Method for electrochemical detoxification and deep dehydration of blue-green algae liquid

A deep dehydration and electrochemical technology, applied in chemical instruments and methods, sterilization/microkinetic water/sewage treatment, water/sewage treatment, etc., to achieve high dehydration efficiency, reduce energy consumption, and improve degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

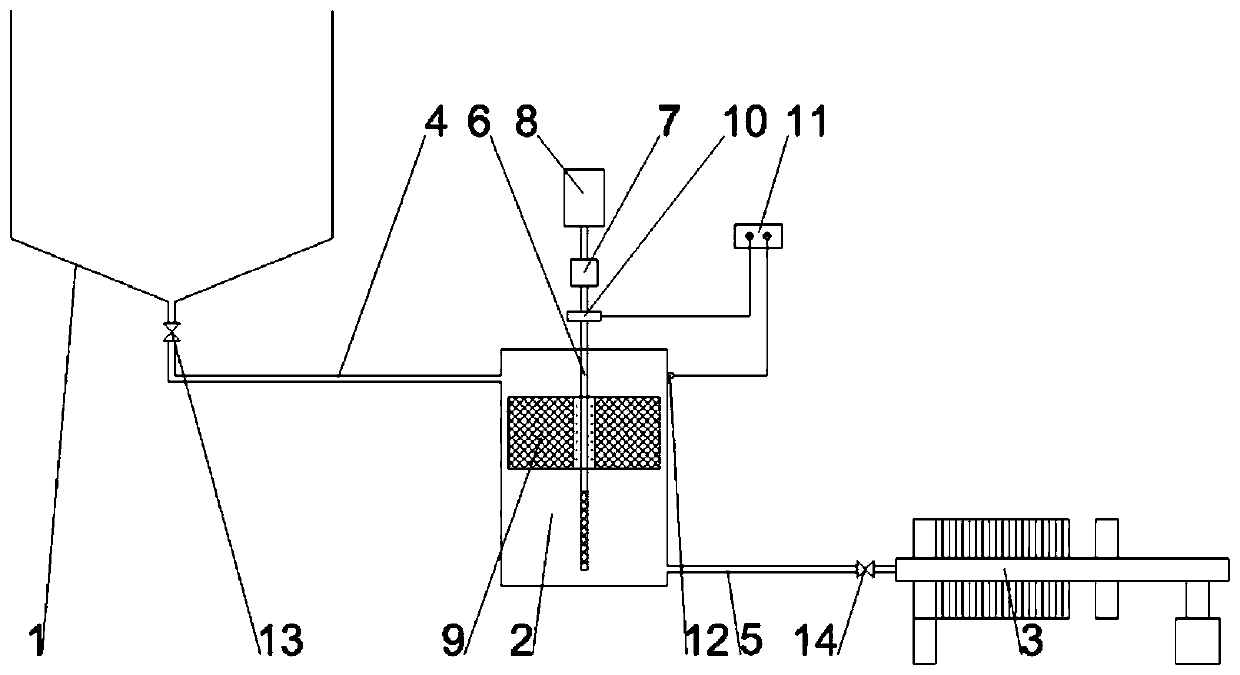

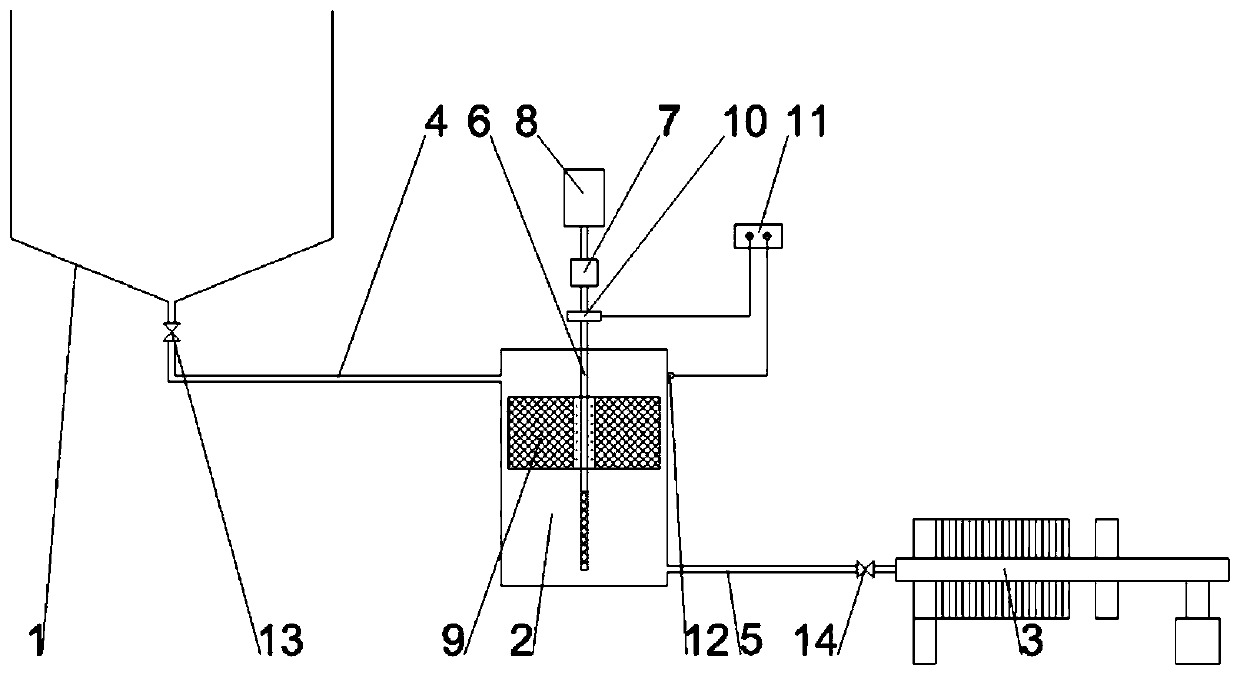

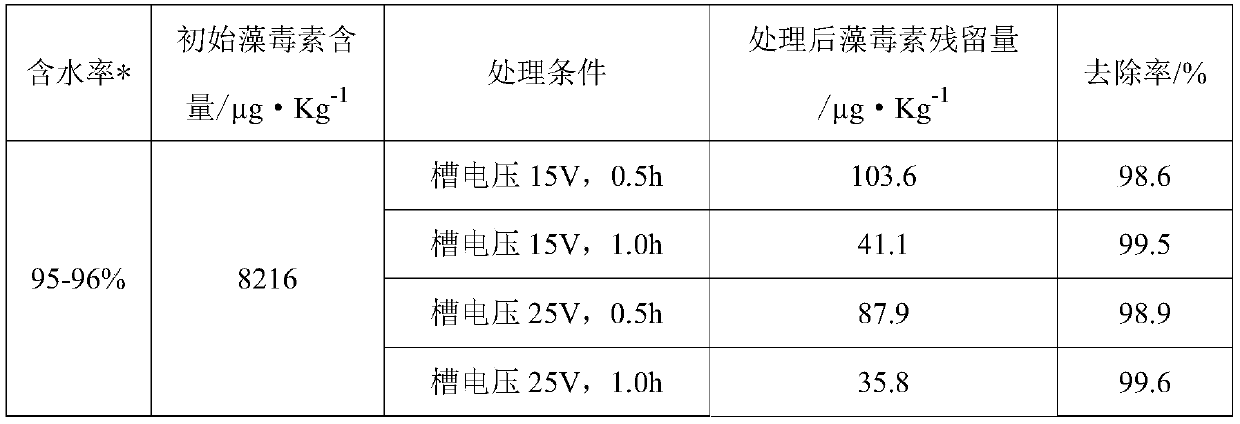

[0036] A method for electrochemical detoxification and deep dehydration of cyanobacteria liquid, comprising the following steps: 1. throwing the salvaged cyanobacteria liquid into a primary sedimentation tank for preliminary static stratification, opening the first valve at the bottom of the primary sedimentation tank, and the cyanobacteria liquid in the lower layer Flow into the electrochemical reactor with agitation function, regularly take away the supernatant after the stratification of cyanobacteria; 2 set the tank voltage and stirrer speed of the electrochemical reactor, the tank voltage is 10-30V, and the speed is set at 50- 200 rpm, time 0.5-1h; open the electrochemical reactor and its stirring function, under the combined action of electric field and anode mechanical stirring, the cyanobacteria cells are broken and dehydrated, and the composite metal oxide active coating in the electrochemical reactor The hydroxyl free radicals produced by the anode of the layered tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com