Combined separation process of pressurized two-product and pressurized three-product cyclone

A three-product and cyclone technology is applied in the field of combined separation of two products with pressure and three-product cyclone with pressure. Simple, high sorting accuracy, saving investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a further detailed description of a combined separation process of a pressurized two-product and a pressurized three-product cyclone of the present invention through specific implementation methods.

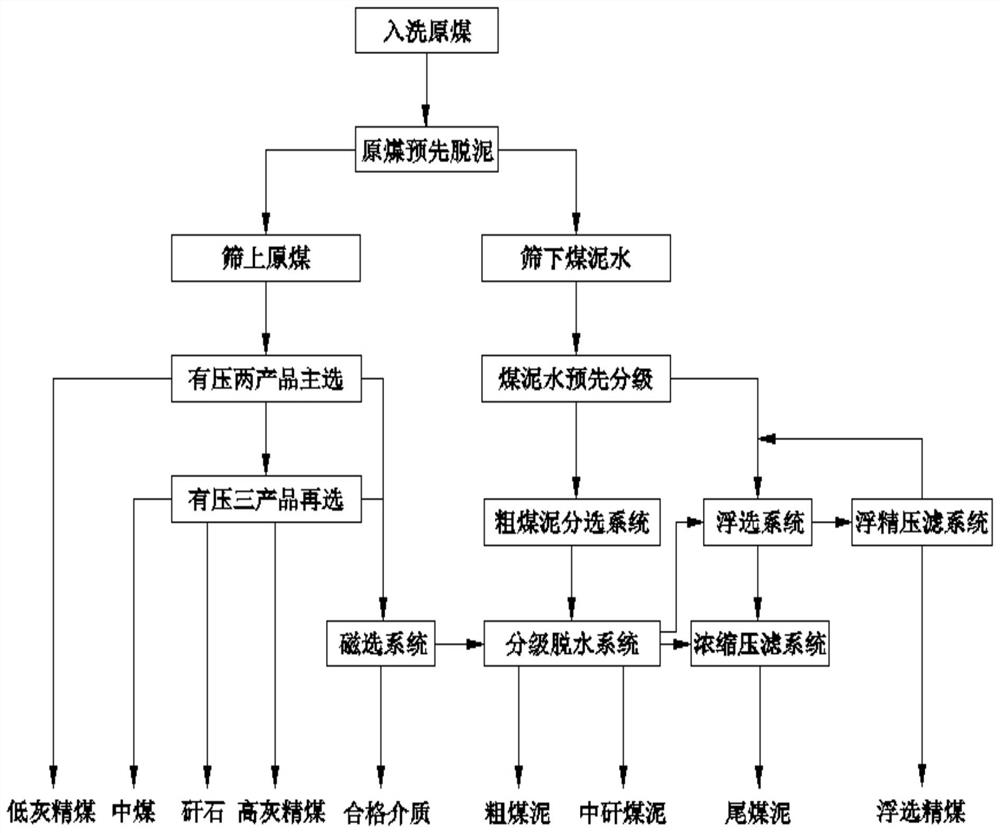

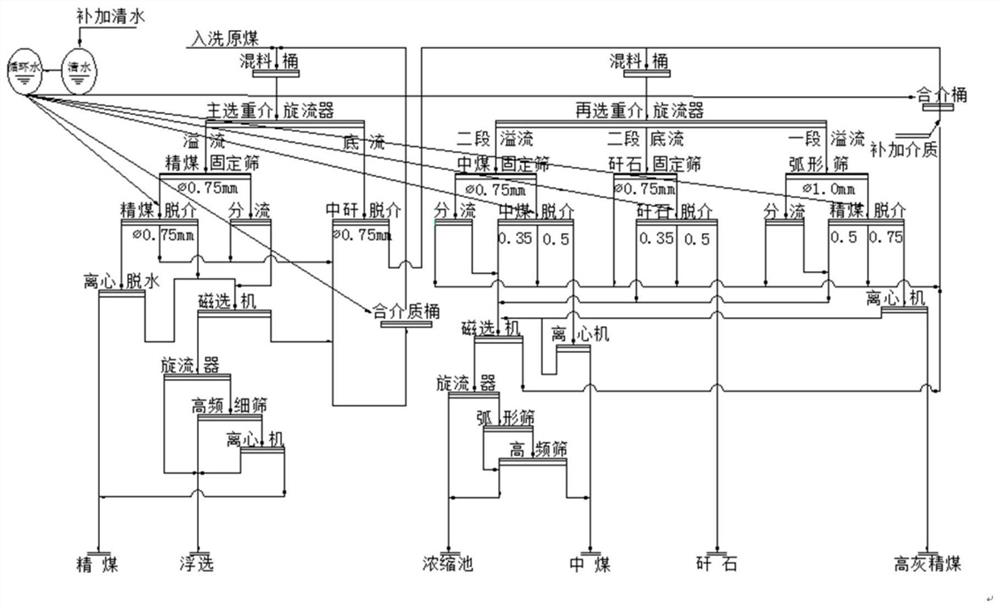

[0019] Depend on figure 1 Shown is a schematic flow chart of a pressurized two-product plus pressurized three-product cyclone combined separation process of the present invention, including: raw coal pre-deliming system, dense medium separation system, magnetic separation system and coal slime water treatment system . It can be seen from the figure that the main selection equipment of the dense medium separation system is a pressurized two-product dense medium cyclone and a pressurized three-product dense medium cyclone. From figure 1 It is further seen that the coal slime water system includes pre-classification of coal slime water, a coarse slime separation system, a flotation system, a concentrated filter press system, a floating fine filter press sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com