Preparation method of graphene-coated silicon particle composite material

A graphene-wrapped, composite material technology, applied in nanotechnology, electrical components, electrochemical generators and other directions for materials and surface science, can solve problems such as agglomeration of silicon nanoparticles, inability to large-scale production, and achieve a simple process , excellent stability, the effect of avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Firstly, silicon nanoparticles and graphite powder are pressed into hybrid carbon / silicon rods at a ratio of 1:1. Put this mixed graphite rod in the electric arc equipment, at the current of 130A, the distance between the cathode rod and the anode rod is 2mm, and fill it with 100K Pa of H 2 and He 2 , the volume ratio is 1:1, the discharge time under this condition is 10min, the discharge is over, and the products in the arc equipment are collected. The obtained silicon / graphene composite material was emulsified for 2 minutes, ultrasonicated for 20 minutes, and freeze-dried for 6 hours to obtain the final product.

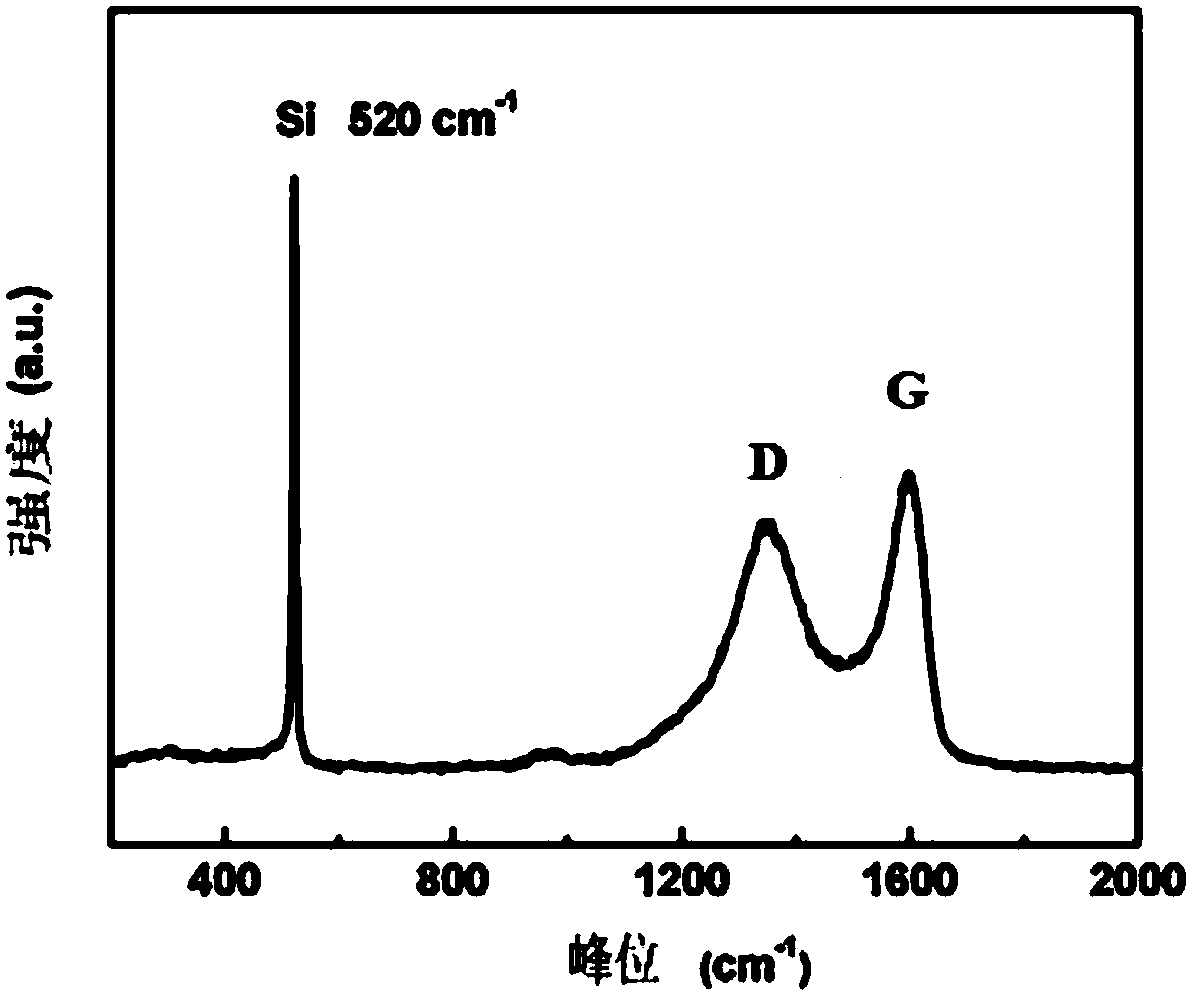

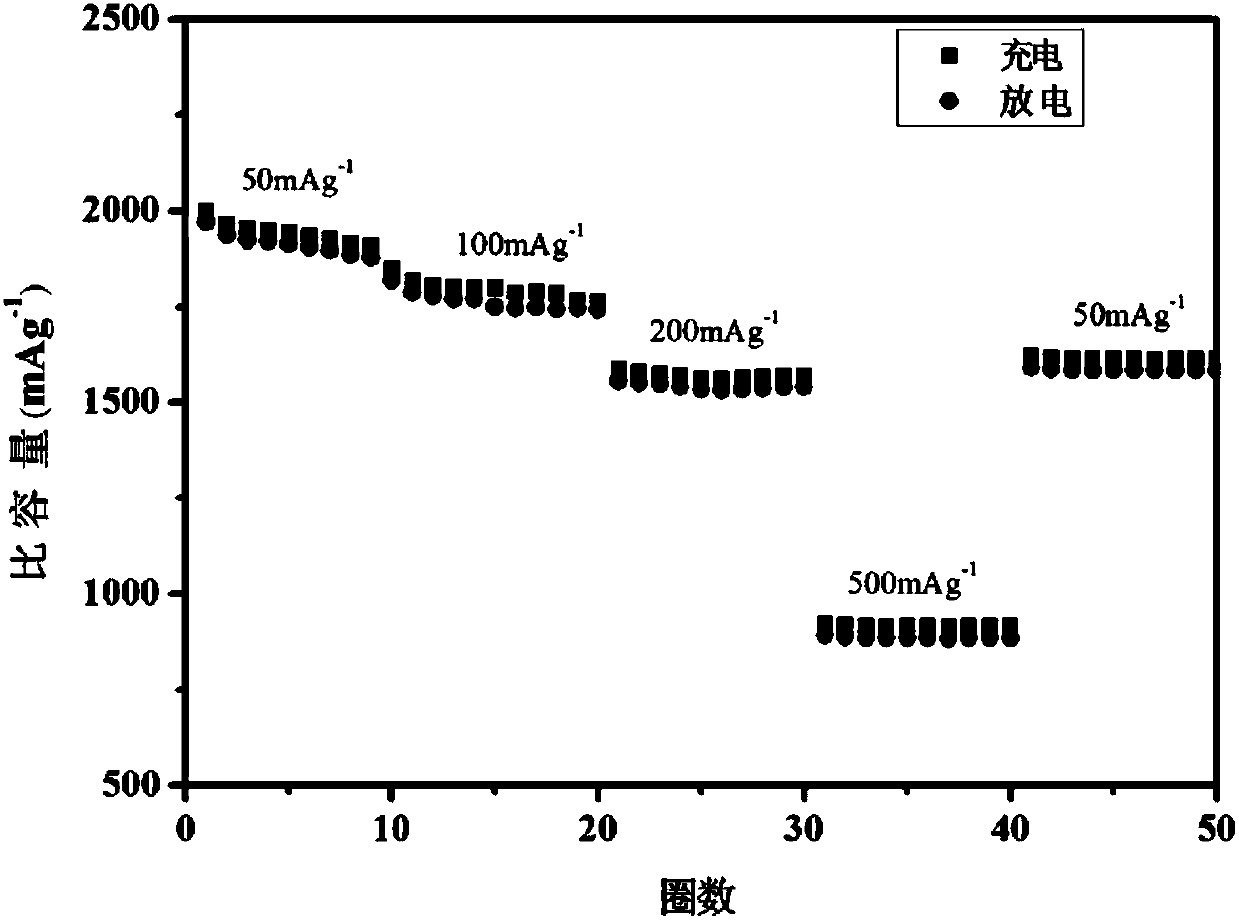

[0044] Using Raman and scanning electron microscopy to characterize the physical and chemical properties of the prepared silicon / graphene composite material, the results are shown in figure 1 , figure 2 , the electrochemical performance test was carried out on the prepared silicon / graphene composite assembled battery, the results are shown in image 3 w...

Embodiment 2

[0048] Firstly, silicon carbide nanoparticles and graphite powder were pressed into hybrid carbon / silicon rods at a ratio of 1:2. Put this mixed graphite rod in the electric arc equipment, at the current of 120A, the distance between the cathode rod and the anode rod is 2mm, and fill it with 100K Pa of H 2 and He 2 , the volume ratio is 1:2, the discharge time is 8min under the condition, the discharge is completed, and the products in the arc equipment are collected. The obtained silicon / graphene composite material was emulsified for 5 minutes, ultrasonicated for 30 minutes, and freeze-dried for 3 hours to obtain the final product.

[0049] The electrochemical performance test shows that the current density is 50, 100, 200, 500mA g -1 Under the charge and discharge rate, their average discharge capacity can still be maintained at 1225, 1146, 984, 690mAh g -1 , when the current density from 500mA g -1 back to 50mA g -1 , the average discharge capacity also reached 1117mA ...

Embodiment 3

[0051] First, silicon oxide powder and activated carbon powder are pressed into a mixed carbon / silicon rod in a ratio of 2:1. Put this mixed graphite rod in the electric arc equipment, at the current of 100A, the distance between the cathode rod and the anode rod is 1mm, and fill it with 100K Pa of H 2 and He 2 , the volume ratio is 1:3, the discharge time is 15min under this condition, the discharge is over, and the products in the arc equipment are collected. The obtained silicon / graphene composite material was emulsified for 6 minutes, ultrasonicated for 40 minutes, and freeze-dried for 6 hours to obtain the final product.

[0052] The electrochemical performance test shows that the current density is 50, 100, 200, 500mA g -1 Under the charge and discharge rate, their average discharge capacity can still be maintained at 2035, 1956, 1594, 980mAh g -1 , when the current density from 500mA g -1 back to 50mA g -1 , the average discharge capacity also reached 1677mA g -1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com