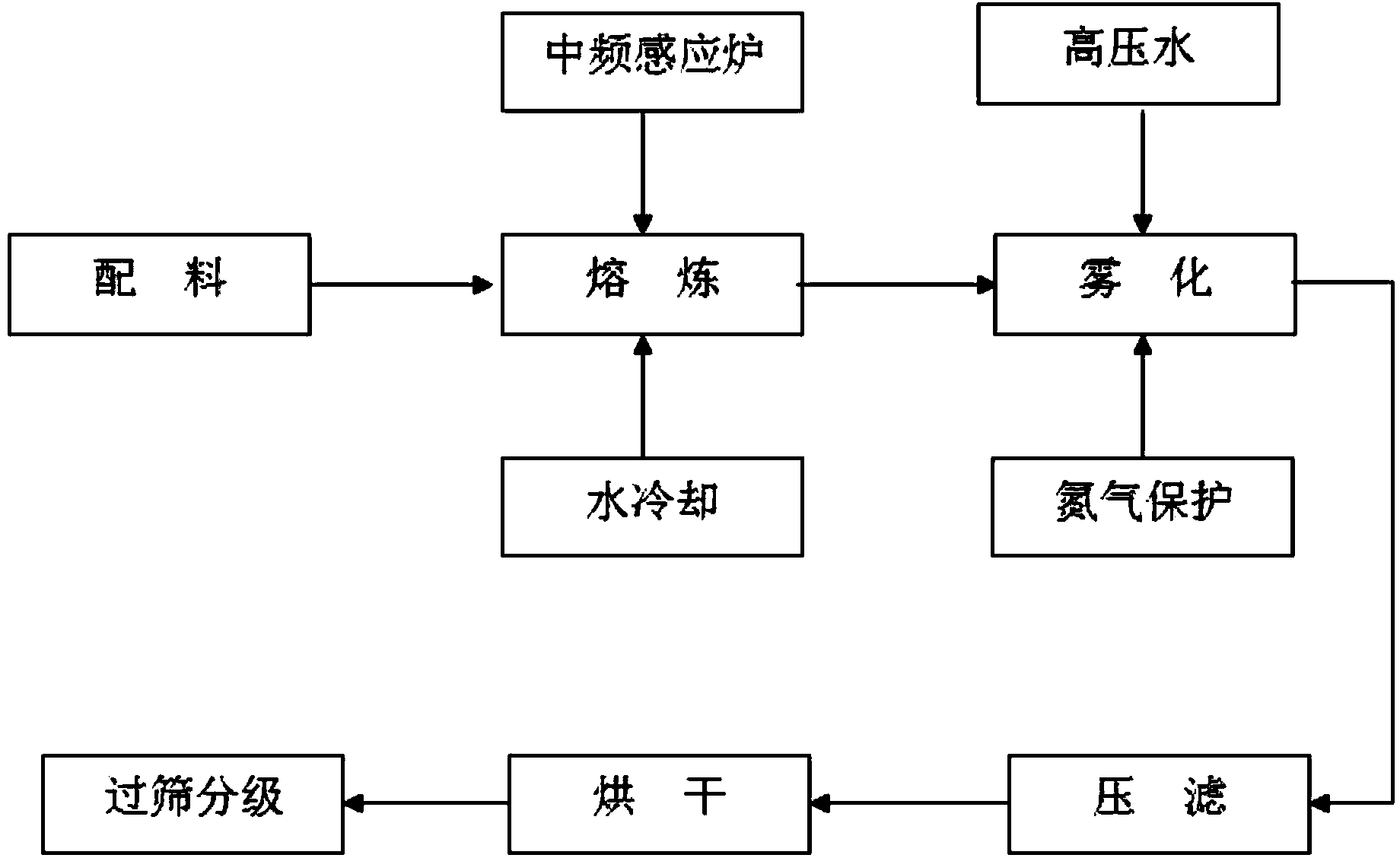

Nickel alloy powder atomization manufacturing process and equipment thereof

Owner:SHANDONG JINSHENGLONG MACHINERY

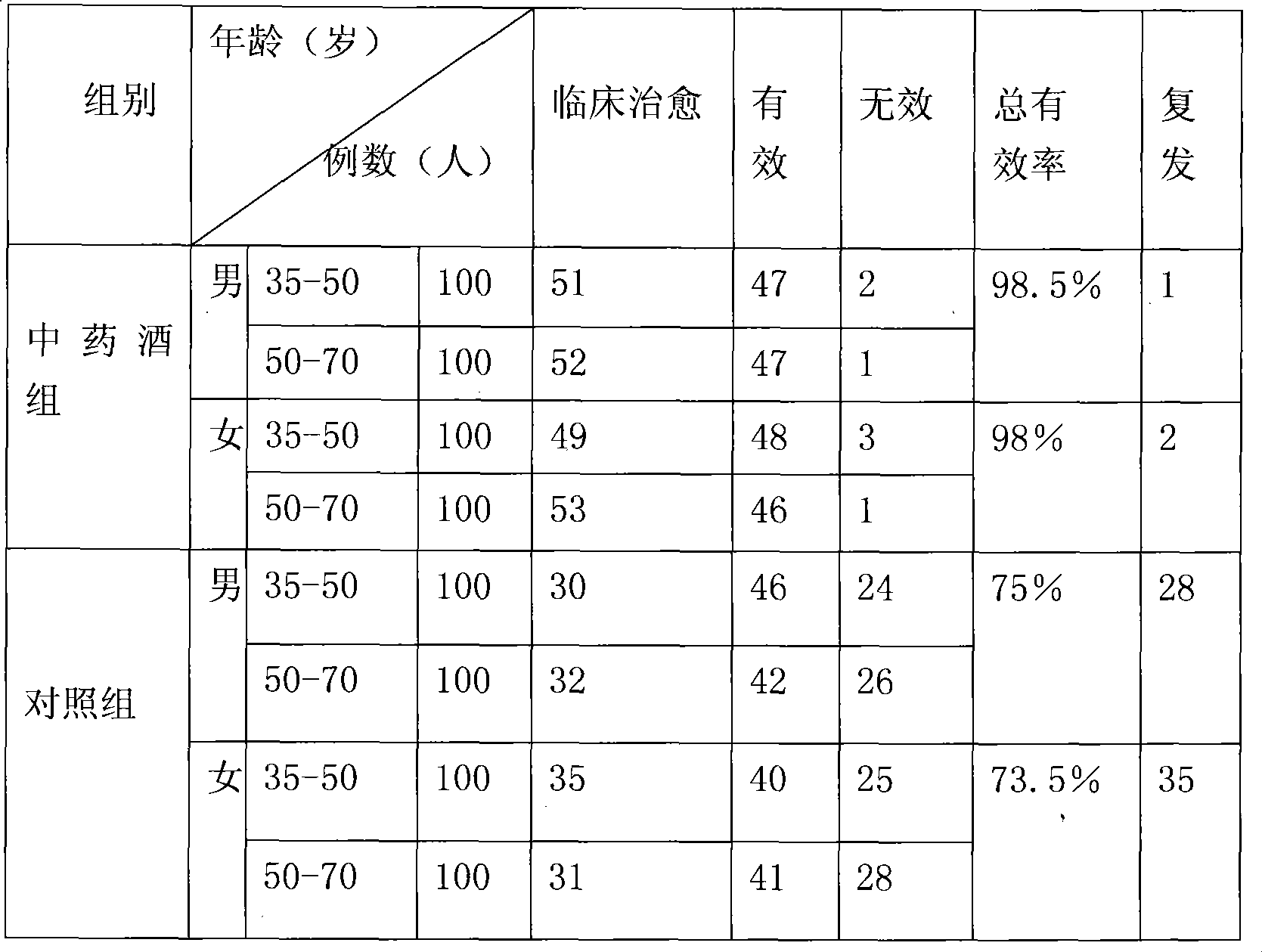

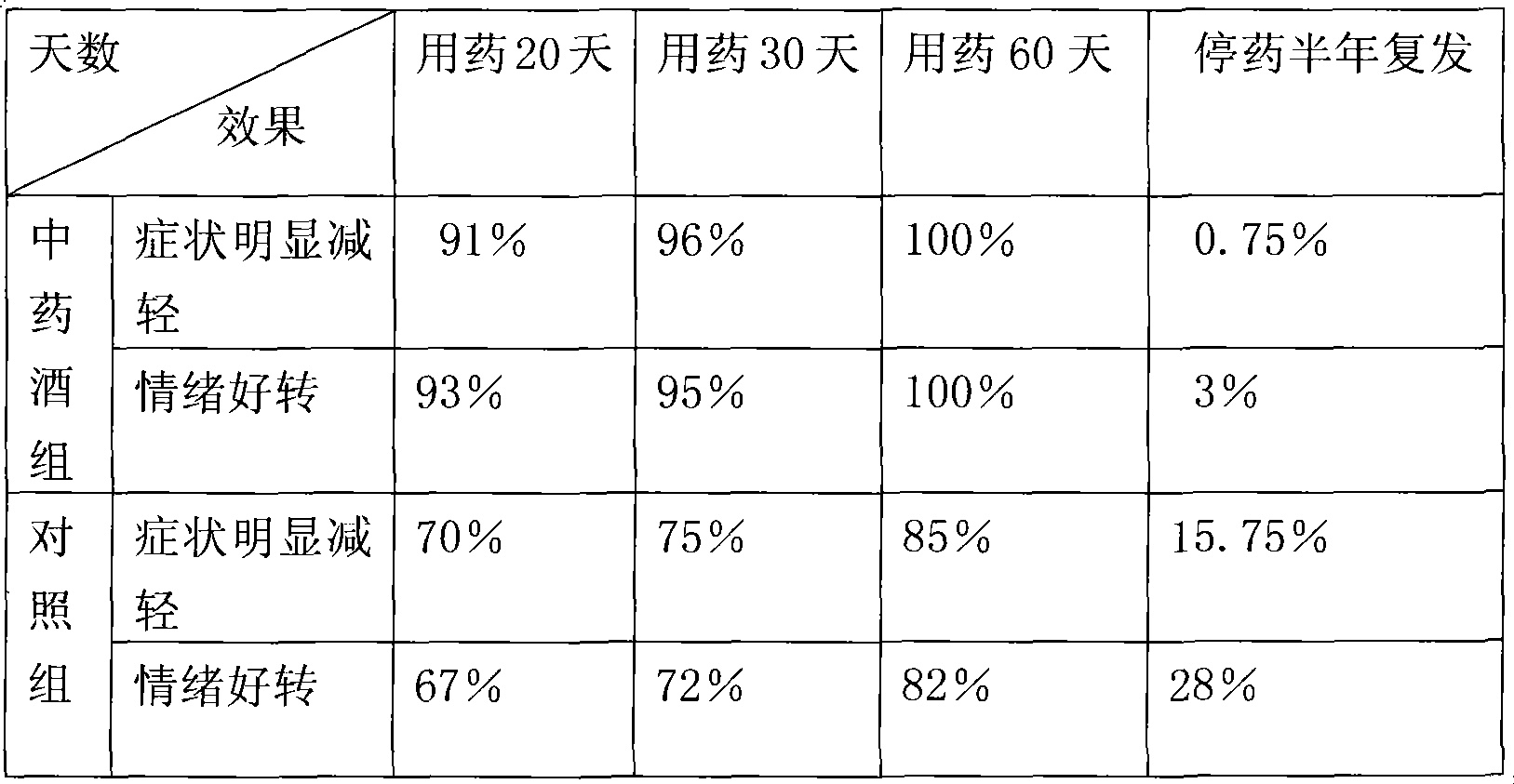

Medicinal wine capable of treating and reinforcing weaked body and building up health and preparation method thereof

InactiveCN101380394AGuaranteed maximum dissolutionMaintain biological activityAnthropod material medical ingredientsAntipyreticDiseaseSaposhnikovia

The invention discloses medicated wine which can be used for treating diseases, tonifying the deficiency and strengthening the body and a preparation method thereof. The medicated wine is prepared from the crude drugs with the parts by weight as follows: 20 to 30 parts of herba cistanches, 25 to 35 parts of cornu cervi pantotrichum, 0.5 to 2 parts of cordyceps sinensis, 15 to 30 parts of saussurea involucrate, 20 to 30 parts of crocus sativus, 20 to 30 parts of divaricate saposhnikovia root, 1.5 to 3.5 parts of lucid ganoderma spore, 45 to 60 parts of fructus lycii, 40 to 60 parts of exocarpium citrulli, 30 to 45 parts of fructus arctii, 4 to 12 parts of hippocampi, 15 to 25 parts of silky ant, 10 to 20 parts of male silk moth and the residual amount of white spirit. From the respect of considering the whole human body, the composing prescription of the oral medicated wine uses drugs dialetically, addresses both the symptoms and root causes, can bilaterally regulate the balance of human body function, motivates internal vitality of the body, regulates the human metabolic function, enhances the immunity of human and has obvious effects of supporting healthy energy to eliminate evils and promoting the functions of all viscera or organs to be normalized.

Owner:LIAOCHENG UNIV

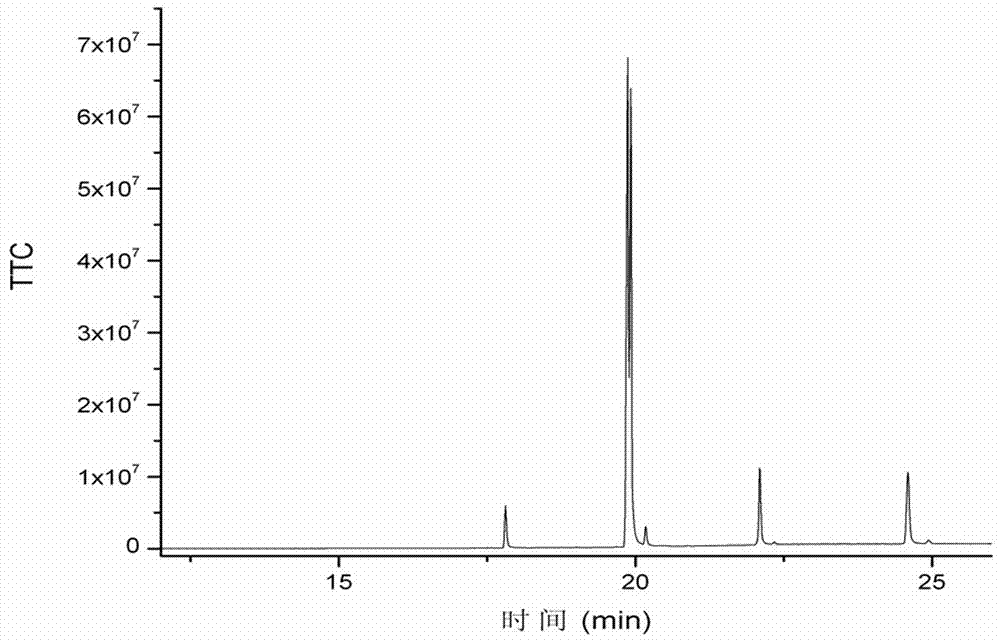

Method for preparing shiny-leaved yellowhorn kernel oil by adopting ultrasound-assisted salt process

ActiveCN103087817AGuaranteed ingredientsFull of nutritionFatty-oils/fats productionEdible oils/fatsMedicineBiochemical engineering

The invention discloses a method for preparing shiny-leaved yellowhorn kernel oil by adopting the ultrasound-assisted salt process and belongs to the field of food and healthcare food. The method comprises the following steps of: freezing and drying shiny-leaved yellowhorn kernels as raw materials at low temperature in vacuum, pulping, mixing pulps, extracting by promoting dissolving by adopting the ultrasound-assisted salt process, and centrifuging at high speed to obtain the high-quality shiny-leaved yellowhorn kernel oil. Because the shiny-leaved yellowhorn kernels are frozen and dried at low temperature in vacuum, the original components of the shiny-leaved yellowhorn kernels are protected from damage. Because the technology of extracting by promoting dissolving by adopting the ultrasound-assisted salt process is used for demulsifying, the oil can be extracted to the maximum extent, high oil yield can be achieved, and the problem of serious common water extraction and emulsification can be solved. Because the ultrasound-assisted salt process is used for extracting, the extracting cycle can be shortened, the energy consumption can be reduced, and high efficiency can be achieved. The method has the advantages that the reaction condition is mild, and the extracting process is environment-friendly.

Owner:NORTHWEST NORMAL UNIVERSITY

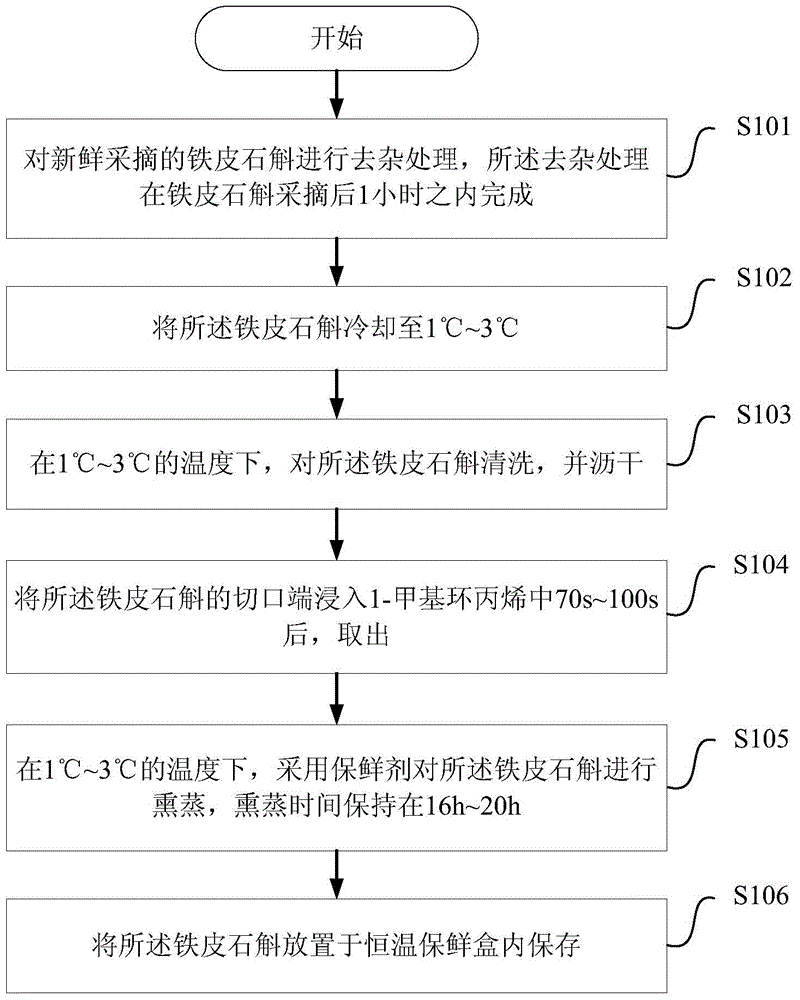

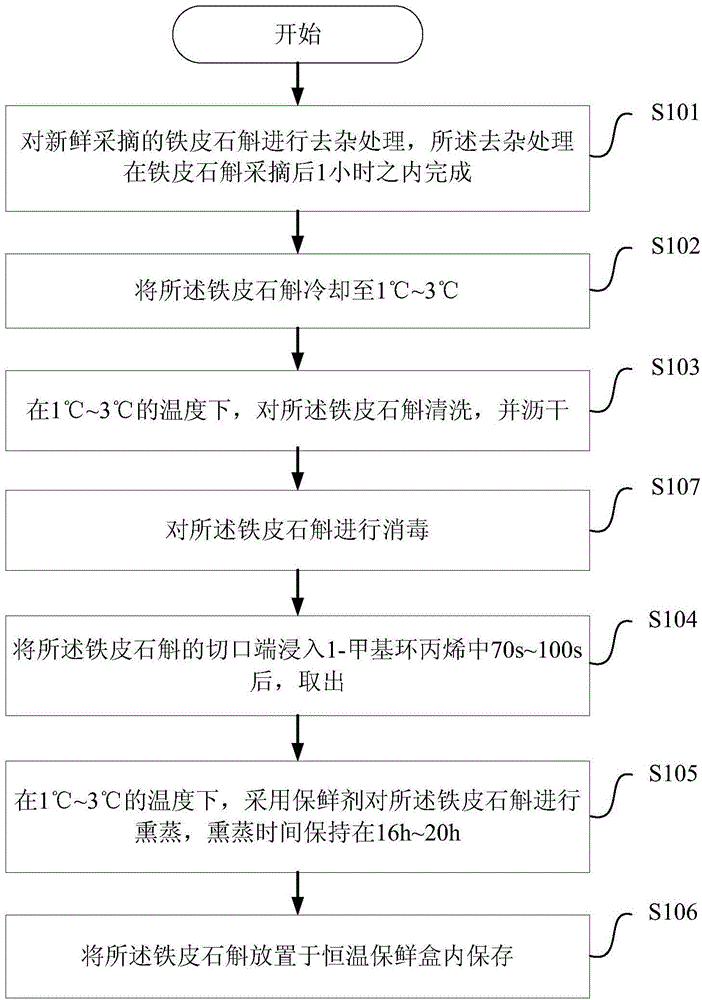

Preservation method of dendrobium officinale

InactiveCN105309421AGood fresh-keeping effectImprove the preservation effectDead plant preservationPreservative1-Methylcyclopropene

The invention discloses a preservation method of dendrobium officinale. The preservation method includes the following steps that after being picked, the fresh dendrobium officinale is subjected to impurity removal treatment, wherein impurity removal treatment is completed within 1 h after the dendrobium officinale is picked; the dendrobium officinale is cooled to 1 DEG C-3 DEG C; the dendrobium officinale is cleaned at 1 DEG C-3 DEG C and then drained off; the cut end of the dendrobium officinale is dipped in 1-methylcyclopropene for 70 s-100 s and then taken out; the dendrobium officinale is fumigated through a preservative at 1 DEG C-3 DEG C, wherein fumigation time is kept within 16 h-20 h; the dendrobium officinale is placed in a constant-temperature preservation box to be preserved. The preservation method is good in preservation effect, long in preservation time, easy to implement and low in cost.

Owner:周继南

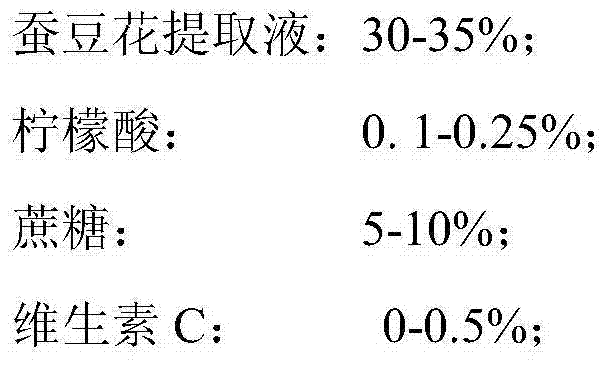

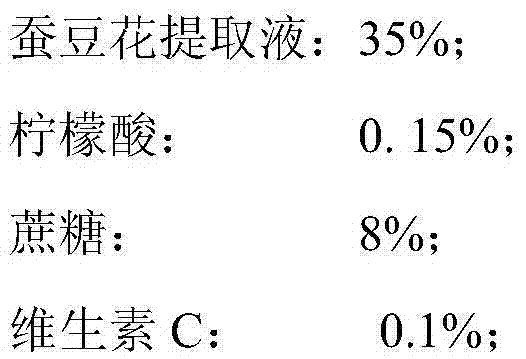

Broad bean flower health beverage

The invention discloses broad bean flower health beverage. The broad bean flower health beverage is prepared from the following components in weight percentage: 30-35% of broad bean flower extracting solution, 0.1-0.25% of citric acid, 5-10% of saccharose, 0-0.5% of vitamin C and the balance of water, the sum of all components is 100%; according to the broad bean flower extracting solution, broad bean flowers are used as raw materials and are extracted to obtain primary extraction solution by adopting an ultrasonic extraction method, then the primary extraction solution is separated and purified by adopting the membrane separation technology, so that impurities such as higher molecular weight proteins and polysaccharide are removed and a broad bean flower extracting solution is acquired. According to the broad bean flower health beverage, only citric acid is adopted to adjust the acidity of the beverage, saccharose is utilized to adjust the sweetness, vitamin C is used for adjusting the sourness, the formulation is scientific and is rich in amino acid, triterpenoid saponin, flavone, anthocyanin and the like; and the broad bean flower health beverage can be taken conveniently, has acid mouthfeel, has broad bean flower scent, and also has the effect of preventing and controlling Parkinson's disease.

Owner:CROP RES INST OF FUJIAN ACAD OF AGRI SCI

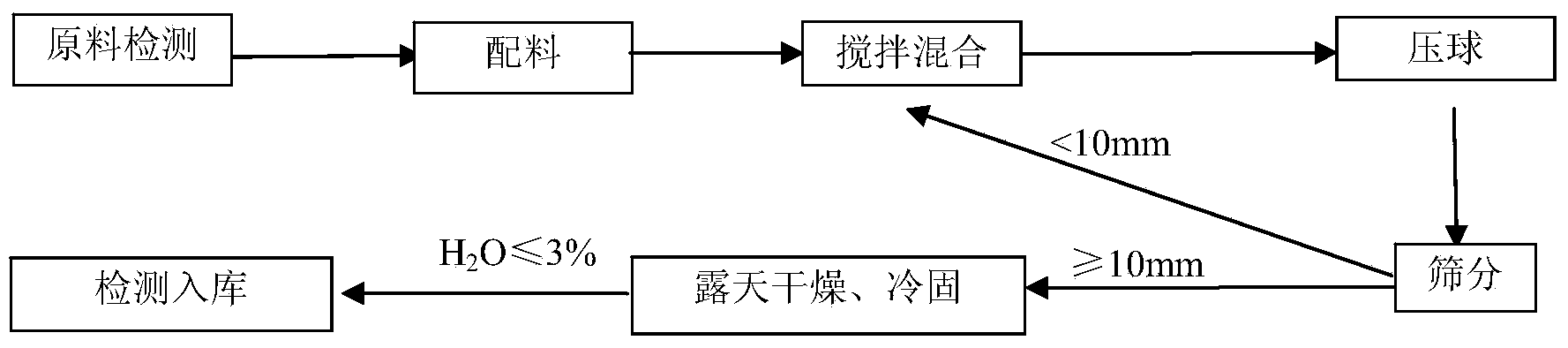

Iron-rich cooled agglomerated pellet and manufacturing technology and purpose of iron-rich cooled agglomerated pellet

ActiveCN103627897AGuaranteed StrengthGuaranteed ingredientsManufacturing convertersManufacturing technologySlag

The invention belongs to the technical field of comprehensive resource utilization and relates to an iron-rich cooled agglomerated pellet, and a manufacturing technology and a purpose of the iron-rich cooled agglomerated pellet. The invention aims at providing the manufacturing technology of the iron-rich cooled agglomerated pellet, which has the advantages of good pelletizing performance, strong knock resistance, improved pulverization situation and high metallic iron yield. The manufacturing technology comprises the steps of (1) predrying, (2) mixing, (3) pelleting, and (4) natural drying. The key improvements of the technology are (1) selection of a binding agent and (2) a natural airing mode. The iron-rich cooled agglomerated pellet prepared by the technology can be used for replacing scrap steel to be applied to a steel converter for smelting. After enrichment sludge replaces the scrap steel, the heat adjustment of the converter is more flexible in comparison with the scrap steel, a slag state in a process is good, slag comes fast, dephosphorization and desulfuration effects are stable, and the total iron yield is 89.29% and reaches an expected level. Compared with the scrap steel, the production technology is superior, and the price is lower.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

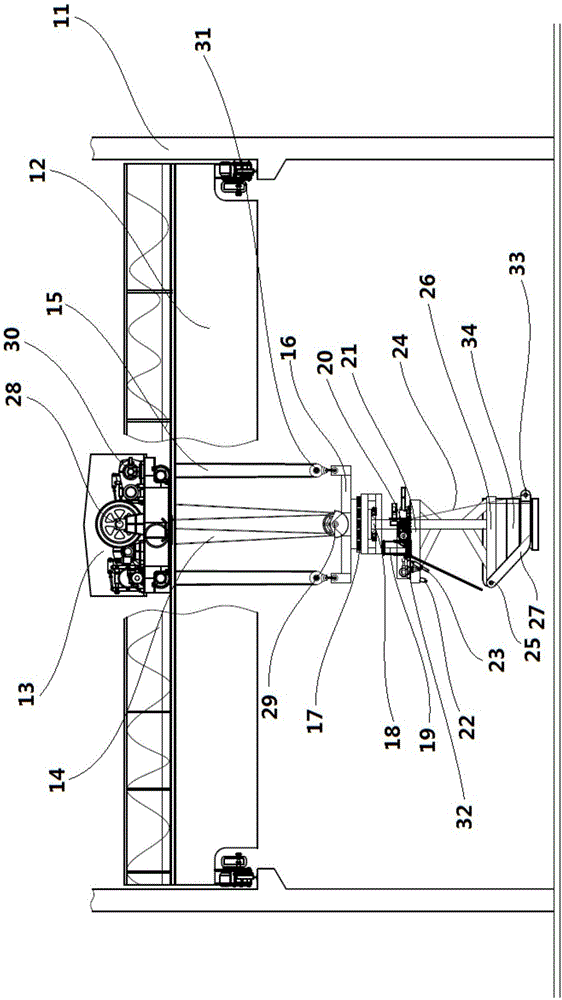

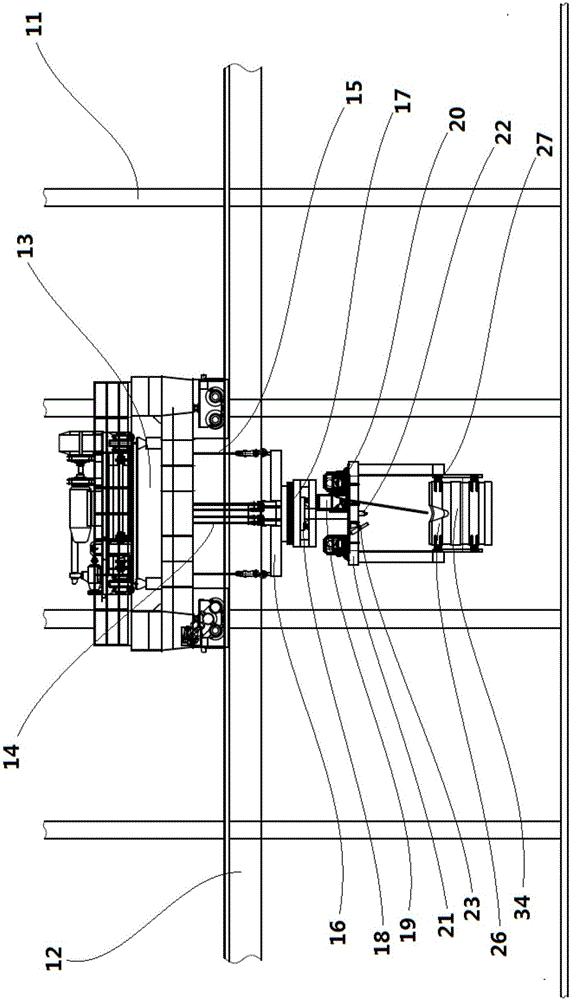

Beam type full-automatic casting machine

ActiveCN106312031APrecise positioningAccurate horizontal positioningMolten metal supplying equipmentsCasting parameters measurement/indication devicesEngineeringMechanical engineering

The invention provides a beam type full-automatic casting machine. The beam type full-automatic casting machine comprises a support, a large crane mechanism movably arranged on the support, a small crane mechanism movably arranged on a cross beam of the large crane mechanism, a lifting system, a slewing mechanism arranged at the bottom of the lifting system, a weighing mechanism arranged on the slewing mechanism, a tilting mechanism arranged on the weighing mechanism, a ladle frame arranged on the titling mechanism and a tilting frame which is driven by the tilting mechanism and can pivot relative to the ladle frame, wherein the top of the lifting system is arranged on the small crane mechanism, and a machine frame of the tilting mechanism is provided with a stream inoculation device, a temperature measuring system and a video system. The beam type full-automatic casting machine can achieve fixed-point quantitative constant-speed high-quality casting.

Owner:NINGXIA KOCEL MOLD

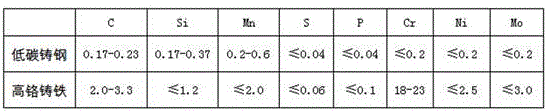

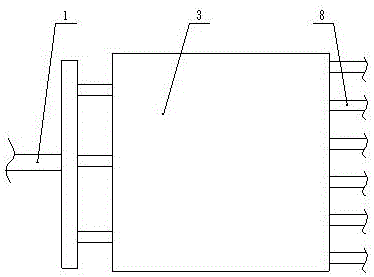

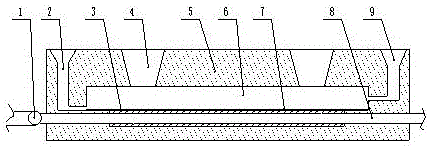

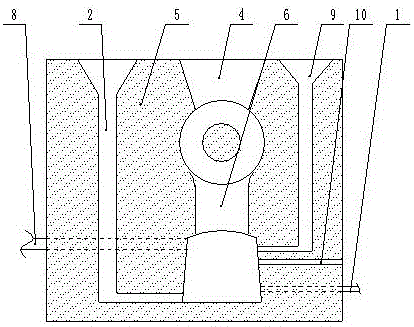

Double-fluid composite iron-based bimetal casting method

InactiveCN106623862AImprove yieldWide range of process parametersFoundry mouldsFoundry coresCarbon steelChiller

The invention discloses a double-fluid composite iron-based bimetal casting method. The melting point of metal of a first layer is not lower than that of metal of a second layer; after the metal of the first layer is poured, a low-carbon steel chiller is used for fast cooling; after cooling is conducted to obtain a certain temperature, the metal of the second layer is poured, and the pouring temperature of the metal of the second layer is not lower than the melting point of the metal of the first layer; and fusion of the metal of the two layers is ensured. Due to the fact that the chiller fast cooling method is adopted, the fusion amount of the metal of the first layer is reduced, components of the metal of the second layer are ensured, and a bimetal composite workpiece with metallurgical bonding is obtained. According to the technological method, the fusion amount of the metal of the first layer is reduced, the components obtained after fusion of the metal of the second layer are ensured, the double-fluid composite qualification rate is increased, and industrial mass production is facilitated.

Owner:邢振国

Method for manufacturing bi-metal composite material by pouring two layers of molten metal with cooling speed adjustable

The invention discloses a method for manufacturing a bi-metal composite material by pouring two layers of molten metal with the cooling speed adjustable. The method comprises the steps that after the first layer of molten metal is poured, water is introduced into a chiller for cooling, and the cooling speed of the first layer of molten metal is adjusted by adjusting the pressure and flow of the cooling water in the chiller or controlling the introduction time of the cooling water; and the second layer of molten metal is poured at the high temperature so that the first layer of molten metal can be fully fused by the second layer of molten metal, due to the fact that controlled cooling measures are taken for the first layer of molten metal, fusion of the first layer of metal achieved through the second layer of metal is guaranteed, superfusion is also prevented, constituents of the second layer of metal are guaranteed, and the bi-metal composite material acquired through metallurgical bonding is obtained. By means of the process method, the qualification rate of composting of the two layers of molten metal is greatly increased; process parameters are simplified; and industrialized production can be conducted conveniently.

Owner:邢振国

Health-care beverage capable of invigorating stomach and promoting digestion and making method thereof

InactiveCN105851740AGuarantee statusGuaranteed ingredientsVinegar preparationFood scienceSide effectDigestion

The invention discloses a healthy drink for invigorating the stomach and eliminating food and a preparation method thereof. The raw materials are tangerine peel, dried hawthorn, fresh yam, apple vinegar, erythritol, honey, xylitol, sweetener and water. The preparation method adopts different processing methods according to the different properties of the raw materials tangerine peel, dried hawthorn, fresh yam, and apple vinegar. The health drink of the present invention is a light red liquid, which integrates the fragrance of medicine and fruit vinegar, has pure fragrance, no peculiar smell, sweet and sour taste, has a certain effect of invigorating the stomach and eliminating food, has no toxic and side effects, and meets the requirements of the State Food and Drug Administration. Regulations related to functional health care.

Owner:河南省淼雨饮品股份有限公司

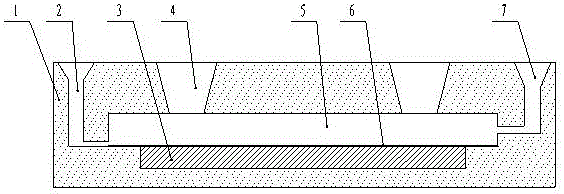

Production process for special-shaped silver-copper busbar and special-shaped silver-copper busbar

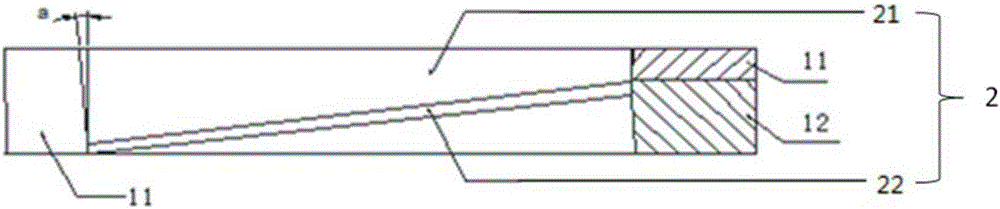

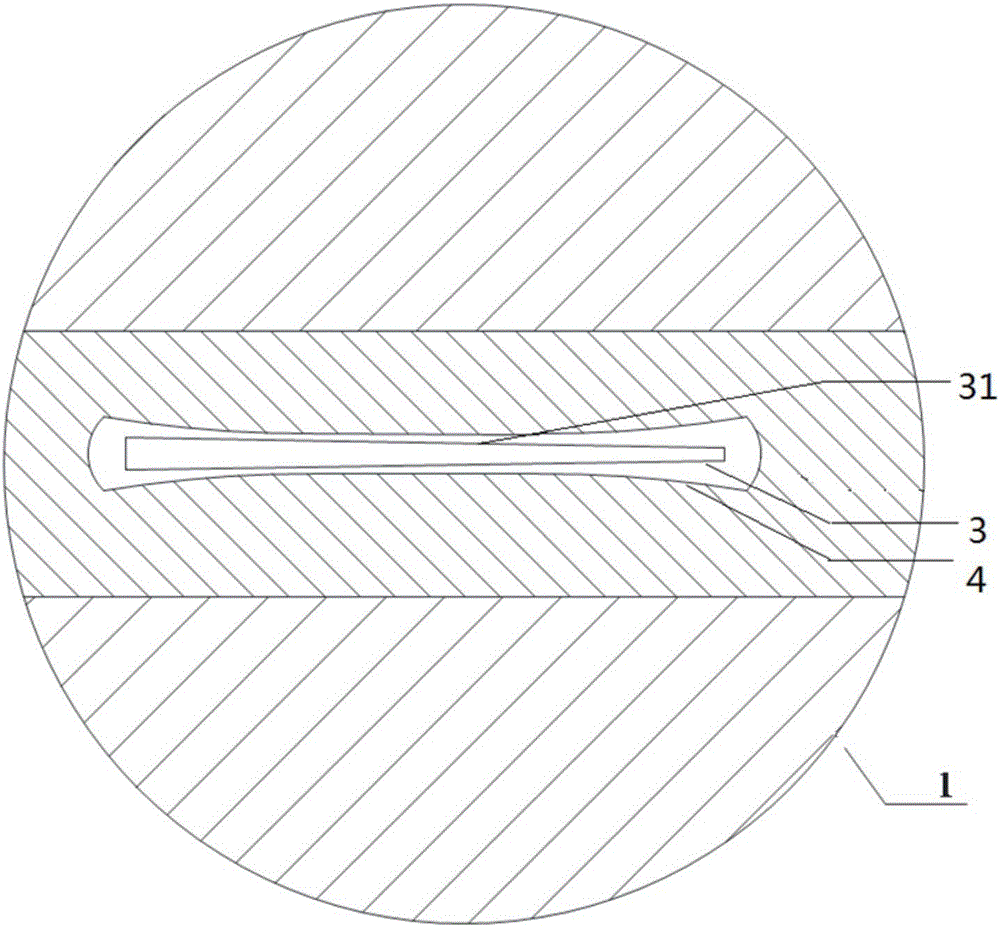

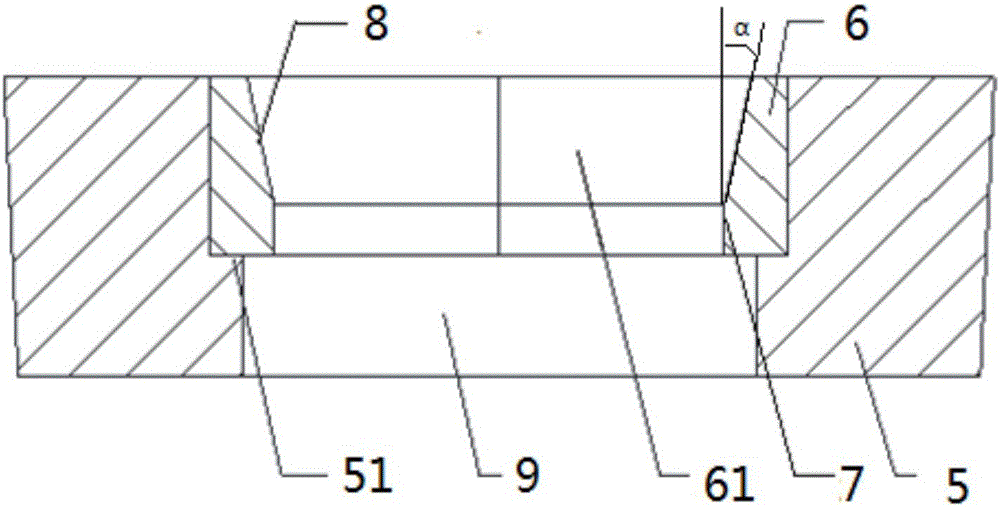

ActiveCN105032972AGuaranteed accuracy and mechanical propertiesGuaranteed uniformityDrawing diesExtrusion diesBusbarSilver copper

The invention provides a production process for a special-shaped silver-copper busbar and the special-shaped silver-copper busbar. In the step of conducting continuous extrusion on a silver-copper alloy rod so as to manufacture a special-shaped silver-copper alloy busbar blank, a sizing belt 22 of an extrusion die 1 which is adopted is in a protruding shape, and the portion, located on the central area of the die, of the sizing belt 22 is bent outwards in the radial direction to form an arc-shaped outwards-protruding part 31. After a whole base body of the die deforms inwards through high temperature and high pressure, the inward deformation range of the central area is the maximum, and therefore the central area is designed into the arc-shaped protruding part, the size of the central area can be large than that of the two sides, the whole area of an outlet can more tend to the straight state, copper products can evenly flow in the deformation process, straightness of appearance of extruded products coming out of the outlet is ensured, and accuracy of the extruded products and uniformity of the mechanical property are ensured.

Owner:JIANGXI GUANGXIN COPPER IND

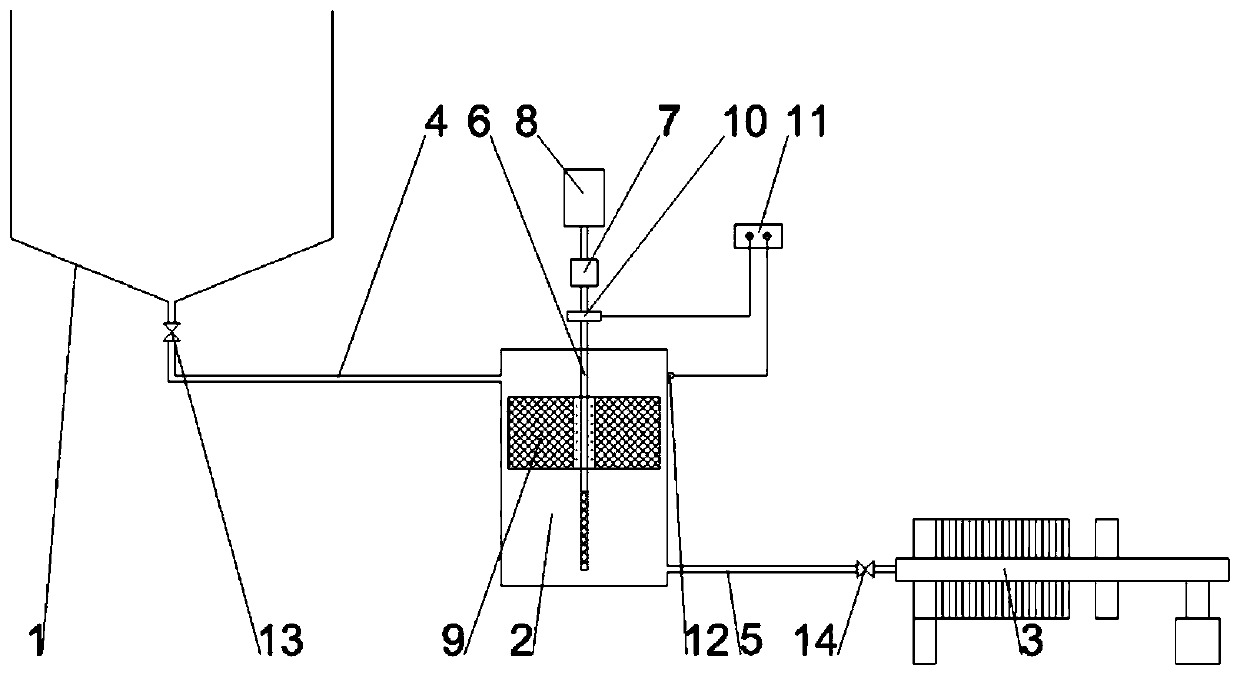

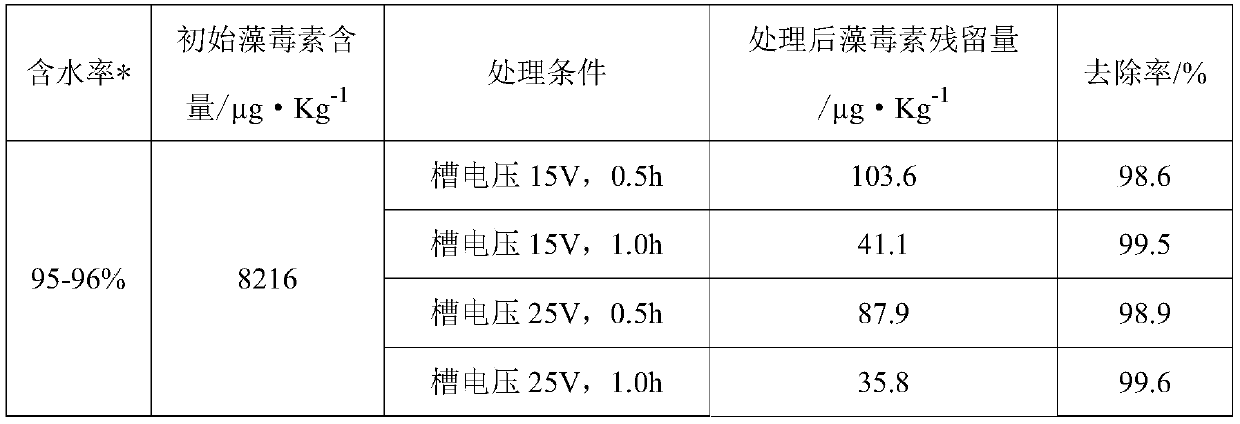

Method for electrochemical detoxification and deep dehydration of blue-green algae liquid

ActiveCN109912083AConducive to deep resource utilizationImprove degradation efficiencyMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processElectrochemical responseHigh pressure

The invention discloses a method for electrochemical detoxification and deep dehydration of a blue-green algae liquid. The method comprises the following steps: the blue-green algae liquid is put intoa primary sedimentation tank for preliminary standing and layering and flows into an electrochemical reactor; the cell voltage of the electrochemical reactor and the rotating speed of a stirrer are set, the electrochemical reactor and the stirring function of the electrochemical reactor are started, blue algae cells are subjected to wall breaking dehydration under the action of an electric fieldand mechanical stirring of an anode, algal toxins released by blue-green algae are continuously oxidized and degraded by hydroxyl radicals generated in the electrochemical reactor, and the processes of wall breaking dehydration and toxin removal of the blue-green algae are completed; the blue-green algae liquid flows into a high-pressure filter press device for deep dehydration, and finally blue algae mud cakes are obtained. According to the method, efficient dehydration of the blue-green algae and efficient degradation of the algal toxins are realized, the method is simple and controllable inoperation, the problems of algal toxin degradation, deep dehydration and inhibition of secondary pollution in the dehydration process in the blue-green algae recycling process are effectively solved,no chemical substances are added, and a solid foundation is laid for deep recycling of the blue-green algae.

Owner:HOHAI UNIV

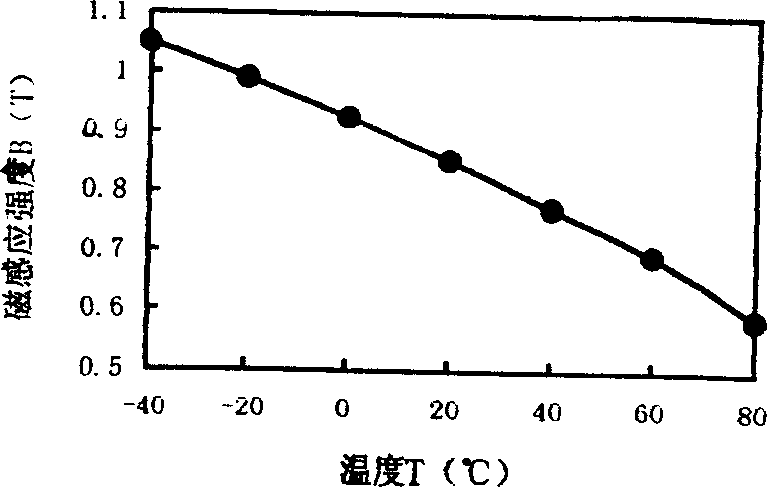

High magnetic induction wide temperature interval linear magnetic temperature compensating alloy and production process thereof

The invention relates to a highly magnetic induction, linear magnet-temperature compensation alloy with broad temperature regioand its production process. The alloy components in percent are as follows: Ni 31.5-32.5%, Mn<=0.4%, Si<=0.3%, C 0.10-1.50%, surplus Fe. The production process is: first adopting vacuum induction melting then casting to make electrode bar, then electroslag remelting it to cast ingot, heating to 1100-1150 DEG C, hot forging hot-rolled sheet blank, heating to 1050 DEG C-1100 DEG C, hot-rolling to sheet, 1050 DEG C-1100 DEG C heat treatment, acid cleaning, cold rolling and obtaining band of finished product thickness, after processing element, using after final ageing treatment 1-2 hours in vacuum heat treatment furnace under 400 DEG C-500 DEG C. The inventive alloy has a wider usage temperature range, temperature point for testing is more than before, and B-t linearity is well, so the inventive alloy surpass the existing FeNi magnet compensation alloy in usage temperature range and magnet compensation ability.

Owner:CHONGQING MATERIALS RES INST

Vertical liquid stirrer

ActiveCN108452714APrevent precipitationGuaranteed ingredientsShaking/oscillating/vibrating mixersFlow mixersSuction forceEngineering

The invention discloses a vertical liquid stirrer. The vertical liquid stirrer comprises a stirring tank, and a liquid inlet hopper and a liquid discharging pipe are communicated with the two sides ofthe stirring tank respectively. The structure is simple; rod sleeves primarily stir liquid; under the action of first springs and arc-shaped blocks, double-sided racks move back and forth and are meshed with sector gears to drive swing rods and second cylinders to swing, so that the swing rods rotate around rotating shafts, the liquid is stirred for the second time, and the second cylinders swing; under the action of second straight rods and third straight rods, second pistons move back and forth; under the action of a suction force, the liquid enters and flows out of the second cylinders andis further mixed. At the same time, the rotating shafts drive first cylinders to rotate. Under the action of second springs and elliptical blocks, first straight rods and first pistons move back andforth, so that the liquid enters and flows out of the first cylinders and is sprayed out from second nozzles to impact the bottom of the stirring tank, the liquid is prevented from depositing at the bottom of the stirring tank, and compositions of the liquid are ensured.

Owner:南通万创混合设备有限公司

Preservation method of dendrobium officinale

ActiveCN105746497AMaintain commodity valueGuaranteed ingredientsDead plant preservationPreservativePreservation methods

The invention discloses a preservation method of dendrobium officinale. The method comprises the following steps: (1), washing picked fresh dendrobium officinale with water at 1 to 4 DEG C, and then cooling the dendrobium officinale to be 0 to 2 DEG C; (2), laying the cooled dendrobium officinale into a preservative at 1 to 4 DEG C, so as to perform soaking treatment on the dendrobium officinale; (3), draining off the soaked dendrobium officinale at 30 to 60 DEG C; (4), performing sealed package on the drained dendrobium officinale, and then storing the dendrobium officinale at 0 to 20 DEG C. The method can effectively keep the original components, color and brittleness, ensures low weight loss ratio, and guarantees the commodity value of dendrobium officinale; the preservation effect is good, the preservation time is long, the method is simple to operate, and the cost is low.

Owner:ANHUI SHANZHENCANG ECOLOGICAL AGRI CO LTD

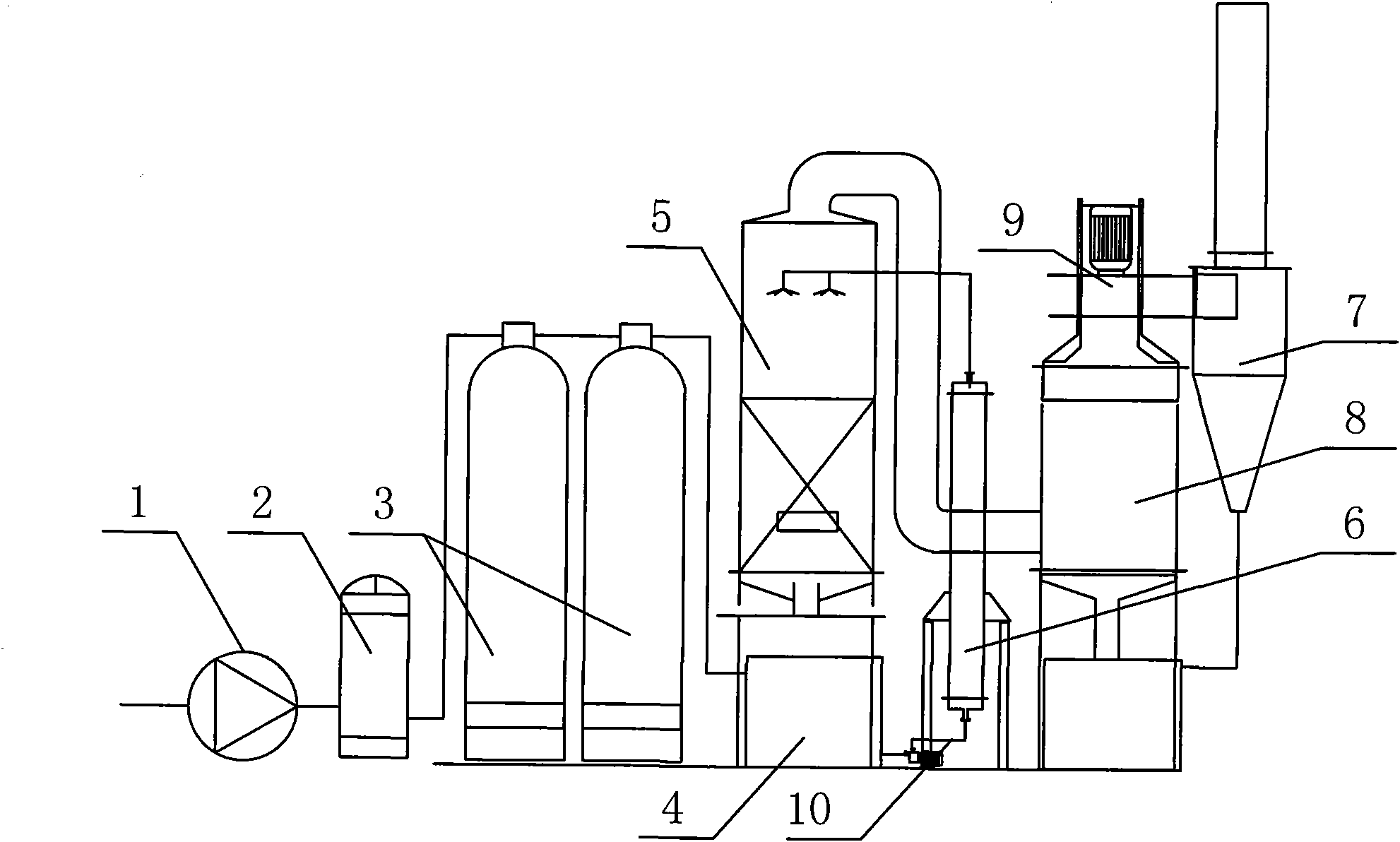

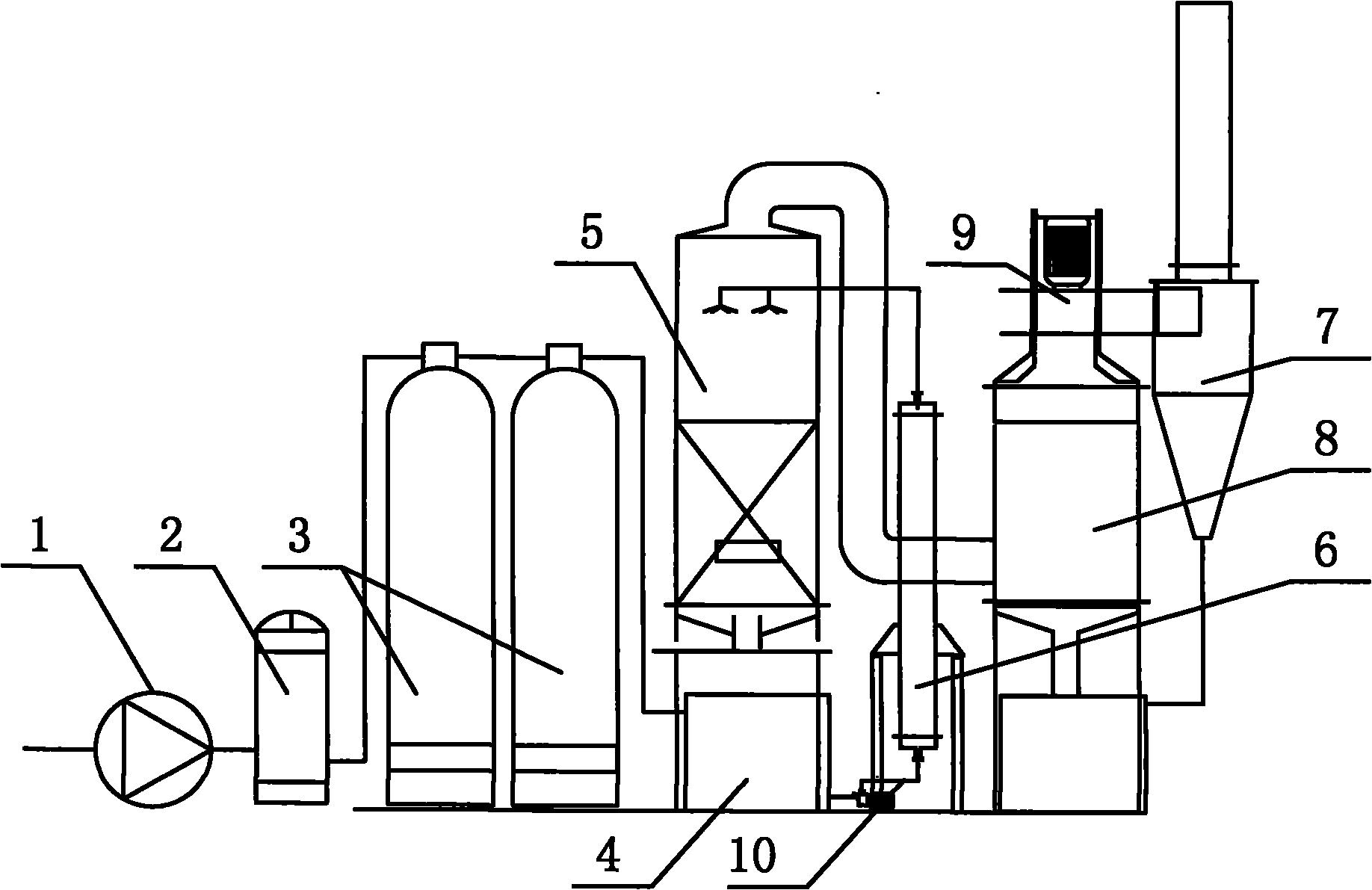

Treatment device of chromium aging liquid

The invention discloses a treatment device of chromium aging liquid, which comprises a conveying pump, a ceramic filter, an adsorber, a liquid storage tank, an evaporator, a heat exchanger and a separator. The aging liquid is conveyed into the ceramic filter via the conveying pump for filtering out suspended matters and micro-particles in solution after being diluted with pure water, then flows into the adsorber for adsorbing and filtering out cations in the solution, is evaporated to the required concentration via the evaporator and is further directly added into a plating bath. The device can carry out circulating treatment on electroplating solution of a production line, effectively remove impurities, such as Fe2 plus, Cr3 plus and the like in the solution, keep the performance of the electroplating solution to be stable for a long time and not age or emit the aging liquid. The treatment device can save raw materials and reduce the treatment cost of pollutants.

Owner:无锡出新环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com