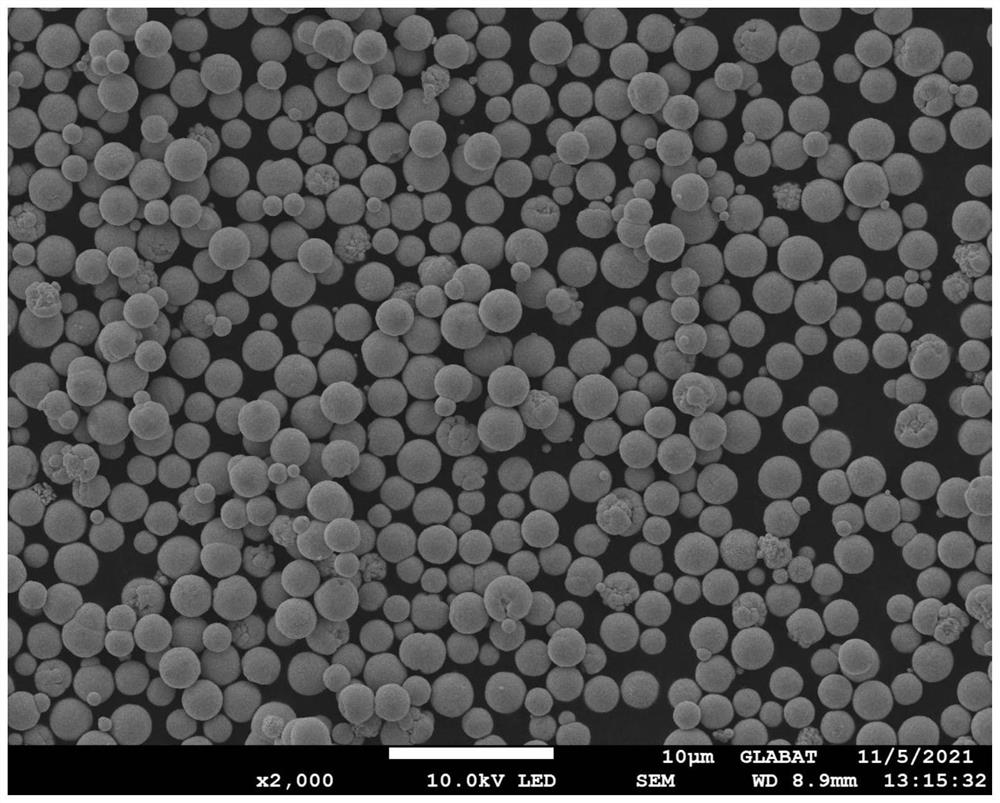

Method capable of continuously preparing micron-sized spherical gold powder

A micron-level, gold powder technology, applied in metal processing equipment, transportation and packaging, etc., to achieve the effect of uniform particle size distribution, smooth surface and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Using commercially available aqueous solution of chloroauric acid (impurity content ≤ 0.005wt%) as the raw material (it can also be made by adding pure gold into aqua regia and then catching the nitrification method), and using a 500mL volumetric flask to prepare gold trichloride with an Au mass concentration of 20g / L The solution is ready to use. Pour the prepared gold trichloride solution into a beaker and add about 70 mL of dilute ammonia water with a concentration of 5% dropwise with stirring at room temperature to form a gold fulminate suspension A with pH=3.5 for use.

[0039] According to the mass ratio of Au:VC:PVA=5:10:1, use 20g VC to prepare 1L of VC aqueous solution with a mass concentration of 100g / L, pour it into a 2L beaker containing 500g of PVA aqueous solution with a concentration of 2wt%, and mix and stir at room temperature. A homogeneous liquid B was formed for use.

[0040]Using the rapid rotation nucleation method, A and B were injected into a ra...

Embodiment 2

[0043] Using commercially available chloroauric acid aqueous solution (impurity content ≤ 0.005wt%) as raw material (it can also be made by adding pure gold into aqua regia and then catching nitrification method), using a 1L volumetric flask to configure gold trichloride with Au mass concentration of 25g / L The solution is ready to use. The prepared gold trichloride solution was poured into a beaker, and about 130 mL of ammonia water with a concentration of 8% was added dropwise with stirring at room temperature to form a gold fulminate suspension A with pH=3.7 for use.

[0044] According to the mass ratio of Au:VC:PVA=5:10:1.1, prepare 2L of VC aqueous solution with a mass concentration of 100g / L with 200g VC, pour it into a 5L beaker containing 440g of PVA aqueous solution with a concentration of 5wt%, and mix and stir at room temperature , to form a homogeneous liquid B for use.

[0045] Using the rapid rotation nucleation method, A and B were simultaneously injected into a...

Embodiment 3

[0048] Using commercially available aqueous solution of chloroauric acid (impurity content ≤ 0.005wt%) as raw material (it can also be made by adding pure gold into aqua regia and then catching the nitrate method), using a 1L volumetric flask to configure gold trichloride with Au mass concentration of 30g / L The solution is ready to use. The prepared gold trichloride solution was poured into a beaker, and about 200 mL of ammonia water with a concentration of 6% was added dropwise with stirring at room temperature to form a gold fulminate suspension A with pH=4.0 for use.

[0049] According to the mass ratio of Au:VC:PVA=5:10:1.2, use 300g VC to prepare 3L of VC aqueous solution with a mass concentration of 100g / L, pour it into a 5L beaker containing 720g of PVA aqueous solution with a concentration of 5wt%, and mix and stir at room temperature , to form a homogeneous liquid B for use.

[0050] Using the rapid rotation nucleation method, A and B were sprayed into a fast rotatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com