High-pressure vacuum sandwich pipeline

A technology of vacuum interlayer and pipeline, applied in pipeline protection, protection of pipeline by thermal insulation, pipe/pipe joint/pipe fitting, etc., can solve problems such as waste of resources and safety risks, and achieve cost saving, large pre-cooling contact area, The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

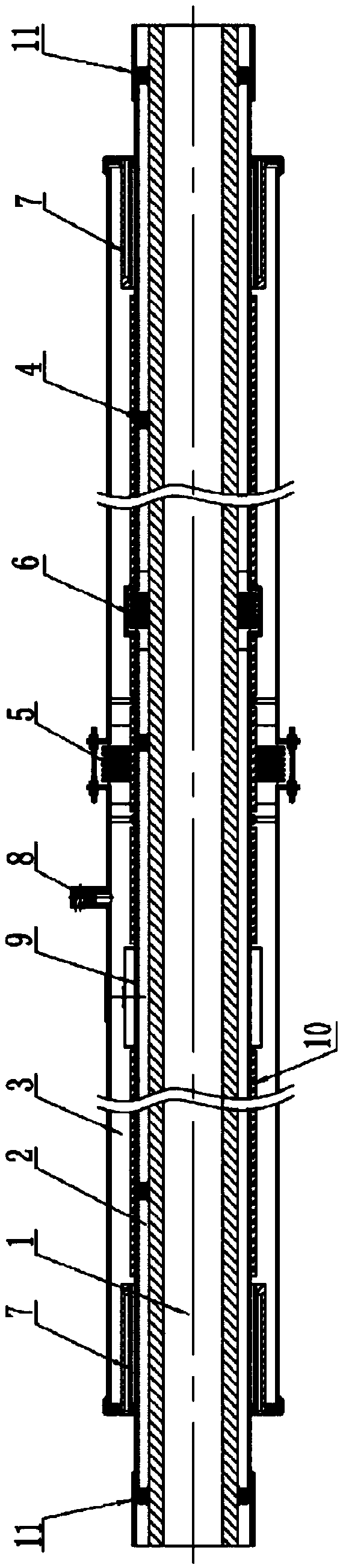

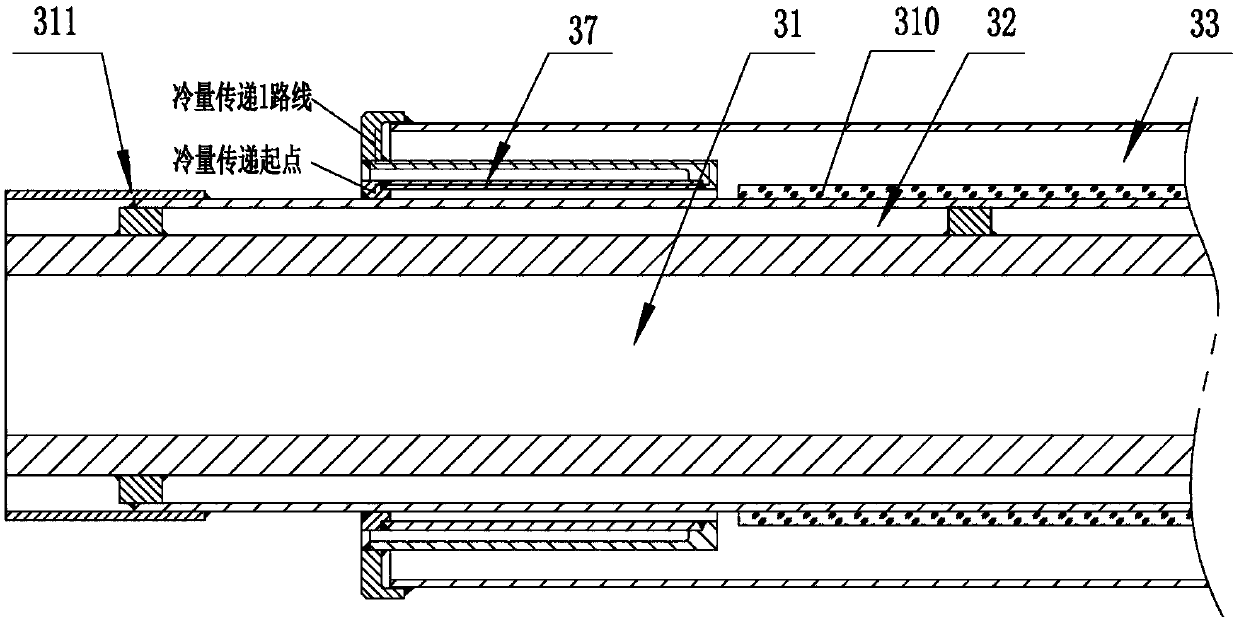

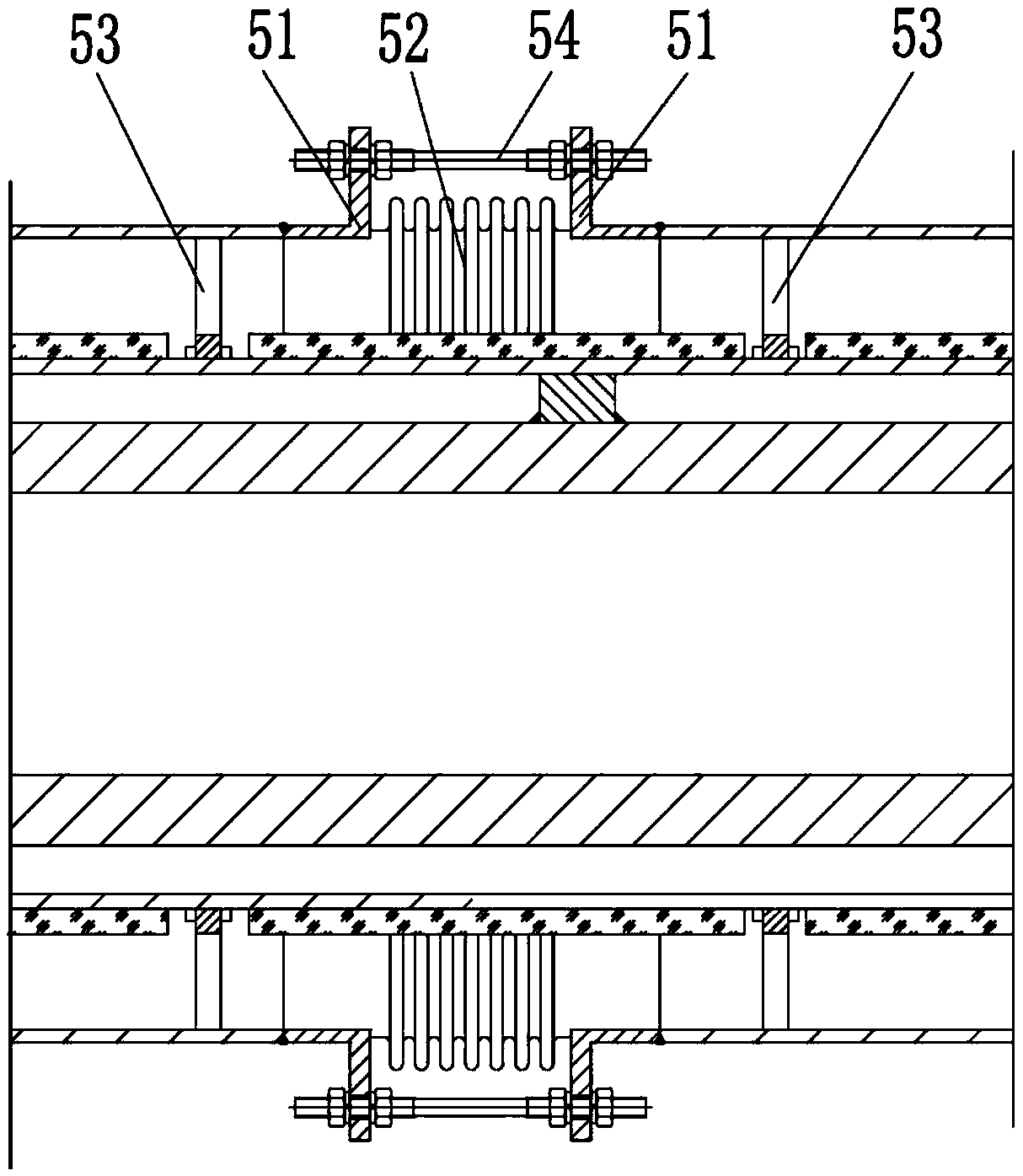

[0031] In order to reduce the consumption of pre-cooling medium in cryogenic liquid transportation pipelines and improve the discharge safety of pre-cooling medium, the present invention provides a high-pressure vacuum interlayer pipeline, which solves the problems of heat conduction and cold and heat compensation in medium transportation. The pipeline may specifically include The inner layer is 30MPa liquid oxygen layer, the middle layer is 1MPa liquid nitrogen layer, and the outer layer is vacuum insulation layer. The pipeline of the invention is used for a wind tunnel heater test, the test medium is liquid oxygen, and the precooling medium is liquid nitrogen.

[0032] Such as Figures 1 to 7 A high-pressure vacuum interlayer pipeline shown includes an inner layer conveying pipe 1, an intermediate pre-cooling pipe 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com