Dense-medium and low-density separation process

A low-density, sorting technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of increasing medium consumption, changing degree of medium consumption, reducing the recovery and reuse rate of magnetite powder, etc. , to maximize the economic benefits of production, control the calorific value, and reduce the consumption of media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

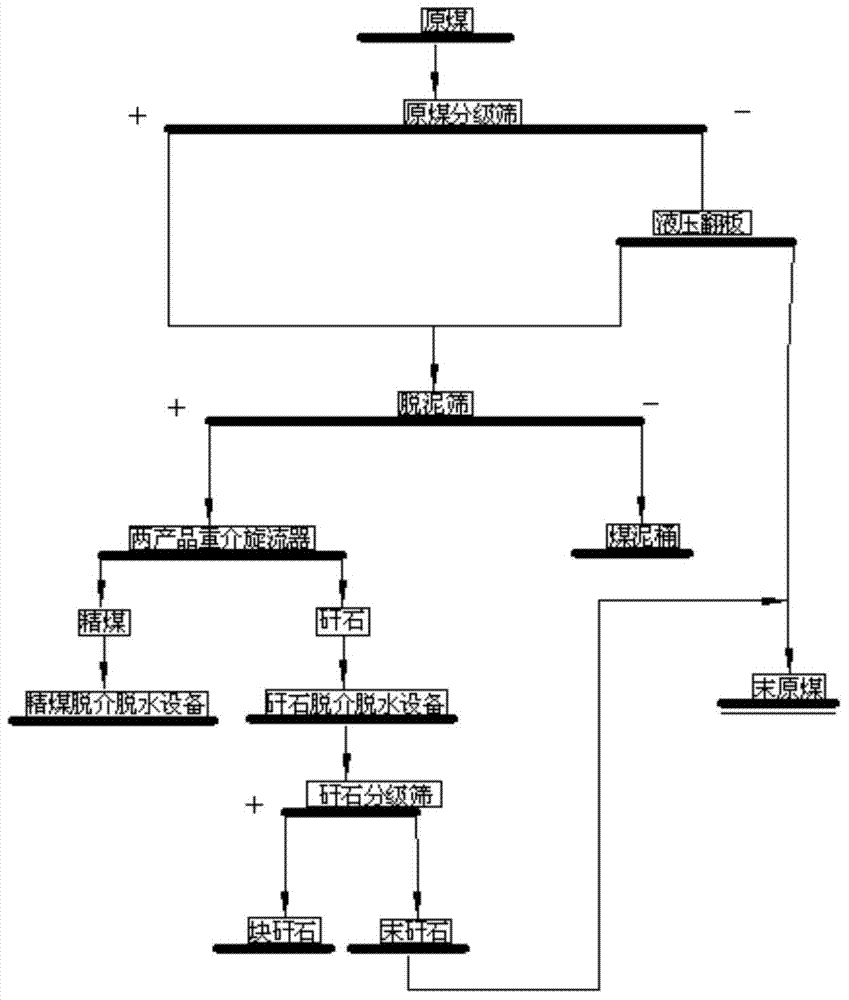

[0008] Such as figure 1 As shown, a dense medium low-density separation process includes the following steps: a. Classify the raw coal by using a raw coal grading sieve; b. The undersize obtained in the above step a is passed through the hydraulic flap through the hydraulic flap It is distributed as the output of the last raw coal; the obtained oversize and the undersize that have not passed through the hydraulic plate enter the desliming screen for desliming and screening; c. The undersizing obtained in the above step b through the desliming sieve for desliming and screening enters Coal slime bucket; the density of the obtained oversize is 1.55g / cm 3 The suspension is a mixture of magnetite powder medium and coal slime water. After mixing it, enter the two-product dense medium cyclone for low-density sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com