Method for preparing metal sizing agent by a compelling, equal-freezing and continuous method

A metal paste, uniform technology, applied in the field of material forming and processing, to achieve the effect of stable quality, uniform mixing and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

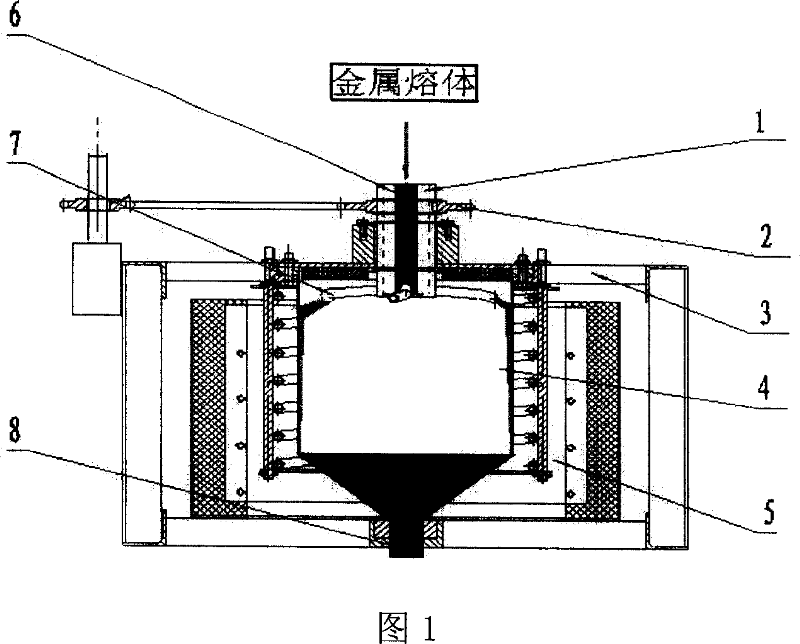

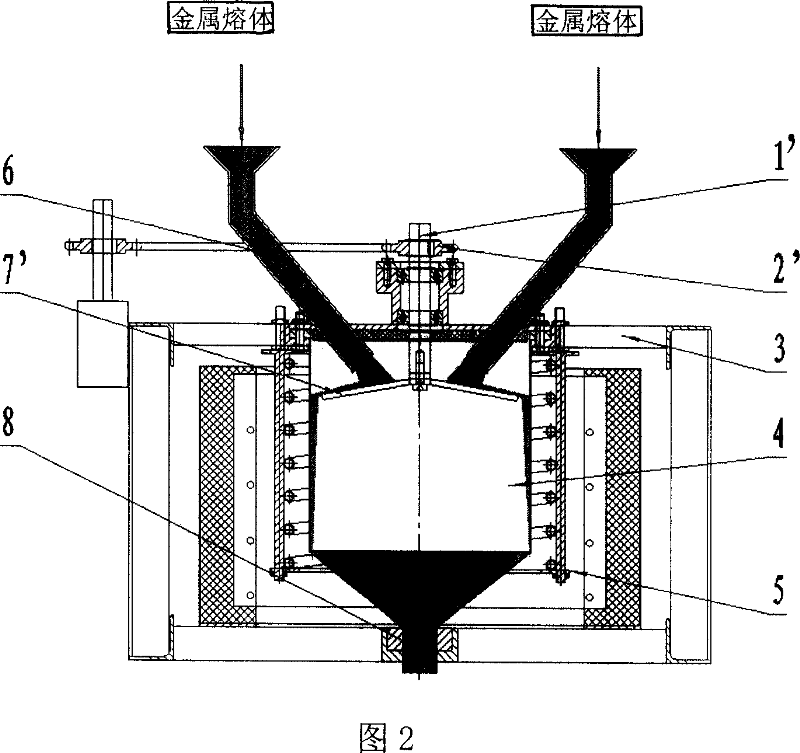

Method used

Image

Examples

Embodiment 1

[0029] A nozzle-type slurry continuous preparation device is used to prepare a semi-solid round billet with a cross-sectional size of 3.5. The material is A357 alloy, and the liquidus temperature is 613°C. The surface roughness of the cast billet is required to be less than 0.25, and subsequent processing does not require peeling treatment. The non-dendrite ratio in the slab is greater than 80%, and the average grain diameter is less than 100 μm, which is used for semi-solid thixotropy. During the production process, the A357 alloy was smelted in a medium-frequency induction furnace, and after degassing and refining treatment, it was left to stand for 20 minutes, and the pouring temperature was controlled at 680°C. The technical parameters adopted in the present invention are as follows: after the pulping chamber is preheated to 600° C., the lower guide pipe is closed, and protective gas (nitrogen or argon, greater than one atmospheric pressure) is sprayed into the pulping cham...

Embodiment 2

[0031] Die-casting of air compressor connecting rod, a key part of commercial trucks, was prepared by using split disc type slurry continuous preparation device. The raw material was ZL108 aluminum alloy, and the liquidus temperature was about 605°C. Due to the high mechanical performance requirements and special service conditions of the aluminum alloy air compressor connecting rod, the castings are prone to casting defects such as pores and looseness, and the pass rate is less than 80%. The technical scheme adopted by the invention is: melting the ZL108 alloy in an intermediate frequency induction furnace, after degassing and refining treatment, standing still for 20 minutes, and controlling the pouring temperature at 660°C. The technical parameters adopted are: after the pulping chamber is preheated to 600°C, close the lower guide pipe, and spray protective gas (nitrogen or argon, greater than one atmospheric pressure) into the pulping chamber. The above-mentioned smelted q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com