Process of producing SPHC with low cost, short flow and high efficiency

A short-process, low-cost technology, applied in the field of iron and steel metallurgy technology, can solve the problems of high production cost, complex process flow, low production efficiency, etc., and achieve the effect of reducing cost, simplifying process and reducing material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

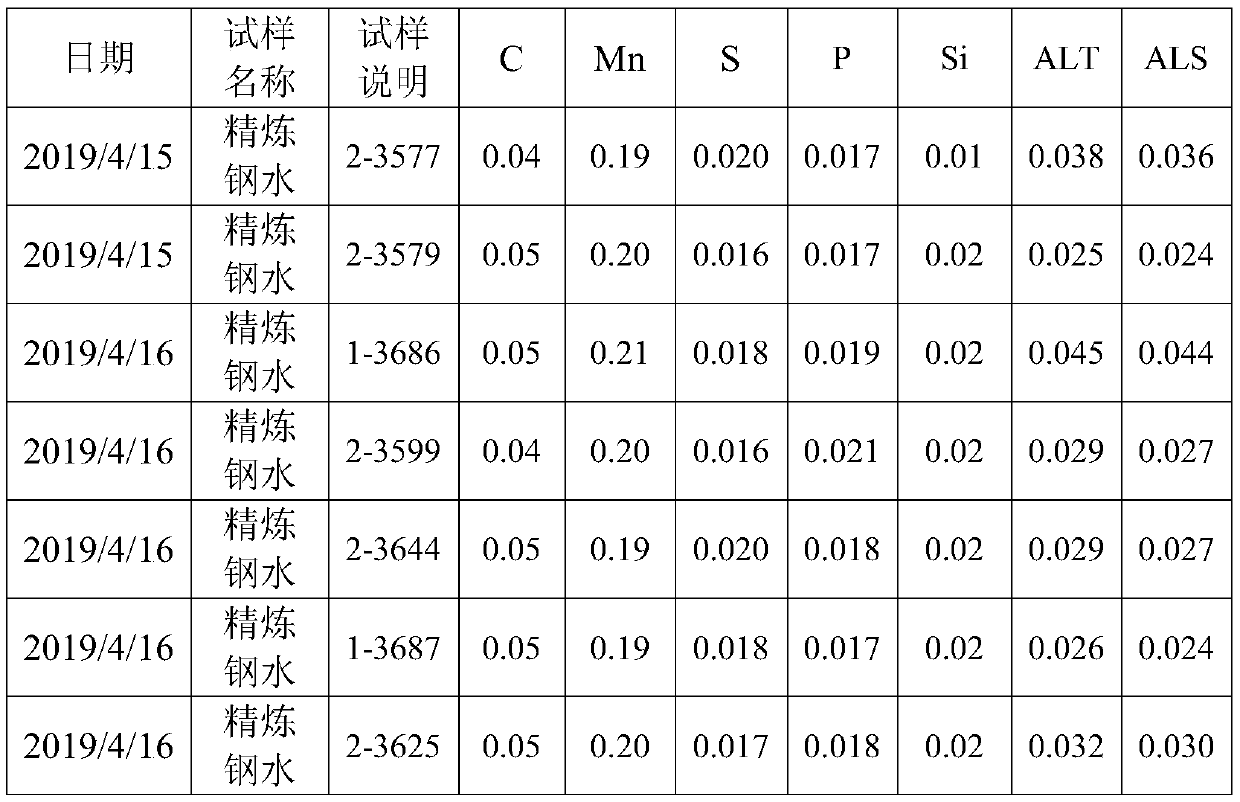

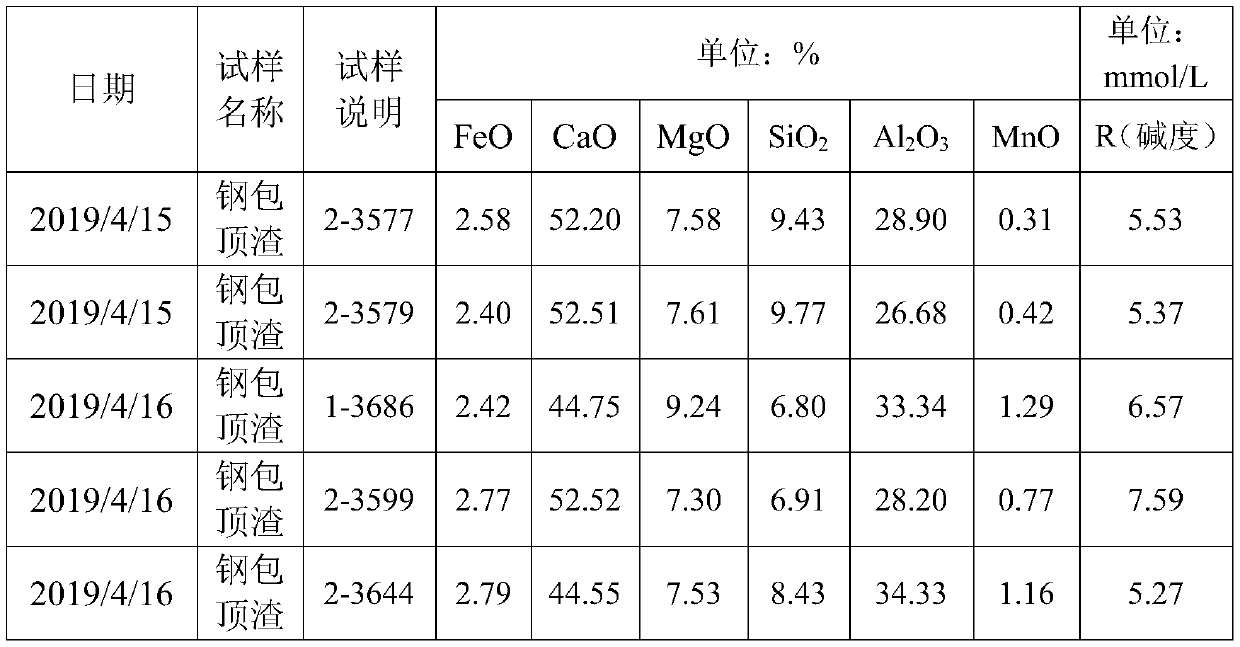

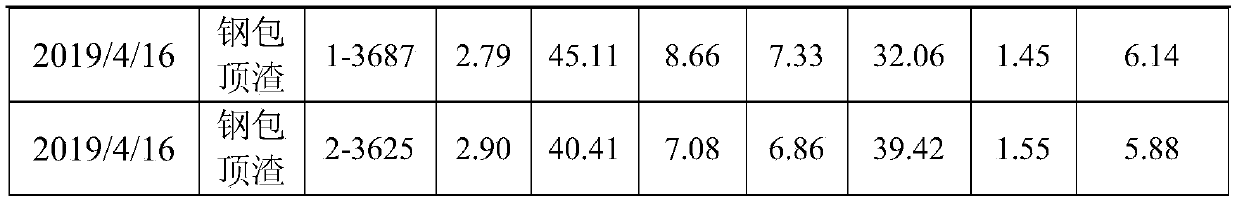

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with specific embodiment:

[0026] 1. Specific examples

[0027] A process for producing SPHC with low cost, short flow process and high efficiency, said process comprising the following steps:

[0028] a. Prepare molten iron and steel scrap

[0029] Using a blast furnace to produce molten iron, the temperature of the final molten iron is 1310°C, the amount of slag in the molten iron is 1cm, the C content in the molten iron is 4.80%, the Mn content is 0.45%, the S content is ≤0.02%, the P content is ≤0.09%, and the Si The content is 0.40%, prepare scrap steel, spare, the mass ratio of scrap steel to molten iron is 1:4, that is, every 100 tons of molten iron needs to add 25 tons of scrap steel;

[0030] According to the different terminal temperatures of the required molten steel, the present invention reasonably matches the steel scrap. The steel scrap must not be damp, contain flammable and explosive i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com