Two-section series high-pressure roller milling-stirring milling short-process grinding system and method

A high-pressure roller mill and high-pressure roller mill technology, which is applied in the field of mineral processing, can solve the problems of unstable pulverized product indicators and complex processes, and achieve the effects of reducing grinding energy consumption and medium consumption, high energy consumption, and sufficient development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

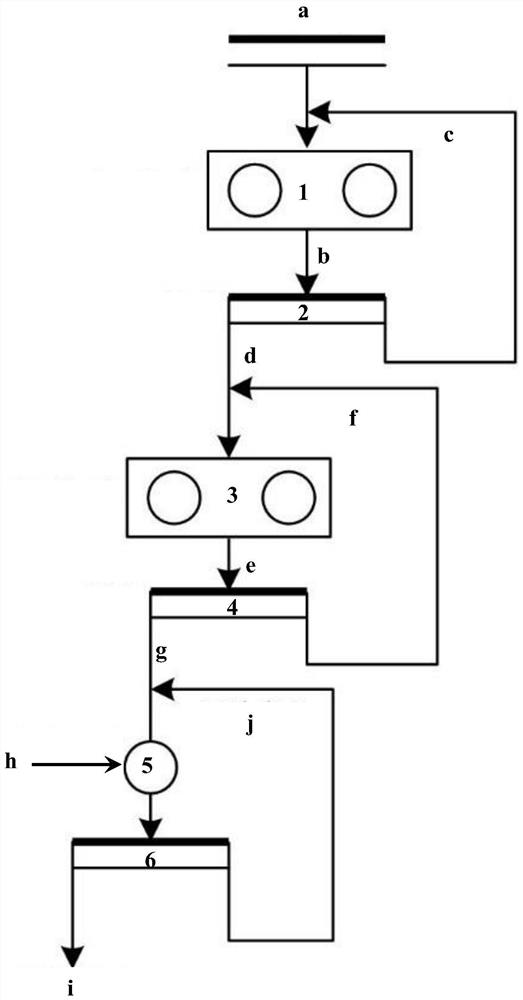

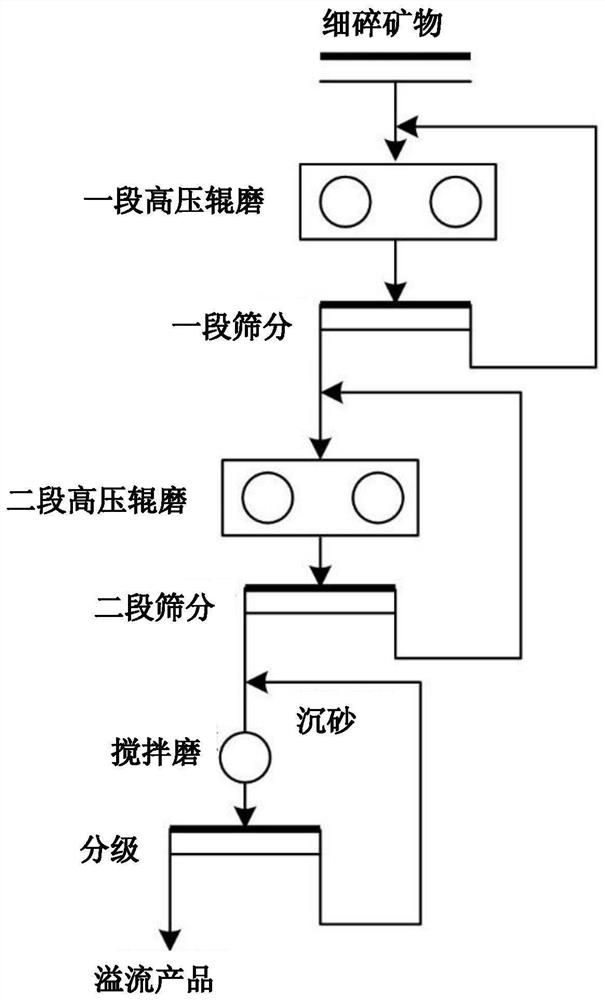

[0035] A two-stage series high-pressure roller mill-stirring mill short-process crushing system, its structure diagram is shown in figure 1, including one section of high pressure roller mill 1, one section of vibrating screen 2, two sections of high pressure roller mill 3, two section of vibrating screen 4, stirring mill 5 and classification equipment 6 (the classification equipment of this embodiment is a hydrocyclone), one section The material outlet of the high-pressure roller mill 1 is connected with the first-stage vibrating screen 2, the over-screen material outlet of the first-stage vibrating screen 2 is connected with the over-screen material inlet of the first-stage high-pressure roller mill 1, and the under-screen material outlet of the first-stage vibrating screen 2 is connected with the second-stage The material inlet of the high-pressure roller mill 3 is connected, the material outlet of the second-stage high-pressure roller mill 3 is connected with the second-sta...

Embodiment 2

[0042] Using the two-stage series high-pressure roller mill-stirring mill short-process crushing system of Example 1, the two-stage series-connected high-pressure roller mill-stirring mill short-process crushing method is the same as that of Example 1, the difference is that:

[0043] (1) The finely crushed mineral particle size is -12mm copper ore sample; the sieve size of the first section of the vibrating screen is 5mm, the mass concentration of the agitated mill is 60%, the volume filling rate of the agitated mill is 70%, the material-to-ball ratio is 0.7, ceramic The diameter of the ball is 6mm, and the grinding time is 3min.

[0044] (2) After the agitated grinding ore product is classified by the hydrocyclone, the concentration of the mineral content in the overflow product is 35%, and the concentration of the mineral content in the settling sand is 65%. The grit-set product is transported to the stirring mill again for grinding operation. The mineral content of -0.074m...

Embodiment 3

[0046] Using the two-stage series high-pressure roller mill-stirring mill short-process crushing system of Example 1, the two-stage series-connected high-pressure roller mill-stirring mill short-process crushing method is the same as that of Example 1, the difference is that:

[0047] (1) The finely crushed mineral particle size is -12mm gold ore sample; the sieve size of the first section of the vibrating screen is 4mm, the mass concentration of the agitated mill is 70%, the volume filling rate of the agitated mill is 75%, the material-to-ball ratio is 0.85, ceramic balls The diameter is 10mm, and the grinding time is 4.5min.

[0048] (2) After the agitated grinding ore product is classified by the hydrocyclone, the concentration of the mineral content in the overflow product is 38%, and the concentration of the mineral content in the settling sand is 62%. Grit products are sent to the stirring mill again for grinding operation. The mineral content of -0.045mm in the overflow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com