Household garbage classified gasification system with rotary kiln gasification and plasma fusion capability

A technology of domestic waste and gasification system, which is applied in the direction of incinerator, combustion type, combustion method, etc., to achieve the effect of avoiding low-temperature resynthesis, good calorific value, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

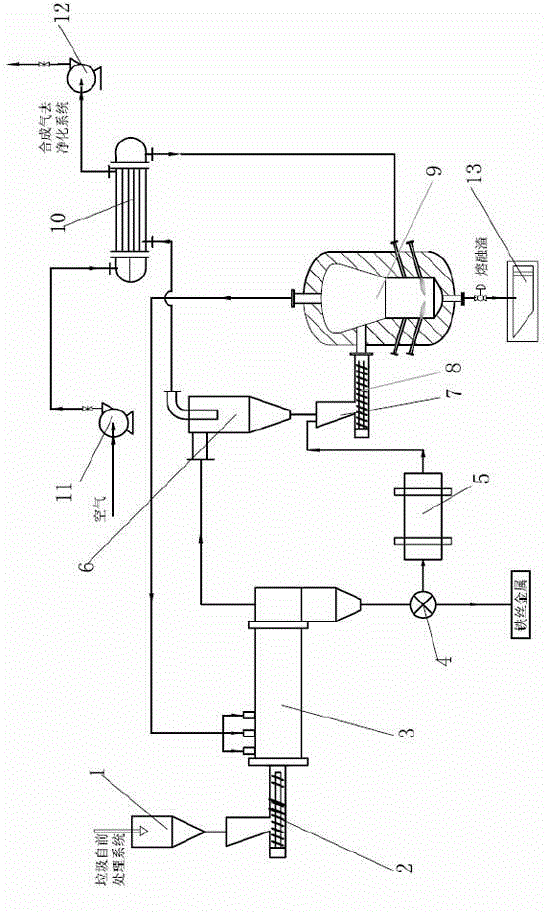

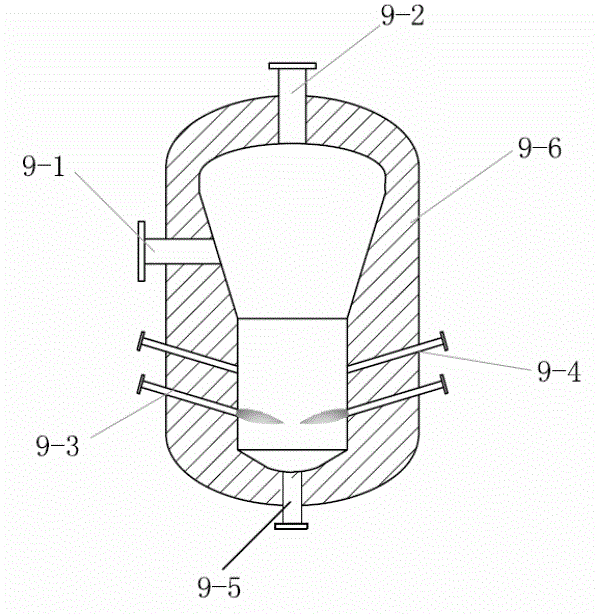

[0025] Such as figure 1 As shown, a rotary kiln gasification and plasma melting domestic waste graded gasification system, including a garbage hopper 1, a garbage feeder 2, a rotary kiln type pyrolysis gasifier 3, a metal separator 4, and a crusher 5 , High temperature cyclone separator 6, ash hopper 7, ash feeder 8, plasma melting furnace 9, air preheater 10, blower 11, induced draft fan 12 and slag pool 13.

[0026] The specific connection relationship of each component in the domestic waste classification gasification system is as follows:

[0027] The garbage hopper 1 is installed on the upper end of the garbage feeder 2, the outlet of the garbage feeder 2 is connected to the inlet of the rotary kiln type pyrolysis gasifier 3, and the gas outlet of the rotary kiln type pyrolysis gasifier 3 is separated from the high temperature cyclone The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com