Activated carbon fiber for supercapacitor and preparation method thereof

A technology of activated carbon fibers and supercapacitors, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of cycle stability that needs to be further improved, obstacles to practical applications, and low conductivity of transition metal oxide materials. Achieve excellent cycle stability and electrochemical rate performance, low raw material cost, regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

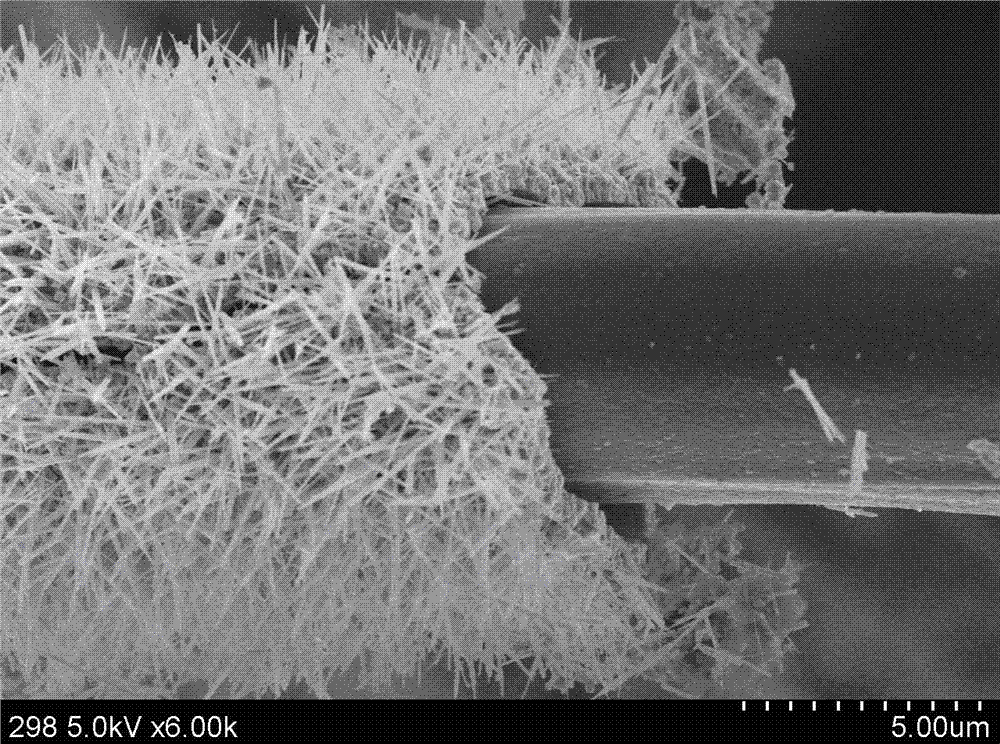

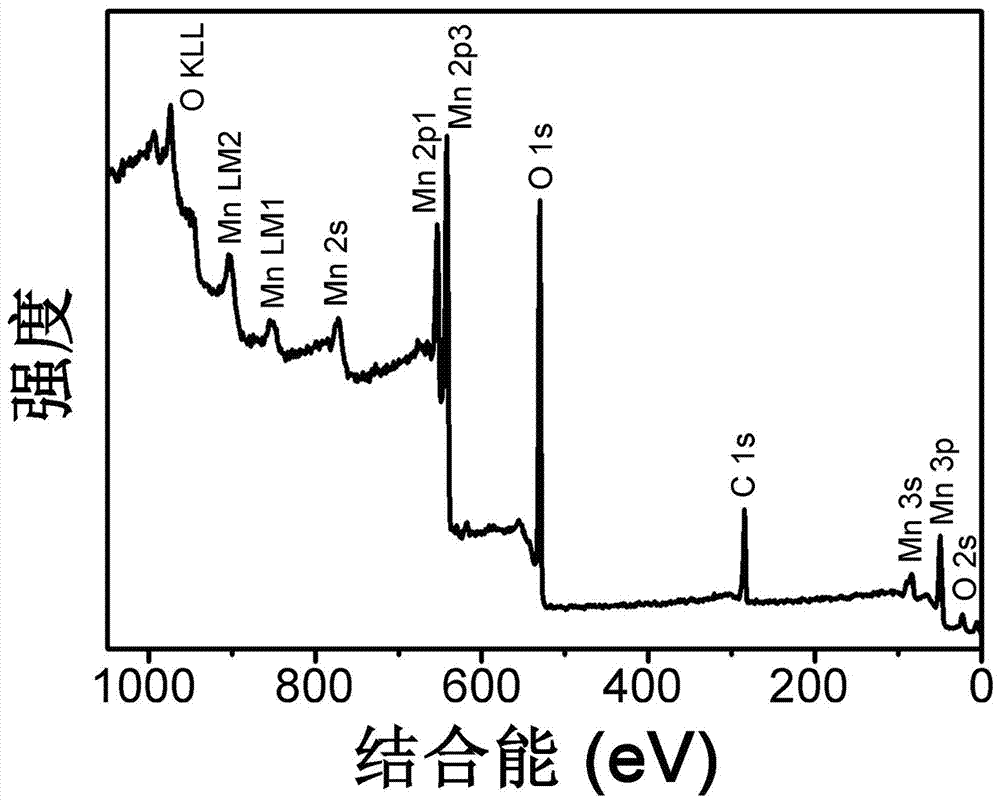

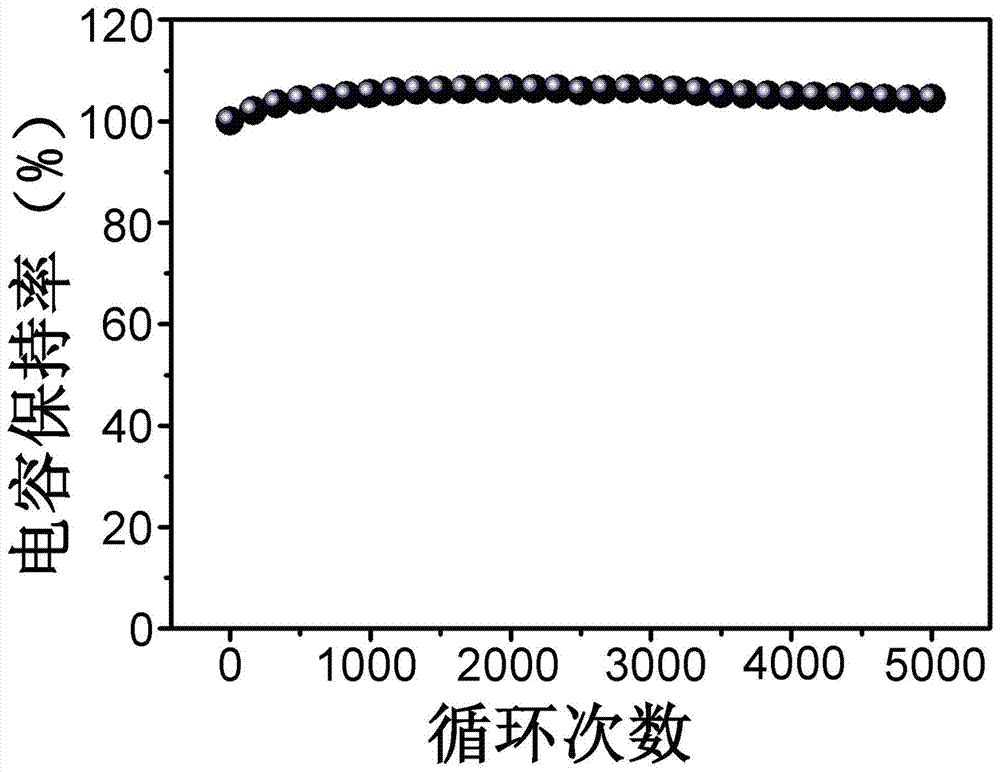

[0038] First, the activated carbon fibers were treated with 20ml of concentrated sulfuric acid at 50°C for 12 hours, then washed with a large amount of distilled water until neutral; then the activated carbon fibers were cleaned with ethanol, acetone and deionized water, and dried for later use; the concentration of 0.005mol / L was prepared. Mn(CH 3 COO) 2 and 0.01 mol / L CH 3 COONH 4 solution, then add 5% volume of DMSO, and mix the solution evenly; then immerse the above treated activated carbon fiber in the precursor solution, at 0.5 mA / cm 2 It was deposited under the electrochemical deposition conditions for 60 minutes, and it can be observed that the surface of the activated carbon fiber is gradually covered by a layer of brown substance; Calcined at 200°C for 2h in a Furnace to obtain the product. Using an electrochemical workstation under the 1V potential window, at Na 2 SO 4 The electrochemical performance test is carried out on the product prepared by the present ...

Embodiment 2

[0040] Firstly, the activated carbon fibers were treated with 30ml of concentrated sulfuric acid at 25°C for 15 hours, and then washed with a large amount of distilled water until neutral; then the activated carbon fibers were cleaned with ethanol, acetone and deionized water, and dried for later use; the concentration of 0.01mol / L was prepared. Mn(CH 3 COO) 2 and 0.005 mol / L CH 3 COONH 4 solution, then add 8% volume of DMSO, and mix the solution evenly; then immerse the above-mentioned treated activated carbon fiber in the precursor solution, at 0.6 mA / cm 2 It was deposited under the electrochemical deposition conditions for 120min, and it can be observed that the surface of the activated carbon fiber is gradually covered by a layer of brown substance; Calcined at 250°C for 3 hours in a Furnace to obtain the product. Using an electrochemical workstation under the 1V potential window, at Na 2 SO 4 The electrochemical performance test is carried out on the product prepare...

Embodiment 3

[0042] First, treat the activated carbon fiber with 20ml of concentrated sulfuric acid at 80°C for 24 hours, then wash it with a large amount of distilled water until it is neutral; then use ethanol, acetone and deionized water to clean the activated carbon fiber, dry it for later use; configure the concentration of 0.1mol / L Mn(CH 3 COO) 2 and 0.02 mol / L CH 3 COONH 4 Solution, then add 25% volume of DMSO, mix the solution evenly; then immerse the above treated activated carbon fiber in the precursor solution, at 5 mA / cm 2 It was deposited under the electrochemical deposition conditions for 120min, and it can be observed that the surface of the activated carbon fiber is gradually covered by a layer of brown substance; Calcined at 300°C for 2h in a Furnace to obtain the product. Using an electrochemical workstation under the 1V potential window, at Na 2 SO 4 The electrochemical performance test is carried out on the product prepared by the present invention in the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com