Method for preparing shiny-leaved yellowhorn kernel oil by adopting ultrasound-assisted salt process

A technology of seed kernel oil and ultrasound of Wenguan fruit, which is applied in the production of edible oil/fat, fat oil/fat, and fat production, can solve the problems of long process cycle, high extraction cost, low oil yield, etc., and achieve rich nutrition. , The effect of shortening the extraction cycle and high oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

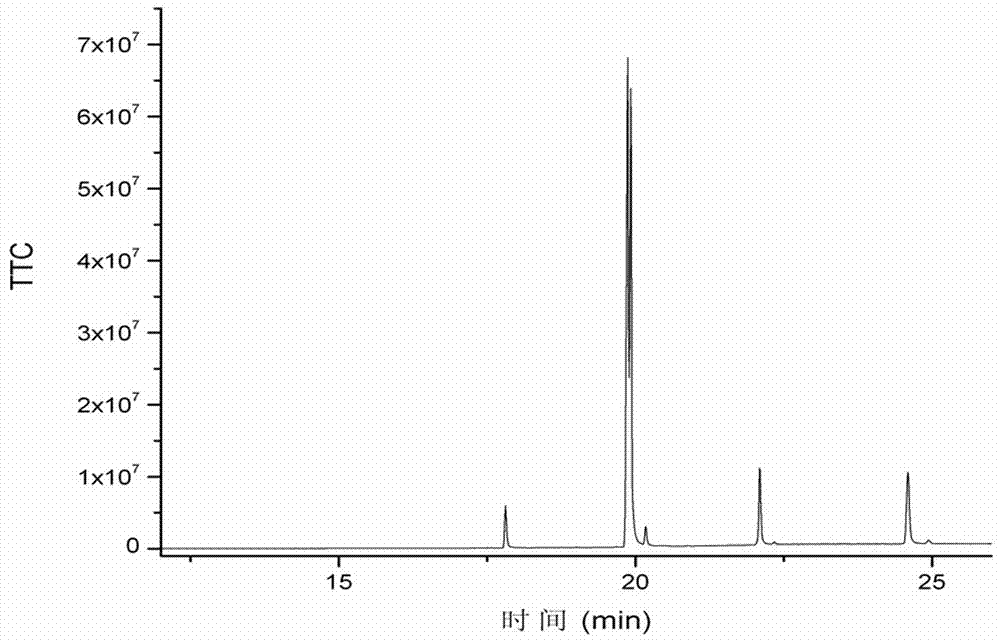

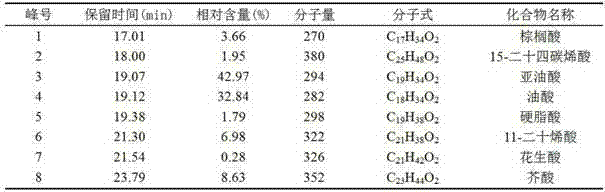

Image

Examples

Embodiment 1

[0035] (1) Take the radix radix radix seed kernels, freeze-dry them at low temperature in vacuum, and then use a sesame oil refiner (adjust the thickness of the disc of the refiner to pass 40 meshes) to refine the pulp to obtain the radix radix radix seed pulp, and refrigerate it for later use;

[0036] (2) Accurately weigh 20g of radix sorbifolium seed pulp, dissolve it with 40ml of sodium chloride aqueous solution with a concentration of 17g / L, and place it in an ultrasonic extractor for extraction: adjust the ultrasonic power to 60KH Z , The stirring speed is 40r / min, the temperature is 50°C, and the extraction time is 60min;

[0037] (3) Centrifuge the extract with a high-speed centrifuge: the centrifugation temperature is 20°C, the centrifugation speed is 7000r / min, and the centrifugation time is 10min; after centrifugation, the upper layer is taken out, which is the pure natural Xantho sorbifolia seed oil. The extraction rate is 63.48%.

Embodiment 2

[0039] (1) Take the radix radix radix seed kernels, freeze-dry them at low temperature in vacuum, and then use a sesame oil refiner (adjust the thickness of the disc of the refiner to pass 40 meshes) to refine the pulp to obtain the radix radix radix seed pulp, and refrigerate it for later use;

[0040] (2) Accurately weigh 20g of sorbifolia seed pulp, dissolve it with 60ml of 33g / L sodium chloride aqueous solution, and place it in an ultrasonic extractor for extraction: adjust the ultrasonic power to 70KH Z , the stirring speed is 50r / min, the temperature is 55°C, and the extraction time is 90min;

[0041] (3) Centrifuge the extract with a high-speed centrifuge: the centrifugation temperature is 25°C, the centrifugation speed is 8000r / min, and the centrifugation time is 15min; after centrifugation, the upper layer is taken out to be the pure natural Xanthania sorbifolia seed oil. The extraction rate is 68.79%.

Embodiment 3

[0043] (1) Take the radix radix radix seed kernels, freeze-dry them at low temperature in vacuum, and then use a sesame oil refiner (adjust the thickness of the disc of the refiner to pass 40 meshes) to refine the pulp to obtain the radix radix radix seed pulp, and refrigerate it for later use;

[0044] (2) Accurately weigh 20g of radix sorbifolium seed pulp, dissolve it with 80ml of sodium chloride aqueous solution with a concentration of 50g / L and place it in an ultrasonic extractor for extraction: adjust the ultrasonic power to 80KH Z , the stirring speed is 60r / min, the temperature is 60°C, and the extraction time is 120min;

[0045] (3) Centrifuge the extract with a high-speed centrifuge: the centrifugation temperature is 25°C, the centrifugation speed is 9000r / min, and the centrifugation time is 20min; after centrifugation, the upper layer is taken out to obtain pure natural Xanthania sorbifolia seed oil. The extraction rate is 61.54%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com