Laser spectroscopy induced component detection system

A detection system, laser light source technology, applied in the direction of material excitation analysis, spectrum investigation, etc., can solve the problems of no patent protection content, etc., to achieve the effect of reducing smelting costs, simplifying the detection process, and improving the detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

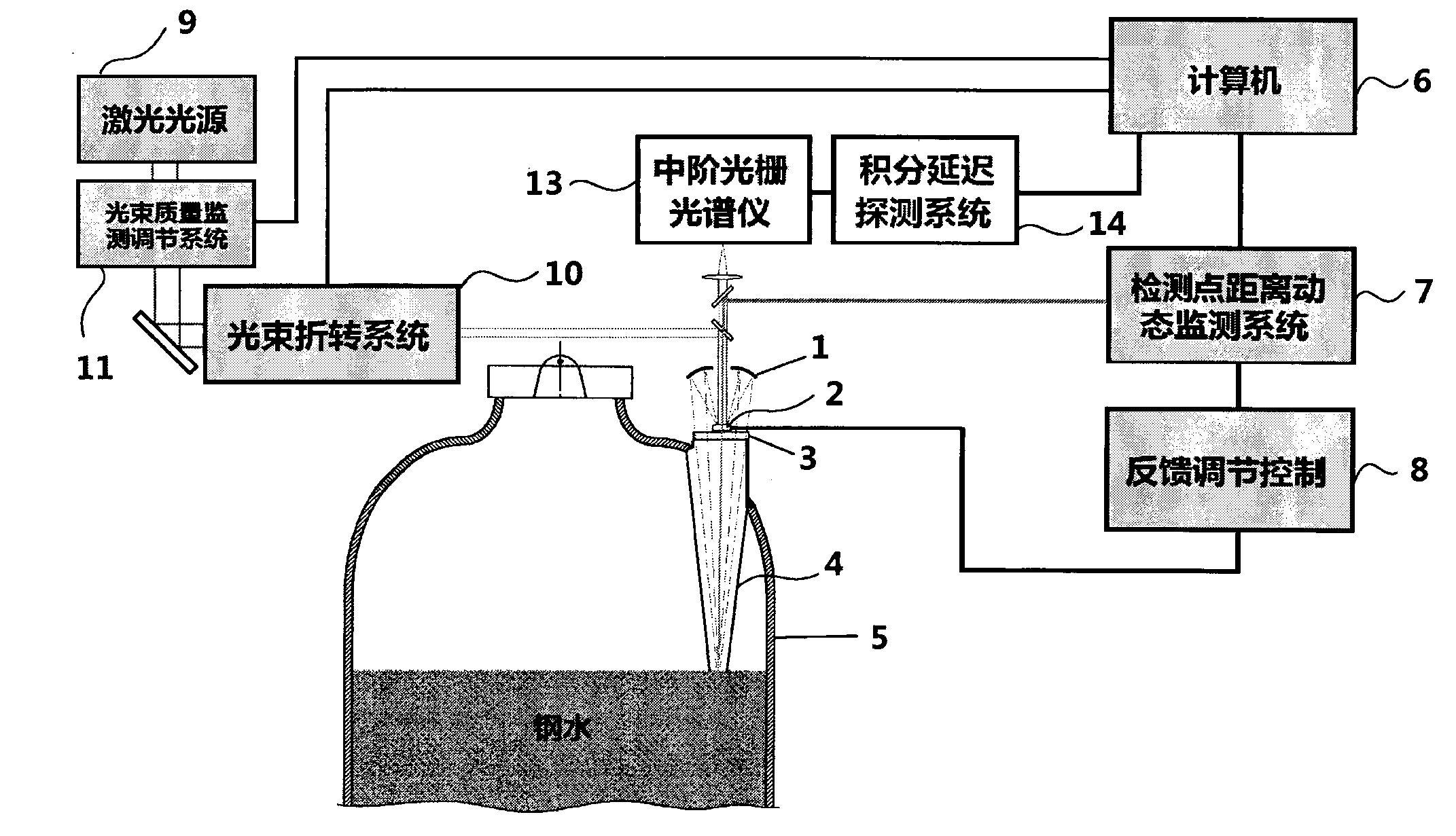

[0031] refer to figure 1 , making a laser spectrum induced on-line molten steel composition detection system. The concave mirror 1 of the system is a concave spherical focusing mirror with a diameter of 200 mm; the convex mirror 2 is a high reflection mirror made of metal; the window mirror 3 is a flat transparent film made of quartz glass, coated with Anti-reflection coating for detection and excitation of laser wavelengths; casing 4 is a protective pipe made of ceramics, with a diameter of 40mm; steel furnace 5 is a 500KG vacuum blast furnace for smelting, produced by a domestic vacuum blast furnace manufacturer; computer 6 is from LENOVO company Desktop personal computer; detection point distance dynamic monitoring system 7 is Nikon LASER 550G model single-frequency laser range finder, and feedback adjustment control device 8 includes an amplifying feedback circuit and a data signal processing circuit. The signal collected by the laser rangefinder is amplified and process...

Embodiment 2

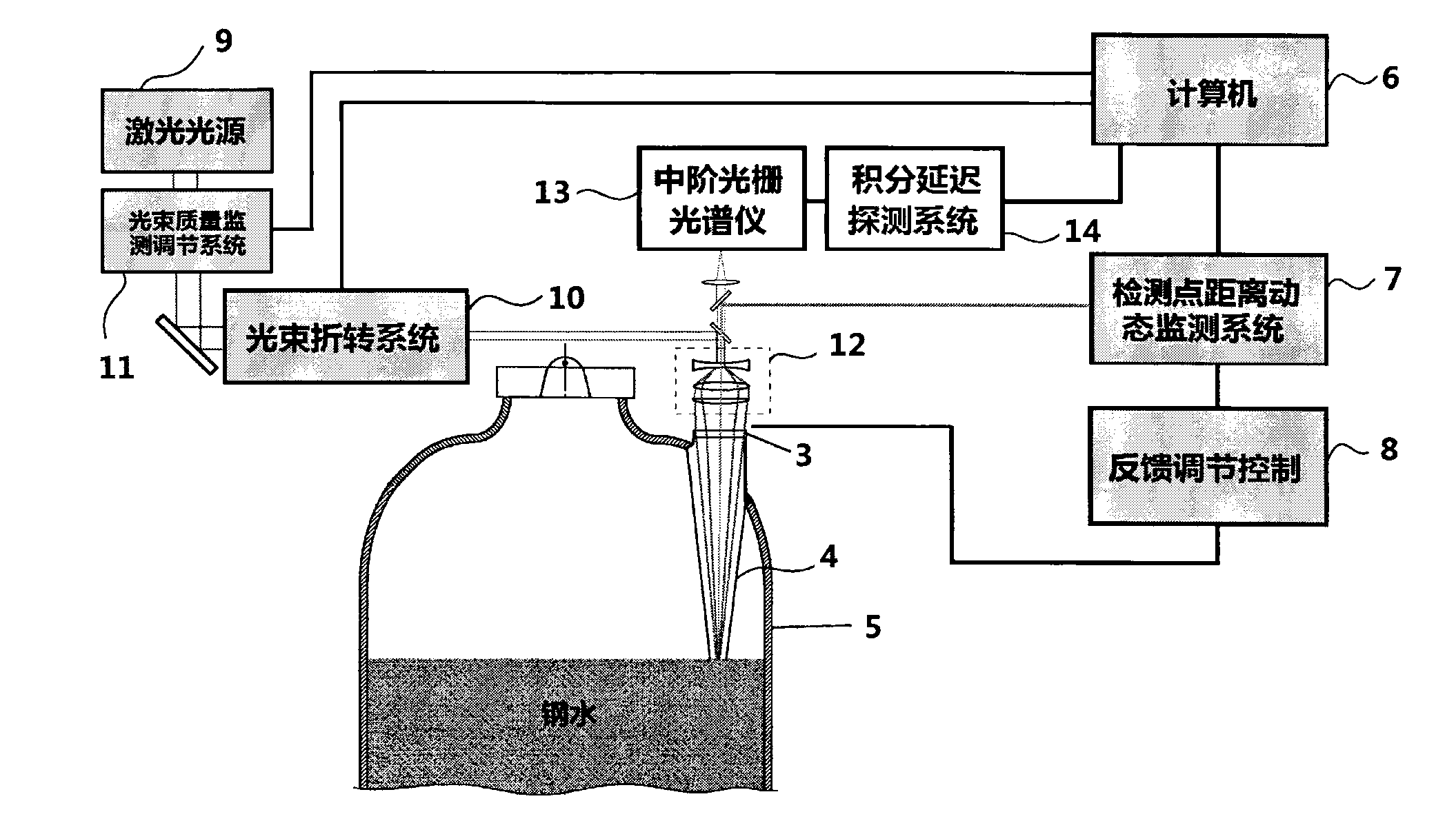

[0033] refer to figure 2, making a laser spectrum induced on-line molten steel composition detection system. The optical focusing structure formed by the concave mirror 1 and the convex mirror 2 of the system is replaced by a lens group 12 . The lens group 12 is composed of 4 lenses for eliminating aberrations, including 1 concave mirror and 3 convex mirrors; the window mirror 3 is a flat transparent sheet made of quartz glass, and the two sides are coated with amplifiers for detection and excitation laser wavelengths. Permeable film; casing 4 is a protective pipe made of ceramics, with a diameter of 50mm; steel furnace 5 is a 200KG electric furnace for smelting; computer 6 is a portable computer of LENOVO; the detection point distance dynamic monitoring system 7 is a dual-frequency laser range finder , the feedback adjustment control device 8 includes an amplification feedback circuit and a data signal processing circuit. The signal collected by the laser rangefinder is am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com