Radiation-grafting-based preparation method for dense medium used for coal preparation

A technology for dense medium and coal preparation, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of difficult recovery and large loss of dense medium powder, and achieve energy saving, medium consumption reduction, and good social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

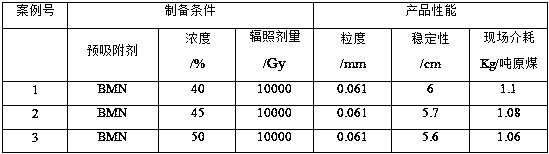

Embodiment 1-3

[0017] A preparation method for preparing a dense medium for coal preparation based on irradiation grafting, the steps are as follows:

[0018] Make the pre-adsorbent castor oil fatty acid sodium (BMN) into an aqueous solution with deionized water at a mass concentration of 40%, 45%, and 50%, and add it and magnetite powder to the mill powder at a mass ratio of 1:1000 In the machine, when the particle size of the mineral powder is 0.075mm, add 50% mass concentration of acrylic acid solution, and its mass ratio with the magnetite powder is 1:1000. After grinding for 30 minutes, the particle size of the mineral powder is about 0.061mm. Radiation source 60 Co, radiation dose rate 2.6×10 3 Gy / h, the irradiation dose is 10000 Gy, the acrylic acid is grafted onto the magnet mineral powder by γ-ray irradiation, and the final product is obtained after filtering and drying.

[0019] The laboratory performance and on-site media consumption of the tested product are shown in Table 1. ...

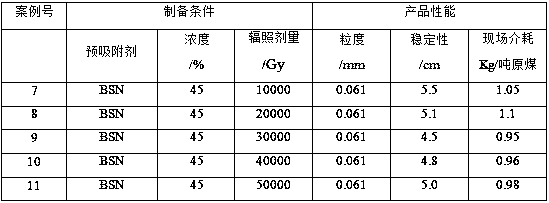

Embodiment 4-6

[0022] A preparation method for preparing a dense medium for coal preparation based on irradiation grafting, the steps are as follows:

[0023] Make the pre-adsorbent sulfonated castor oil (BSN) into an aqueous solution with deionized water at a mass concentration of 40%, 45%, and 50%, and add it and magnetite powder to the milling powder at a mass ratio of 1:1000 In the machine, when the particle size of the mineral powder is 0.075mm, add 50% mass concentration of acrylic acid solution, and its mass ratio with the magnetite powder is 1:1000. After grinding for 30 minutes, the particle size of the mineral powder is about 0.061mm. Radiation source 60 Co, radiation dose rate 2.6×10 3 Gy / h, the irradiation dose is 10000 Gy, the acrylic acid is grafted onto the magnet mineral powder by γ-ray irradiation, and the final product is obtained after filtering and drying.

[0024] Product performance data is shown in Table 2.

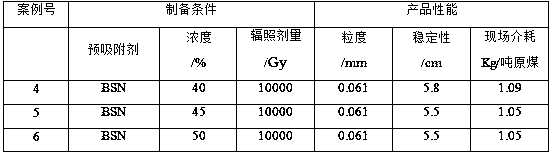

Embodiment 7-11

[0026] A preparation method for preparing a dense medium for coal preparation based on irradiation grafting, the steps are as follows:

[0027] The pre-adsorbent sulfonated castor oil (BSN) is made into an aqueous solution with deionized water at a mass concentration of 45%, and it is added to the pulverizer with magnetite powder at a mass ratio of 1:1000, and ground to ore When the powder particle size is 0.075mm, add 50% mass concentration of acrylic acid solution, and its mass ratio with magnetite powder is 1:1000. After grinding for 30 minutes, the particle size of mineral powder is about 0.061mm. 60 Co, radiation dose rate 2.6×10 3 Gy / h, the irradiation dose is 10000, 20000, 30000, 40000, 50000Gy, the acrylic acid is grafted onto the magnet mineral powder by γ-ray irradiation, and the final product is obtained by drying after filtration.

[0028] Product performance data are shown in Table 3.

[0029] Table 1

[0030]

[0031] Table 2

[0032]

[0033] table 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com