Method for manufacturing bi-metal composite material by pouring two layers of molten metal with cooling speed adjustable

A composite material and bimetal technology, which is applied in the field of bimetal composite materials with adjustable cooling rate two-liquid casting, can solve the problems of low qualification rate of bimetal composite and excessive fusion amount, etc., and is convenient for industrialized large-scale production. Expanded, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

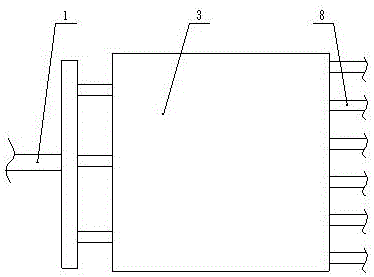

[0019] Example 1: 500×500×50mm composite wear-resistant plate

[0020] The bimetal composite wear-resistant plate is composed of low-carbon cast steel and high-chromium cast iron. The thickness of the high-chromium cast iron layer is 25-35mm, and the hardness requirement is ≥55HRC. The thickness of the low-carbon cast steel is 15-25mm, and the impact toughness is not less than 50J. .

[0021] Process analysis: Comparing the composition of low-carbon cast steel and high-chromium cast iron in the table below, it can be seen that the composition of Si, Mn, P, and S after fusion has little change, mainly due to the change of C and Cr. From the physical properties of the two, the thermal conductivity of low-carbon cast steel is higher than that of high-chromium cast iron. The melting point of low-carbon cast steel is about 1590-1610°C, and the melting point of high-chromium cast iron is about 1400-1450°C. If the composite wear-resistant plate requires welding connection, in order ...

Embodiment 2

[0029] Example 2: Bimetal Composite Hammer

[0030] The product in this embodiment is a crusher hammer head, the hammer head part is made of high manganese steel, the hammer handle part is made of low carbon cast steel, and the size of the hammer head part is 100×240×225 mm.

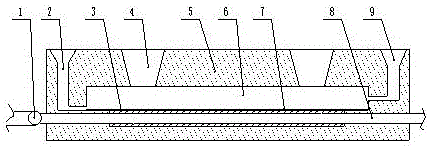

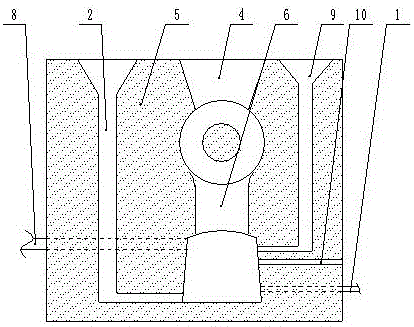

[0031] See attached for gating system image 3 and 4 , including water inlet pipe 1, first layer metal runner 2, cold iron 3, riser (observation hole) 4, sand mold 5, cavity 6, paint 7, water outlet pipe 8, second layer metal runner 9 and overflow Mouth 10. Two cold irons 3 are symmetrically arranged, and each cold iron is connected to a water inlet pipe 1 and an outlet pipe 8. The diameter of the water inlet pipe is Φ16mm, and the diameter of the water outlet pipe is Φ24mm. The cross-sectional area ratio of the two is 1:2.25. The outlet pipe 8 has a length of 300mm, and the outlet extends into a closed water tank placed underground. The air volume of the water tank is not less than 3m³, and the total...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com