Atomization assisting CVD thin film deposition method

A thin-film deposition and thin-film deposition device technology, applied in the field of atomization-assisted CVD thin-film deposition, can solve problems such as inability to ensure consistent concentration of precursor solution, inability to ensure credible and repeatable process parameters of film composition, and inability to avoid precursor reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0045] A method for atomizing assisted CVD film deposition, characterized in that it comprises the steps of:

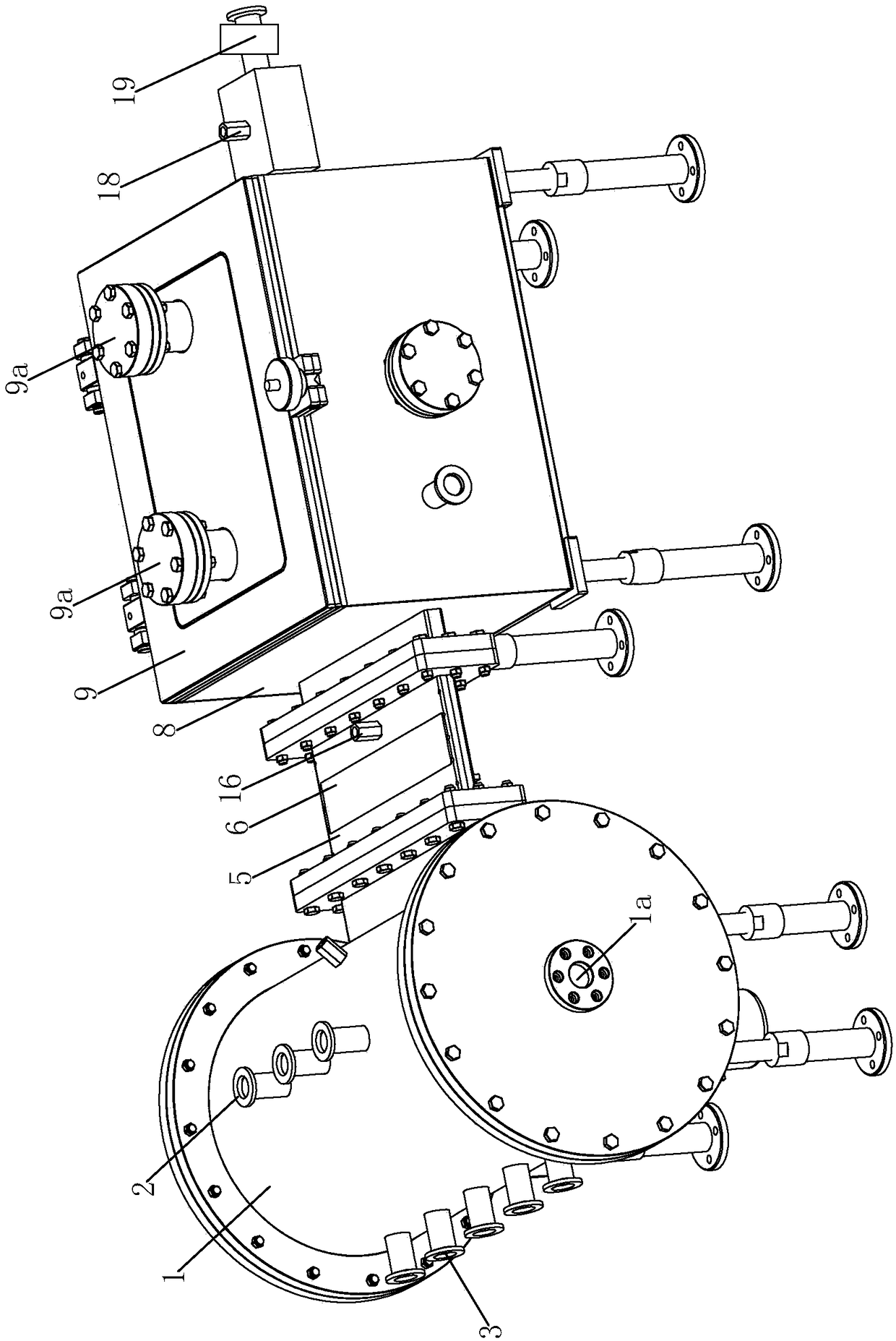

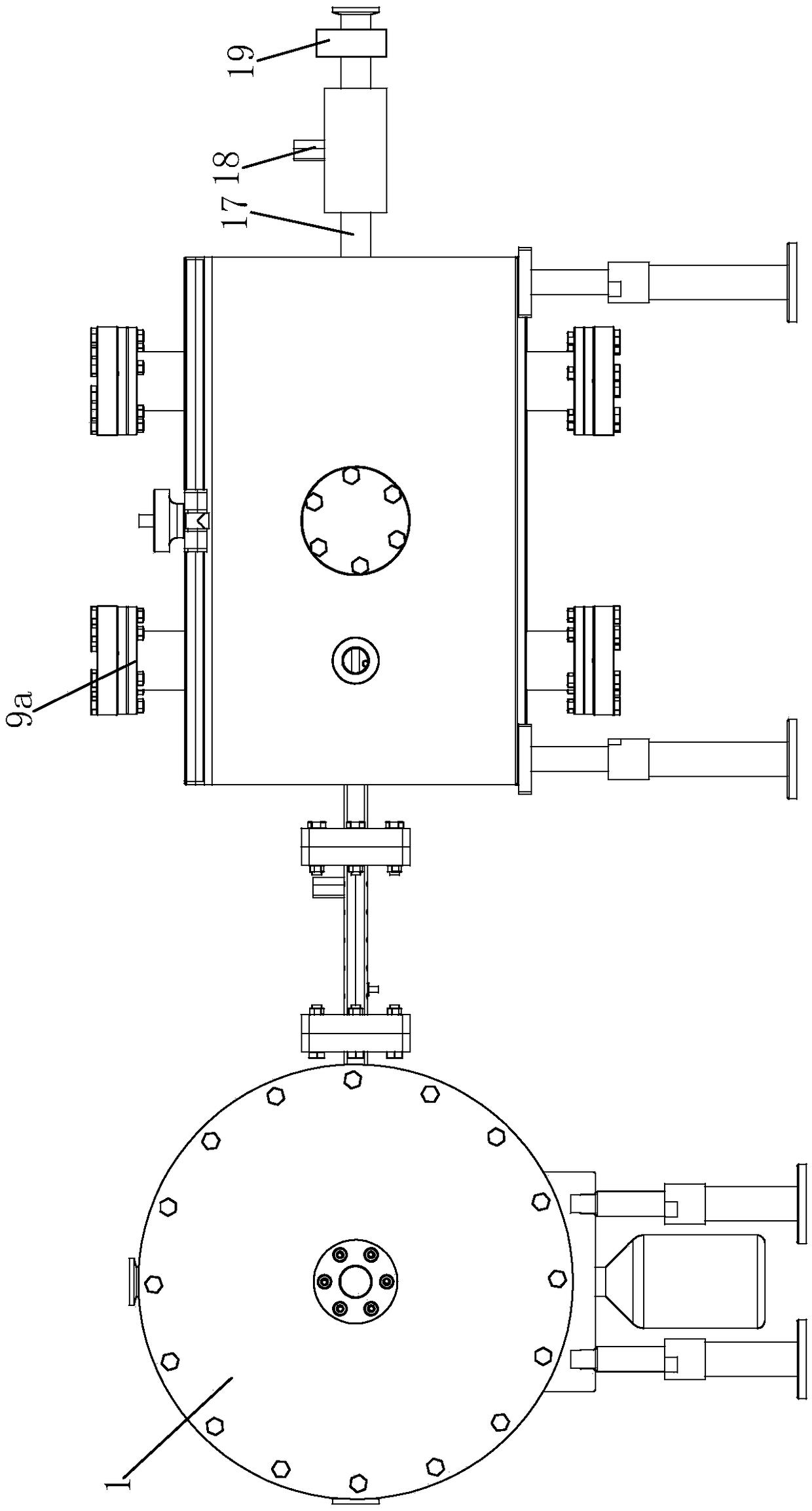

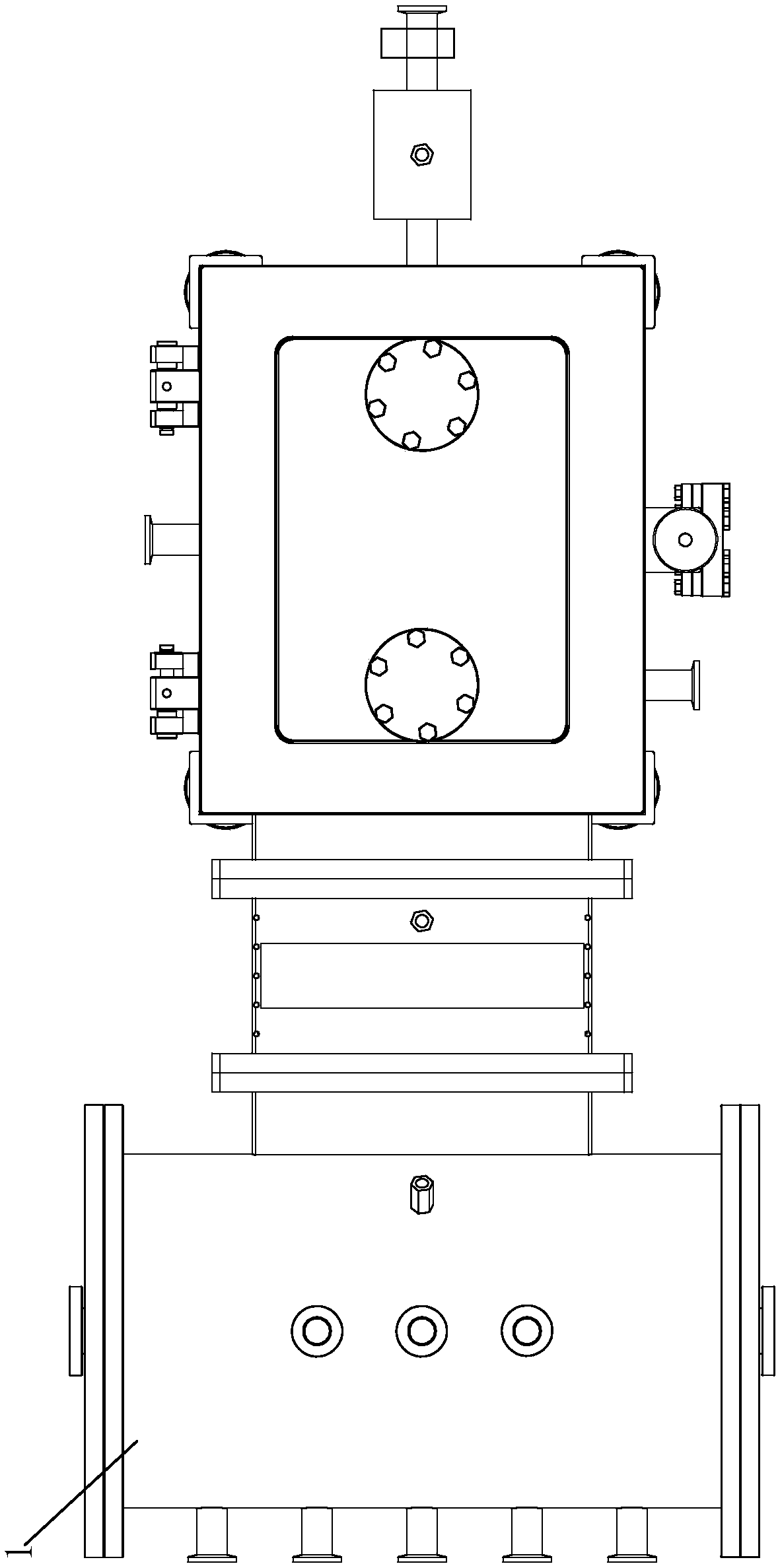

[0046] Step a: Design an atomization-assisted CVD film deposition device, such as Figure 1-5 As shown, an atomization-assisted CVD film deposition method mainly consists of three parts including a buffer mixing chamber 1 , a transition chamber 5 and a reaction chamber 8 . Wherein, the buffer mixing chamber 1 is made of corrosion-resistant material, preferably stainless steel. The top of the buffer mixing chamber 1 is vertically provided with multiple gas-phase material inlet pipes 2. In this case, the number of gas-phase material inlet pipes 2 is three, and they are arranged side by side. In mixing chamber 1. The left side of the buffer mixing chamber wall is provided with multiple aerosol inlet pipes 3. In this case, the number of aerosol inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com