RH vacuum system regulating vacuum device and application

A vacuum system and vacuum device technology, applied in the field of iron and steel smelting, can solve the problems of increasing the vacuuming time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

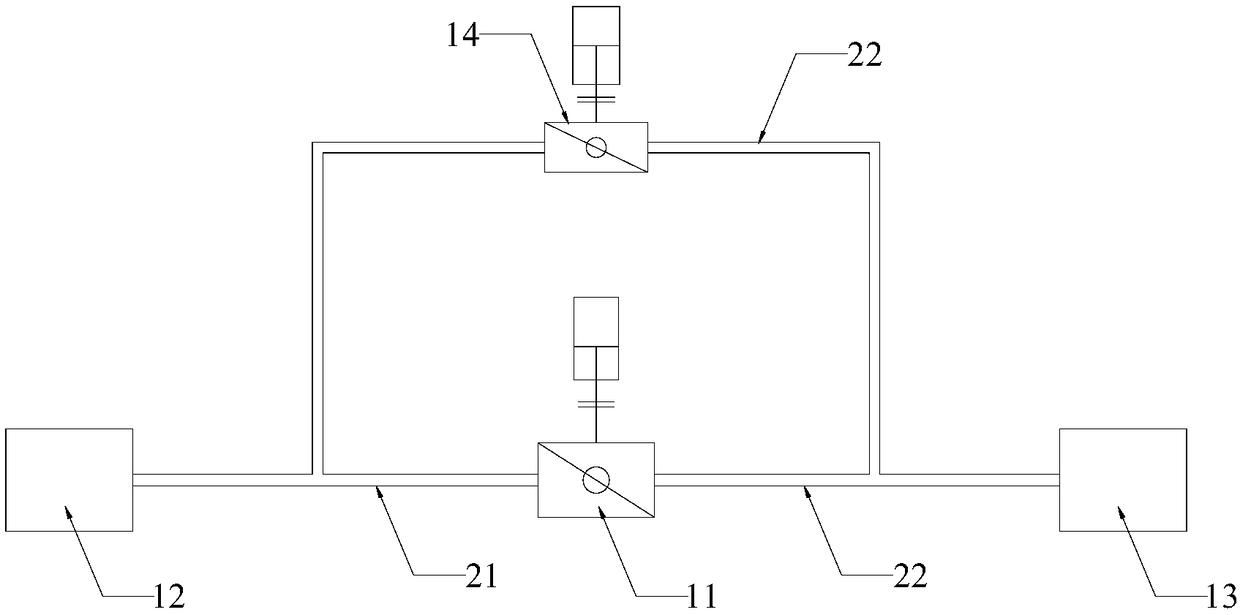

[0024] see figure 1 , A RH vacuum system regulating vacuum device provided by an embodiment of the present invention includes: a vacuum main valve 11 , a first pipeline 21 , a second pipeline 22 , a bypass pipeline 22 and a bypass valve 14 . One end of the first pipeline 21 is connected to the main vacuum valve 11 , and the other end is connected to the vacuum tank 12 of the RH vacuum refining device; one end of the second pipeline 22 is connected to the main vacuum valve, and the other end is connected to the vacuum pump 13 .

[0025] Wherein the bypass valve 14 is installed on the bypass pipeline 22, the diameter of the valve is about DN300mm, and the diameter of the valve is determined according to the pressure difference on both sides and the time required to balance the pressure. The inner diameter ratio of the bypass pipeline 23 and the first pipeline 21 is 1:5.

[0026] In the embodiment, after each furnace is processed, first close the vacuum main valve 11, open the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com