Method for preparing silicon nitride compound silicon carbide ceramic from crystalline silicon cutting waste materials

A silicon nitride composite silicon carbide and crystalline silicon cutting technology, which is applied in the field of ceramic technology and comprehensive utilization of secondary resources, can solve the problems affecting the economy of ceramic catheters, limited practicability, and reduced high-temperature mechanical properties, etc. And mechanical stability and economic guarantee, reduce production costs, improve the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

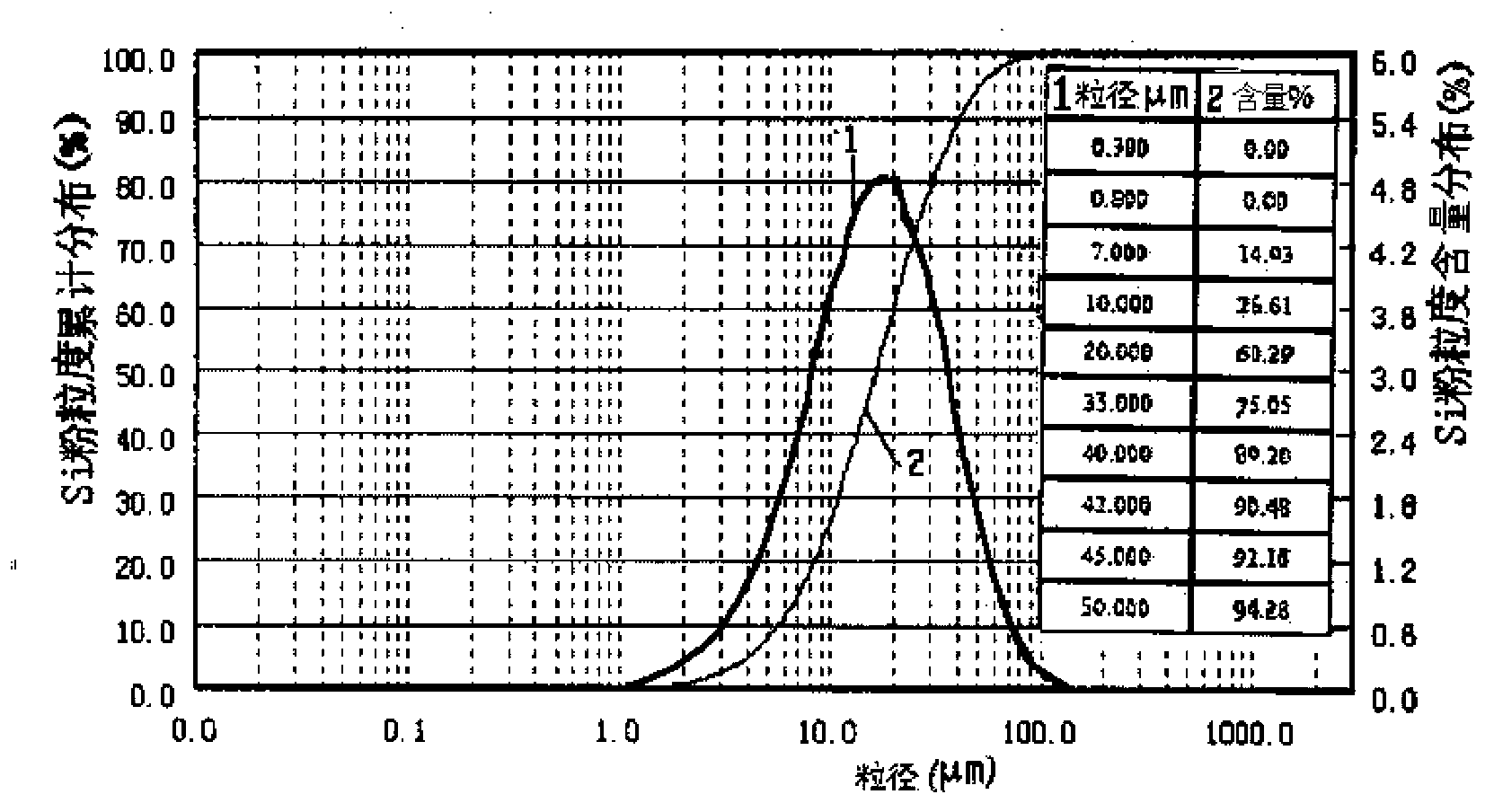

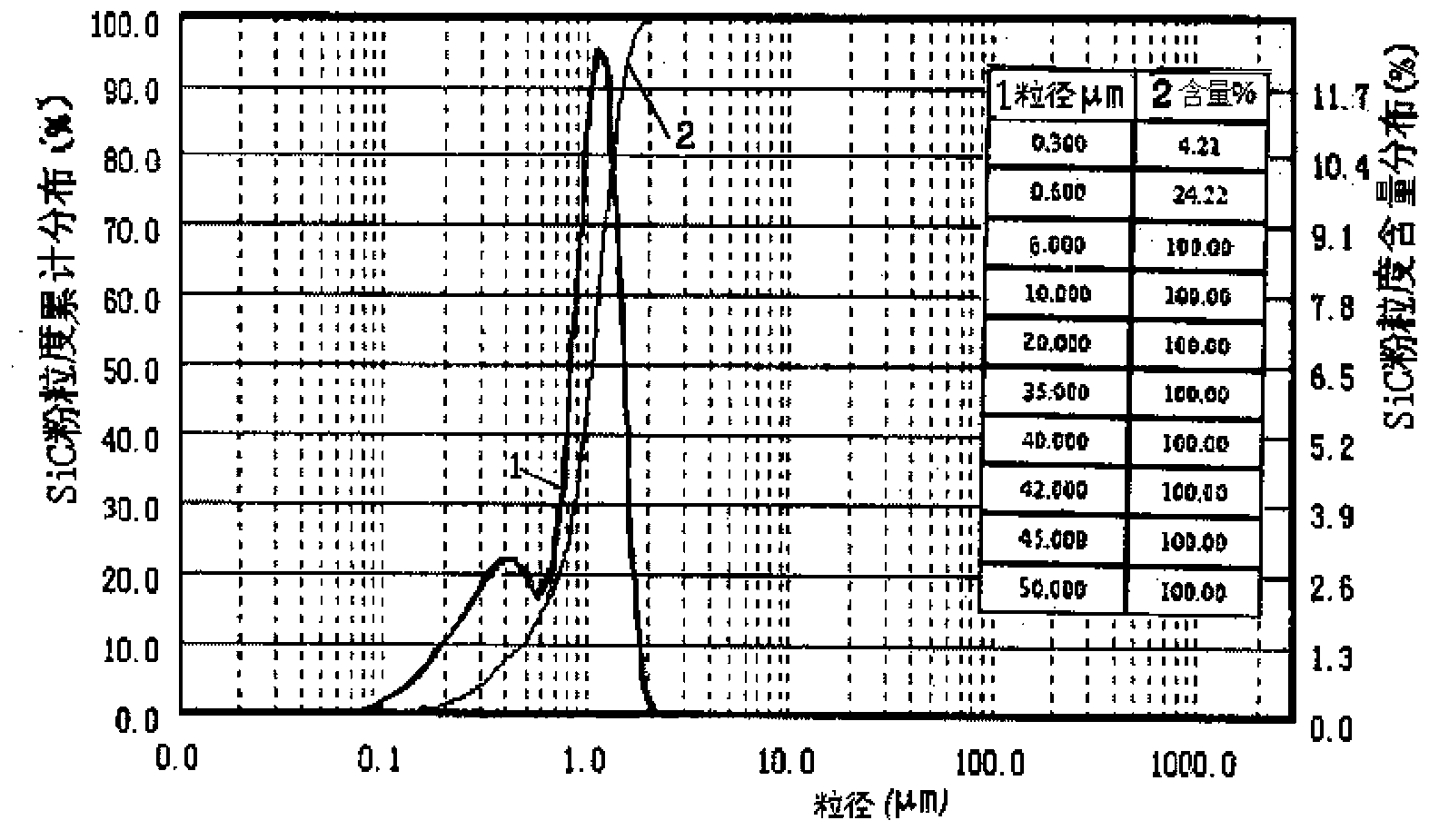

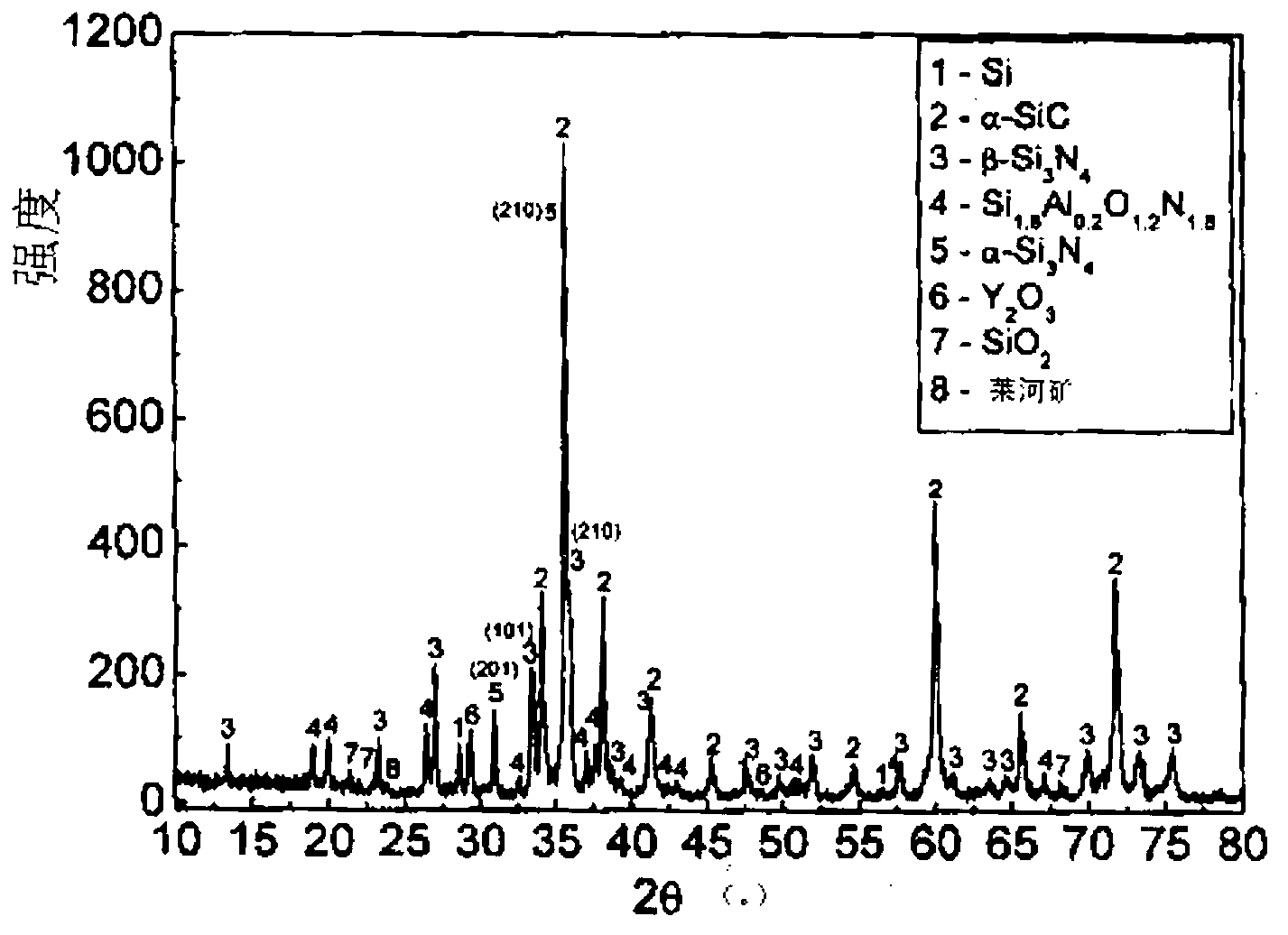

[0020] SiC micropowder in 15wt% diamond wire-cut crystalline silicon waste Si powder and 85wt% multi-filament wire-cut crystalline silicon waste, and sintering aid 3.0wt%Al 2 o 3 , 1.0wt%Fe 2 o 3 and 0.5wt%Y 2 o 3 , weighed according to the proportion, after ball milling, drying, granulation and molding, under high-purity nitrogen atmosphere, the temperature was raised to 800°C at 1°C / min and kept for 2h, the temperature was raised to 1150°C and kept for 4h, and finally the temperature was raised to 1550°C, nitrogen After sintering for 5 hours, the sintered body is a silicon nitride composite silicon carbide composite ceramic, with a Vickers hardness of 1.45GPa and a flexural strength of 0.113GPa; (such as figure 1 , figure 2 , image 3 , Figure 4 shown).

Embodiment 2

[0022] SiC micropowder in 16wt% diamond wire-cut crystalline silicon waste Si powder and 84wt% multi-filament wire-cut crystalline silicon waste, and sintering aid 2.8wt%Al 2 o 3 , 0.5wt%Fe 2 o 3 and 2.0wt%Y 2 o 3 , weighed according to the proportion, after ball milling, drying, granulation and molding, under high-purity nitrogen atmosphere, the temperature was raised to 800°C at 1°C / min and kept for 2h, the temperature was raised to 1150°C and kept for 4h, and finally the temperature was raised to 1560°C, nitrogen After sintering for 6 hours, the sintered body is a silicon nitride composite silicon carbide multiphase ceramic with a Vickers hardness of 1.67GPa and a flexural strength of 0.115GPa.

Embodiment 3

[0024] SiC micropowder in 19wt% diamond wire-cut crystalline silicon waste Si powder and 81wt% multi-filament wire-cut crystalline silicon waste, and sintering aid 3.2wt%Al 2 o 3 , 0.8wt%Fe 2 o 3 and 1.9wt%Y 2 o 3 , weighed according to the proportion, after ball milling, drying, granulation and molding, under high-purity nitrogen atmosphere, the temperature was raised to 800°C at 1°C / min and kept for 2h, the temperature was raised to 1150°C and kept for 4h, and finally the temperature was raised to 1570°C, nitrogen After sintering for 7 hours, the sintered body is a silicon nitride composite silicon carbide multiphase ceramic with a Vickers hardness of 1.64GPa and a flexural strength of 0.135GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com