Dense medium coarse slime sorting device and sorting process

A heavy medium, coarse slime technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of increased ash content of coarse slime, influence of clean coal yield, poor desliming effect, etc. The effect of improving the selection accuracy, improving the sorting effect and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

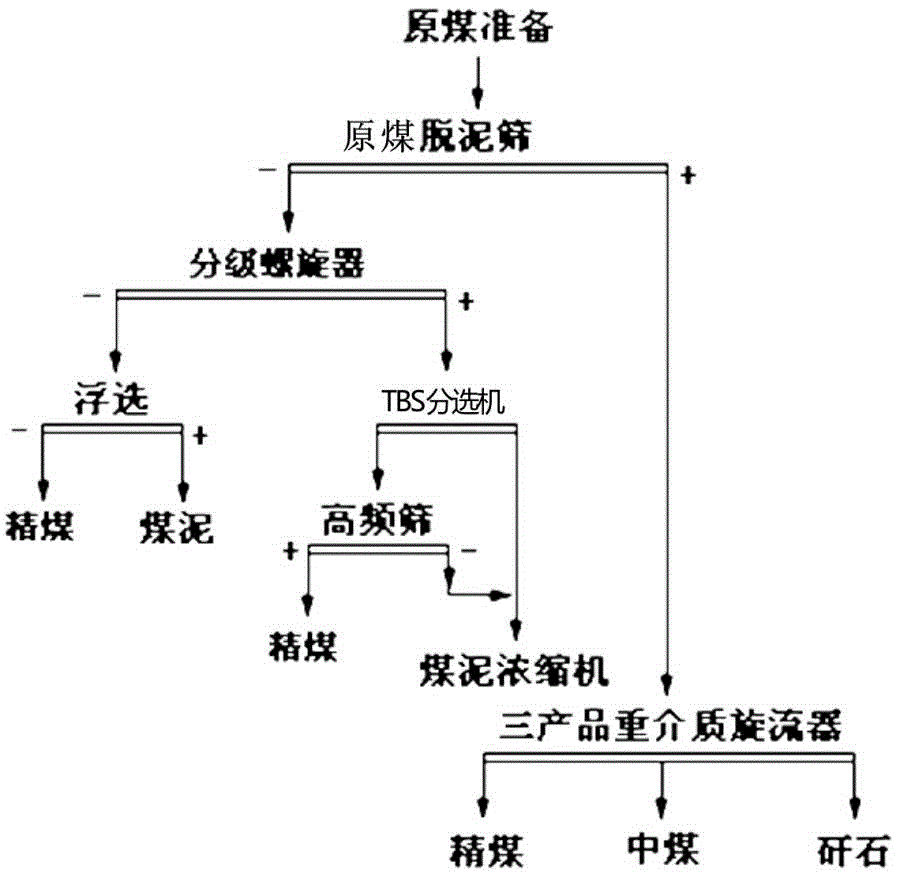

[0064] The dense medium coarse coal slime separation process is carried out according to the following steps:

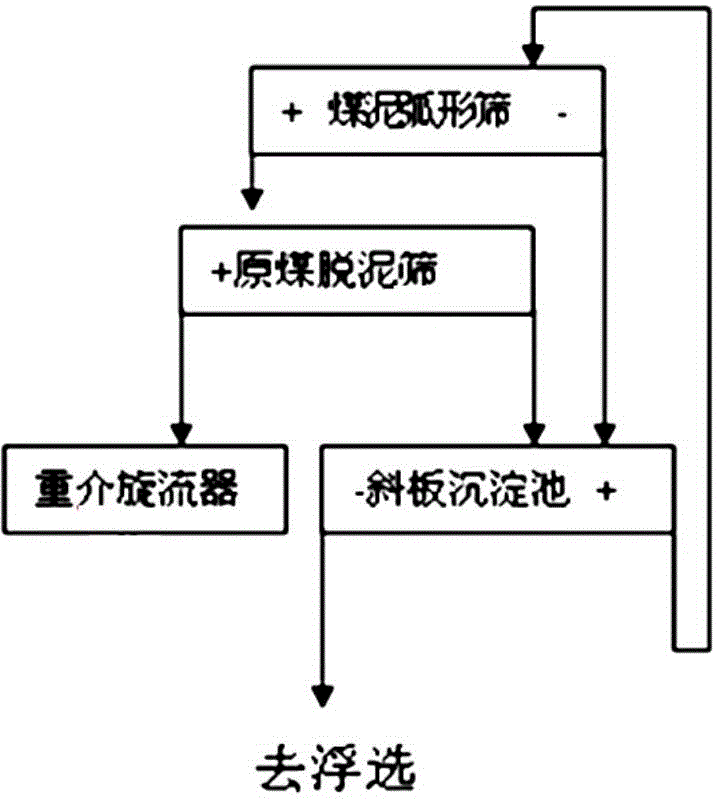

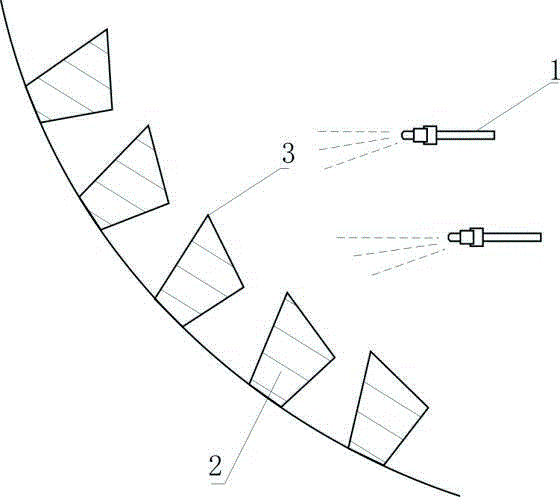

[0065] 1) The raw coal is deslimed through the desliming sieve, and water is sprayed on the desliming sieve during the desliming process. The oversize produced is coal slime with a size of 1 mm or more, which is then processed in a dense medium cyclone. The coal slime below 1mm under the sieve enters the conical inclined plate sedimentation tank for treatment.

[0066] 2) Coal slime with a bottom flow of 0.5mm-1mm produced by the conical inclined plate sedimentation tank enters the TBS grading cyclone for treatment.

[0067] 3) The coal slime with an underflow of 0.5mm-1mm produced by the TBS classifying cyclone enters the TBS sorter for sorting.

[0068] 4) After being sorted by the TBS sorter, the underflow of the TBS sorter is the tailings with an ash content greater than 60%, which enters the medium coal / gangue magnetic tail barrel for processing.

[0069] 5) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com