Treatment device of chromium aging liquid

A treatment device and aging solution technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of uneconomical, waste of resources, etc., and achieve the effects of fast operation, material saving, and easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

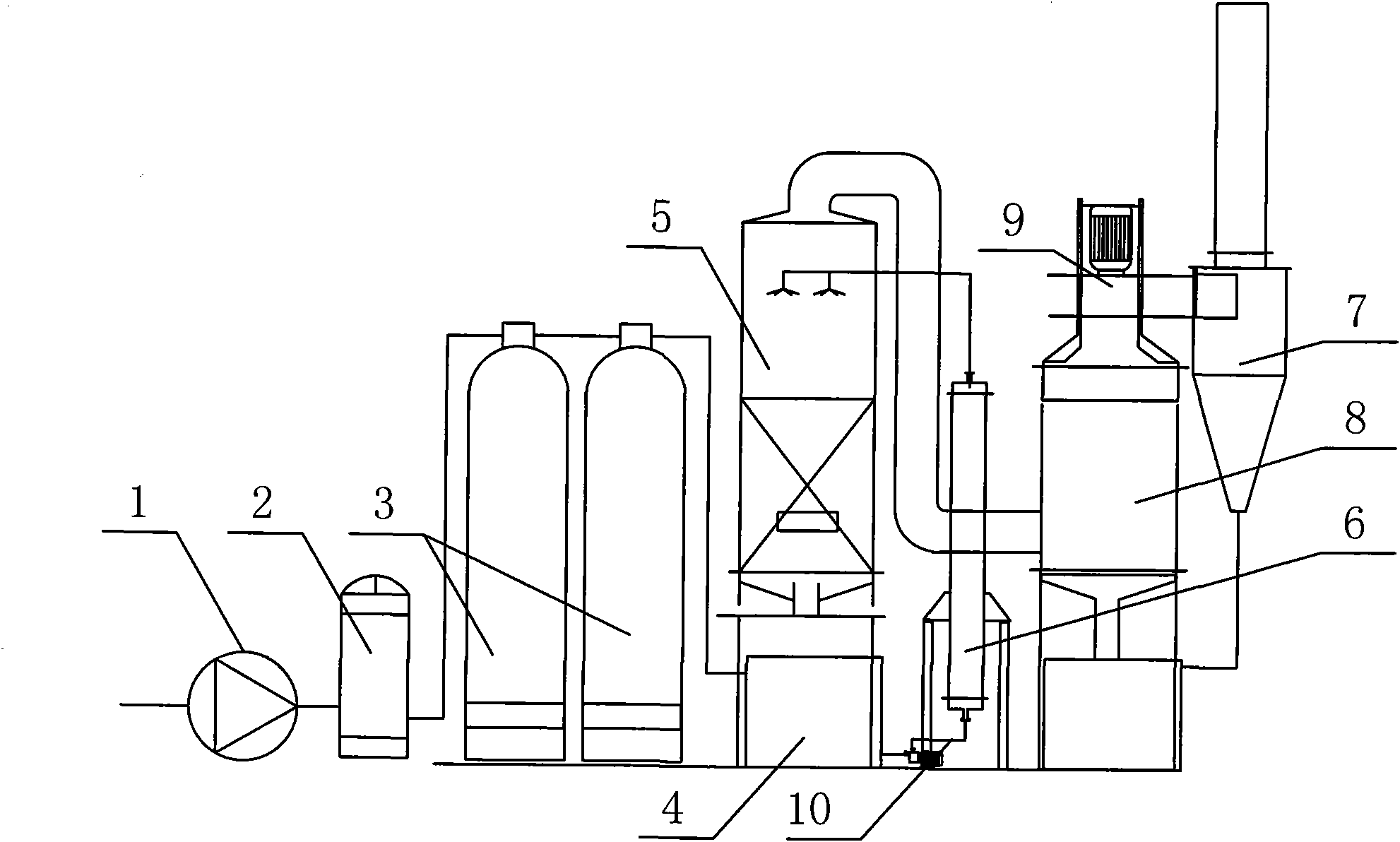

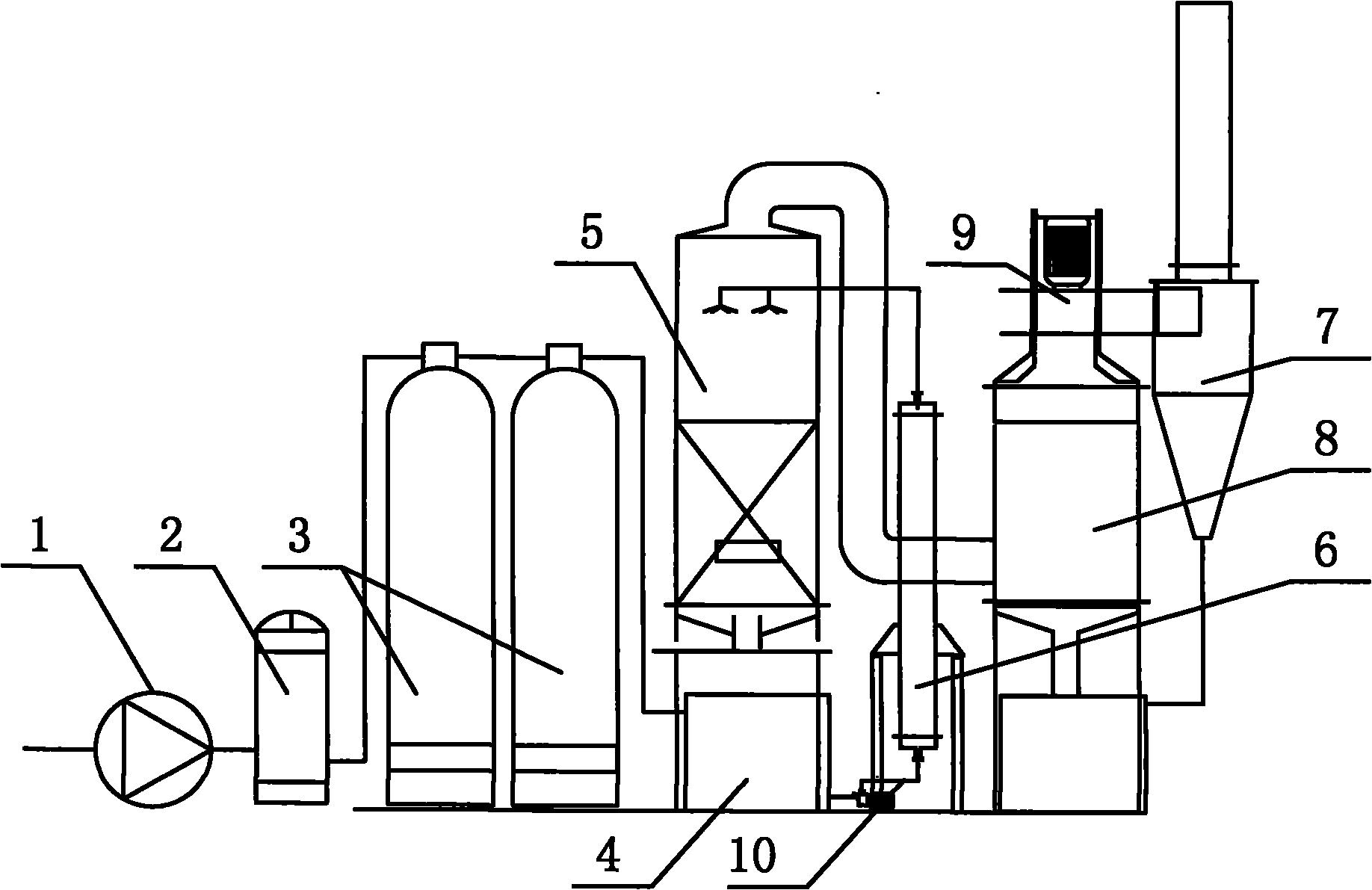

[0018] like figure 1 As shown, a chromium aging liquid treatment device includes a delivery pump 1, a ceramic filter 2, an adsorber 3, a liquid storage tank 4, an evaporator 5, a heat exchanger 6 and a separator 7, and the adsorber 3 adopts two The first stage adsorber, the transfer pump 1 is directly connected to the ceramic filter 2, and then enters the second stage adsorber 3 after passing through the ceramic filter 2, and then enters the liquid storage tank 4. 10. The liquid in the liquid storage tank 4 is sucked into the heat exchanger 6, and comes out of the heat exchanger 6 into the evaporator 5 for spraying. The sprayed liquid is recovered from the lower part of the evaporator 5 and enters the liquid storage tank 4. After spraying The gas is transported into the recovery tower 8 by the upper pipeline, and a fan is installed at the top of the recovery tower 8 for air supply.

[0019] After the aging solution is diluted with pure water, it is transported by the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com