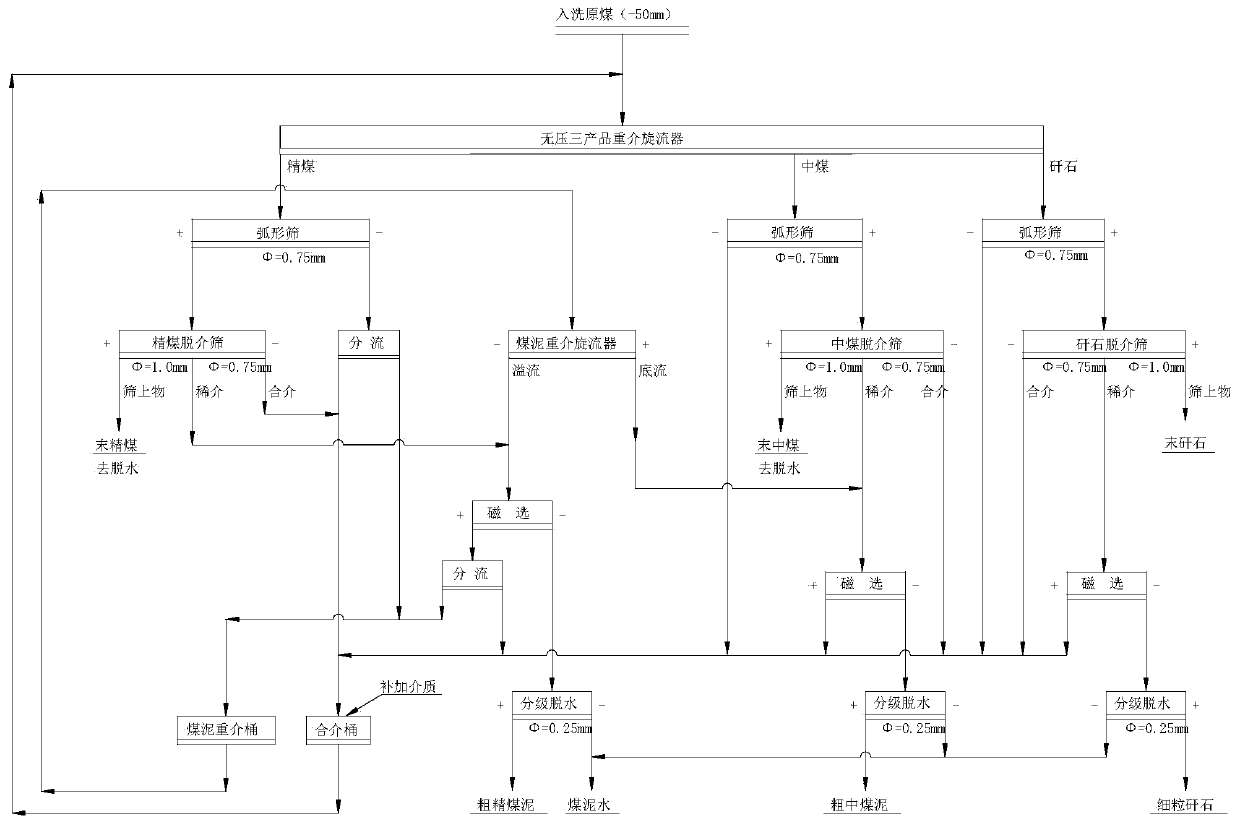

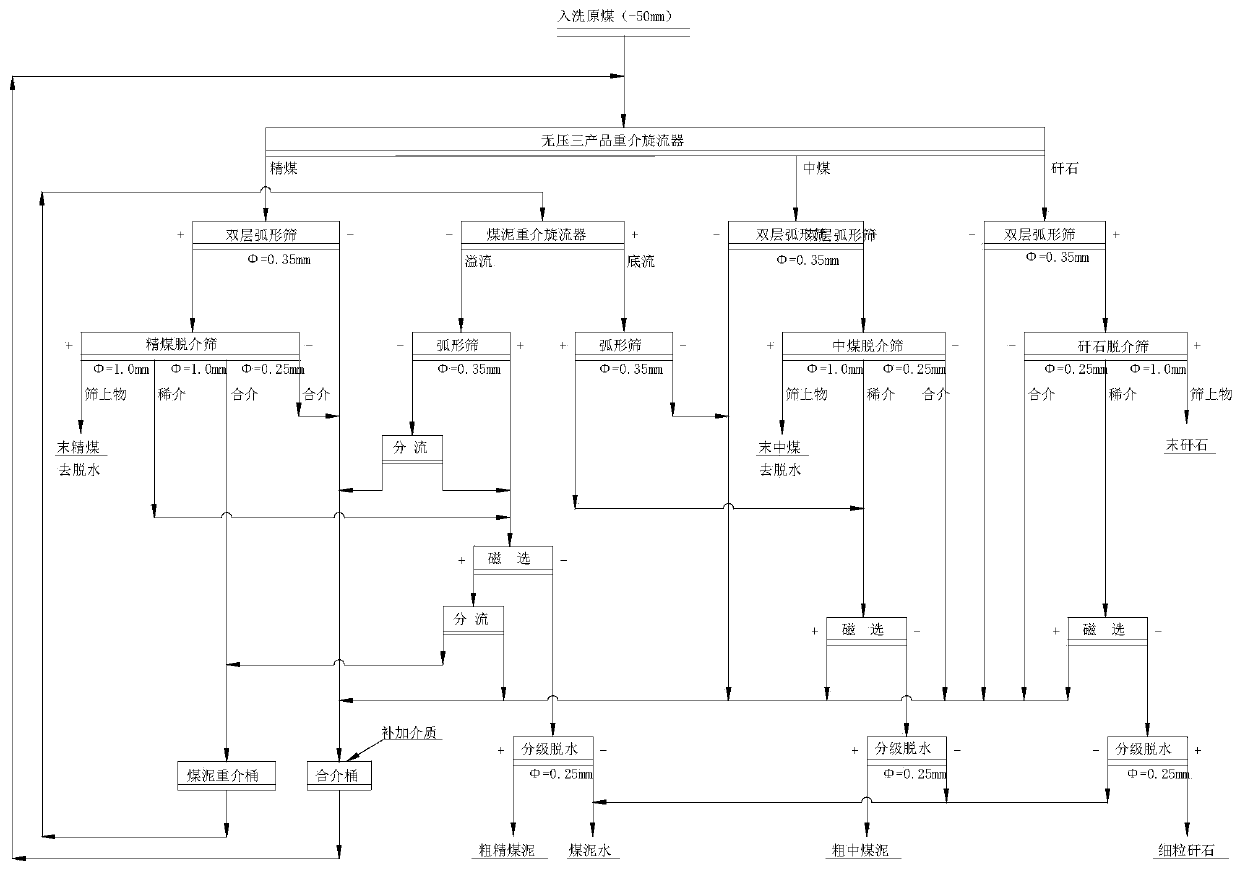

Constant-low-splitting-based non-pressure three-product and slime dense medium separation improved process

A three-product and slime technology, which is applied in the dense medium coal preparation process, non-pressure three-product and coal slime dense medium separation improvement process, can solve the problems of unstable coal slime heavy medium separation and high medium consumption, and achieve Reduce adverse effects, high sorting efficiency, increase the effect of equipment and links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

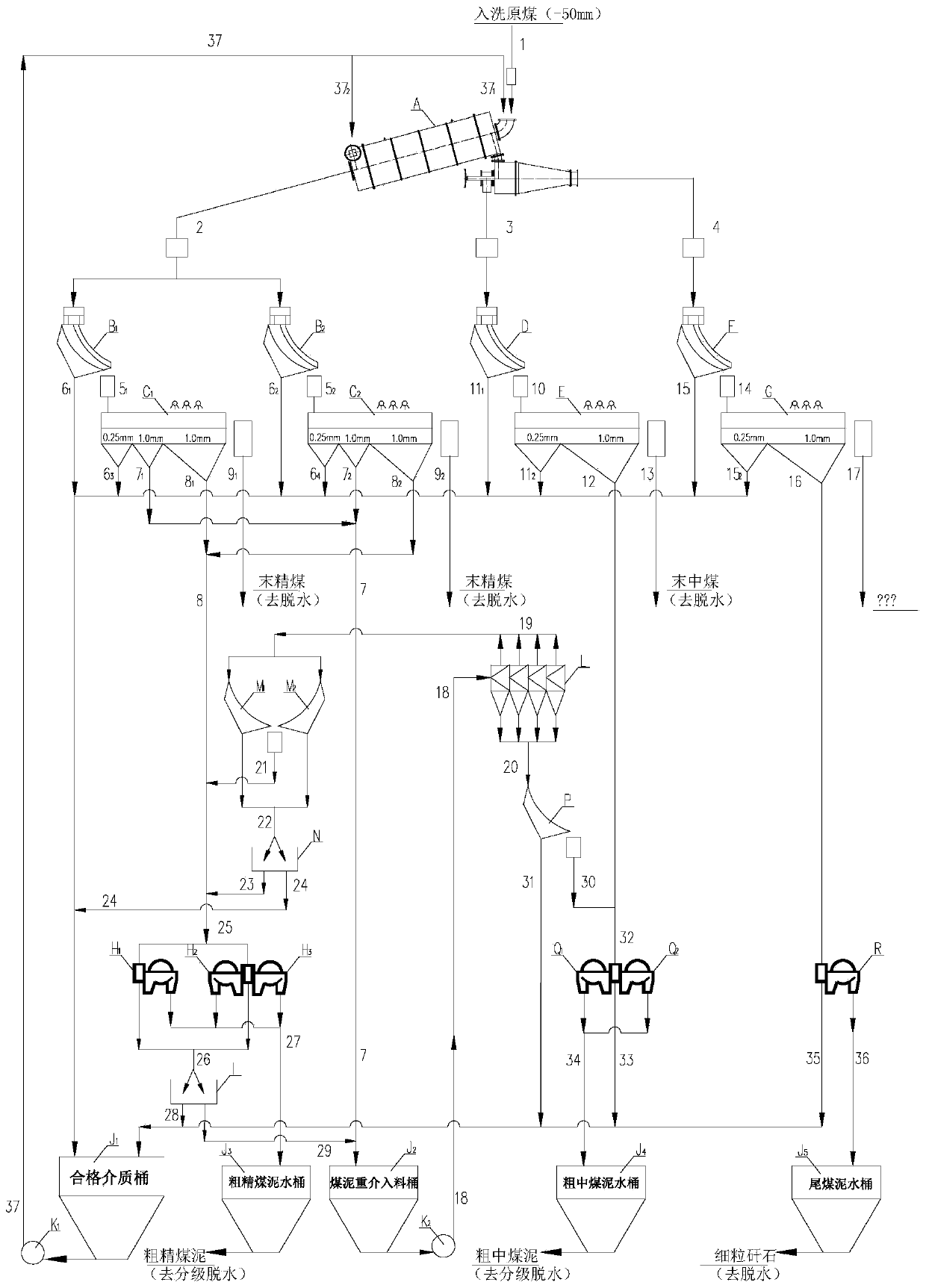

[0046] Such as image 3 As shown, taking a coal preparation plant with a production scale of 2 million tons per year as an example, the present invention will be further described in detail in conjunction with the equipment connection diagram. Clean coal, medium coal, and gangue are separated by 2 sets, 1 set, and 1 linear vibrating screen respectively; clean coal, medium coal, and gangue are recovered by using 3 sets, 2 sets, and 1 magnetic separator respectively. The clean coal and the medium coal of the second stage are separated by 2 sets and 1 set of curved sieves respectively.

[0047] Selected raw coal (-50mm) 1 in qualified medium 37 1 、37 2 Sorting in the pressureless three-product dense-medium cyclone A under the action to obtain the final clean coal 2, the final medium coal 3 and the final gangue 4.

[0048] The final clean coal 2 passes through the double-layer one-stage clean coal curved screen B 1 , B 2 and a clean coal removal screen C 1 、C 2 Remove mediu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com