Production process for special-shaped silver-copper busbar and special-shaped silver-copper busbar

A production process and special-shaped technology, applied in the direction of electrical components, circuits, cables/conductors, etc., can solve the problems of small head filling dissatisfaction, rotten edges, uneven mechanical properties, etc., to ensure uniformity, good straightness, The effect of ensuring accuracy and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a production process for special-shaped silver-copper bars, including the following steps:

[0047] S1: Melting and alloying silver ingots and cathode copper to obtain a silver-copper alloy melt;

[0048] S2: The silver-copper alloy melt is treated by the up-drawing method to obtain an oxygen-free silver-copper alloy rod;

[0049] S3: Continuously extruding the silver-copper alloy rod to form a special-shaped silver-copper alloy billet;

[0050] S4: Drawing the silver-copper alloy billet at least once to obtain the finished silver-copper row;

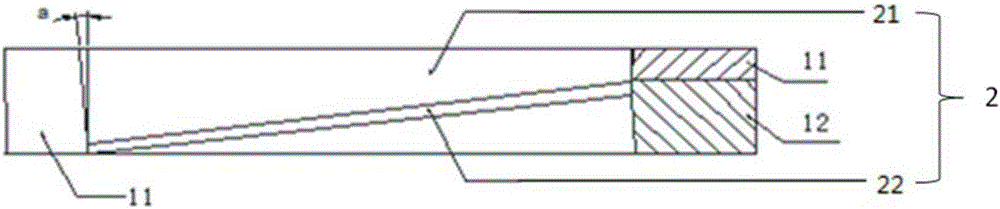

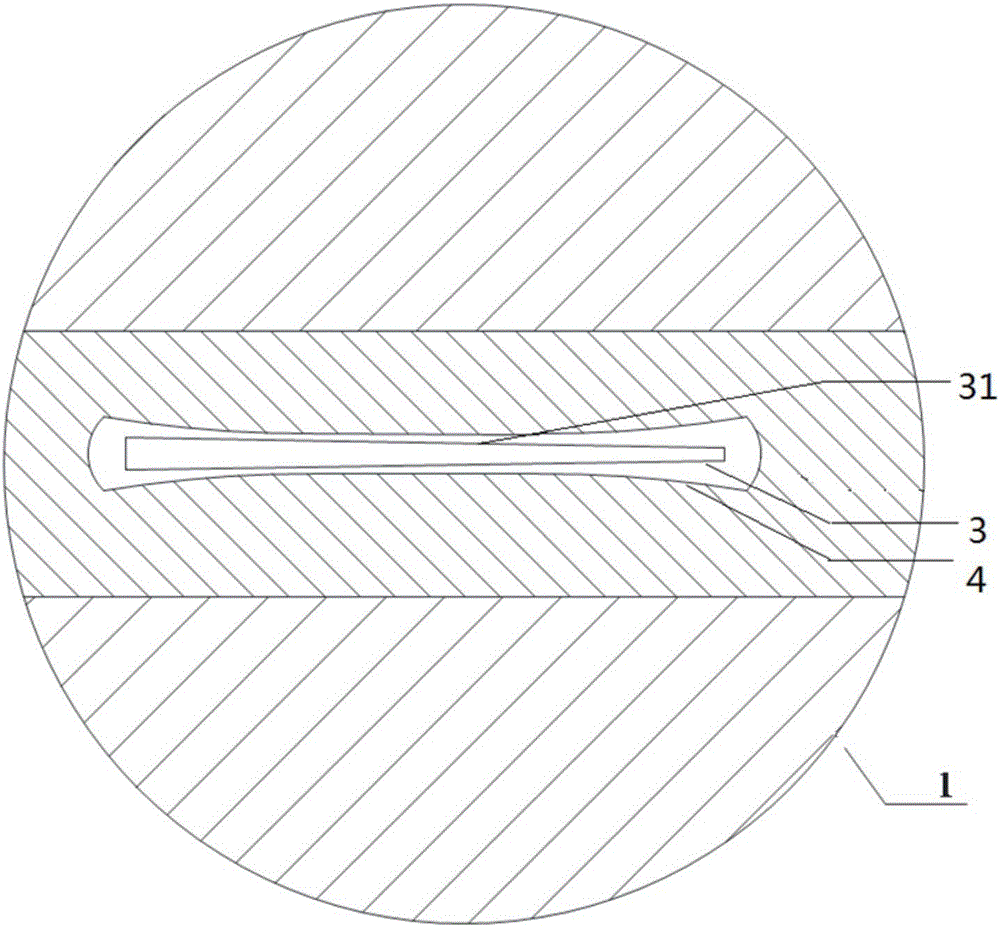

[0051] Wherein, the sizing band 22 of the extrusion die 1 adopted in the step S3 is convex, and the sizing band 22 is located in the axial central area of the die, and is bent radially outward to form an arc-shaped convex portion 31, Such as figure 2 shown.

[0052] In the above-mentioned extrusion die, since the sizing belt 22 is convex, the central area of the pressure is provided with an arc-s...

Embodiment 2

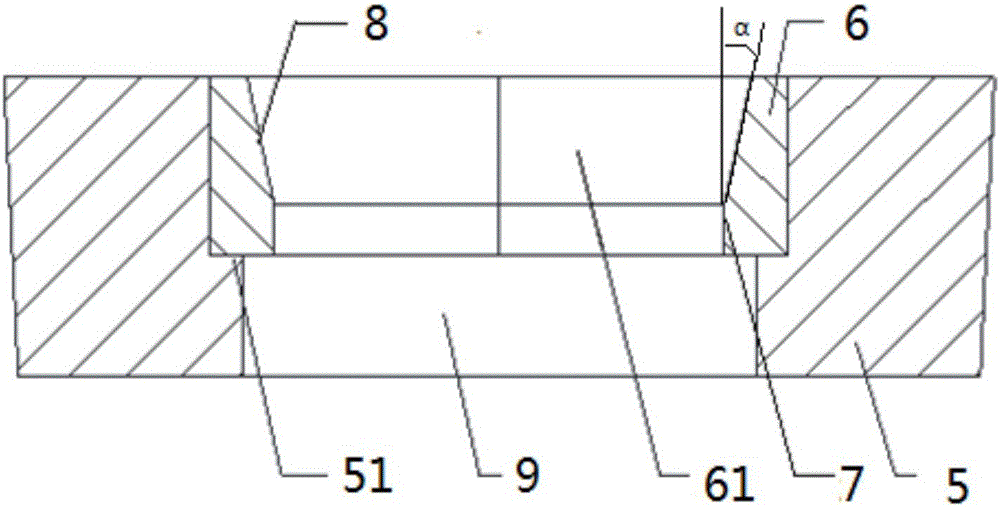

[0067] This embodiment provides a production process for special-shaped silver-copper bars, which is a deformation based on Example 1. In this embodiment, the silver-copper alloy blanks are drawn at least once to obtain special-shaped silver-copper bars. In the step of finished copper bars, the sizing band 7 of the drawing die 6 used is concave, such as image 3 As shown, the part of the sizing belt 7 located in the axial central area of the mold is bent radially inward to form an arc-shaped inner concave part 71, as Figure 4 shown.

[0068] In the drawing die mentioned above, the size of the central part of the cavity formed by the sizing belt 7 is smaller than the size of its two sides. In this way, in the specific drawing operation, although the center of the drawing die is under a large force, the metal filling force is large , but because the size of the cavity in the center is smaller than the size of the cavity on both sides, the filling of the metal in the center i...

Embodiment 3

[0070] This embodiment provides an extrusion die, such as figure 1 As shown, it includes: a mold base 1; a cavity 2, which is arranged on the mold base, and has an inlet 4 and an outlet 3; a sizing belt 22, which is arranged on the mold base 1, and the sizing belt 12 is convex, The portion of the sizing belt 22 located in the pressure center area is bent radially outward to form an arc-shaped convex portion 31, such as figure 2 shown.

[0071] Since the sizing belt 22 is convex, the pressure center area is provided with an arc-shaped convex part 31, so that the inner diameter at this place is originally larger than the inner diameters on both sides. After deformation, all areas at the exit of the sizing belt 33 can reach a straight state , so as to ensure the straight shape of the extruded product from the outlet, and ensure the accuracy of the extruded product and the uniformity of mechanical properties.

[0072] As a preferred embodiment, the mold base 1 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com