Steam coal dense medium separation process capable of effectively reducing slime content

A steam coal and separation technology, applied in the field of coal separation technology, can solve the problems of not being able to increase the calorific value of commercial coal, the huge coal slime water treatment system, and the difficulty of production management, so as to reduce the amount of secondary coal slime and improve Commercial coal quality and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

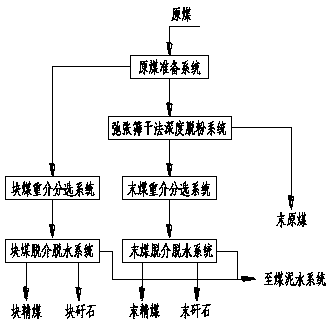

[0022] Example 1, such as figure 1 As shown, the technological process provided in this embodiment comprises the following steps:

[0023] (1) The raw coal is screened and crushed with a raw coal screening crusher, and the particle size is controlled to 200mm. Then it enters the raw coal grading screen equipment for screening operation, and the grading particle size is 9mm, and the raw coal with a particle size of 200-9mm and the final raw coal with a particle size of less than 9mm are obtained. , the raw coal with a particle size of 200-9mm enters the desliming screen for desliming operation, and the desliming particle size is 3.0mm;

[0024] (2) Feed the raw coal with a particle size of less than 9mm obtained in step (1) into the raw coal relaxation screen for dry deep de-powdering operation, control the particle size to 3mm, and obtain the raw coal with a particle size of 9-3mm (on the sieve) and a particle size of less than 3mm Minimal raw coal (under-sieve), the equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com