Double-fluid composite iron-based bimetal casting method

A bimetallic and iron-based technology, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of large amount of double-liquid composite fusion and high rejection rate of bimetallic composite, and achieves the expansion of the range of process parameters and facilitates industrialization High-production, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

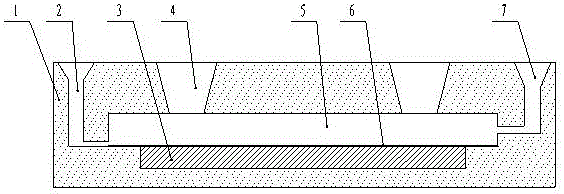

[0014] Example: 500×500×50mm composite wear-resistant plate

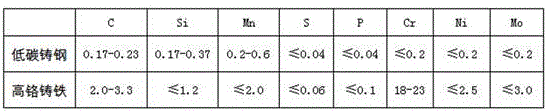

[0015] The bimetal composite wear plate is made of low carbon cast steel and high chromium cast iron, and its composition is shown in the table below. The finished product requires high chromium cast iron layer thickness 25-35mm, hardness requirement ≥55HRC, low carbon cast steel thickness 15-25mm, impact toughness not less than 50J.

[0016]

[0017] Process analysis: Comparing the composition of low-carbon cast steel and high-chromium cast iron in the above table, it can be seen that the composition of Si, Mn, P and S after fusion has little change, mainly due to the change of C, Ni and Cr. In terms of the physical properties of the two, the thermal conductivity of low-carbon cast steel is higher than that of high-chromium cast iron. High-chromium cast iron, so low-carbon cast steel with a high melting point is used as the first layer of metal, and high-chromium cast iron with a low melting point is used as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com